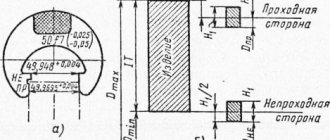

The dimensions of the mouth (hole) of the keys, the end of the keys for products with a key recess and the dimensions for the key of products with increased, normal and rough accuracy are given.

DIMENSIONS OF THE JOINT (HOLE) OF THE KEY AND TO THE WRENCH (GOST 6424-73)

Nominal sizes S, S1, S2, S3

| Limit deviations | |||||||

| key sizes | turnkey sizes | ||||||

| covering S | covered by S1 | covered by S2 | covering S3 | ||||

| Keys | Products | ||||||

| normal accuracy | rough precision | increased accuracy | normal accuracy | rough precision | |||

| 2,5*; 3,0* | — | — | -0,040 | — | — | — | +0,09 +0,03 |

| 3,2 | +0,08 +0,02 | — | -0,048 | -0,16 | +0,12 +0,04 | ||

| 4,0; 4,5; 5,5 | +0,12 +0,02 | ||||||

| 6,0* | +0,15 +0,03 | ||||||

| 7,0 | -0,058 | -0,20 | +0,15 +0,05 | ||||

| 8,0; (9,0) | +0,18 +0,03 | -0,36 | |||||

| 10,0 | +0,19 +0,04 | +0,24 +0,04 | |||||

| (11,0) | -0,120 | -0,24 | -0,43 | +0,18 +0,06 | |||

| 12,0; 13,0 | +0,24 +0,04 | +0,30 +0,04 | |||||

| 14,0; (15,0); 16 | +0,27 +0,05 | +0,35 +0,05 | |||||

| 17; 18 | +0,30 +0,05 | +0,40 +0,05 | +0,18 +0,06 | ||||

| 19; 21; 22; 24 | +0,36 +0,06 | +0,46 +0,06 | -0,140 | -0,28 | -0,52 | +0,21 +0,07 | |

| 27; 30 | +0,48 +0,08 | +0,58 +0,08 | -0,84 | ||||

| 32 | -0,17 | -0,34 | -1,00 | -1,00 | 0,25 +0,05 | ||

| 34; 36; 41; 46; 50 | +0,60 +0,10 | +0,70 +0,10 | |||||

| 55; 60; 65; 70 | +0,72 +0,12 | +0,92 +0,12 | -0,20 | -0,40 | -1,20 | -1,20 | +0,30 +0,10 |

| 75; 80 | +0,85 +0,15 | +1,15 +0,15 | |||||

| 85; 90; 95; 100 | — | -0,87 | -1,40 | -1,40 | — | ||

| 105; 110; 115; 120 | +1,00 +0,20 | +1,40 +0,20 | |||||

| 130 | +1,25 +0,25 | ||||||

| 135 | +1,00 +0,20 | -1,00 | -1,60 | -1,60 | |||

| 145; 150 | +1,25 +0,25 | ||||||

| 155; 165; 170; 175; 180 | — | ||||||

| 185; 200; 210 | -1,15 | -1,90 | -1,90 | ||||

| 225 | +1,50 +0,30 | ||||||

* Can only be used for products with a key recess and for keys for this recess. Notes: 1. Dimensions in brackets may be used for previously manufactured products. 2. Sizes 17, 19, 22 and 32 mm are not preferred.

POSITIONS FOR WRENCH (GOST 13682-80)

Key size standard range

34,0; 36,0; 41,0; 46,0; 50,0

• Can only be used for products with a key recess and for keys for this recess. GOST 6424-73 also provides for nominal sizes of 55 - 225 mm. Notes: 1. Dimensions in brackets may be used for previously manufactured products. 2. Sizes 17, 19, 22 and 32 mm are not preferred.

42. Places for wrenches (GOST 13682-80)

Dimensions, mm

The standard establishes the smallest dimensions of spaces for the heads of wrenches with a wrench opening from 3.2 to 225 mm.

43. Supporting surfaces for fasteners (GOST 12876-67 as amended in 1987)

The standard applies to supporting surfaces for fasteners with a rod diameter from 1 to 48 mm,

manufactured according to state standards.

Supporting surfaces for hex heads of bolts and screws, for hex nuts with normal spanner size and for washers _

Fastener thread diameter

D (limit trip according to H15)

Fastener thread diameter

D (limit trip according to H15)

Fastener thread diameter

D (limit trip according to H15)

| Bearing surfaces for hexagonal bolt heads hexagonal nuts with reduced wrench and undersize |

Fastener thread diameter

D (limit trip according to H15)

Fastener thread diameter

D (limit trip according to H15)

The size t is set by the constructor.

44. Supporting surfaces for heads of screws and screws, for lock washers (GOST 12876-67)

Supporting surfaces for cylindrical and semicircular heads of slotted screws and for cylindrical heads of hexagonal socket screws

Fastener thread diameter

D (preliminary trip according to H14)

t (preliminary trip according to H14)

t1 (limit trip according to H14)

Dimensions ?1 and ?z are given for screws with normal or light spring washers in accordance with GOST 6402-70.

