One of the most common methods of heat treatment of metals is steel hardening. It is with the help of hardening that the required characteristics of the finished product are formed, and its incorrect implementation can lead to excessive softness of the metal (non-hardening) or to its excessive fragility (overheating). Our article will talk about what proper hardening is and what needs to be done to achieve it.

Steel hardening

General information about steel hardening technology

The main goals achieved by the hardening + tempering complex:

- increased hardness;

- increasing strength characteristics;

- reduction of ductility to an acceptable value;

- the possibility of using hollow products instead of solid ones, which allows reducing the weight of the metal product and the metal intensity of the production process.

Main stages of hardening:

- heating to temperatures at which the structural state of the metal changes;

- shutter speed set in the technological map;

- cooling at a rate that ensures the formation of a given crystal structure.

After hardening, tempering is carried out, which consists of heating the metal to temperatures below the line of phase transformations, with a further slow decrease in temperature. The result of heat treatment is influenced by:

- heating temperature;

- rate of temperature rise;

- holding period at quenching temperatures;

- cooling medium and rate of temperature decrease.

The key parameter is the heating temperature, on which the restructuring and formation of a new structural lattice depends. Based on the depth of action, hardening is divided into volumetric and surface. In mechanical engineering, volumetric hardening is usually used, after which the hardness of the surface and core differs slightly. Surface heat treatment is in demand for parts for which high surface hardness and a viscous core are important.

Methodology

In order to carry out the work of hardening steel, you need to take into account how such a process is carried out correctly. Hardening is a process of increasing the hardness of the surface of an iron or alloy, which involves heating a sample to a high temperature and then cooling it. Despite the fact that at first glance the process in question is simple, different groups of metals differ in their unique structure and characteristics.

Heat treatment at home is justified in the following cases:

- If necessary, strengthen the material, for example, at the cutting edge. An example is the hardening of chisels and chisels.

- If it is necessary to increase the plasticity of an object. This is often necessary in the case of hot forging.

Professional hardening of steel is an expensive process. The cost of 1 kg of increasing surface hardness costs approximately 200 rubles. It is possible to organize hardening of steel at home only taking into account all the features of increasing surface hardness.

What steels are hardened?

Not all steel grades can be hardened. Grades with a carbon content below 0.4% practically do not change hardness at quenching temperatures, so this method is not used for them. Hardening technology is most often used for tool steels.

Table of correct quenching and tempering conditions for certain types of tool steels

| steel grade | Steel hardening temperature | Cooling medium after quenching heating | Holiday temperature | Cooling environment after tempering |

| U7 | 800°C | water | 170°C | water, oil |

| U7A | 800°C | water | 170°C | water, oil |

| U8, U8A | 800°C | water | 170°C | water, oil |

| U10, U10A | 790°C | water | 180°C | water, oil |

| U11, U12 | 780°C | water | 180°C | water, oil |

| P9 | 1250°C | oil | 580°C | air in the oven |

| P18 | 1250°C | oil | 580°C | air in the oven |

| ШХ6 | 810°C | oil | 200°C | air |

| ШХ15 | 845°C | oil | 400°C | air |

| 9ХС | 860°C | oil | 170°C | air |

How to bend hardened metal

The following types of presses are usually used for bending metal blanks and products in production.

- Pneumatic and hydraulic. This is standard metal bending equipment. The blanks are placed between punches and dies. This allows you to bend even thick parts and products. Hydraulic presses are used more often. Their advantages are low cost and ease of operation.

- Rotary. Metal bending occurs between special beams and plates. The technology is excellent for processing simple hardened metal products with small dimensions.

- Rotary. On these machines, special rollers bend the hardened metal. Rotary machines are most often used for small-scale production of large-sized products.

Bending metal on a machine

Note! Good productivity is achieved when using rotary and rotary presses. Processing occurs automatically. There is no need to calculate the effort in advance.

Types of hardening - with and without polymorphic transformation

Hardening of steels proceeds with a polymorphic transformation, non-ferrous metals and alloys - without them.

