Machines for performing forging and stamping operations (or rather, because some equipment is usually created for the developed technology, and not vice versa) are a common type of device for metalworking.

For example, in machine- and instrument-making enterprises or factories for the production of metal structures, for every 5 metal-cutting machines there is necessarily one piece of equipment for pressure processing. And not only metals: for example, the same PET bottles are produced on injection molding machines, which are also specialized stamping equipment.

Types of stamping technologies

The stamping process of processing blanks can be carried out using the hot or cold method. These technological varieties involve the use of special equipment and the use of certain metal processing conditions.

Cold stamping is one of the types of stamping

The hot stamping method processes workpieces that are preheated in special devices to a given temperature. Hot stamping is necessary when there is not enough equipment power to process a cold alloy. Heating devices can be electric or plasma ovens. This method requires accurate calculation of the parameters of the finished part, taking into account the shrinkage of the metal during the cooling process.

In cold stamping, parts are formed due to the mechanical pressure of the elements of the stamping press. Cold stamping is considered a more common method of metal processing. It does not require additional equipment, complex calculations or mechanical modification of parts. Thanks to this method, the strength properties of the material increase. The resulting products are distinguished by high surface quality and precision.

This is interesting: Radial drilling machine 2M55: characteristics and documentation

Subtleties of technology

Stamping, or stamping, as this technological operation is often called, is a process in which a metal workpiece undergoes plastic deformation under pressure. As a result of such an impact, for which special equipment is used, a finished product of the required size and shape is formed from the workpiece. Deformation of a metal workpiece can be carried out with its preheating, then this process is called hot stamping. If there is no preliminary thermal effect on the workpiece, then cold stamping of the metal is performed.

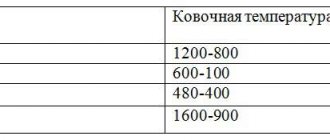

Classification of basic stamping operations

Evolution of equipment development

Until the 15th and 16th centuries, almost all metal products were produced by private workshops and small workshops. However, the beginning of the Great Geographical Discoveries with the accompanying increase in the tonnage of sea vessels required the production of fairly large anchors and other ship equipment. It was no longer possible to forge such large parts by hand with a hammer. As a result, the first mechanical hammers powered by water power appeared.

Further, the impetus was the development of weapons and vehicles, and in the 19th century entire metalworking giants with steam equipment emerged.

The invention of hydraulic presses made it possible to introduce stamping as the main technology for mass production of products. And the further emergence of electric motors gave impetus to the development of crank presses, which form the modern basis of forging and stamping equipment.

Types of stamping equipment

To produce products from sheet metal, presses equipped with various stamps are used. During operation of the equipment, the upper component of the die moves, the lower part remains stationary.

Deformation of the workpiece occurs at the moment of contact between parts of the equipment. There are various models of stamping presses, which allows you to choose the right machine to produce the required parts.

Hydraulic Punching Machine

Presses for metal stamping are:

- crank type;

- hydraulic;

- radial forging type;

- electromagnetic type.

Crank presses are a simple type of equipment and can be double or triple acting. The presses got their name from the crank mechanism, which is the main structural element of the machine. The principle of operation of the mechanism is based on the transformation of rotational motion from the drive into reciprocating periodic movement of the press element - the slide.

Equipment at the production of Tochnost LLC

In his work he uses modern automatic presses produced by the largest foreign brands:

- ESSA, Switzerland;

- "KAISER", Germany;

- "FICO FISHER", Germany.

They can provide a punching force of up to 20 tons and at the same time meet all technological requirements, allowing the output of products of the highest quality.

Cold stamping of metal to order using crank presses is a fairly simple and economical technology that ensures high speed of mass production under automation conditions (and therefore with minimal influence of the human factor). The absence of temperature changes allows for maximum compliance with the specified dimensions of the part.

Read also: Furnaces for ion plasma nitriding

The method has one more advantage - reducing the cost of goods makes it possible to increase the volume of products, which, in turn, will lead to lower prices. Regular clients of Tochnost LLC have been able to verify the flexibility of our pricing policy more than once.