Supporting surfaces for countersunk and semi-countersunk heads of screws and screws and for lock washers with teeth for screws with countersunk and semi-countersunk heads

Fastener thread diameter

D3 (preliminary trip according to H14)Fastener thread diameter

45. Supporting surfaces for rivets with countersunk and semi-countersunk heads

23

| a1 (limit off -2°) | — | — | 12 | 19.4 | 20 | |||||

| 1.4 | — | — | 14 | 23 | 24 | |||||

| 1.6 | — | — | 16 | 2 | 3,6 | 6 | 7 | 17 | 26 | 27 |

| 3 | 4,8 | 8 | 20 | 29 | 30 | |||||

| 3.5 | 9.5 | 22 | 32 | 33 | ||||||

| 4 | 10.5 | 24 | 35 | 36 | ||||||

| 5 | 13 | 27 | 36 | |||||||

| 6 | 9,7 | 11 | 30 | 40 | 41 | |||||

| 8 | 36 | 48 | 49 |

General instructions for tables 43, 44, 45

1. Processing of supporting surfaces according to table. 43 is carried out in technically justified cases. Size t

set by the designer.

When the depth t

exceeds 1/3 of the height of the bolt head (nut), dimensions

D

should be taken from the table. 42.

2. Between the supporting and cylindrical surfaces, a radius of curvature of no more than 0.3 mm is allowed. The supporting surfaces for hexagonal bolt heads without washers and for cylindrical and semicircular screw heads without washers between the supporting plane and the through hole must have a chamfer of 0.5 x 45° for fasteners with a thread diameter of 12 to 20 mm and 1 x 45° for parts with thread diameter over 20 mm.

3. Diameters of through holes dh

- according to GOST 11284-75 (Table 30). For supporting surfaces for cylindrical screw heads, through holes according to the 3rd row of the table. 30 are not recommended.

4. For supporting surfaces according to table. 44 when designing a connection, it is allowed to increase the dimensions t, t1, t2, t3—

In the case of using the 1st row of through holes in accordance with GOST 11284-75 (Table 30), to reduce the gap between the screw head and a cylindrical surface with a diameter

D

,

it is allowed to reduce the diameter D. 46. Processed T-shaped grooves (GOST 1574-91)

Dimensions, mm, of T-slots used in metal-cutting machine tables comply with ISO standard 299-87

Tolerance field width a,

no more than: guide grooves - H8, clamping grooves - H12.

The roughness of the side surfaces, determined by size a,

should be no more than

Ra

6.3 µm, the other surfaces no more than

Ra

20 µm according to GOST 2789-73.

Instead of chamfers e, f

and

g,

to round the corner with a radius not exceeding the dimensions of the chamfers. If there is an odd number of T-slots, their symmetrical arrangement relative to the guide slot should be preferred. In the case of an asymmetrical arrangement of T-shaped grooves relative to the guide groove, as well as in the case of an even number of grooves, the guide groove must be clearly marked. The design and dimensions of T-slot bolts are in accordance with GOST 13152. It is permissible to replace the bolted connection with any other device that meets the requirements of interchangeability.

Manufacturing of bolts.

The formation of metric threads on bolts is carried out by cutting or rolling:

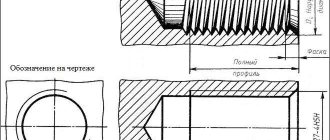

The bolt thread is made on a thread rolling machine (left) and on a lathe (right)

Hex head bolts can have normal and fine pitch threads, with the standard providing only one fine pitch for each diameter. Bolts with semicircular and countersunk heads are made with threads only with a normal pitch.

How to determine the turnkey size of a bolt and nut?

Any person, even not associated with mechanics, has to unscrew and tighten bolts and nuts in everyday life. To do this, we most often use a wrench, of which there are about fifteen varieties today. The classic and most common tool is the double-sided open-end wrench, which can be found in every man’s toolbox. The dimensions of its working profiles are marked on its handle, for example: 7x8 or 17x19, etc. These numbers indicate the distance from one sponge to another in millimeters.

In technical reference books for fasteners, the turnkey size is designated by the letter “S”. But we won’t see it on the fasteners themselves. Experienced mechanics can visually determine by the size of the fastener head “how much wrench” should be taken for an M10, M12 or M16 bolt? And inexperienced craftsmen can easily make a mistake in their choice. And when the connection is in a hard-to-reach place, you will have to select a tool by trial. If a small key simply does not fit, then a large one, if it does not fit tightly, can “lick” the edges of the part and then further unscrewing can be problematic.

Unscrew the cut nut

It is not always possible to choose the right tool. Especially when you need to turn in the dark, with insufficient lighting. Or the second case. The nut was pinched. As a result, the sharp edges of the edges were cut off and became “bald.” What is the way out of the situation?

Tool manufacturers have developed helical sockets that are designed to remove problem fasteners. Due to its “corkscrew” shape, the key catches and securely fixes the nut. This is how you can emerge from the most hopeless situation as a winner.

Determining the key number by the diameter of the fastener thread

The “wrench” size of a hex bolt or nut is the distance between two parallel faces. You can quickly and accurately find out it, without resorting to a ruler or caliper, by the diameter of the threaded part, which is indicated in the technical information for the fastener. The fact is that each standard thread diameter corresponds to a certain size of the working profile of the fastener - main (normal), reduced and enlarged. Bolts with reduced and increased head sizes are much less common.

