Purpose and principle of operation of the winch

The winch is used in many branches of human activity.

This is a special mechanism designed to lift a load vertically or move it horizontally by transmitting force from the drum drive to a flexible traction element, for example, a cable or chain.

Depending on the type of winch, it can be used to perform the following tasks:

- Move the car. Here the mechanism is most often used to pull a vehicle to some static object, in cases where the car is not able to move independently, for example, “sat down” in the sand. Using a winch, the vehicle can pull itself up or pull up other vehicles. In general, a winch installed on any vehicle, especially one designed for off-road driving, including a snowmobile and ATV, is used to free stuck equipment.

- Lifting a load is the most obvious way to use the mechanism. So winches are the basis of lifting systems of various cranes, including truck and tower ones. Car enthusiasts and craftsmen also buy special hand winches for garages as an alternative to hoists. By the way, the hoists themselves, as well as the crane beams, which are found in almost every large workshop, are also built on the basis of a winch mechanism.

- On the water, winches are used as part of the anchoring and mooring devices of both small boats and huge ships.

It should immediately be noted that despite the similar principle of operation, each type of winch is designed to perform a very specific, limited job.

The simplest version is installed on a well to lower and raise a bucket of water.

This is interesting: Power regulator on a triac and thyristor - we outline it

What is a winch?

So, the winch is a simple lifting mechanism that has been used for many years. It is no secret that earlier winches also existed, but they were primitive, and in particular had a manual drive. Today, almost every winch has a motor that eliminates manual labor and makes the job easier for the builder or installer.

Electric winch

The manual mechanism is also used, for example, when you need to secure something to the roof rack of your car. We are talking about a lever mechanism that has a simple design. Many people make winches themselves, for example, when in construction matters they have to lift buckets to the second floor.

In this case, a metal frame is welded from reinforcement and placed on a concrete slab. On the frame there is a wheel through which a rope is passed. A person from below, by a hook on a rope, hooks a bucket of sand or ready-made solution, and lifts it by moving his hands and pulling the winch towards himself. There are many options, so let's look at each of them separately.

Types of winches

Today, the most common are lever and drum hand winches.

Lever winch

This type is most often used by car owners. And this is no coincidence, because a manual lever-type mechanical winch has undeniable advantages - size and the ability to operate even in the absence of a rigid attachment to the support.

The kit with a manual lever winch often comes with other useful accessories:

- extension cable;

- block that increases traction force;

- bark protection sling;

- cable arrester and protective gloves.

The standard design consists of a metal frame with a built-in mechanism and a lever. Another important element of this device is the ratchet - a kind of wheel on which thrust teeth are located. A steel pin rests against each of these teeth, which prevents the wheel from twisting in the opposite direction, thereby ensuring optimal cable tension

In this case, the winch frame takes on the entire load, so it is very important that it is made of high-quality and thick metal

Drum winch

The manual drum winch consists of:

- drums (there are models with one, two and even three drums);

- gearbox (gear or worm);

- lever;

- a band brake, which allows emergency stoppage of work in case of unforeseen situations, which has a positive effect on operational safety.

The principle of operation is as follows: the gear train, followed by the shaft with the drive gear, is driven using a lever. A friction clutch is installed at the end of the gear, and at the end of the drum there is an annular groove, the dimensions of which correspond to the dimensions of the clutch. Due to this, the rope attached to the drum is wound and lifts the load along with it.

You should be aware of the disadvantages of a drum manual winch:

- limited rope length;

- the small circumference of the inside of the drum. When using a steel cable, it forms a strong bend, so it fails very quickly;

- weak cable laying mechanism.

Criterias of choice

The design features of the equipment are not the only aspect that needs to be considered when purchasing a tool. There are several other important points that require attention:

- Rope length . Longer parts are more convenient. Although it is quite difficult to find a winch with a cable of more than five meters on the market.

- Traction force . Often sellers claim that five hundred kilograms of traction force is enough. However, in practice, this indicator is often not enough and the equipment does not cope with the task. The optimal weight is considered to be at least a thousand kilograms.

- Cross section of the cable . In this case, a too thick element is not the best option, since a small length of it will fit on the drum. The optimal diameter is six millimeters, which is quite enough, for example, to remove a car from a mud trap.

- Belt or cable . Both of these components can be used on a winch. But which one it is is a personal decision of the owner. The belt is rather short-lived, but easy to use and cheaper. The cable can last much longer, but it is difficult to lay it on the drum. If the equipment will be used infrequently, then it is probably better to acquire the first option.

As a conclusion, we can briefly list the main aspects regarding this equipment:

- For use in a garage, it is better to purchase drum-type winches with a worm gear. And to use the equipment in field conditions, a lever modification is better suited.

