Which is better - a silage harvester or a baler (for example, PRF-145) for preparing grass silage - a question that has been actively discussed by manufacturers since the middle of the last century, when the first baler was manufactured.

This discussion can continue as long as necessary, and the best judge is economics, which does not take into account personal tastes and beliefs, but evaluates everything in numbers.

Domestic agricultural enterprises are already well familiar with the technology of making grass silage using a roll baler.

Many farms have seen its effectiveness . The main points of the grass silage harvesting technology using a baler that are worth paying attention to are:

- feed quality

- efficiency of work

- economic efficiency.

Let's take a closer look at each of the points.

Roll baler for hay PRF-145

Review of the roll baler PRF 145: adjustment, principle of operation and where it is more profitable to buy

After the grass has been cut, windrowed and dried, it must be collected. Previously, this hard work was done manually, but over time, special agricultural machines were created for these purposes - balers, which collect dried plant mass for subsequent pressing into bales or rolls. Depending on the shape given to the hay or straw mass, these units are divided into bale and roll units. Among such equipment, it is worth highlighting the PRF 145 model baler produced in Belarus.

Advantages and disadvantages

This model greatly facilitates the collection of cut and dried plant matter and has a number of important advantages, namely:

- a closed pressing chamber makes it possible to reduce the loss of feed material to almost zero;

- The rolls are formed in such a way that the inner layers of hay are loose, and the outer layers are denser. This allows air to circulate freely between the layers, ensuring the safety of the compressed plant mass;

- the automatic control system makes it possible to constantly monitor all operating indicators of the PRF 145 baler;

- the design of the unit allows for collecting into bales not only fresh plant mass, but also completely dried;

- the operator has a wide viewing angle, which gives him the opportunity to carry out his work more accurately;

- the chain pressing mechanism provides the unit with a high degree of reliability;

- strength of all components and ease of operation.

In principle, this model of press assembler has no disadvantages, and timely cleaning, maintenance and proper operation of the unit significantly increases its service life.

Device

The round baler, model PRF-145, consists of the following main components:

- the face, which includes a shaft, drive, gearbox, as well as a container for winding material;

- a pick-up consisting of a coupling and a shaft, and which during operation rests on wheels;

- wheel frame on which the pressing chamber is installed;

- pressing chamber with two compartments and a device for forming rolls from plant matter;

- hydraulic system;

- electrical equipment.

Economic efficiency

Any technical or technological advantages to a certain extent affect the economics of the enterprise. Let's define each advantage in monetary terms.

1.Losses during loading and transportation.

When using a silage harvester to make alfalfa silage, approximately 6% of the green mass is lost compared to a baler. As you know, leaf mass is protein.

Let's do the calculation for our example. From 300 hectares with a yield of 20−25 t/ha (for all cuttings), we collect approximately 6,000 tons of fresh mass (4,080 tons in test weight). So, the annual loss after the combine and trucks is approximately 360 tons of alfalfa silage per year, which in terms of dry matter is 126 tons.

With a protein content of 20% in dry matter, the loss is 25.2 tons of protein per year. This amount of protein would yield approximately 1000 liters of milk/ha! In terms of the entire area of alfalfa, 303.6 tons of milk/year remain on the field, which in monetary terms, even at today’s milk price, is more than 100 thousand euros!

Features of operation

The unit for collecting dried plant mass and forming it into rolls works as follows. The rollers that pick up the mown grass are activated by forward movements. The hay enters the bale chamber, in which it is formed using a special drum device.

Next, compaction is performed using a special grid, after which twine is fed into the compaction chamber, which is used to wrap a roll of hay. A hydraulic cylinder opens the chamber lid and pushes the finished roll out. After this, the entire technological process is repeated.

The resulting hay rolls are pressed tightly enough, which makes it possible to pack them with polymer film. Since the top layers are dense and the inner layers are looser, the bales do not deteriorate and the likelihood of mold occurring is reduced.

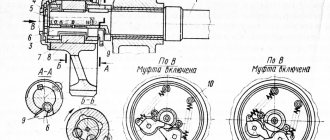

Round baler diagram

1. – drum for selecting plant mass; 2. – pressure grid; 3. – upper roll; 4. – hydraulic cylinder; 5. – pressing device; 6. – lower rollers; 7. – apron; 8. – winding mechanism; 9. – hitch; 10. – drive mechanism; 11. – support-drive pneumatic wheels.