Using the table, you can easily determine which wrench size is suitable for a particular bolt from M1 to M110.

Table 1. Wrench sizes for metric bolts and nuts.

| Thread diameter, M | Key size | ||

| main S , mm | reduced S , mm | increased S , mm | |

| M1 | 3.2 | — | — |

| M1.2 | 3.2 | — | — |

| M1.4 | 3.2 | — | — |

| M1.6 | 3.2 | — | — |

| M2 | 4 | — | — |

| M2.5 | 5 | — | — |

| M3 | 5.5 | — | — |

| M4 | 7 | — | — |

| M5 | 8 | — | — |

| M6 | 10 | — | — |

| M7 | 11 | — | — |

| M8 | 13 | 12 | — |

| M10 | 17 (16) | 14 | — |

| M12 | 19 (18) | 17 | 21 (22) |

| M14 | 22 (21) | 19 | 24 |

| M16 | 24 | 22 | 27 |

| M18 | 27 | 24 | 30 |

| M20 | 30 | 27 | 32 (34) |

| M22 | 32 (34) | 30 | 36 |

| M24 | 36 | 32 | 41 |

| M27 | 41 | 36 | 46 |

| M30 | 46 | 41 | 50 |

| M33 | 50 | — | 55 |

| M36 | 55 | 50 | 60 |

| M39 | 60 | 55 | 65 |

| M42 | 65 | 60 | 70 |

| M48 | 75 | — | 75 |

| M52 | 80 | — | 80 |

| M56 | 85 | — | — |

| M60 | 90 | — | — |

| M64 | 95 | — | — |

| M68 | 100 | — | — |

| M72 | 105 | — | — |

| M76 | 110 | — | — |

| M80 | 115 | — | — |

| M85 | 120 | — | — |

| M90 | 130 | — | — |

| M95 | 135 | — | — |

| M100 | 145 | — | — |

| M105 | 150 | — | — |

| M110 | 155 | — | — |

Some modern ISO standards specify other hex head sizes; they are listed in parentheses in the table.

The dimensions of the wrench mouth are defined in the GOST 6424-73 standard. With proper selection, the gap between the working jaws of the tool and the edges of the fastener does not exceed 0.1 - 0.3 mm.

Fastener weight

It's good if you need to tighten a couple of nuts. But what if you have to work on an industrial scale and the number of fasteners runs into hundreds and thousands. Then a weight table will come in handy. The main indicator here is the nominal thread diameter. of GOST 5915-70 start from it .

| Nominal thread diameter, mm | Theoretical weight 1000 pcs. nuts, kg |

| 1,6 | 0,074 |

| 2 | 0,141 |

| 2,5 | 0,272 |

| 3 | 0,377 |

| 3,5 | 0,497 |

| 4 | 0,800 |

| 5 | 1,440 |

| 6 | 2,573 |

| 8 | 5,548 |

| 10 | 10,220 |

| 12 | 15,670 |

| 14 | 25,330 |

| 16 | 37,610 |

| 18 | 53,270 |

| 20 | 71,440 |

| 22 | 103,150 |

| 24 | 122,870 |

| 27 | 175,280 |

| 30 | 242,540 |

| 36 | 416,780 |

| 42 | 623,880 |

| 48 | 956,200 |

Selection of inch wrenches

The size of an inch wrench is expressed in inches and does not indicate the width of the wrench, but the diameter of the thread of the inch fastener it is designed to work with. The hexagonal working profile of inch bolts and nuts differs in size from the metric standard profile by fractions of millimeters. Therefore, metric wrenches will either not fit tightly onto the edges of inch fasteners, or will not fit at all. To work with it you need inch keys and socket heads.

Table 2. UNC/UNF Threads and Wrench Nut Sizes.

| Thread diameter (key size), inch | Wrench nut size, inch | Wrench nut size, mm |

| 1/4 | 7/16 | 11.11 |

| 5/16 | 1/2 | 12.7 |

| 3/8 | 9/16 | 14.29 |

| 7/16 | 5/8 | 15.88 |

| 1/2 | 3/4 | 19.05 |

| 9/16 | 13/16 | 20.63 |

| 5/8 | 15/16 | 23.81 |

| 3/4 | 1 1/8 | 28.58 |

| 7/8 | 1 5/16 | 33.34 |

| 1 | 1 1/2 | 38.10 |

| 1 1/8 | 1 11/16 | 42.86 |

| 1 1/4 | 1 7/8 | 47.63 |

| 1 3/8 | 2 1/16 | 52.39 |

| 1 1/2 | 2 1/4 | 53.15 |

| 1 3/4 | 2 5/8 | 66.68 |

| 2 | 3 | 76.20 |

| 2 1/4 | 3 3/8 | 85.73 |

| 2 1/2 | 3 3/4 | 95.25 |

| 2 3/4 | 4 1/8 | 104.76 |

| 3 | 4 1/2 | 114.30 |

Marking

Let's say we saw this code:

Nut M10-6N.5 (S18) GOST 5915-70.

Here M10 is the thread diameter in mm, 6H is the tolerance range, 5 is the strength class, S18 is the spanner size, that is, the external distance between parallel edges.

We told you how to select a nut for metric, inch and hex keys. They gave advice on unscrewing the cut fasteners and provided a table with weights.