Hardening of steels with polymorphic transformation

In carbon steels, when temperatures rise above a certain level, a series of phase transformations occur, causing changes in the crystal lattice. At critical temperatures, the value of which depends on the percentage of carbon, the decomposition of iron carbide occurs and the formation of a solution of carbon in iron, called austenite. With slow cooling, austenite gradually disintegrates, and the crystal lattice acquires its original state. If carbon steels are cooled at a high speed, then, depending on the quenching mode, various phase states are formed in them, the strongest of which is martensite.

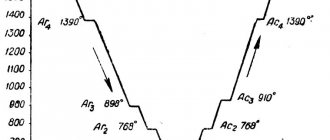

To obtain a martensitic structure, hypoeutectoid steels (up to 0.8% C) are heated to temperatures above the Ac3 point by 30-50°C, for hypereutectoid steels - 30-50° above Ac1. Using this technology, metal-cutting tools are hardened and products are strengthened, which are subject to friction during operation: gears, shafts, races, bushings. When heated to lower temperatures, the structure of hypoeutectoid steels, along with martensite, retains softer ferrite, which reduces the hardness of the metal and worsens its mechanical characteristics after tempering. Such hardening of steel is called incomplete and in most cases is a defect. But it can be used in some cases to avoid cracks.

Hardening without polymorphic transformation

Hardening without polymorphic transformation occurs in non-ferrous metals and alloys that have limited solubility of secondary phases at ordinary temperatures, in which polymorphic transformations do not occur at high temperatures. When temperatures increase above the solidus line (this is the line below which only the solid phase is located), the secondary phases completely dissolve. During rapid cooling, secondary phases do not separate out, since this requires a certain time. After such heat treatment, the non-ferrous alloy is thermodynamically unstable, so over time it begins to decompose with the gradual release of a secondary phase. This decomposition process, which occurs under natural conditions, is called natural aging, and when heated, it is called artificial aging. As a result of aging, an equilibrium structure is obtained. The characteristics of the material depend on the selected process mode.

Hardening of non-ferrous metals and alloys, unlike carbon steels, often does not lead to an increase in strength. Copper-based alloys, for example, often become more ductile after such maintenance. For such materials, tempering is usually used, which relieves stress after casting, rolling, stamping, forging or pressing.

Technological nuances: how to properly harden metal

The procedure itself includes three steps - heating, holding and cooling. Depending on what result you want to get and what material you are working on, you choose different parameters: limit, duration, and cooling methods. Here is a table with several steel grades:

| Brand | Temperature in degrees | Cooling medium |

| y9, y9a, y10, y10a | from 770 to 800 | water |

| 85khf, x12 | from 800 to 840 | oil |

| hwt | from 830 to 830 | |

| 9xs | from 860 to 870 | |

| xv5 | from 900 to 1000 | |

| 9x5vf | from 1000 to 1050 | |

| p9, p18 | from 1230 to 1300 | saltpeter |

There are two main purposes of heat treatment:

- increasing strength - this is necessary for knives, axes, drills and other tools used to process hard surfaces;

- increasing the plasticity of the product. For example, before forging or bending - it is used not in everyday life, but in a small private business.

When carrying out the heating technology, you should monitor the color of the workpiece. It should be deep red with an orange or yellowish tint depending on the type. There should be no black or other colored spots on the surface.

When carrying out the heating technology, you should monitor the color of the workpiece. It should be deep red with an orange or yellowish tint depending on the type. There should be no black or other colored spots on the surface.

How to properly harden metal and iron if there is no special kiln for firing? Use a blowtorch or make a regular fire - its temperature and burning time are high enough to do work that does not exceed domestic needs.

Cooling can be carried out in various ways. If you urgently need to reduce the heat in one area of the product, you can use a directed stream of cold water. Water, and therefore rapid, cooling is necessary for alloy and carbon steels. After heating, you should take the element with tongs (if it is a small knife, an ax) and place it in a previously prepared container with liquid. When leaving, cool gradually - first with water and then with oil.

And the third option is gradual cooling in the fresh air. This is also an effective method when you need to leave a slight plasticity effect. Let's watch a video on this topic:

Steel hardening methods

The hardening method is chosen depending on the chemical composition of the steel and the planned properties.