If the customer wishes, the manufacturer installs an automated control system (ACS) on the baler, which makes it possible to monitor the operation of all mechanisms and remotely control the bale winding device. SAC allows you to reduce equipment downtime and increase unit productivity. An optional bale counter and wider tires are also available for low ground pressure and a smooth ride.

Operating principle and design of the press

When studying the PRF 145 roll baler, it is advisable to note that it is produced in a company located on the territory of the Republic of Belarus, which specializes in the production of agricultural equipment for various purposes. The unit operates according to a simple algorithm, which involves collecting, pressing, and dispensing the finished bale or roll of hay outside.

When considering the operating principle of this unit in more detail, you should remember that hay harvesting with its help is carried out in several stages:

- Special rollers collect the hay, which then enters the bale chamber.

- The molding process takes place inside it, which is carried out using a drum mechanism.

- After successful shaping, the hay is compressed using a grid.

- Using a mechanism, the molded compressed hay is fed onto the twine for subsequent wrapping.

- The hydraulic cylinder opens the chamber, after which the finished bale is pushed out.

Reviews from PRF-180 owners about operating experience

In general, peasants agree that round balers are more convenient, more technologically advanced and more practical than square balers. And productivity is higher, and it takes much less time to clean and store rolls than bales (one bale weighs about 15-20 kg). Farmers note: even if the weather turns bad and rain clouds appear, you can quickly remove and roll up windrows of hay or straw from a large area with a roller pick-up and save them from dampness. This trick won't work with bales.

A haystack loads finished rolls of hay.

Among the disadvantages of the PRF-180 pick-up, it is necessary to make the windrows uniform and uniform for clean, high-quality harvesting. Therefore, sometimes preliminary preparation and alignment of the windrows is required. Not everyone likes the size and weight of the rolls (too large). Almost all owners of the “PRF-180” talk about the low quality of the metal from which it is made, nostalgically recalling the high-grade metal that agricultural machinery was made of during the Soviet era. However, the quality and integrity of the assembly of the Bobruisk plant does not raise any complaints.

It is significantly superior to “PRF-110”, “PRF-145”, “PRF-150”, etc. baler models. Within an hour you can roll up to 25-30 rolls of hay or straw. In general, the “PRF-180” is characterized as an unpretentious and reliable agricultural machine for large farms, or for the production of feed in large volumes for sale.

Machine Specifications

Having studied the design and operating features of such units, it is necessary to study in more detail the technical characteristics of the PRF 145. The equipment is of the semi-trailer type and has the following operating parameters:

- working width - 1.45 m;

- roll length and diameter - 1.2 m and 1.45 m;

- the weight of one roll is 150-375 kg, depending on the type of plant material;

- productivity 4-5.5 thousand kg per 1 hour;

- speed during operation is 6-12 km/h, and during transportation 25 km/h;

- device dimensions - 4.15x2.3x2.4m.

Such a unit has become widespread and is used everywhere for agricultural needs and processing large volumes of plant materials.

The lineup

The roll modification PR145s is designed for harvesting wet hay, since its bale chamber is located on the side, which allows the operator to expand the viewing angle for ease of control.

The PRF145B series boasts a smaller picking mechanism, which allows you to collect small crops without much effort. Some models of both modifications are equipped with an automatic control system for the operating parameters of the device, thereby maintaining high efficiency during operation.

Price

Prices for such equipment greatly depend on the condition and year of manufacture. If you plan to purchase a new unit of the PRF 145 series in the basic configuration, it will cost the buyer 325-470 thousand rubles. At the buyer's request, the manufacturer can additionally install an automated control system for operating parameters on the equipment.

Due to the wide distribution of such pickers, it is possible to purchase a used analogue. In this case, the price will depend on the age of the equipment and its technical condition. A serviceable but used PRF 145 will cost the buyer 210-340 thousand rubles per unit of equipment.

Round baler pr-145s: technical characteristics

In this article we will talk about the PR-145S roll baler produced by Bezhetskselmash Plant OJSC, one of the most common models of this forage equipment. The main, and almost the only task of this trailed unit is to facilitate as much as possible and reduce the farmer’s manual labor to a minimum by mechanizing the process of harvesting hay or haylage.