Socket wrench sizes for hexagon socket bolts

In mechanical engineering and instrument making, along with hexagonal fasteners, bolts with a cylindrical head are widely used, for screwing which an angled hexagon wrench is used. They are manufactured according to DIN 912 or GOST 11738-84 standards, according to which each thread diameter must correspond to a certain turnkey size (the distance between the opposite faces of the internal hexagon).

| Thread, M | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 |

| Key size, mm | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 14 | 17 | 17 | 19 | 19 | 22 | 24 | 27 |

Before you start disassembling any part of a car, servicing a bicycle, or repairing garden equipment, it’s a good idea to make sure you have all the necessary tools. It is good to have turnkey size charts for bolts and nuts on hand. When repairing old equipment, the problem of unscrewing damaged parts often arises. To work with fasteners with worn edges, you can purchase special socket heads with a spiral profile AN0400120 in the Krepcom store, and to remove bolts with torn heads we offer a set of thread extractors AG010048.

Stud sizing technology

Studs, like other hardware, are distinguished by the presence of metric threads, therefore they have the corresponding abbreviation MDxPxL. The decoding is also no different from the previous fasteners:

- M - the letter denotes the metric thread of the hardware;

- D - used to indicate diameter;

- P - type of step, indicator in millimeters;

- L - data on the length of the working part of the structure.

The type of measurement is selected in accordance with the appropriate GOST standard, as well as the type of stud. In total, there are 2 large groups for determining the ownership of hardware:

- structures that are used for installation in smooth holes;

- fasteners with an end that screws into a hole.

In the first case, the working part is presented along the entire length of the hardware; in the second case, only the shank is used, while the end for twisting is not taken into account.

Hairpins, like other hardware, are produced according to the following standards:

- hardware with DIN 975 thread;

- dimensional version corresponding to DIN 976-1;

- structures intended for installation in smooth areas are regulated by GOST 22042-76, 22043-76;

- hardware for creating a durable flange connection GOST 9066-75.

There are also other options that differ in the twisted end and length. For them, other GOST standards apply.

Standard sizes of open-end wrenches

Any tool has its own characteristics and parameters. There are also generally accepted standard sizes of open-end wrenches. To determine the size , you need to pay attention to the span of the part that its motionless jaws have. This is the so-called throat of the instrument. The handle of any open-end wrench has a digital marking. This is the size in millimeters that determines the width between the jaws.

Standard sizes can range from minimum (2.5x3.2 mm) to maximum (70x80 mm).

These are acceptable GOST standards that cannot be violated under any circumstances. GOST also specifies other characteristics of open-end wrenches, for example:

- A special calculation of the maximum deviations of the pharynx size is carried out;

- Any manufactured open-end wrench must have specified strength and hardness;

- The trademark marking is established;

- The decorative and protective coating of the key, etc. is taken into account.

Types of keys

Now let's look at what varieties there are.

The most commonly used wrenches have two jaws. Another name for it is a double open-end wrench (GOST 2839). If you need to unscrew a fastener with a mag of 18 or 20 mm between opposite edges, then you need to choose a tool with a handle on which the designations 18 and 20 are located. It happens that in force majeure circumstances a tool of the required size is not always at hand. In this case, a key one size larger is suitable . When using a tool that is not suitable for its intended purpose, you need to use a knife or screwdriver, install them in an empty space.

Types of horn instruments:

- composite (GOST 16.983). Their design contains an end structure nozzle, a hollow socket and a handle, short or long;

- adjustable (GOST 7275.75). These are open-end wrenches where the size can vary;

- narrow profile keys. These are specific keys for a certain type of activity;

- There are star, Bristol and hex keys (GOST 11737.93) that are used to work with bicycle and computer equipment, with screwing in fasteners in hard-to-reach places that border almost on jewelry work.

Mass types of keys

Touching on the topic of wrenches, an unforgettable image of an open-end wrench appears before your eyes. The nuts are fixed using lips that look like horns. This is where the name comes from. The second name for such means is used by GOST - open-jaw wrench. The center lines of the handle and head most often intersect at an angle of 15-20 degrees. When manipulating in tight spaces, this configuration will make the work easier. The angles between the axes of the head and handle are made in different sizes; opposite heads have different slopes from each other. Horn models are typically divided into various modifications:

- Double-sided instruments have two jaws of different dimensions. Usually their size designations are adjacent (18−19 mm). The jaws can have different thicknesses: thin ones work in hard-to-reach places, while thick ones are used for loosening nuts made of soft materials.

- For one-sided ones, the body is lengthened in order to increase the moment of force when interacting with fasteners. It is used in assembly production for operations with the same type of nuts. Some models have a locking shank for tube extensions.

- High-speed with a modernized working profile and a shortened jaw for high-speed movement of the key from one element to another. The rotation changes when the tool is turned one hundred and eighty degrees.

- Profile cuts on the lips of open-end wrenches increase the number of contact points and shift the location of the boundaries of the fastening components relative to the jaw. The turning force does not damage the structure in the planes of the nut or in the heads of the bolts, and allows you to unscrew deformed elements.

