Features of use

Solid waste presses are versatile and are used for processing solid waste of almost any type. This could be, for example, waste paper, aluminum cans, plastic bottles, disposable tableware, textiles, etc.

The scope of use of such equipment is quite wide. Waste paper presses can be used:

- in regular supermarkets and self-service stores;

- on the territory of markets of different specializations;

- in office premises and warehouses;

- at industrial enterprises.

Equipment design

A cardboard press is a special hydraulic machine that turns waste into bales of standard sizes 70 x 50 x 60 cm. Subsequently, enterprises hand them over to companies involved in recycling recyclable materials, thus receiving additional income (provided they are sorted before pressing) .

This type of machine is a large box for receiving waste with a piston-press descending from above. Also, the design elements of this type of equipment are:

- electric hydraulic pump;

- bed;

- pressure distributor;

- locking mechanism;

- magnetic switch;

- limit switch.

The functional part of such a machine consists of hydraulic cylinders and sliders. The press is controlled using a special handle. The pressure inside the device is monitored using a pressure gauge. Industrial installations of this type have a more complex design.

Homemade wood sanding machine - an example of a successful design

An old three-phase motor from a small ventilation station was used as the power plant. The advantage of this connection is that it is possible to organize reverse (in this case we are talking about the disk design of the machine). Sometimes, changing the direction of rotation of the sandpaper is necessary.

Connection using capacitors, the circuit has been discussed more than once on this resource. The working disk is cut from a plywood sandwich. Two sheets of 15 mm thickness are glued together with PVA glue, and then turned into a circle.

The entire bed, guides, and tool rest are made from the same 15 mm plywood. Since a homemade woodworking machine is made from wood (pardon the pun), additional attachments can be created. For example, a useful option for tilting the desktop.

Plywood was not chosen by chance. A powerful electric motor (especially for older people) is a source of parasitic vibrations. The wooden frame smoothes out vibrations that interfere with normal work. A stop device is installed on the hand rest for fixing horizontal angles.

Popular: How to make a homemade wood splitter with your own hands

Don't forget about work safety. On top of the rotating disk we attach an arch - a protective casing. This measure is not for aesthetics; touching the rotating disk can break your finger or seriously damage your skin.

Important! The surface of the tool rest must be sanded to perfect smoothness. The varnish coating is undesirable; it will wear off unevenly and the workpiece will be difficult to move.

Similarly, you can assemble a drum machine. It will be useful, for example, when preparing boards for flooring or a wooden table.

The main thing is the massive frame. The support bearings and wide drum are taken from a decommissioned conveyor belt, as is the motor.

The main task is to ensure an ideal horizon between the drum axis and the tabletop. The working surface is ground until final polishing. It is better to take harder material for the table.

Oak boards are too expensive, so you can use beech. A mandatory element of a drum sander is a table height adjuster. The screw mechanism must have a lock to prevent spontaneous unwinding due to vibration.

If the frame is not very heavy, you should secure the legs to the floor. Otherwise, the machine may overturn during work. When processing thick and uneven boards, the force applied is serious.

Conclusion: There is absolutely no need to spend your savings on purchasing industrial machines. All the designs considered can be made independently.

Types of cardboard presses

Machines of this type differ mainly only in power, average pressure mass, dimensions and productivity. In this regard, there are two main types of cardboard presses:

- mini installations;

- "standard" series;

- industrial models.

Mini presses for cardboard and paper are usually used in offices, shops, small industries, etc. Large industrial enterprises use presses of high power and productivity. Such equipment can process not only relatively soft materials such as cardboard or plastic, but also waste remaining after processing metal and wooden blanks. Models of the “standard” series have slightly higher productivity than the mini, but less than the pro.

Steps: How to remove the drill chuck from the Interskol drill?

The Interskol drill has many advantages. It is lightweight and easy to handle; when working at heights, you can hang it on your belt, thereby freeing your hands. You can change the number of revolutions.

Firstly, it is in the cheapest segment compared to competitors such as:

- Bosch;

- Makita;

- Metabo et al.

There is a function for locking the engine speed: press the on/off lever all the way, then press the lock button and release the lever. The rotation is locked and you can continue working, concentrating on the workpiece rather than the pressure of the drill.