Our baler is capable of picking up hay or straw laid in windrows and pressing them into rolls of a cylindrical shape and a certain diameter, tying it with twine in the process. The use of a baler allows you to reduce labor costs, increase profitability and make the work of preparing feed, transporting it, storing and distributing prepared feed to animals more convenient, mechanizing most of the work.

Feed quality

How exactly does the PRF-145 baler affect the quality of feed? Firstly, and this is the most important thing, during the preparation of silage from alfalfa using a baler, the leaf mass is not lost - it is not blown away by the wind under load, and the main proportion of the protein in alfalfa is contained in the leaves.

Secondly, the cutting length of green mass is 4-6 cm, fully meeting the needs of ruminants . Shorter cutting, according to recent research by British scientists, causes active loss of dry matter during storage.

Of course, these statements could be questioned if it were not for the results of analyzes of alfalfa silage made on domestic farms that use various technologies for the preparation of roughage.

So, this year, even the workers of the Austrian laboratory “Rosenau”, who analyzed domestic feed, were pleasantly surprised that one of the farms received 100 points out of 100 possible for the quality of alfalfa silage. This farm uses a baler to make grass silage.

As the results of the analysis show, alfalfa silage is characterized not only by a high protein and energy content, but also by a correct fermentation process , which directly affects the taste of the feed and, accordingly, the amount of its consumption.

Due to complex actions, including feeding such silage, the farm managed to increase milk yield per milking cow by 26%. Today, the farm receives 24-25 liters of milk from a cow per day compared to last year’s 18 liters. At the same time, the share of concentrated feed in the diet did not change.

Operating principle of the PR-145S baler

To operate the baler, a tractor with a power take-off shaft and a traction class of at least 1.4 t.p. is required. When the PTO is turned on, the torque from the tractor, through the cardan transmission, begins to be transmitted to the pick-up mechanisms.

The unit captures the mown grass or straw and sends it to the chamber where the pressing process begins. In the chamber, with the help of special grids and rolling pins, the hay is rolled up and compressed.

The roll will be compressed to a given density, which is set by the operator using tension springs. The value of the specified density ranges from 80 to 200 kg per m3. After reaching the set density, the last stage in roll formation starts.

After the roll is formed, the twine is automatically supplied, and the process of wrapping the roll begins. Upon completion of the tying, the twine is cut, and with the help of two hydraulic cylinders the chamber is opened and the finished roll is unloaded into the field.

Purpose of "PRF-180" on the farm and its main features

The main purpose of the beltless round baler "PRF-180" with a permanent bale chamber is to mechanize and automate the process of harvesting hay and straw, reducing manual labor to a minimum. This is a tractor semi-trailer with one axle and a cylindrical bale chamber. The chamber is of a completely closed design, helping to reduce the amount of feed loss to a minimum. The baler collects windrows of hay or straw cleanly and efficiently, no less efficiently than with a rake and fork. And it rolls them into rolls weighing up to 700 kilograms of hay and up to 400 kg of straw, securing these rolls with twine.

The result of the work of "PRF-180" in mowing.

The PRF-180 model is intended for use with tractors of the 1.4 class (Belarus MTZ-80 and MTZ-82, YuMZ-6, etc.) and the second traction class (Belarus MTZ-1221 ", "LTZ-155", etc.) and the type of towing device of the tractor "TSU-1Zh". Equipped with a PTO (power take-off shaft), hydraulic system, electrical equipment outputs. The design of this baler is simple and reliable. It allows you to obtain rolls of hay and straw with a dense structure on the outside, but with a loose middle, for better air circulation and to prevent spoilage.

The device of the PR-145S baler

The PR-145S baler, like any other complex agricultural machine, includes various systems and mechanisms:

- The unit is based on a frame; it serves to fasten all components and mechanisms of the machine, as well as its chassis.

- The hitch is used to couple the press to the tractor. It has increased strength and a reliable towing mechanism. Its design on this pick-up is somewhat different from its analogues. It is located not in the middle, but on the left. With this arrangement, the tractor does not move over the windrow, passing it between the wheels, but to the left along the way. This prevents the tractor from hitting the windrow and allows for better control of the process.