Hardening with cooling in one environment

The rate of cooling of steel after hardening depends on the environment in which it is carried out. The highest speed is provided by cooling in water. This method is used for medium-carbon low-alloy steels and some grades of corrosion-resistant steels. When the carbon content is more than 0.5% C and high alloying, water is not used as a cooling medium, since such alloys become cracked or completely destroyed.

Intermittent quenching in two cooling media

Step hardening is used for parts made of complex alloy steels. Large parts, after heating, are dipped in water for several minutes, and then cooled in oil to +320...300°C, after which they are left in the air. When cooled in oil to room temperature, the hardness of the product decreases significantly.

Isothermal maintenance

Hardening of high-carbon grades is a complex process consisting of normalization followed by heating to the hardening temperature. The heated parts are lowered into a bath of saltpeter, heated to temperatures of +320...+350°C, and kept.

Svetlaya TO

This heat treatment is used for high-alloy steels and consists of heating them in an environment of inert gases or in a vacuum, which ensures a light-colored metal surface. Light hardening is used in mass production of standard products.

Heat treatment with self-tempering

At a high cooling rate, heat remains inside the part, which, when gradually released, relieves stress on the internal structure. This process can only be entrusted to specialists who can accurately calculate the time the product is in the cooling environment.

Jet

Cooling is carried out with an intense stream of water. This process is used when it is necessary to harden individual parts of products.

Manufacturing a chamber for hardening metal

The main materials for the manufacture of home furnace bodies for steel hardening are solid refractories in the form of blocks of various sizes and fireclay clay.

In such a furnace, a temperature of over 1200 °C is reached, so it is possible to harden products not only from carbon or tool steel, but also from high-alloy steel. When making home stoves from fireclay clay, a cardboard frame is first made according to the shape and size of the working chamber, which is then covered with a layer of fireclay.

A heating coil is wound over it, and then the main heat-insulating layer is applied. With this design, the heating area is isolated from the heating element, which is important when it is necessary to harden steel that is sensitive to oxides and carbon burnout.

The most common design of home hardening furnaces are installations whose thermal bodies are made of fireclay bricks or similar refractories. The operating temperature of such materials is more than 1400 °C, so in such furnaces it is possible to harden almost any type of steel and many refractory alloys.

Structurally, such a home oven is similar to a conventional wood-burning oven, only it is much smaller in size. The metal in it is heated using an electric spiral placed in grooves along the perimeter of the internal space.

If it is necessary to qualitatively harden steel, it must be heated to a precisely specified temperature, so most of these homemade products are equipped with thermostats (they can be freely purchased on Aliexpress).

The video below shows the design of such a home furnace with end loading and a thermostat, which allows you to harden steel with precise temperature conditions. Its thermal body is made of mullite-silica refractory plates ShPT-450.

A detailed description of the design and recommendations for creating a top-loading furnace, in which you can harden products up to 54 cm in length, can be seen in the following video. Here the thermal body of the furnace is made of fireclay bricks (ShB type) and a thermostat is also used. In addition to the top loading, a special feature of this device is a kanthal spiral, which lasts many times longer than traditional nichrome and fechral.

Equipment for hardening

The equipment is divided into two main groups - heating units and cooling baths. At modern enterprises, the following are used to obtain quenching temperatures:

- thermal muffle furnaces;

- induction heating equipment;

- installations for heating in melts;

- laser heating devices;

- gas plasma devices.

The first three types of installations are in demand for volumetric hardening, the last three - for the surface process.

Quenching equipment is steel containers, graphite crucibles, furnaces that contain molten metals or salts. Quenching baths for liquid media are equipped with heating and cooling systems. Their design may include special mixers for mixing liquid media and eliminating the steam jacket.

Equipment and features of the process

Special equipment is often used to heat the surface. This is due to the fact that heating steel to the melting point is quite difficult. The following equipment is often used at home:

- electric oven;

- blowtorch;

- thermal oven;

- a large fire that is surrounded to redirect the heat.