There are non-standard options for removing the chuck from a drill; for example, not all Interskol drills have special grooves on the axis for fixing with a wrench.

The most important thing is to never hit the chuck with a hammer or other tools when unscrewing - you can not only break the chuck, but also damage the axle. The first step is to loosen the bolt in the usual way. Then you can use a gas wrench, grab the edge of the part being removed and, with a jerk or a slow movement forward, unscrew the insert. To avoid the problem of the cartridge being unable to be removed in the future, lubricate all parts with Lithol or other lubricant.

In the photo you can see the quick release chuck on the left and the key chuck on the right. There is an opinion that a key chuck grips drills better, but based on many years of experience with key chucks and keyless chucks, I dare say there is no difference. Both types of chucks clamp with equal success. Only the convenience and speed of changing drills on a drill with a keyless chuck is undeniable. There is no need for a wrench, which is constantly lost during operation, unless it is attached to the auger or tied to it with a rope, two hands are needed to clamp the auger.

Main technical characteristics

Models of the “standard” series have relatively small dimensions and an average pressure weight of 8-10 tons. The performance of such machines depends, among other things, on power. For example, using a 2-2.5 kW mini-installation allows you to produce 4-5 briquettes of standard sizes per hour. Industrial models can exert 30-40 tons of pressure on waste. Their productivity is much higher.

Mini waste compaction plants operate with a force of 2-9 tons. Their main distinguishing feature is their small size (from 2000x645x420 cm). This model can be installed, for example, in a small office or store. Any waste paper press works from the mains. Mini-installations are connected to a network of 220 V, industrial and “standard” - 380 V.

The main technical characteristics that you should pay attention to when purchasing equipment of this type are power, average pressure mass, productivity and dimensions. Of course, when choosing equipment of this type, it is worth looking at the manufacturer’s brand.

Classification by drive type

After many years of working with paper waste, engineers began to develop various designs of waste paper presses, differing in the following characteristics:

- type of drive

- size

- download type

- pressing force

- working chamber area volume

- mobility

By size, we can distinguish professional, compact and standard waste paper presses.

Depending on the type of drive, which determines the design features, a press for cardboard products can be:

- hydraulic

- mechanical

- hydromechanical

Hydraulic

The operation of such a press is carried out using a hydraulic drive. The device processes waste paper, rubber, plastic and other similar materials.

The press control system can be automatic, semi-automatic or manual.

According to their characteristics, hydraulic presses are divided depending on:

- size

- productivity

- pressing forces

- speed of movement of the work plate

The hydraulic drive can be a powerful stationary press or a mobile mini-device.

Mechanical

Mechanical products have a manual drive. It differs from other drives by having the following features:

- small-sized

- little weight

- low performance

- does not require power supply

- low pressing force

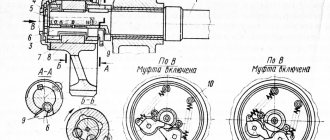

In terms of design, a manual press can be screw, rotary, eccentric and lever-crank.

The devices are used in production where waste volumes are small.

Hydromechanical

Hydromechanical presses have a lever drive. Distinctive features of the device are:

- High speed and low effort at the beginning of the press stroke.

- At the end of the stroke, the press force increases and the speed decreases.

- Low energy costs for processing raw materials.

The devices are capable of pressing metal waste, which is why they are often used in mechanical engineering. Hydromechanical presses have high productivity and provide economical material processing.

Technical characteristics of the machine PGP-15M

Next, as an example, we will consider what parameters the popular domestic press for cardboard PGP-15M has. The main technical characteristics of this model are shown in the table below.

| Parameter | Meaning |

| Average pressure mass | 15 tons |

| Dimensions | 300x150x90 cm |

| Weight | 900 kg |

| Bale size | 900x1000x750 mm |

| Number of binding threads | 3 |

Principle of operation

Recycling waste using equipment such as a hydraulic cardboard press is extremely simple. This procedure looks like this:

- the collected waste is placed in a chamber box;

- the machine is connected to the network;

- the press lowers onto the waste and presses on it with a certain force;

- as a result, a bale is formed;

- the resulting bale is tied with threads and unloaded from the container.

Waste can be loaded into the chamber several times during the pressing process.