A crank press is a device whose operating principle is to convert rotational motion into translational motion. The crank mechanism built into it, which performs all key operating operations, consists of fixed and moving elements.

The crank presses produced in Russia and used at the Tochnost enterprise also have their own advantages:

- provide optimal performance;

- guarantee high precision of parts;

- comply with all current technical requirements;

- designed for long-term and stable operation.

Their development uses steel that has undergone special processing and additional surface hardening.

You can find out the prices for cold metal stamping at Tochnost LLC, as well as get advice from our specialists or leave a request by phone.

Stamping is one of the most common types of metal processing, which is a deformation that gives the part the required shape by extruding a certain relief, pattern, or holes on the surface. This process is carried out on special presses of various designs.

Operating principle and design of various types of presses

metal stamping workshop

Any standard stamping machine consists of the following main components: motor, transmission, actuator. The transmission and motor together make up the "drive". The main characteristic of the drive is the type of connection between the engine and the actuator: mechanical or non-rigid (liquid, gas, steam). Working parts of the press: rollers, slider, cross-beams, rollers, women.

Crank press

The machine drive rotates, the movement on the slide is converted to reciprocating.

Under the influence of this movement, the metal is processed using a stamp. All machine parts are made of durable steel and equipped with stiffeners. The movement of the slider occurs according to a strict schedule. The force on the slide reaches 8 thousand tons. Crank forging plants make it possible to speed up, simplify and reduce the cost of production of parts, saving up to 30% of rolled stock. All crank machines are divided into simple, double and triple action. The crank press is capable of performing the following types of work:

- stamping in open and closed dies;

- burr formation;

- extrusion;

- firmware;

- combined processing.

A mechanical press acts on the material with an impact, while a hydraulic press, applying less force, gets a greater effect. Therefore, the latter are used for the manufacture of large products with thick walls.

Hydraulic presses

Hydraulic Press

Capable of stamping surfaces, pressing and forging metal products. They are also used for recycling metal waste. The operation of the machine is based on increasing the force of pressure on the metal many times. The press consists of two communicating cylinders with water, between which a pipe passes. Pistons are installed in the cylinders. The operating principle of the press is based on Pascal's law.

Radial forging apparatus

Processes metal using the hot method. The blank enters the heating module, which operates on the induction principle. Here it is heated, when the metal becomes sufficiently pliable, it is fed through a conveyor to a gripping mechanism, which feeds the workpiece directly into the processing zone. Forging or stamping is carried out with strikers; during the process, the workpiece rotates all the time, due to which it is processed evenly on all sides. The press is powered by an electric motor connected by a V-belt drive to the shafts. They are placed vertically and direct movement to the connecting rod and striker, between which the slider is installed. To ensure that all movements of the mechanism are synchronous, there are copying drums. The blank holder is rotated by an electric motor through worm gears. The spring clutch slows down the movement at the right moments.

Electromagnetic press

This is the latest development, which is just beginning to be used in industry. The working body of the machine is the core of an electromagnet, which moves under the influence of an electromagnetic field. The core moves the slider or die, the springs return the slider to its original position. Such machines are characterized by high productivity and efficiency. Today, there are models with a small amplitude of movement of the working body - 10 mm and a force of no more than 2.5 tons.

Operation of a roughing stamping machine in the video:

Types of stamping and equipment

Two types of stamping are used in production:

With the hot method, heated metal is processed. At the same time, the quality of the material improves: it becomes denser and more homogeneous. The advantage of the cold method is that a layer of scale does not appear on the surface, the dimensions of the part are more accurate, and the surface is smoother.

Stamping can be sheet or volumetric. The sheet method is used to produce: dishes, jewelry, watch parts, climate control equipment and microcircuits, weapons, medical equipment, parts for automobile, mechanical and machine tool manufacturing. The resulting parts do not require further processing. During volumetric pressing, cold or hot metal is forced into molds.

In metalworking, presses are used for:

- production of forgings;

- pressing of gears and bearings;

- volumetric and sheet stamping.

Pressing machines can be based on mechanical or hydraulic principles and process materials statically or percussively.