- The abutment tooth of the ratchet must be wide enough to prevent unintended slippage of the fastener.

- It is better to choose a winding drum with a diameter of more than 45 millimeters.

- A high-quality lever winch frame is made of metal thicker than three millimeters.

- The equipment will better cope with the assigned tasks if its traction force is at least 1 thousand kilograms.

- The optimal cable thickness is six millimeters.

- It is worth choosing a mechanism with a telescopic lever. Alternatively, this element can be equipped with a special amplifier.

Types of winches and their applications, operating principle and application of the winch

Lifting equipment is one of the most necessary assistants in work. So, for lifting loads, a winch is considered one of the most convenient devices. A winch is a device for moving loads using a moving flexible element - a rope, chain or cable. The use of a winch was known back in the days of slave-owning Egypt and even then made it possible to significantly speed up the lifting and movement of goods. At that time, they were driven by muscle or horse-drawn power. The development of technology and production made it possible to use a mechanical drive, which greatly facilitated the work with the winch.

Currently, there are two main types of winches in use: manual winches and electric winches.

Manual winches are a universal and cheap solution for lifting loads on construction sites, warehouses, small industries, and are also excellent for auxiliary and installation and dismantling work. The scope of application of hand winches is very wide, since their operation does not require a source of electricity.

Hand winches include lever winches, drum winches and mounting and traction mechanisms. The operating principle of a manual lever winch is based on pulling the rope through the body using clamps that alternately clamp the rope and advance it in the appropriate direction. In a manually driven drum winch, the lifting and lowering of loads is done by manually rotating one or two handles mounted on the drive shaft. To speed up the lifting of light loads, two-speed winches are made. The mounting and traction mechanisms are unique in their own way and are less similar to other hand winches. The principle of their operation is based on pulling the rope through the winch mechanism, which allows the use of ropes of unlimited length.

Electric winches are lifting equipment intended for lifting and transport operations during construction, installation and other works, drilling rigs, for completing various construction lifting devices, mast lifts, cranes, as well as for moving railway cars and tanks.

Traction winches are designed for lifting and transport operations for installation, construction and other works, as well as for completing construction lifting devices. These traction winches are attached to any surface convenient for you, for example: floors, walls, ceilings, using fastening on a horizontal or vertical platform.

Shunting winches are intended for moving railway cars at rail warehouses, and are used at loading and unloading areas, which allows replacing a diesel locomotive. These winches are classified as single-drum and double-drum, and according to the type of energy consumed - electric and pneumatic.

Auxiliary winches and drilling winches are designed for transporting loads and tools from receiving bridges to drilling sites, lifting loads, making up and unscrewing casing pipes.

Scraper winches are designed for delivering rock mass separated from massifs during underground mining. They are also used in open-pit mines and are used as a means of mechanizing the storage of lump and bulk materials. The winch is driven by turning on or off the working and idle drums using a hand brake. The mine winch is intended for the movement of equipment and cargo, installation and loading and unloading work in mine conditions.

The advantages of using winches are low physical effort during use, simplicity of design and control, compact size and reliability, and large traction forces. With the help of a winch you can significantly facilitate the work associated with lifting and moving loads, this will save time and money.

Classification of winches by area of application

The purpose and design of the winch depend on the tasks that will be solved with its help. The variety of equipment allows the design of the mechanism to take into account all the features and requirements associated with the specifics of the work.

The construction winch is designed for maximum simplicity, high lifting speed, limited load weight and equipment mobility. Attention is paid to safety - the load must be fixed, lowered smoothly, and begin and end movement with minimal jerks.

The design of the elevator and drilling winch ensures operation with a wide range of heights, long cables, and especially reliable emergency stop mechanisms. Particular attention is paid to reliability and safety; elevator systems take into account the requirements for smooth running and stopping, restrictions on stretching and sagging of the cable. Such mechanisms have several cables to redistribute loads.

The design of the cargo winch of a crane and truck crane takes into account a wide range of load weights, load distribution over several cables, reliability of locking and smooth return, speed and safety requirements, especially in the event of a sudden failure of the power system.

The design features of a car winch allow it to be used as a means of creating horizontal traction for self-pulling. Attention is paid to the possibility of operation from a motor and a manual lever drive with a ratchet mechanism and a frog winch format.

The best manual lever winches

The design of a manual lever device is very simple - a steel frame with a mechanism inside. Traction is carried out by a lever attached to the body

Which manual lever winch to choose, and how to determine reliability? First of all, you need to pay attention to the thickness of the frame. Many people do not recommend buying units with frame thickness less than 3 mm

The category presents the best winches that have a reliable frame size.