- Cardan transmission. Allows you to remove torque from the tractor PTO and transmit it to the baler gearbox shaft.

- The gearbox receives torque from the cardan transmission, converts it and transmits it to the pick-up and press.

- Picker. He picks up hay from the mown wolf and sends it to the press chamber.

- The pressing chamber includes two internal compartments of different sizes. Rolls are formed inside these chambers.

- The pressing mechanism is double-circuit, closed type, located inside the pressing chamber;

- Mechanism for feeding and cutting twine;

- The hydraulic system consists of high-pressure hydraulic hoses and two hydraulic cylinders.

Operating principle of the PRF-180 pick-up

In the process of forward movement across the field, the spring teeth of the pick-up mechanism rake the entire swath and feed the forage mass into the bale chamber. The lower rollers and rolling pins spin the roll into a mass, and due to the upper pressure grid, it is pressed and compacted. When the specified level of bale density is reached, a sound signal is given to the operator. If the roll is fixed with twine, the machine operator needs to manually feed the twine into the chamber, after which the roll is wrapped and the rope is cut mechanically. The finished roll is unloaded using the lower rollers after opening the press chamber.

In the open position of the camera, the selection mechanism is supported by springs and rests with wheels on the ground, and in the raised position it is secured with latches. To bring it into working position, the tractor power take-off shaft is first connected. The latches open only when the pick-up drive shaft begins to rotate.

Operation of the PR-145S baler

The use of the PR-145S pick-up is advisable for both large and small farms, when harvesting high-yielding grasses in large volumes. The closed press chamber eliminates hay loss during operation. The press works equally well in all climate zones, the only condition being the absence of stones protruding from the ground by more than 30 mm.

The main competitive advantages of the picker:

- The blade located on the side prevents the tractor from hitting the windrow and provides a better overview of the process;

- Automatic monitoring of roll density according to specified parameters;

- Can be aggregated with both imported and domestic tractors;

- Reduced hay loss during operation due to a closed press chamber;

- Economical in maintenance.

Feedback from farmers about the PR-145S baler:

- I have been using the PR-145S for several seasons now. The first year was a mess, it was done rudely, there were a lot of shortcomings, almost every day the jambs made themselves felt. But by the end of the season, everything seemed to have settled down, and it needed tweaking and fine-tuning along the way. Now it works fine, I'm quite happy. Among the faults corrected: the alarm for the start of wrapping rolls goes off when it wants, and not when it is needed; the roll was tied with twine unevenly, which is why the rolls turned out to be slightly cone-shaped; Well, just a few minor things: the welding was not of good quality, or they forgot to tighten the nut.

- It worked for two seasons without any complaints, there were of course some shortcomings, but not critical. What spoiled the impression the most at first was the alarm system, there was a lot of play in the contacts, they close whenever they want, hence the large number of false signals. My opinion is not bad, quite a budget press, although it requires some improvements.

About enterprises -

Bobruisk has been working since 1974. In Soviet times, it produced fertilizer spreaders with a lifting capacity of 8 to 18 tons. (More than 26 thousand such agricultural machines per year). In the 90s, it became obvious that the only way for an enterprise to survive in new economic conditions was to reorient production towards new, competitive types of products and significantly expand the range of products.

Since that time, he began to produce a wide range of goods that were in demand on the market in all republics of the former Soviet Union: trailers and semi-trailers for cars and tractors, including tippers; scales; grain grinders (crushers); equipment for harvesting and post-harvest processing/sorting of potatoes; garage doors of all types; fences and fences, stoves and barbecues, etc.

It was also decided to start production of machines for mechanizing forage harvesting work. Moreover, the issue of mechanization of labor in the procurement and distribution of feed was approached in a comprehensive manner. Balers of the “PRF” type are produced in various modifications, so that they can be used in both large and small peasant farms, and even in subsidiary farming.

.

In parallel with the balers, the plant's design bureau developed and subsequently put into production TR-F-5 roll transporters; unwinder-distributor of roughage - RGK-1; four-rotor disc mower KDN-210, rake-tedder GVR-630 and feed dispenser KRF-10. Thus, Bobruiskagromash produces agricultural machines for each stage of feed procurement and feed distribution.