Crank machines perform cold and hot metal stamping by pressure: drawing, punching and cutting. Hydraulic presses are used for volumetric forging of metal. According to technological capabilities, presses are divided into: universal, special and specialized. Universal ones can be used for almost any type of forging (for example, a hydraulic forging machine). Specialized machines perform only one technological process (example: crank pullers). Special presses produce a specific type of product using one technology.

Features of open and closed dies

Closed stamping

Stamping equipment can be equipped with open or closed dies. In an open die, excess metal flows into a burr or flash that performs a specific function. The main disadvantages of this technology are: loss of alloy due to flash, reduction in product quality due to cut fibers when removing burrs.

Closed dies are used to produce simple shaped products. This flash-free technology is characterized by metal savings, no costs for cutting burrs, and high product quality due to all-round compression. Metal fibers are not cut. The closed die processing method is used for low-plasticity alloys. The main disadvantages are: the need for precise dosage of the alloy, the complex design of the die.

In modern manufacturing, stamping is primarily a preparatory operation that allows the production of parts for both electronics and aircraft or watercraft. The resulting products are subsequently subjected to welding, cutting, riveting and other processing methods depending on the technological process.

Related video: Sheet stamping

This is interesting: Types and characteristics of welding inverters

What is stamping: Types, technologies and tools

But with the scientific and technological revolution, special equipment was invented, which was modernized over the years. To understand how important technology is for industry, let’s say that parts for car bodies are produced in a similar way, which made it possible for their mass production.

Thanks to stamping, craftsmen are able to produce flat or three-dimensional parts of different sizes. The main tool is a stamp, which is attached to a press or similar type of equipment. There are two types of technology - hot and cold, the differences between which lie in the execution conditions.

For each of them, precise devices and tools are selected, established norms and rules are taken into account.

Features of the technology

You can familiarize yourself with the requirements for processing using this method by reading GOST 18970-84. The classification of the process does not end with the indicated types; there are other categories that are determined by the purpose of the technical process and technological conditions.

For example, there is separation stamping, that is, when metal blanks are divided into parts. Parts are subjected to various form-changing operations - cold extrusion, punching and other procedures. It is important to know that each method has its own scope.

Stamping, during which the workpieces are preheated, is used exclusively in production. Because this process is highly complex and accurate calculations will be required to implement it. Hot stamping allows you to produce such necessary products as:

- boiler bottoms;

- hemispherical objects;

- hull elements used in shipbuilding.

This pressing of parts is a very delicate and complex job that cannot be done at home.

What is necessary?

Even processing of aluminum (the softest metal) is carried out using special equipment. It can be crank or hydraulic. But even the most innovative equipment is not enough for high-quality stamping.

Deformation of metal blanks requires knowledge, because the dimensions of objects are first calculated and drawings are created. Only in this case will the finished metal products meet state standards.

The correct choice of equipment is no less important, so the master must clearly understand the shape, tolerances and parameters of the finished product, as well as what operation will help achieve the desired.

If processes such as punching or cutting are used, then a simple-action device is used. But for the hood you need something more powerful, for example, double-action equipment.

How does the process work?

Stamping work varies depending on the technological standards used. The first step is to carry out calculations and draw up a diagram of the future metal object, taking into account all operations carried out in the future.

If it is decided to use the hot stamping method, then the product is heated with flame furnaces or other electric heating equipment. The metal is deformed and takes the desired shape under the influence of hydraulic pressure.

The cold type of processing requires a different approach - in this case, the load is created solely by pressure. This method is advantageous because the resulting metal object does not require additional cutting. The product can be either flat or voluminous, large or small.

The sequence of stages in both cases is almost the same, with the exception of preheating the workpieces when performing hot stamping.

The technology appeared at the end of the 19th century, but its improvement continues to this day. It is in demand in industries such as mechanical engineering and instrument making. Because with high productivity, material consumption is minimal.

Types of stamping

Sheet metal is deformed by either high pressure or a combination of pressure and temperature. According to these conditions, the technology is divided into two large groups - hot and cold, each of which has its own advantages and disadvantages and scope of application.

In addition, both methods have their own subtypes, for example, hot volumetric stamping or cold sheet stamping.