Bison "Professional"

Cable hand winches Zubr “Professional” are considered the most reliable, affordable mechanisms. The robust metal frame provides a reliable load capacity of up to 4 tons. The main hook is made of special carbon steel that is resistant to breakage. The frame can withstand high loads and is resistant to destruction. A special switch increases safety when winding/unwinding the cable. Double solid forged ratchet provides reliable traction with maximum lifting capacity. The reinforced pawl ensures safety and trouble-free operation. Fastening points made of hardened steel increase product quality, efficiency, and durability. Warranty 6 months, cable length – 3 m, nominal weight 6.73 kg.

Advantages

- Reliability due to hardened steel;

- Light weight, small dimensions;

- Bag included;

- Traction load 4 t;

- Acceptable price.

Flaws

Short cable.

Many users note that the model features a comfortable anatomically shaped handle that provides a comfortable grip. One of the advantages is its compact dimensions and ease of use.

Sparta

Manual winch for lifting cargo Sparta with a single ratchet wheel is suitable for lifting and moving cargo in a vertical, horizontal, inclined plane. It is often used during installation and unloading work at construction sites, where speed is not needed and loads are moved over short distances. To hold loads, the model is equipped with a ratchet brake. A strong 5mm diameter steel sling ensures reliable movement, lifting and holding. Two standard hardened steel hooks securely secure the weight, increasing safety when moving. Traction mechanism with a lifting capacity of 600 kg. Maximum traction load with a block is 1.5 tons. Steel cable length is 1.5 m. Warranty – 3 months, weight – 1.8 kg.

Advantages

- Lightweight model;

- Little weight;

- Strength;

- Budget price.

Flaws

Low load capacity.

The model will be a good choice for carrying out work with small loads. It is worth purchasing for those who do not want to pay more for unnecessary traction characteristics.

Mirax

The Mirax lever cable mechanism will become a universal assistant when work takes you on the road. To operate the hand tool, no power supply is needed at all. Easily copes with moving loads on horizontal and inclined planes. The mechanical device is small in size and does not take up much space in the trunk. Two hardened carbon steel hooks, double ratchet mechanism. The ergonomic plastic handle on the handle makes it easy to grip. A reinforced frame and high-quality components will ensure a long service life. Steel sling with a diameter of 4 mm, length - 1.8 meters. Weight 2.3 kg. Traction force 1.5 t.

Advantages

- Lightweight but durable frame;

- Good traction force;

- Endurance;

- Copes with inclines up to 15 degrees.

Flaws

- No brake;

- Short cable.

Many consumers note that the work will require an additional towing strap, since often the length of 1.8 m is not enough to engage the winch hook with the fulcrum.

How to get a car out using the simplest means?

There are situations on the road when you can’t count on outside help. The prudent driver has a crowbar in the trunk, which serves as an axis of rotation, and a piece of pipe as a drum. A lever is welded to it. The presence of a cable is assumed by itself. It takes a little sweat to get the car out of the mud.

Making a device that will help you out in a difficult situation is simple:

- The crowbar is driven into the ground and a pipe is put on. It should provide a place for attaching the cable - some kind of hole or welded ears.

- One end of the sling is hooked to the pipe, the other - to the car. Make a loop, insert a lever and begin to rotate.

- The cable is gradually wound up, the car moves slowly.

It is known that the longer the lever, the less physical effort is required. If the size is too large, it is inconvenient to use: the optimal parameters are 80 cm with a slight tolerance in one direction or the other.

The use of a manual mechanical winch to pull out a car requires compliance with certain conditions. Choose a direction that prevents the car from getting stuck even more in the mud. The wheels are set straight to reduce drag. If possible, choose a higher location for fixing the device - the required physical strength is reduced.

Types of winches

During installation, construction or repair work, various equipment is used to lift loads. But very often you have to not just lift the load vertically, but move it horizontally. In such cases, winches come to the rescue - mechanical devices for vertical and horizontal movement of loads. Using this device, you can pull out a car stuck in the mud, pull up a machine, moor a ship, or, for example, move heavy concrete blocks.

Winches are manual and electric. Each type of winch has its own advantages and disadvantages.

A manual lever-type winch is used in everyday life and when performing simple installation work. It has small dimensions and functions without rigid attachment to the surface. Thanks to its small size, the manual lever winch is easy to install in hard-to-reach places.

A manual drum-type winch operates on the principle of winding a cable onto a drum. It consists of a housing, a gear drum, two bearings and a handle. The device is used to perform simple work, allows you to lift loads to the height of a person and provides double traction force.

A manual winch of the worm type has an “Archimedes screw” (worm) in its design. Its advantage is its miniature size, variety of mounting methods and reliability.

The mounting and traction mechanism is one of the types of winches. It works on the principle of a lever and includes “cams” in its design. The cable is pulled in the desired direction and passes through the cams, moving the load. The advantage is that any length of cable can be used.