Removing the Screw Chuck

On drills with a reverse function, the drill chuck is additionally secured with a locking screw, which is visible through the open jaws.

Locking screw in screw chuck.

The sockets on the screw head can be Phillips, hex or even star. Have a suitable screwdriver, wrench or bit ready. Use tools with a full socket and precise fit.

Loosen the chuck mounting screw.

Measure the size of the wrench on the drill shank. This will probably be 14mm for a medium tool or 17mm for a more powerful machine.

Select a wrench for the chuck.

Prepare a wrench with thin jaws. You can use a suitable wrench from a bicycle repair kit or sand the edges of a regular wrench using an emery wheel.

Prepare a wrench.

While holding the drill rod with a wrench, use a screwdriver to unscrew the screw clockwise (left-hand thread).

Be careful not to break the splines.

If the thread does not “go”, secure the drill chuck in a vice and hit the screw head through the steel rod several times with a hammer.

Now the thread will become plastic and the bolt will unscrew.

The clamping screw is unscrewed.

Then unscrew the cartridge itself counterclockwise (right-hand thread) using two wrenches: one for the tube and one for the cartridge.

Difficulties may arise. Try increasing the leverage by holding the hex key in the handle.

As a last resort, use a vice and place a drill in it, as in the photo below.

Move the cartridge from its place by striking the collar secured by the square head.

This method can be used to unscrew fairly jammed cartridges.

Remove the threaded insert from the drill.

After cleaning, reinstall the chuck in reverse order, keeping in mind the different thread directions.

Before tightening the locking screw, run some paint onto the threads.

In this case, you can use a hex key clamped in a chuck. This will allow the lever to be pulled out and, if “flipped”, the tool itself can be used. To use this tool, hold the hex key in a vise and clamp it, or tap it on a table while turning it at low speed.

Cardboard press: equipment price

The cost of this type of equipment directly depends on its technical characteristics. Mini-installations designed for waste processing are estimated at approximately 75-112 thousand rubles. The price for “standard” series presses is about 92-150 thousand rubles. For professional equipment of this type you will have to pay about 140-400 thousand rubles. In addition to new waste presses, used models are also sold on the modern domestic market, the cost of which depends not only on the technical characteristics, but also on the condition of the components and mechanisms. But, of course, the price of such equipment will be lower in any case.

Tools

From time to time, every home craftsman needs to grind and adjust metal parts. This work can be done either manually or mechanically. The first option will require a lot of time and effort. The second greatly facilitates the grinding procedure and ensures good processing accuracy of the part. For mechanized processing of a part, you will need special equipment - a surface grinder. This is an invaluable item for metalworking.

If you regularly work with metal, then sooner or later there will be a need to purchase such a machine. There are two options: buy or try to assemble it yourself. The first option will cost a pretty penny and is advisable in cases where working on such a machine will bring in money, i.e. actually a business. The second option is cheaper. And although the capabilities and parameters of such equipment will be lower, nevertheless, its capabilities are quite sufficient for home needs. Since the topic of machine tool building is quite complex, this article does not claim to be comprehensive information. Rather, this is an attempt to understand the structure of a surface grinding machine and recommendations for those who decide to make such a machine with their own hands.

Content

Purpose and design of a surface grinding machine

Any metal part goes through a grinding stage. In industry, specialized machines are used for these purposes. They can be fully automated, i.e. CNC or semi-automatic. In everyday life, having such a machine is almost a luxury. This is true both in terms of the cost of such equipment and its capabilities. But since this article is about homemade surface grinding machines, it is simply necessary to know their structure. Otherwise, we would have to “reinvent the wheel.” Therefore, it is more advisable to consider a factory machine and copy its structure, adapting it to your needs.

So, a surface grinding machine is designed for processing profile and flat surfaces of parts. A professional machine is capable of providing surface processing accuracy of up to 0.16 microns. In everyday life, this figure, although desirable, is not critical, but in homemade machines it is practically unattainable. Unless you are a milling machine operator or lathe operator at an arms factory with 20 years of work experience.

The main component of any machine, and a surface grinding machine is no exception, is the bed. Its dimensions and strength will depend on the required characteristics (sizes) of the parts intended for processing. Factory machines have a cast frame, predominantly made of cast iron. Due to its massiveness, it excellently dampens vibration, and in grinding and finishing parts, this is practically the main condition.