Hot volumetric

During such pressing, a sample of the workpiece is processed by pressure, temperature and a stamp, as a result of which the original material is given the appropriate configuration. A square, round or rectangular sheet of metal is used as a blank.

The scope of application of the method is serial and mass production of parts. The advantages are:

- low amount of waste;

- high performance;

- the ability to obtain items of extremely complex configuration;

- high quality and precision of products.

Overview of IPONMAC presses and their characteristics

| Model series | KD 23D | HL41 | PG41 |

| Nominal force, t | 10-80 | 40-315 | 40-315 |

| Opening height/clearance, mm | 130-280 | 800-1600 | 800-1600 |

| Table/bottom plate size, mm | up to 520*860 | up to 1400*1200 | up to 1400*1200 |

| Drive power, kW | 1,1-7,5 | 5,5-30 | 5,5-30 |

| Weight, kg | 600-5280 | 3000-36000 | 3-36000 |

Design features

All units for processing metal workpieces have approximately the same structure. Three main nodes can be distinguished. These include:

- equipment engine;

- torque transmission;

- actuating mechanism.

The first nodes form the drive system, on which the functioning of the actuator depends. Each organ is responsible for a specific result. Therefore, you should understand what types of machines there are.

Hydraulic and crank type stamping presses

From the moment people learned to perform metal forming, the work of the specialist who did it was considered one of the most honorable. Over time, the need for metal products obtained using forging technology only increased, and the actively developing industry began to need them. All this led to the fact that for forging, not the manual labor of blacksmiths, but special equipment for stamping was used.

A fairly common type of device used for forging is a kind of hammer analogue - a stamping press. Using such stamping equipment, it is possible to perform a whole list of technological operations, namely: changing the shape of the workpiece by means of its plastic deformation, forming a given relief on its surface, cutting out individual fragments, etc. On such a device, in particular, they give shape to the workpieces for the manufacture of which casting was used. Presses used for stamping operations can be crank or hydraulic.

Press diagrams: a – vertical hydraulic; b – horizontal; c – crank; g – friction; d – hydraulic screw

A crank press is used in cases where it is necessary to perform simple metal forming by pressure. The main element of such equipment, which converts the rotational movement of the drive motor shaft into reciprocating movement of the slider, is the crank mechanism. That is why a crank press is often called a stamping crank press. It is very popular both among manufacturers and private craftsmen; there are even models of a tabletop crank press. This popularity is explained not only by the high efficiency and functionality of this equipment, but also by the fact that maintenance and repair of crank presses does not cause any special problems.

Hydraulic stamping press 4-column

Hydraulic stamping presses are equipped with two working chambers in which the required pressure is created in the working fluid. The liquid under pressure enters the cylinder with another piston, through which reciprocating motion is imparted to the slide.

How are dies made for cold stamping?

Cold sheet metal stamping technology

A stamp is a specific type of equipment that is actively used in the sheet stamping process. It directly affects the material, deforming it. After processing, the metal acquires the same shape as that characteristic of the working part of the stamp. This tool is installed on special hammers and presses that drive it.

The stamp consists of two parts - a matrix and a punch. The last element is fixed on a special slider, due to which the tool moves. Metal deformation occurs at the moment the punch is pressed against the matrix.

Stages of production of cold stamping dies

High demands are placed on the process of creating stamp sketches and their actual production. The correct formation of the products themselves and their quality depend on the quality of the resulting equipment. Typically, stamp production occurs in the following sequence:

Cold die forging

- A sketch of the stamp is drawn up taking into account all the requirements presented.

- Using a special computer program, a stamp diagram is created.

- The rationality of the resulting equipment is determined, and if necessary, the sketch is adjusted.

- The places where holes of the required size and shape will be formed in the future are determined.

- After approval of the drawings, the production of the stamp begins immediately.

Workpieces made of metal will be correctly processed by cold stamping if all the equipment is selected effectively. Stamps are one of the main elements influencing the quality of the work performed. In their production, modern CNC equipment is used, which allows for the necessary quality control.

Types of technological operations

Technological operations with metal sheets are separating and forming.

Separation stamping operations are performed on equipment equipped with special tools. As a result, a certain part is separated from the workpiece along a straight line or a given contour. The separation of part of the sheet occurs in the following processes:

- Segment _ To perform this action, the equipment is equipped with disk, vibration devices or guillotine shears.