Since 1995, Novosibirsk has been producing NASH brand sunflower and corn harvesters, and since the early 2000s, also cultivators, drum mowers and roll balers of several types. Including a model similar to the Bobruisk “PRF-180” - “PR-180M”. Let's consider the main technical characteristics, features of the design and operation of this agricultural machinery.

Choosing a used PR-145S baler: features of choice

In general, the design of the PR-145S press is not complicated, and even a person who has not previously encountered such equipment can understand what is what. Therefore, when choosing a used unit, the main thing is to know what to look for so as not to overpay and save yourself from unnecessary repairs in the future.

The first place it would be nice to look is the gearbox. Opening the top cover and assessing the wear of the gears takes 5 minutes; whether the seller will do this is another question. Also pay attention to the coupling connecting the cardan to the gearbox.

Inspect the rolling pins; on the PR-145S they are hollow and will bend if the pick-up is used incorrectly.

These presses often have problems with the alarm, and most often it is not adjusted but simply turned off. Ask how it works and whether the alarm works on the press you are planning to purchase. A disabled alarm often leads to overloading of the bunker, as a result of which it warps and welds break.

The price for a baler in good working condition will be approximately 250 thousand rubles for a unit from 2005-2006, then increasing. A new device costs about 400 thousand rubles.

Decree of the Government of the Russian Federation dated 02/08/2017 No. 145

Approved by Decree of the Government of the Russian Federation of February 8, 2022 No. 145

1. These Rules determine the procedure for creating and maintaining a catalog of goods, works, and services to meet state and municipal needs, including the composition of the information included in it.

2. The catalog of goods, works, and services to meet state and municipal needs (hereinafter referred to as the catalog) means a systematic list of goods, works, and services purchased to meet state and municipal needs, formed on the basis of the All-Russian Classifier of Products by Type of Economic Activities (OKPD2) OK 034-2014 and including information in accordance with these Rules.

(Clause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation of October 6, 2017 No. 1217. - See previous edition.)

3. The formation and maintenance of the catalog is carried out in a unified information system in the field of procurement, including through information interaction with other information systems in cases established by the legislation of the Russian Federation on the contract system in the field of procurement of goods, works, services to meet state and municipal needs, as well as information systems maintained by authorized federal executive authorities.

(Clause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation of October 6, 2017 No. 1217. - See previous edition.)

4. The formation and maintenance of the catalog is ensured by the federal executive body for regulating the contract system in the field of procurement (hereinafter referred to as the authorized body), including as a result of interaction with the federal executive bodies responsible for the formation and (or) maintenance of information systems, as well as those carrying out state registration of goods in the established field of activity, through:

(Paragraph as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation of October 6, 2017 No. 1217. - See previous edition.)

a) generating information included in the catalog in accordance with these Rules;

b) keeping the catalog up to date;

c) information support for catalog users.

(Subclause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation dated October 6, 2017 No. 1217. - See previous edition.)

4.1. For the purpose of information interaction provided for in paragraph 3 of these Rules, the authorized body establishes the composition, procedure for sending and signing the information provided for in subparagraphs “b” - “d” of paragraph 10 and specified in subparagraph “b” of paragraph 14 of these Rules, by federal executive authorities, carrying out the formation and (or) maintenance of relevant information systems, as well as state registration of goods in the established field of activity.

(The paragraph was additionally included from April 24, 2022 by Decree of the Government of the Russian Federation of April 12, 2018 No. 444.)

5. For the purpose of ensuring the formation and maintenance of the catalogue, the authorized body has the right, in accordance with the legislation of the Russian Federation, to engage a legal entity that is the operator of the catalogue.

6. The catalog must be publicly available 24 hours a day for review and use without charging a fee.

7. The catalog does not include information that constitutes a state secret.

8. The catalog is maintained in Russian. In cases provided for by federal laws and regulations adopted in accordance with them, information may be included in the catalog using letters of the Latin alphabet.

9. The catalog is formed and maintained in electronic form. The catalog position is formed in accordance with paragraph 10 of these Rules.

(Clause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation of October 6, 2017 No. 1217. - See previous edition.)