- A wrench with a working profile in the form of a ring, which is put on the mounting surface, is called a spanner. They can have rings at both ends of the working plane. There are edges along the inner diameter. There are six or twelve of them. The hex power tool unscrews tight, soured connections easily and without damage. Twelve-sided is used when working space is limited. The working profile can be made elongated for the use of attachments. The undoubted advantage of the attachment tool is the permissibility of exerting a large force on the unscrewing planes and working in cramped areas. The weak point is discomfort when working with threads of increased length.

- Devices that have a horn-type head on one end and a cap or end-type head on the other are classified as combined. Their heads are the same size on both sides. The dimensions of the body length are different: when space is limited - shortened standard increasing forces - elongated ones creating the maximum peak of pressure - extra long.

- A tool with a variable working profile is called an adjustable tool. The transformation occurs due to a screw mechanism or slider, which moves the moving part to the required width. The clamping of the fixing parts is not tight, which leads to the rolling of the edges. A plus is the possibility of using it with nuts of various diameters.

How to choose an open-end wrench?

How to choose the right tool so that it meets all GOST standards? The variety of models shows that there are different types of products for every need. You need to consider the purpose of its use and the complexity of the task you set for it. The material used for the production of modern nut products is special tool steel ; it consists of an alloy of vanadium and chromium.

There is also one unique tool that will help solve all problems at once, and eliminate the need to think about which open-end wrench to choose.

There are universal models that contain all products at the same time. This tool can handle nuts of various sizes with all types of heads.

It does not slip on a smooth surface due to its powerful teeth, which is its main advantage. There are also electric keys, the name speaks for itself. This tool can be powered by battery or batteries. Therefore, each home craftsman himself determines which products are best suited for him.

The price category is quite varied. Most often, the price depends on the versatility of the technical characteristics and the manufacturer. The cheapest is a single-sided horn instrument, where the open mouth has 3.1–85 millimeters.

When purchasing, you also need to remember about the long handle , which can limit the amplitude of movement of the key when turning. If one of the jaws is shortened, then, naturally, the radius of the wrench increases. In this case, you will be able to place the head on the side of the nut. If the handle is artificially enlarged, the applied force increases, and the jaw jaws will separate or even break. A hammer will be able to help set them in place when spreading, but the material will not be as strong as before. When you have a product made of 40xFA or 40x steel, then there is a method of hardening the sponge.

There is another option on how to repair a broken or worn out pharynx.

By welding the metal layer, you can adjust the volume of the throat using an abrasive tool.

When the open gap is more than 25 mm, then this option for restoring the product will be the most effective. The service life of carob products can range from a year to five. When talking about durability, they always mean a ring wrench (GOST 2906). It cannot be crushed, but it can wear out. There are restrictions on the use of this type of key. It can only be used if it is put on the nuts, but it cannot be used to unscrew, for example, union bolts of flexible hoses. The advantage is the hexagonal or twelve-sided jaw, which makes it possible to carry out work more intensively.

How to make an open-end wrench with your own hands?

For those who decide to make this instrument themselves, there are some small recommendations. You need to start manufacturing using a sample of a ready-made similar product. Complete a drawing of the required product, taking into account which you will make your key.

First, we make a blank from a steel sheet with a size several millimeters larger than the external size of the sides of the finished product.

There are difficulties with thick instruments .

You shouldn't cut it out with a hacksaw. And choosing a gas torch as a cutting tool is contraindicated. It is advisable to use forging in the process. This can be done by flattening a metal rod. Then, when the workpiece is ready, we begin to make markings. If the workpiece does not have very smooth edges, then it is advisable to file them down to remove scale. Afterwards it is necessary to apply paint to the treated surface. You can use quick-drying varnish or paint. Applying the sample is done after the paint has completely dried. It is advisable to use some kind of press to prevent the sample from slipping when delineating.

The scriber is a metal sharpened wire. Then the final marks must be placed on the separation of the workpiece and the sample, retreating a few millimeters from those already made, and then marking them. First, place the core at the risk with an inclination, and level it when striking with a hammer. The step between the pits in the pharynx should be 4–5 mm.

Then we drill out the throat. You can use an electric drill with drills with a diameter of 5–6 mm. The drill should not get too hot. You can cool it in water. Then, when you make the second shed, you need to remove the excess.

Well, at the end you need to harden the part. At home, this can be done using gas. If you use a special stove or forge , it will be ideal. To remove the product, use pliers by lowering the key into the water. It is necessary to remove and immerse until the sponges completely darken. This is the technology for making an open-end wrench.

Nut wrench dimensions.

Table of sizes of hex keys for nuts and bolts depending on the thread according to GOST.

A wrench is one of the main tools for assembling and disassembling both helical two-stage gearboxes of the Ts2U type and single-stage worm gearboxes Ch.

But, since there is no need to keep the entire set of keys or heads on hand, we provide a table that allows you to determine the set of necessary tools based on the thread sizes of hex nuts and bolts.