The small-sized electric winch is lightweight (up to 40 kg), easy to transport and operates on a 220 V network. Depending on the design, it can be installed permanently on a beam or on a moving carriage. The lifting capacity of small-sized winches is limited to one and a half tons.

The small-sized planetary winch has a planetary type gearbox (drive wheel and driven wheels). With small dimensions and weight, it provides sufficient power to lift cars.

An assembly winch, powered by electricity, is an industrial equipment used in construction and installation work. The weight of such devices is from 250 kg.

The traction winch performs lifting and transport functions. The high power of this equipment is designed to provide high tractive effort. For example, they can be used to move trolleys for construction cranes.

A reliable and powerful electric winch ensures high speed of moving the load, and its use does not require physical strength.

What types of crane winches are there?

There are two main types of winches on a truck crane:

Truck crane cargo winch

- Cargo (main and auxiliary);

- Arrowheads.

The first type of equipment withstands all the mechanical force of the load being lifted and lowered. Such auto winches are equipped with a powerful traction rope (cable or chain), which is connected at one end to a lifting hook. The second end is attached to the drum. The forward movement of the cable to the hook is transmitted through a system of rollers.

Boom winch device

Auxiliary devices, which are, in fact, cargo, are installed on imported models of truck cranes with a combined jib. They allow you not to rearrange the cable or remove the heavy hook, but to use your own separate cable on the jib. This additional equipment greatly simplifies the work if you need to feed the load very high.

Boom winches are not used on models with a telescopic boom design. They are used only on truck cranes where there is no hydraulic control for lifting the arm. In this case, the device replaces the role of a hydraulic cylinder. It is equipped with a cable that must withstand not only the weight of the boom itself, but also the load, since the latter also exerts mechanical force.

Also, boom devices are subject to more intense dynamic loads, because they change the extension of the boom arm when it is loaded, thereby performing both vertical and horizontal displacement of the load.

Design features

The most popular today are drum models and mechanical lever-type manual winches. Although these tools have a similar purpose, however, the principle of their operation is somewhat different.

Drum type equipment

In terms of its external qualities, this type of tool is reminiscent of automobile winches with which special vehicles are equipped. Their design includes a gearbox and a drum. The first is usually a worm or gear type. The drum in this device is designed for winding tape or steel cable around it.

Worm-worm mechanism variations have an undeniable advantage, namely that their gearboxes have a much simpler system for locking the device at the right moment. Thanks to this, the safety of using this equipment significantly increases. This tool is also distinguished by its high reliability and variety of fastening tactics. Although it also has certain disadvantages:

- The large size of the equipment makes it more comfortable to use in a room like a garage.

- Relatively light weight that this type of equipment can pull.

- Complex operating mechanism.

- The need for ongoing maintenance.

- A kind of “conflict” with dirt.

From the above it follows that this type of winches is not the best option for use on mobile devices.

As for gear devices, their design also includes a gearbox and a drum, however, unlike worm devices, they are easier to manufacture and therefore somewhat cheaper. The cable is attached to them using a ratchet, which has good reliability.

The gearbox is characterized by ease of maintenance. A rather important point is the quality of the metal used in the manufacture of gears, therefore, when choosing such equipment, it is not recommended to give preference to cheaper, untested analogues. It is better to choose a well-known manufacturer.

The main disadvantages include the following:

- A method of laying a cable, which often gets into the cavities of the gearbox gears and ceases to perform its functions.

- Small internal diameter of the drum, which causes strong bending of the steel cable. As a result, the latter deteriorates quite quickly.

- Due to the dimensions of the device, the size of the drum is limited, and this, in turn, limits the range of action of the mechanism.

From the above, we can conclude that the process of using drum-type winches in field conditions may not always be comfortable. It is better to use this mechanism in the garage.

Lever type equipment

Winches of this type are most often used in mobile devices. It is these that drivers usually purchase in order to be able, if necessary, to rescue the car from a trap.

The standard structure of the device includes a frame made of metal, inside which there is a mechanism activated by pressing a lever located on the equipment body. Due to the fact that greater force can be applied to the lever, the device is effective in cases where drum winches would not cope. The traction force of such a mechanism can reach several tons. Moreover, this figure can be further increased by strengthening the standard lever. Some manufacturers immediately include a special amplifier in the equipment package or manufacture this element using the telescopic method.

The main components of the device include a ratchet that secures the cable in a taut state. It is a kind of wheel on which persistent teeth are located. A locking pin rests against them in turn, preventing the wheel from spinning in the opposite direction. This ensures tension in the cable.

In this case, the main load is placed on the equipment frame, as a result of which the latter must be made of durable metal of the appropriate caliber. Otherwise, the device will become deformed. Experts recommend abandoning the option of a winch with a frame whose metal thickness will be less than three millimeters.