- Trimming . This operation separates the extreme parts of the resulting product.

- Punching . Holes of various configurations are created in a metal sheet using a stamp.

- Felling . A shaped part with a closed contour is obtained from the workpiece.

Form-changing operations are intended to create a product with different parameters and dimensions without mechanical destruction. The following types of these operations are distinguished:

- Beading. The contour of the workpiece or the internal holes are exposed to the stamp to form beads of certain sizes.

- Hood. This operation is a type of volumetric stamping, in which a spatial element is obtained from a flat material.

- Crimping To narrow the ends of a hollow workpiece, a stamp with a conical-type matrix having a narrowing working area is used.

- Flexible. As a result of the operation, the curvature of the surface changes by bending the metal and deforming the workpiece.

- Molding is a change in the shape of individual sections by reducing the thickness of the part without disturbing the external contour of the product.

- Puklyovka. Connecting two plates with a stamp without using additional elements.

Stages of stamp manufacturing

A major role in ensuring the required quality of the finished product is played by the design of dies for cold stamping, due to which the part is formed with the required geometric parameters. Working drawings of such working tools installed on stamping presses can be made in both two- and three-dimensional formats. To solve this problem, appropriate knowledge and skills are required.

The development of a drawing and the subsequent production of a stamp used for cold stamping are carried out in several stages:

- drawing up a sketch of the future stamp;

- studying the scheme according to which the material will be cut, checking such a scheme using a special computer program;

- editing the sketch, if necessary;

- final verification of the dimensions of the developed stamp;

- designation of the position and exact dimensions of the holes that will be made on the working surface of the stamp.

When developing dies, you often have to choose between the quality of the future part and the cost of production.

When developing dies for cold stamping, it is necessary to break the drawing of the finished product into separate parts and carefully study them. After this procedure is completed, the production of stamps is carried out. In this case, it is necessary to pay special attention to the requirements for the parameters of the finished product. For each stage of the cold stamping technological process, a route map is developed, which takes into account both the execution time of individual operations and the characteristics of forgings at individual processing stages.

Most dies are made of carbon or alloy steel, but aluminum and copper alloys are sometimes used

In such a matter as cold stamping of a metal workpiece, many parameters are important, which, in particular, include the sequence of technological operations, the distribution of material in the cavity of the working tool, the equipment used and processing modes.

The process of manufacturing dies for cold stamping also imposes serious requirements, since the quality of the formed product depends on the accuracy of this tool.

Stamping of parts, in which sheet metal is used as a workpiece, can include a whole list of mechanical operations. Such operations include, but are not limited to, cutting, punching, extruding, bending, cold heading, forming, crimping and drawing. In this case, cutting, punching and a number of other technological operations are classified as separation operations, and cold heading, molding, bending, etc. are classified as shape-changing operations.

Types of Sheet Forming Separation Operations

Types of sheet metal forming operations

Radial forging equipment for hot metal processing

A radial forging machine is used to produce shafts of various diameters with high productivity. With such a unit it is possible to set up production of up to 300 thousand finished products per year, which is quite enough to supply a large manufacturing enterprise with them.

The limited use of such a machine for metal stamping is explained not only by its high cost, but also by the fact that setting up its operating modes is a rather complex process, so it is advisable to perform it only if you plan to produce products of a certain diameter in large quantities.

Radial forging machine (RFM) ensures high stamping accuracy, producing parts with minimal allowances

The sequence of actions during which radial forging is performed is as follows.

- The part is fed into an induction device to bring it to the required heating temperature.

- After the metal acquires the required degree of plasticity, the part is sent along a roller container (rolling table) to a gripping device, with the help of which it is fed into the processing zone.

- There, the workpiece is fixed by elements of another gripping device, after which it is acted upon using special strikers.

- To ensure uniform processing on all sides, the part is constantly rotated, for which a special gripping mechanism is used.

Schemes of operation of forging machines of radial and rotary type

In order to set in motion the working mechanism of equipment for radial forging, a kinematic diagram is used, the elements of which are:

- drive motor;

- V-belt transmission;

- four vertically mounted shafts with eccentric axle boxes;

- a connecting rod with a striker and a slider attached to it.