Dimensions of nuts and bolts depending on the thread according to GOST 5915-70

| Thread diameter M | M2 | M2.3 | M2.6 | M3 | M3.5 | M4 | M5 | M(5-6) | M6 | M7 | M8 | M(8) | M10 | M(10) | M12 | M(12) |

| Wrench size mm | 4 | 4,5 | 5 | 5,5 | 6 | 7 | 8 | 9 | 10 | 11 | 13 | 14 | 16 | 17 | 18 | 19 |

| Thread diameter M | M14 | M(14) | M16 | M18 | M20 | M(22) | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 |

| Wrench size mm | 21 | 22 | 24 | 27 | 30 | 32 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 |

| Thread diameter M | M52 | M56 | M60 | M64 | M68 | M72 | M76 | M80 | M85 | M90 | M95 | M100 | M105 | M110 | M115 | M120 |

| Wrench size mm | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 130 | 135 | 145 | 150 | 155 | 165 | 170 |

Please also note that when assembling gearboxes, it is advisable to use torque wrenches that allow tightening with the recommended torque. Insufficient tightening of threaded connections threatens oil leaks in the housing, and excessive force will lead to stretching of the bolts, which will ultimately also lead to loosening of the connection. The required force values must be indicated in the product data sheet, some of which are posted in our catalog. To unscrew a nut or bolt, a regular open-end wrench or socket is sufficient.

Technical drawing

Popular

Drawing Basics

Construction

Mechanical Engineering

Design of bolts and nuts. A bolt consists of a rod and a head. The rod has the shape of a cylinder and is threaded. The end of the cut part of the rod is made in the form of a sphere, cone or cylinder. The heads of the bolts have the shape of a hexagon, square, rectangle, etc. For special bolts, such as foundation bolts, the rod ends with a truncated pyramid, a hook, a special head and other shapes, and for hinged bolts in accordance with GOST 3033-45, it ends with an eye. Bolts are divided into clean (OST 3522 and 3523), semi-clean (OST/NKTP 3524) and black (OST 20035-38). Bolts according to OST/NKTP 3523 differ from bolts OST/NKTP 3522 only in the smaller head. The bolt designs are shown in Fig. 307, and their symbols are given in table. 9.

Nuts come in hex, square, round and wing nuts. By design, hex nuts are divided into ordinary and castle nuts, with one chamfer and two, and according to surface cleanliness they are divided into clean, semi-clean and black. Depending on the purpose and operating conditions, appropriate nuts are used.

Ordinary hex nuts are the most common in general mechanical engineering. They are used in stationary installations, machines, apparatus and other structures that are not subject to shocks. In aircraft, auto and tractor manufacturing, where connections are subject to variable loads and vibration, castle nuts are used or ordinary nuts with locks of various designs are used.

Hexagonal and square nuts are manufactured according to OST/NKTP 3310, 3311 and 3312; lamb - according to GOST 3032-45. The designs of the nuts are shown in Fig. 308, and in table. 10 shows their symbols.

Nuts and bolts are standard parts, so all elements have specific dimensions. The main size of bolts and nuts is the outer diameter of the thread.

1. Drawing bolts according to OST dimensions (Fig. 309). Let a semi-clean M36 bolt with a length of 75 mm OST/NKTP 3524 be given. It is required to construct three projections of it. We write down from the table OST/NKTP 3524 the dimensions necessary for construction, namely: bolt length l = 75 mm,

length of the cut part l = 55 mm, head size D = 63.5 mm, head height h = 24 mm, chamfer height C = 4.5 mm and wrench size S = 55 mm.

According to OST/NKTP 32, we find, according to the bolt diameter, the internal thread diameter d1 = 30.8 mm. We construct three projections using these dimensions.

Draw the outline of the bolt without a chamfered head. We calculate the diameter of the chamfer circle D1 using the formula: D1=0.95S.

We construct curves of intersection of faces with a conical chamfer. These curves should be hyperbolas, but in drawings they are usually replaced by circular arcs. Let's build these arcs.

To do this, we describe a circle on the plan with radius D1/2. We are planning

on the horizontal axis of point a and project them onto a vertical projection; we get points a'. Then, using a 30X60° triangle through points a', draw straight lines a'm' at an angle of 30° to the end of the head. By connecting m' and

m' we get points e' To construct curves on the faces, you need to have one more point. We mark point k on the plan, which will be the third point for the curve e'-e'. Find the vertical projection of this point. To do this, from the center O3 with radius O3k we describe an arc until it intersects with the mm axis at points c, along which we obtain points c' on the straight line a'm'. Then we draw a horizontal line through c', which will intersect the vertical lines drawn through the midpoints of the faces and, thus, we obtain third points on all faces (on the vertical projection such a point is designated k' for the middle face). Having three points, it is easy to find the centers of the radii of the arcs. The center 0 for the radius R is determined if we make notches from e' and k' with an arbitrary radius and draw a straight line through their intersection points, which, intersecting with the axis of symmetry, will give the center O. The same is done when finding the center O1 and determining the radius R' 1. The construction of the view on the left is shown with sufficient clarity in the drawing.

Bolts are drawn according to OST dimensions when drawing up working drawings.

2. Drawing bolts in a simplified way (Fig. 310). Let's construct three projections of an M36 bolt with a length of l=75 mm. In the previous example, the bolt was constructed according to the dimensions of the OST. But these are the same sizes

can be specified as a function of the outer diameter of the bolt thread d. The dimensions for constructing the bolt elements (internal thread diameter d1 head height h, dimension D and length of the threaded part of the bolt) are taken

equal: d1 = 0.85d; h =0.7d; D = 2d; l=l.5d. The end of the bolt is made in the form of a sphere, the radius of which R is taken equal to d or 1.5 d.