The mechanism has small dimensions, so its operation is possible even in very inconvenient places and conditions. And also the lever type of mechanism does not require mandatory fastening of the case

However, when purchasing this modification, you should pay attention to the size of the winding drum, since the smaller it is, the greater the effort required during the work process. You should not opt for a product with a diameter of this element less than 45 millimeters

Features of a manual winch

In fact, the entire system is tied to the drum. Special attention is paid to him, because virtually 50% of success in work depends on him. Due to it, the cable is wound and unwound, thus moving the loads horizontally.

- The minimum load that the cable will be able to handle is 150 kg. The maximum is 10 tons.

- It is noteworthy that when purchasing a cable, the maximum permissible load is often not indicated; instead, there is a marking.

- If you don’t have the knowledge to decipher it yourself, you can ask a consultant at the store where the winch was purchased.

Manufacturers declare the loads for which their products are designed. However, it is worth considering that equipment of the same class, but from different manufacturers, may have different load thresholds.

Chinese devices, for example, have a load threshold less than stated, so it is not recommended to use them to their full capacity; they should be loaded no more than 80% of the maximum.

Russian models, as a rule, work exactly with the stated characteristics. It is recommended to purchase the highest quality devices from the Armavir plant; it has existed for a very long time, has proven itself exceptionally well, and is widely recognized by users.

Operational Capabilities

Those who prefer a high-quality hydraulic winch and carry out the installation correctly can count on very rich functionality. The mechanism is directly controlled through levers – as a rule, there are two of them. The main advantage of branded models is the support of several traction modes. For example, in the basic order, the unit performs free unwinding and locking, and the remaining several modes differ in different tension transmissions. A modern hydraulic traction winch supports several speeds, which can also be controlled via a remote control.

Manual winches

Manually driven winches are used mainly as auxiliary equipment when vertical, horizontal or inclined movement of loads is carried out during installation and loading and unloading operations. They can be single drum or lever (no drum).

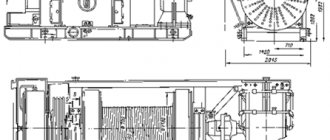

| Fig.1 Manual drum winch |

In the drum winch body (Fig. 1), consisting of two sidewalls connected by coupling bolts, shafts are mounted on which a smooth cargo drum, a transmission mechanism (gears) and a load-resistant automatic brake are located. Raising and lowering the load is done by manually rotating one or two handles mounted on the drive shaft. To quickly lift light loads, hand winches are made with two speeds. The lifting speed is changed by moving the gear block along the axis of the drive shaft.

An automatic load-bearing brake, consisting of a ratchet stop and a disc brake, provides braking of the drum when lowering the load and stops it instantly if the worker releases the winch drive handle. Since the load brake is located on the second shaft, gear shifting is possible with a raised load.

Winches are available in floor and wall versions.

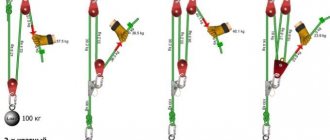

| Fig.2 Manual lever winch |

The scope of use of manual lever winches (Fig. 2) is the movement of loads during installation and dismantling work, in warehouses, for towing cars, etc. These mechanisms are characterized by high reliability and ease of operation, the ability to work in any spatial position, small dimensions and weight, complete autonomy and versatility. They can function in any conditions and do not require any preparatory work.

The principle of operation of the winch is based on pulling the rope through the traction mechanism using special clamps that alternately clamp the rope and thus advance it in the appropriate direction.

Construction of the cargo winch mechanism

From a mechanical point of view, a winch is a unit that combines a frame, a drum, a gear system, a brake mechanism, a steel rope, a system of rollers and couplings.

A cargo winch driven by a hydraulic motor consists of the following elements:

Cargo winch - components

- Gear mechanism;

- Cable winding element;

- Hydraulic drive;

- Band type brakes;

- Brackets.

The drum rests on bearings, one of which is mounted in a bracket, the other in a gear half-coupling mounted on the shaft of the gear mechanism. To transmit rotation from the gear shaft, two gear-type coupling halves are provided. One of them is rigidly attached to the drum. Any cargo winch drum has a groove (stream) for laying the cable during winding.

The brake system pulley is mounted on a rapidly rotating shaft of the gearbox mechanism. The brake itself combines two brakes of a normally closed type band design. Each of them has a brake band with a lining, a working brake spring, a hydraulic release and a bracket.

When the hydraulic motor is turned off, the brake is closed and holds the drum stationary. As soon as the working fluid begins to rotate the hydraulic drive shaft, it simultaneously enters the hydraulic brake release, and it releases the mechanism. You can also release the drum manually.

Using a hand winch

Basically, hand winches are manufactured in the following types:

- drums;

- lever;

- installation and traction.