The main automatic elements of the machine are the tracing drums, which are responsible for both the synchronous approach of the strikers and the subsequent movement of the workpiece. The rotation of the grip in which the workpiece is held is imparted by an electric motor through the worm gear elements. The braking of this mechanism, which occurs during forging, is provided by a spring clutch.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

One of the types of forging equipment is a horizontal forging machine, in which the workpiece is also located parallel to the ground. Devices of this type are used primarily for forming end thickenings on rod-type workpieces. During processing, the part is located in a split matrix, the channels of which are oriented in the horizontal plane.

The processing process performed on such a machine occurs in the following sequence.

- The workpiece is placed in the stationary part of the matrix.

- The moving part of the matrix, connected to the slider, is driven by the crankshaft.

- Approaching the stationary half of the mold, the movable part of the matrix tightly covers the processed rod.

- After clamping the part with the top of the mold, the crankshaft connected to the connecting rod drives the impact punches.

- At the end of processing, all moving parts of the machine return to their original position, and the moving and stationary parts of the mold are opened.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Let's consider how some separation operations are carried out.

cutting

When cutting, a certain part is separated from a part by cutting it along a curly or straight line. This separation operation is performed using a press made in the form of scissors of different designs.

This operation is intended mainly to prepare the workpiece for other processing methods.

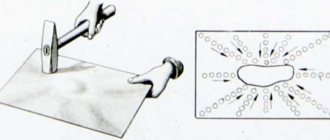

Punching

An operation called punching is used to create holes of different shapes in a workpiece. During punching, part of the metal is completely removed from the workpiece, and its weight decreases.

The figure shows a diagram of the punching process.

Felling

Using the process of cutting out a metal part, a finished product has a closed contour.

The figure shows a diagram for manufacturing a part using cutting.

2. Form-forming deformations include changes in the shape and size of a product when its individual areas are moved, without leading to its general destruction. These include drawing, bending, relief molding, twisting, crimping and other operations.

Let's consider some types of operations that do not lead to physical destruction of the form.

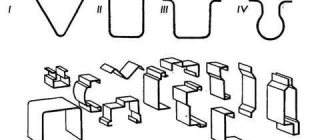

Hood

Using drawing, hollow volumetric products are obtained from flat sheet blanks. For example, in this way parts are made in the shape of a hemisphere, cylinder, cone, cube and other types. The figure shows different hood options.

Bending

Using the bending operation, a sheet product is given a given bending shape. Depending on the type of bending, this operation makes it possible to obtain curved products of different configurations. Some of them are shown in the figure.

Relief molding

This type of operation involves modification of local parts of the product, its external configuration remains unchanged. The figure shows diagrams of some molding operations:

It is also possible to use combined operations, including separation and shaping of one part.

The technological process of cold stamping consists of stages that are associated with the nature of the deformation operation and depend on the type of stamping equipment used.

The development of the technical process is carried out in the following sequence:

- The structure of the main operations is indicated, including their nature, quantity and sequence of execution.

- The initial, intermediate and finished dimensions of the part are calculated, as well as the necessary deformation forces to achieve the desired result.

- Documentation of the technological process is carried out.

Additional operations can be introduced into the technical process, with the help of which the workpiece is brought to a form convenient for processing. These include cleaning, straightening sheets, applying lubricants and other operations.

After stamping, the product can be subjected to a number of auxiliary operations, which include annealing and etching. With the help of such operations, the required mechanical characteristics are given to the finished product. To increase the wear resistance of products obtained by cold stamping, various protective coatings are applied to their surface.

If a sheet metal workpiece needs to be subjected to volumetric stamping, then such an operation can be performed according to two technological schemes.

The first of them consists of three operations:

- preliminary heat treatment of the workpiece (this is necessary in order to reduce the strength of the metal);

- preparing the workpiece surface for stamping;

- directly from the stamping itself.

When performing cold stamping according to the second technological scheme, one more stage is added to the three above stages - preliminary preparation of dimensional blanks, from which finished products will be formed.