The construction of the bolt is clear from the drawing.

Bolts are drawn using this method when drawing up assembly drawings. Drawing a hexagonal ordinary nut with two chamfers according to the dimensions of the OST. Let it be required to construct three projections of the M36 nut (Fig. 311).

The design dimensions for this nut according to OST/NKTP 3311 are as follows: D = 63.5; H = 28; S = 55. The internal thread diameter d1 is found according to OST/NKTP 32; d1 = 30.8. The procedure for constructing projections can be recommended as follows: 1) construct the axial and center lines; 2) set aside the height of the nut H and draw horizontal straight lines; 3) with radius D/2 we describe a circle on the plan into which we inscribe a regular hexagon; 4) calculate D1 and construct a second circle of radius D1/2 on the plan. With the same radius we make notches on the vertical projection on the horizontal straight lines that limit the ends of the nut, on both sides of the axis of symmetry, and we obtain segments a' - a'. Through the ends of these segments we draw straight lines at an angle of 30° until they intersect with the ribs. We obtain the projections of the edges of the nut e'-e', etc. In order to simplify the construction of the intersection of the conical surfaces of the chamfers with the faces of the nuts, we replace the hyperbolas with circular arcs, as in the construction of the bolt head. Drawing of nuts according to OST dimensions is carried out when drawing up working drawings.

A simplified method of drawing ordinary hex nuts . For the same reasons that were given when describing the simplified method of drawing bolts, a simplified method of drawing nuts is used (Fig. 312).

With this method of drawing, all dimensions are also expressed as a function of size d. The method for constructing projections is the same as for the bolt head. Unlike the bolt head, the height of a normal nut is H=0.8d.

Drawing of nuts with one chamfer is carried out according to the dimensions of the OST and is done in the same way as nuts with two chamfers.

In fig. 313 shows the construction of a low nut for pipe products, called a lock nut. Lock nuts are manufactured according to OST 774 dimensions. The rules for drawing these nuts are the same as for nuts according to OST/NKTP 3310, 3311, with the only difference being that the chamfer in this case is made at an angle of 15° instead of 30°, adopted for normal nuts.

Drawing connections of parts with bolts . In fig. 314 shows a sample drawing of a bolted connection between two parts. The connection is made using clean bolts, nuts and washers.

The initial data for drawing such a connection are the thickness of the parts to be connected and the diameter of the bolt thread. The remaining dimensions of the bolt elements, nut and washer are taken according to the diameter of the bolt thread according to the tables of the corresponding OST. The length of the bolt is determined by counting and then rounded to the nearest size according to the OST table. Bolts and nuts are drawn according to the previously stated rules.

To determine the minimum bolt length, consider an example.

Let the following be given: the thicknesses of the parts to be connected are b1 = 25 mm and b2 = 35 mm; bolt thread diameter d = M36.

The minimum bolt length is determined by the formula

S — washer thickness — 6 mm (OST/NKTP 3233); H — nut height — 28 mm (OST/NKTP 3311); s — thread pitch—4 mm (OST/NKTP 32); c — bolt chamfer height—4.5 mm (OST/NKTP 3522).

Substituting the corresponding numerical values into the formula, we get

l = 25 + 35 + 6 + 28 + 4 + 4.5 = 102.5.

Comparing the resulting size with the nearest length dimensions for clean bolts according to OST/NKTP 3522, we find the bolt length l = 105 mi. There we also find the length of the threaded part of the bolt l=55 mm.

The diameter of the hole for the bolts is calculated using the formula d = 1.1 d. In this example, d = 1.1 -36 = 39.6 mm. Rounding to the nearest larger integer, we get d = 40 mm.

To complete the drawing of the assembly, it is necessary to apply dimensions, put down part numbers and draw up a specification.

This is done as shown in Fig. 314.

In practice, connections of parts with hinged bolts are also used (Fig. 315, a and b). Instead of a head, these bolts are equipped with an eye at one end. In these connections, wing nuts are often used, and less commonly, ordinary hex nuts. Hinged bolts are used in those structures where frequent disassembly of the connection is required, for example in vacuum boilers, hatches, doors and other mechanisms. Such a connection is drawn according to the nominal dimensions specified in GOST 3033-45 and 3032-45.

A special type of bolts are foundation bolts (Fig. 316), which are widely used when strengthening machines, columns, anchor supports and other structures on foundations. Bolts of this type are divided into long and short.

Short foundation bolts are used for fastening to the foundation of machine tools, low-power motors, racks, frames and units that are not subject to large overturning moments, impacts and shocks.

The end of the short bolts, embedded in the foundation, is made in the form of a truncated pyramid with jagged edges or in the form of hooks, screw twists, etc. Short foundation bolts are placed in the foundation sockets and then filled with concrete.

Long bolts are used for fastening anchor supports, internal combustion engines, high-power electric motors, turbines, pumping units, etc. The length of such bolts ranges from 500 to 2500 mm or more. When installed in a foundation, an anchor plate of a rectangular or oval shape is put on the head of bolts of this type, which is embedded in the foundation at a certain depth. Examples of connections with foundation bolts are shown in Fig. 316, a and b, and also in Fig.50.

Foundation bolts are drawn according to their nominal dimensions; nuts and washers are drawn using one of the above methods.