Manual units are used on construction sites, warehouses, automobile and home workshops, and country houses. The first type is used for lifting, lowering, and moving small-sized cargo with limited weight. The source of movement is the rotation of the drum manually. The body of the product must be rigidly fixed to the selected surface.

Mounting and traction units are structurally different from drum and lever devices. They can use ropes or slings of any length. The principle of operation is to pull the rope through the mechanism in a given direction. One option for such a device is the so-called worm winch. It uses a gear drive with reversible force. The main disadvantage of such systems is the increased coefficient of friction created between the gear and the worm screw. This circumstance leads to rapid wear of the entire mechanism.

All manually driven structures are used as auxiliary (additional) lifting equipment. Especially in cases where there is limited free space.

Which winch to choose: chain or worm?

Hand winches have become an integral part of many processes in production, during the construction of various buildings, while solving household and other problems. At the same time, buyers now have many types of lifting equipment available to choose from, which may differ in their parameters, design, operating features, etc. Chain and worm winches especially stand out among them. But which model should you choose? This is what we will talk about now.

How to choose an electric winch?

Paying attention to the load capacity, some owners forget about other characteristics of this useful device, which leads to mistakes when purchasing equipment. Let us describe the main parameters affecting operation:

- Type of installation - in the garage, a mobile electric suspended winch with a trolley drive is more useful. You can mount these mechanisms on a wall or horizontal plane. Choosing a car electric winch requires a special approach taking into account the vehicle model.

- Power - the traction force is affected by the mass of the load, the friction factor (resistance to movement), the lift factor (the car is pulled up or forward).

- Power type – 220 or 380 V or battery.

- Control type – equipped with an electric winch with a wired or remote control.

- Rope length.

- Rope diameter.

- Weight and dimensions of the model.

Rating of electric winches

A properly selected electric winch can help out the car owner in difficult situations, help at a construction site or in the garage. There is a wide variety of interesting models on the market, so viewing the ratings will not be a bad idea before purchasing a useful device for your home. We offer a small TOP of electric winches of different types:

- Electric winch COMEUP SEAL GEN2 9.5S

– runs on 12 V, pulling force 4300 kg, hermetic design, aluminum case, synthetic cable.

Winch MASTER WINCH MW X8288

– unit power 6.8 hp, cable 32 m, traction force 3760 kg, power supply 12 V.

Octopus 9000

affordable automotive electric winch - motor power 1.5 kW, traction force 4000 kg, remote control with a cable 4.5 m long.

Sturm eh72201

– power 540 W, lifting height 12 m, load capacity 400 kg, a good option for workshops.

DENZEL TF-250 52011

– electric lifting winch for construction sites with a lifting capacity of 250 kg, 540 W motor, 220 V power supply, lifting height 12 m, speed 10 m/min.

How to make a hand winch with your own hands: 5 simple and proven methods

A winch is an indispensable thing in the household. It can also provide an undeniable service to car enthusiasts.

Winch functions for cars

Manufacturers install a winch on vehicles that often drive off-road. The fact is that when a car slips or cannot drive up a slope, it is this device that helps to get out of the “trap”.

By installing a winch on a passenger car, you can safely drive on any road surface, including washed-out roads and potholes.

However, it is used not only to pull a car out of a hole or tow it, but also to transport goods. Therefore, manufacturers produce a wide variety of these devices.

What types of winches are there?

Conventionally, they are classified according to:

- designs;

- connection method;

- technical features.

In addition, they are divided into removable, which are installed if necessary, and non-removable (installed on the front of the vehicle).

The winch can be of several types:

- Manual – the advantages include compact size. Most often they are of the drum type, when the cable is tensioned on a reel and rotation occurs using a handle. The disadvantages include the fact that it can work with cargo whose weight does not exceed 1 thousand kg.

- Mechanical - comes into action with the help of a motor, since there is no independent driving unit. The design is quite bulky and is not popular among car enthusiasts.

- Electric is the most convenient option. The drum moves using an electric motor. Power comes from the car battery. Loading capacity reaches up to 4 thousand kg.

- Hydraulic – has a rather complex design. It operates silently and has great power, but is unreliable because it can fail at any time.

There is no need to purchase the device. Making a manual winch with your own hands is quite simple. First of all, you need to decide on the type and parameters of the device.

The device is equipped with a so-called “anchor”, which clings to a hard surface and helps to pull out the vehicle. A do-it-yourself anchor winch can be made from almost any scrap metal

It doesn’t matter what the “anchor” looks like, the main thing is that it clings well and does not deform under high loads

While using the device, it is prohibited to stand within the radius of the cable.

Do-it-yourself winch from the starter

A homemade winch from a starter is made from materials that are always available in the garage. The basis, of course, is the starter, and the device itself runs on battery power.