10. The following information is included in the catalog item:

a) catalog item code generated in accordance with paragraph 12 of these Rules;

(Subclause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation dated October 6, 2017 No. 1217. - See previous edition.)

b) name of the product, work, service (for the purposes of these Rules, the name of the product, work, service is understood as the name of the corresponding product, work, service included in the catalog position, which is not a trade name and does not contain an indication of a specific manufacturer and (or) place origin of the goods);

c) units of measurement of the quantity of goods, the volume of work performed, services provided in accordance with the All-Russian Classifier of Units of Measurement OK 015-94 (OKEY) (if available);

(Subclause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation dated October 6, 2017 No. 1217. - See previous edition.)

d) information containing a description of a product, work, service, if such a description is formed in accordance with paragraph 13 of these Rules;

(Subclause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation dated October 6, 2017 No. 1217. - See previous edition.)

e) background information:

codes corresponding to the product, work, service in accordance with Russian and international classification and cataloging systems (if available);

(Paragraph as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation of October 6, 2017 No. 1217. - See previous edition.)

information on standard contracts, standard contract terms to be applied when purchasing goods, work, services (if available);

f) date of inclusion in the catalog of the item;

(Subclause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation dated October 6, 2017 No. 1217. - See previous edition.)

g) date(s) of the beginning of mandatory application of the information included in the catalog item;

(Subclause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation dated October 6, 2017 No. 1217. - See previous edition.)

h) expiration date for the catalog item (if necessary);

(Subclause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation dated October 6, 2017 No. 1217. - See previous edition.)

i) additional information in accordance with paragraph 19 of these Rules.

11. The clause has lost force since October 9, 2022 - Decree of the Government of the Russian Federation of October 6, 2022 No. 1217. - See the previous edition.

12. The catalog item code is generated for each catalog item and is a unique digital code based on the code of the All-Russian Classifier of Products by Type of Economic Activities (OKPD2) OK 034-2014.

(Clause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation of October 6, 2017 No. 1217. - See previous edition.)

13. The description of goods, work, services in accordance with the requirements of Article 33 of the Federal Law “On the contract system in the field of procurement of goods, works, services to meet state and municipal needs” (hereinafter referred to as the Federal Law) includes the following information:

a) consumer properties and other characteristics of goods, work, services, including functional, technical, quality characteristics, operational characteristics (if necessary), formed taking into account the following information:

(Paragraph as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation of October 6, 2017 No. 1217. - See previous edition.)

if the specified characteristics have a quantitative assessment, then units of measurement are used in accordance with OKEI. If there is no unit of measurement in the OKEI, in respect of which the authorized body has decided to include in the description of a product, work, or service, the authorized body sends to the federal executive body ensuring the development, maintenance and application of the OKEI, an appeal for inclusion of such a unit of measurement in the OKEI. In this case, before the inclusion of the corresponding unit of measurement in the OKEI, such a unit of measurement is included in the description of the product, work, service and is considered a temporary value;

(Paragraph as amended, put into effect on April 24, 2022 by Decree of the Government of the Russian Federation dated April 12, 2018 No. 444. - See previous edition.)

in relation to each characteristic that has a quantitative assessment, its specific value, or an exhaustive list of specific values, or ranges of acceptable values (minimum or maximum acceptable values), or unchangeable values, including taking into account the requirements for a product, work, service, established in accordance with Article 19 of the Federal Law;

(Paragraph as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation of October 6, 2017 No. 1217. - See previous edition.)

in relation to each characteristic that does not have a quantitative assessment, an exhaustive list of the relevant properties of the product, work, service is indicated, including taking into account the requirements for procurement objects established in accordance with Article 19 of the Federal Law;

b) information on technical regulations applicable to goods, works, services, adopted in accordance with the legislation of the Russian Federation on technical regulation (if any), documents developed and applied in the national standardization system, adopted in accordance with the legislation of the Russian Federation on standardization (if any) availability);

(Subclause as amended, put into effect on April 24, 2022 by Decree of the Government of the Russian Federation dated April 12, 2018 No. 444. – See previous edition.)

c) if necessary, specifications, plans, drawings, sketches, photographs, digital models, results of work, testing, requirements, including with regard to testing, test methods, packaging in accordance with the requirements of the Civil Code of the Russian Federation, markings, labels, confirmation compliance of processes and production methods in accordance with the requirements of technical regulations, standards, technical specifications, as well as in relation to symbols and terminology;

d) the subclause has lost force since October 9, 2022 - Decree of the Government of the Russian Federation of October 6, 2022 No. 1217 - see the previous edition.