The next part of such a machine is the work table. As a rule, this is a magnetic plate of a given size, but there are machines with special fastenings for parts. The main feature of surface grinding machines is the mobility of the table. It makes circular or reciprocating movements. The shape can be round or rectangular.

In factory machines, the table is driven by a hydraulic system. In a domestic environment, such a system will cost the owner quite a lot, so a reliable mechanical system will be sufficient.

The working surface of the surface grinding machine moves along guides. In professional equipment they have high precision and durability. For a home machine, these characteristics are also required. The maximum precision of surface processing of the part will depend on this. Also critically important is the smooth sliding of the table, without jerking. To achieve this, friction must be kept to a minimum. If this requirement is ignored, then when jerking the table with a fixed part, you can forget about grinding accuracy.

Mechanical models

In addition to this type of hydraulic equipment, mechanical presses can be used to process waste. The advantage of such equipment is that it can be installed even outdoors. Such machines are small in size and weight (within 100-150 kg). Very often, mechanical units are installed in the bodies of cars that collect recyclable materials.

Mechanical presses operate on the principle of conventional screw pressure. The force in them can range from 4 to 32 tons.

general information

Resanta SAI-220 is a portable welding inverter designed for manual arc welding with coated electrodes. To operate it, it is enough to have a socket and a 220V household power supply. When welding, you can use electrodes with a diameter of up to 5 millimeters. The maximum welding current is 220 Amperes, which is enough for students and summer residents. The open circuit voltage is 85V. The arc ignites without any problems, so you can weld all types of metals.

The equipment in SAI-220 is standard. There are two cables with a holder and a terminal, the cables themselves are 2 meters long each. Also in the box you will find a power cable, its length is 170 cm. We believe that this is clearly not enough to perform some work. So use an extension cord.

There is nothing else in the box. If necessary, you can buy a model with a convenient case, and also purchase a welding mask and other personal protective equipment separately.

The device is equipped with additional functions “anti-stick” and “hot start”. Now even the cheapest inverters have these functions, so they won’t surprise you. But one cannot fail to note the presence of such functionality in SAI-220. After all, the “anti-stick” and “hot start” functions will especially appeal to those who are just starting to learn the basics of welding. They simplify and speed up your work.

Benefits of use

It is worth installing a cardboard press in a store, warehouse or office space, if only because in this case you can:

- Save on waste removal. Recycling costs are usually much less than the cost of transporting recyclables to a disposal site. To store a ton of compressed waste, only 1.5-3 m2 of space is needed.

- Free up part of the production space. Bales take up much less space than solid waste itself.

Bales can be stored indoors, according to regulations, for an unlimited time. The standard sizes of bales allow them to be transported with maximum convenience both by rail and by car. The press is extremely simple to operate and does not require the operator to have any special knowledge or skills. This type of equipment can be operated by one person.

Removing the threaded chuck, with reverse screw

To remove the chuck from the axle, you must first unscrew the central screw. To access it, spread the cams all the way. Then insert a screwdriver or screwdriver and pull out the screw with a sharp movement. The bolt thread is located on the left side. The screw itself is sealed and very difficult to turn.

It should also be noted that it is necessary to use a quality tool. When I worked with a Chinese screwdriver, the socket simply broke off. The screw itself remained in the same place. Only hitting the screw helped, then the head moved and the process began. After unscrewing the screw, remove the cartridge body itself.

Then unscrew the cartridge itself from the thread. In this case, the thread returns to the screw. It is very difficult to detach the threads as they “stick” during operation. This requires significant effort, but the process can be sped up.

In this case, you can use a hex key clamped in the handle. This will allow you to lengthen the lever and, if there is a “reverse”, use the tool itself. To use the tool, either hold the hex key in a vise and clamp it, or tap it on a table while rotating it at low speed.

In modern drills, such as Interskol or Makita, the drill or other accessories are clamped in the chuck using a cam mechanism: 3 or 4 cams hold the cutting tool in a secure position and can only move along the axis of the drill shaft. The keyless chuck is manually adjustable; more advanced designs used in modern drilling machines are key operated.