It is desirable that the gearbox for the winch be planetary. You can find it on old Zhiguli models.

For manufacturing you will need: cables, cable, gears, drum, starter, gearbox, sheet of metal.

- Secure the drum seats with bolts and a welding machine.

- Assemble the drum with gearbox.

- The starter is assembled to the gearbox using adapters.

- Equip the input shaft with a gear. It is necessary to ensure that the size of the teeth matches the design. If the shaft connects freely to the gear, then the manufacturing process is proceeding correctly.

- Place the gear onto the cylinder. After the structure is securely fastened, the electrical wiring is connected.

If dirt or dust gets into the device during assembly, everything should be cleaned and only then primed and painted.

Drive unit

The hand winch mechanism is most often equipped with a gear or worm drive.

The main element of a gear drive is the gear wheel. The teeth engage nearby gears, which have corresponding recesses, and the mechanism rotates. A mutually simple number of teeth on mating elements allows the load to be evenly distributed and their abrasion to be reduced.

A worm drive uses a threaded screw called a worm instead of teeth. It also interacts with the gear wheel. This design ensures smoother operation of the mechanism and an effective increase in torque. But the friction in it is higher, and therefore the main elements wear out faster.

Types of automobile winches

Depending on the drive design, winches for SUVs are:

- Manual.

- Electrical.

- Mechanical.

- Hydraulic.

Each of these types has its own advantages and disadvantages, so the choice is ambiguous. You need to focus on the most common situations that can happen to the car. Of course, a lot also depends on its design.

You also need to take into account the total weight of the vehicle, moreover, fully equipped, in order to purchase a winch powerful enough for this load. If it turns out to be weak, it will simply be useless in an extreme situation, since it will not be able to move the car. The traction force of the winch should be 2.5 times the weight of the car, then it will easily cope with the task without the need to unload things.

Stayer Maxpull 4310-4

Since choosing a winch for an SUV is not so easy, we will consider all these types in more detail, and then we will present the best models that have proven themselves well in practice.

Manual mechanisms

These are the simplest and cheapest devices. They are activated manually, to do this you have to rotate the handle or move the lever. By design, they are lever, drum and worm.

Manual winches for off-road vehicles are not suitable for everyone, since the thrust they develop is usually small. They can be used on light cars weighing up to 1-2 tons, and jeeps are much heavier. But there are also quite powerful designs, with a thrust of 4-5 tons.

Electrical devices

Electric winches for SUVs are much better and are the most popular. Such devices are powered from the on-board electrical network - from the battery. They are very easy to use and are launched with the press of a button. Their cost is quite reasonable, and installation and connection does not cause problems.

Such car winches develop quite a lot of force and some models can pull out a car weighing up to 6 tons. But you need to have a very good and capacious battery, since it is not always possible to start a car stuck in the mud to recharge.

Mechanical devices

Unlike manual options, mechanical winches for SUVs are driven not manually, but by a motor, using a special shaft that is connected if necessary.

The choice of such a winch may be limited by the design of the machine - not all have the ability to connect an additional shaft. One of the advantages is quite a lot of power, which is enough to pull the car out of any trouble. But for this you need to start the engine, which is not always possible, and this is the main disadvantage of this design.

Hydraulic devices

In devices of this type, a drum with a cable is driven by a hydraulic system. They are usually connected to the power steering. The force developed is quite sufficient and they work silently and smoothly, but they have many disadvantages:

- The cost is higher than other options due to the complexity of the design.

- The engine must be running.

- When turning the steering wheel, they may behave unstably, as the pressure from the hydraulic booster changes.

Finding a hydraulic winch for your SUV can be difficult as you need to consider connectivity options. Meanwhile, hydraulic winches do not have any special advantages over other designs.

Hydraulic winch Runva 10000 LBS

Winch price

Today there are absolutely any type of winch available for sale. You can buy them both in stock and to order in online stores. For example, speaking about the price segment, let's look at the main options, indicate their scope and offer an approximate purchase price.

The cheapest and most common is the lever winch. Today it can be purchased at a cost of up to 5,000 rubles. Of course, there are more expensive options, but in everyday life a winch from 3 to 5 thousand rubles is quite suitable. The more expensive version is an electrical modification.

It can operate both in a household network, from 220 volts, and in an industrial network, 380 or more, depending on the modification. There are varieties that, with a small update to the car, can be installed in the car and powered from the on-board network. This type will cost from 5 to 10 thousand rubles, inclusive.

A more expensive and more powerful version is the hydraulic winch. It can operate both from trucks and special equipment. It has a high load capacity, which justifies its cost. Such a machine will cost from 40,000 rubles; it runs on a hydraulic pump or power steering.