14. Catalog items are formed and included in the catalog in the following order:

a) the formation and inclusion in the catalog of information provided for in subparagraphs “a” and “e” of paragraph 10 of these Rules is ensured by the authorized body automatically using software and hardware;

(Subclause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation dated October 6, 2017 No. 1217. - See previous edition.)

b) the information provided for in subparagraphs “b” - “e” of paragraph 10 of these Rules is included in the catalog by the authorized body on the basis of information provided, inter alia, by federal executive authorities responsible for the formation and (or) maintenance of relevant information systems, as well as state registration of goods in the established field of activity, regional information systems in the field of procurement, operators of other information systems in cases established by the legislation of the Russian Federation and other regulatory legal acts on the contract system in the field of procurement of goods, works, services to meet state and municipal needs. In this case, the information provided for in subparagraph “d” of paragraph 10 of these Rules is included in the catalog after agreement with the Federal Antimonopoly Service;

(Subclause as amended, put into effect on April 24, 2022 by Decree of the Government of the Russian Federation dated April 12, 2018 No. 444. – See previous edition.)

c) the information provided for in subparagraphs “g” – “h” of paragraph 10 of these Rules is generated by the authorized body taking into account the requirements of paragraph 18 of these Rules;

(Subclause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation dated October 6, 2017 No. 1217. - See previous edition.)

d) the information provided for in subparagraph “i” of paragraph 10 of these Rules is included in the catalog in accordance with paragraph 19 of these Rules.

15. The information specified in paragraph 10 of these Rules, including before its inclusion in the catalog position, is considered at a meeting of the expert council for the formation and maintenance of a catalog of goods, works, services to meet state and municipal needs under the authorized body. The regulations on the expert council for the formation and maintenance of a catalog of goods, works, services to meet state and municipal needs and its composition are approved by the authorized body.

(Clause as amended, put into effect on April 24, 2022 by Decree of the Government of the Russian Federation dated April 12, 2018 No. 444. - See previous edition.)

16. Information included in the catalog, with the exception of information provided for in subparagraphs “a” and “e” of paragraph 10 of these Rules, must be signed with an electronic signature of an authorized official (persons) determined by the authorized body or the catalog operator (in the case its involvement for the purpose of ensuring the formation and maintenance of the catalog in accordance with paragraph 5 of these Rules), the type of which is provided for by Federal Law.

(Clause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation of October 6, 2017 No. 1217. - See previous edition.)

17. Keeping the catalog up to date is carried out by making changes to it in the manner prescribed by paragraphs 14 and 15 of these Rules, and by generating and entering information containing relevant changes into the catalog by the authorized body.

(Clause as amended, put into effect on April 24, 2022 by Decree of the Government of the Russian Federation dated April 12, 2018 No. 444. - See previous edition.)

18. Information included in a catalog item in accordance with subparagraph “a” of clause 10 of these Rules is subject to application from the day a new catalog item is included in the catalog. In this case, the start date of the mandatory application of information provided for in subparagraphs “b” - “i” of paragraph 10 of these Rules is set after 30 days from the date of inclusion of a new catalog item in the catalog, unless otherwise established by the authorized body.

(Clause as amended, put into effect on October 9, 2022 by Decree of the Government of the Russian Federation of October 6, 2017 No. 1217. - See previous edition.)

19. Catalog items in accordance with Article 33 of the Federal Law may include additional information about specific goods, works, services, including information about the characteristics of such goods, their manufacturers, trade names, names of places of origin of goods, prices per unit quantity of goods, volume of work, services and (or) prices per unit of measurement of the quantity of goods, volume of work, services, conditions for the supply of goods, performance of work, provision of services. This information is generated, among other things, by manufacturers and (or) suppliers (contractors, performers). The grounds and procedure for the formation and inclusion of such information in the catalog are determined by the authorized body in agreement with the Federal Antimonopoly Service.