When purchasing new rims, each owner is faced with the selection of the correct and reliable fasteners for their wheels. At first glance, the task seems quite difficult, but we will try to explain in an accessible and short way what you should pay attention to.

Types and differences of wheel fasteners

When selecting, you should pay attention to the following important parameters. The main differences are:

Pressing surface

The pressing surface of a bolt or nut serves to tightly press the disc to the hub or brake disc of the car, preventing the wheel disc from moving. Bolts and nuts have several types of such surface. The most common is a cone at an angle of 60° in front of the head; it may or may not have a 1.3mm headrest There are also nuts with a spout at the end. Less common are nuts with a 30° cone. Some people are accustomed to thinking that flare nuts are universal because... capable of pressing almost any disc. But due to an incorrectly selected pressing surface, the destruction of cast disks is possible. Or at best an imbalance .

There are also nuts with an enlarged cone, with press washers, eccentrics and others.

There are bolts with an eccentric tolerance of 2.4mm. Such bolts make it possible to install disks from other cars, for example, on Japanese ones from German ones and vice versa. But the parameters of the disks and hubs should not exceed 2.4mm. For example, 5x114.3 - 5x112, 5x110 - 5x108, 5x115 - 5x114.3, 4x98 - 4x100. A cone moving relative to the threaded well of the disk will allow the disks to be attached without distortion.

Head size

When choosing a nut. If the nut is a closed type, you should pay attention to the length of the head so that the pin does not rest against the head inside the nut. Which will lead to under-tightening of the wheel. It is also worth paying attention to what wrench your nut is used for. A size that is too large may leave no room for the socket head of a wrench or impact wrench. On some models of alloy wheels with narrow wells, it is possible to install nuts only with an internal key, such as a hex or sprocket. For open nuts, only the wrench size is important.

Pros and cons of closed and open nuts.

- — Rusting of threads and studs, ingress of reagents.

- + Low price.

- + 99% of the studs do not rust.

- - Price.

When choosing bolts. As a rule, the head or head of the bolts has standard sizes for keys 17, 19 and 21. With the exception of “secrets”.

Thread sizes

Thread sizes for a nut imply the diameter of the threaded connection and the thread pitch . For bolts, the length of the threaded part is taken into account. It is important that a bolt that is too small will not be able to provide a reliable connection to the hub. And if it is too long, it can damage the parking brake elements when driving. An ideal bolted connection is considered when the protrusion of the bolt is no more than 1-2 turns.

You can see the exact information in the instructions for your car or consult with specialists.

How to determine thread sizes yourself

For nuts, the marking is formed MDxP .

For bolts and studs marking MDxPxL .

- M - metric thread icon;

- D —thread diameter in millimeters;

- P - thread pitch in millimeters;

- L - length in millimeters.

To determine the marking of the nut, you should measure the parameters of the stud. To measure you will need a caliper. For bolts and studs, dimension D is measured by the outer diameter of the thread.

The pitch P can be measured with a caliper or a simple ruler. Count a certain number of turns, measure the distances between these turns and divide by the number of turns. This way you can roughly determine the thread pitch. Then compare with the table of metric threads and the closest size and the correct pitch will be.

Length L is measured from the beginning of the bolt to the head or washer.

IMPORTANT! For imperial and metric thread sizes, the measurements are slightly different.

Measuring Thread Diameter (D)

Thread Pitch Measurements (P)

Bolt length measurements (L)

Material of manufacture

Nuts are made from steel, aluminum or titanium. Bolts are made of steel only. The material of manufacture does not play a big role; both of them are able to provide reliable clamping of the wheel. It is only worth noting the different service life for different use. Titanium ones are highly durable and reliable, but the downside is the high price. Aluminum is more affordable, sometimes silicon and magnesium are added to add strength. The best price-quality option is steel. But sometimes bolts and nuts are made from ordinary metal; such products are softer and rust quickly.

Coating

The nut can be coated with or without chrome plating. Chrome significantly prevents rusting of products, but steel nuts can also maintain their shine. In any case, when choosing, you should not be guided by aesthetic properties.

Tightening bolts and nuts on discs

To ensure reliable wheel clamping, the clamping surfaces of the disk wells and nuts can be lubricated with graphite lubricant to reduce the friction force. When using a torque wrench, the permissible tightening is 105 - 120 Nm. But it is better to use the recommendations for your car model.

Without torque wrench. After installing the wheel in a crosswise sequence (for 5 studs, one at a time), tighten the wheel until it stops. Then lower the car onto the wheel (remove the jack) and tighten the wheel in the same order, adding force on each lap, walk about 3 laps.

Secrets

To protect your expensive wheels, there are bolts and nuts with special keys, but often the owners themselves fall into their own trap when replacing seasonal tires or worn out pads. Always keep your safety head in the car so that in case of a tire puncture you can put on a spare tire. And under no circumstances lose it.

But you can also get into an awkward situation because of low-quality, cheap secrets. Which simply wear out quickly and do not provide enough grip. The nuts simply cannot be unscrewed. In this case, it is better to contact specialists in advance to remove the secretion. You should not try to unscrew such a nut yourself using a hammer and chisel. Most likely, you won’t achieve anything other than disk damage. A proven and working 100% effective method (for steel nuts) to carefully weld a nut with a head under a normal key.