You can also distinguish one type of winch, which has a gasoline drive. It is considered a stationary device because it allows you to work even far from civilization. Among gasoline engines, there are modifications with a worm drive, which cost between 5 and 10 thousand.

The cheaper version has a drum drive. Such winches can cost from 2 to 4 thousand, inclusive. Drum machines are used for simple tasks; worm machines, on the contrary, are used where more effort is required. Cargo winch , garage winch, and also shunting varieties are accepted on a large scale

Elevator mechanisms are in great demand. They are designed to lift people on special elevators, which is where the name comes from. Today they are used at construction sites, in mines for lifting people on elevators, for unloading waste rock, as well as in other places where high load capacity is required. Such mechanisms are complex, so they cost from 150,000 rubles.

There are special winches on sale with modifications for the car. Today, these mechanisms are used directly in working with machines, which allows them to be used for self-evacuation, as well as to get vehicles out of hard-to-reach situations without the help of heavy trucks.

Such winches cost from 8,000 rubles, but a good mechanism that can cope with the weight you need will cost 30,000 rubles. With such a winch, driving off-road will not be scary at all. A variety can be considered a special motor winch, which is installed on towed equipment. It costs about 19,000 rubles per device.

There are own winches for navigation. Yes, their focus is narrow, but they are quite sold on the domestic and world markets. This is an anchor winch , which is used to raise the anchor on boats and yachts.

Their cost is low. They cost 6,000 rubles, have a moisture-resistant body, a powerful metal cable that does not decompose when exposed to moisture. They have the ability to connect to the onboard power supply circuit of the boat itself.

Among the types of boats, I would like to highlight those that are used for moorings. In this case, when the ropes are lowered into the water, they are attached to the winch, and you can move towards the shore at the selected speed. This is convenient, especially if there is a strong current.

Additional items

Various types of cables are used as equipment. The steel version is durable and has high strength, but if broken, it poses a great danger to people nearby. Specialized cable arresters are used to prevent such situations; in the absence of such a device, any material can be used.

Kevlar cable has less strength, but it is not capable of causing harm to others when it breaks. Among the advantages, it is worth noting convenient operation at low temperatures, since synthetics are not subject to freezing, as well as moisture resistance and lack of stretching even with repeated use.

Types of cables

There are mainly two types of cables used - metal and synthetic. The option of twisting steel threads may seem preferable, but, oddly enough, it has significant drawbacks. Firstly, you should not place special hopes on metal in terms of strength. Over time, some of its threads break, and at some point it is necessary to replace it. Secondly, a hydraulic winch with a metal cable is unsafe. Those same broken threads can injure the skin of your hands and damage your clothing, and if you miss the moment of critical wear, then a complete rupture of the cable during the pulling process can lead to tragic consequences. Synthetic is also not perfect, but it is less dangerous, less dynamic and lasts longer with proper care. Such a cable should be protected from sunlight, and after use in contact with sand, the fibers should be thoroughly washed.

Worm gear device

Before starting assembly, mark the fastening points with your own hands, using not only the drawing, but also applying the existing blanks. This will allow you to determine the correct location points where it is possible to cut something off or replace a part that is not suitable in size. Quite stringent requirements are imposed on the operation of the mechanism: no wobbles, excessive tightness of fit, so that the parts do not wear out prematurely.

The proposed drawing is used as a guide for the work. The dimensions of the structure depend on the Glist gear. It is selected taking into account the required winch performance. Based on the parameters of the worm gear, a lifting device is manufactured according to the diagram.

Components and their role in the winch:

- The Glist gear, which must have strong teeth and sufficient thickness, transmits force to the shaft.

- It is made from thick-walled pipe. A round piece of metal with a diameter similar to the inner ring of the gear is welded at one end. To fix the cable, drill a hole through it.

- Bearings on which the shaft rotates. If the work is planned to be intermittent, it is permissible to use bushings.

- The case is durable and made exactly to size. The design must ensure that there are no gaps between the mechanism components.

Glist gear

The frame is assembled from two pieces of channel with a wide flange of 200 mm, different in size: 300 and 400 mm. The long one is located on the right side, where the gear and drive handle are installed. Sections of 4 mm metal are also used. Through holes for the shaft are marked and drilled in the channels, as well as 4 more for the side plates. These are two rectangular pieces with a triangular cutout in the bottom right corner.

Collected in the following sequence:

- Bearings or bushings made of brass are installed on both ends of the shaft;

- put on the plates and secure them to the channel with bolts with groovers for the nuts;

- put the gear on the shaft, fix it with a key, install a metal sleeve;

- finally assembled first from the side of the long channel, then from the short one.

The mechanism is ready for use for any purpose. It is indispensable in construction; it is used to pull out cars and install them in garages. To reduce the load on the drum, a block system is used.