Mobile forge for heating parts

When choosing a heat source, you should take into account the fact that the part must be completely placed in the oven or fire on which the heating is carried out. It will also be correct to select equipment based on the type of metal that will be processed. The higher the strength of the structure, the more the alloy is heated to impart plasticity.

In cases where only part of the part needs to be hardened, jet hardening is used. It provides for a jet of cold water to hit only a certain part of the part.

A water bath or barrel or bucket is often used to cool steel. It is important to take into account the fact that in some cases gradual cooling is carried out, in others it is rapid and abrupt.

Hardening process technology

Heating and holding

The heating temperature of steel during hardening depends on its chemical composition. In general, there is a pattern - the lower the percentage of carbon, the higher the heating temperature should be. Lowering the heating temperature leads to the fact that the desired structure does not have time to form. Consequences of overheating:

- decarbonization;

- surface oxidation;

- increase in internal tension;

- change in structural components.

Products of complex shapes are preheated. To do this, they are dipped two or three times in salt baths for several minutes or kept for a short time in ovens heated to temperatures of +400...500°C. The holding period is determined by the dimensions of the product and their quantity in the oven. All parts of the product must be heated evenly.

Table of hardening temperatures for various steel grades

| Brand | Temperature, °C | Brand | Temperature, °C |

| 15G | 800 | 50G2 | 805 |

| 65G | 815 | 40ХГ | 870 |

| 15X, 20X | 800 | 3Х13 | 1050 |

| 30Х, 35Х | 850 | 35ХГС | 870 |

| 40Х, 45Х | 840 | 30ХГСА | 900 |

| 50X | 830 |

The heating temperature is measured using pyrometers - contact and non-contact, infrared devices.

Cooling

For cooling, water is used - pure or with salts dissolved in it, alkaline solutions. For alloy steels, blowing or cooling in mineral oils is used. In isothermal and stepwise processes, molten salts, alkalis and metals are used for cooling. Such environments can alternate with each other.

Vacation

Depending on the required temperature, tempering is carried out in oil, alkaline or saltpeter baths, furnaces with forced circulation of air flows, and hot sand.

Low tempering, carried out at +150...+200°C, serves to eliminate internal stresses, slightly increase ductility and toughness without significantly deteriorating hardness. Low tempering is in demand for measuring and metalworking tools, and other parts that must combine hardness and wear resistance.

For high-speed steels, tempering is carried out at temperatures of +550...580°C. This procedure is called secondary hardening because it leads to an additional increase in hardness.

How to cut threads in hardened metal

Tools made from high-speed steels and carbide alloys are also best suited for this operation. Taps are used to cut internal threads, and dies are used for external threads.

Internal threading technology

To cut internal threads of a certain size, three taps are usually used: rough (No. 1), semi-finish (No. 2) and finishing (No. 3).

Proceed according to the following scheme.

- Make the markings.

- Punch the hole.

- Lubricate the future hole and drill.

- Secure the part.

- Install the drill.

- Set the cutting mode. Start processing at low speeds. After the drill is immersed in the metal, the speed can be gradually increased.

- Drill a hole for the thread and countersink. Remove the shavings. Lubricate the #1 tap and the workpiece.

- Install the tool. The axes (its and the holes) must match.

- Make the first pass. After each full turn of the tap, make a half turn in the opposite direction. If necessary, remove chips.

- Make passes using semi-finishing and finishing taps.

External thread cutting technology

For this, dies are used. Process workpieces using this technology.

- Place the tool in a holder of the appropriate size. Secure the die with screws.

- Make a chamfer at the end of the workpiece.

- Apply coolant to the surfaces.

- Place the die on the workpiece. Its plane must be perpendicular to the axis of the workpiece.

- Cut the thread. After one or two turns, return by half a turn.

- Make sure the threads are cut accurately.

Possible defects after hardening

Heating, holding, cooling and tempering of steel are carried out in accordance with technological maps developed by specialists. Violation of the developed and approved technical process and/or heterogeneity of the workpiece structure can cause various defects. Among them:

- Uneven heating and/or cooling. They lead to deformations and the formation of cracks, non-uniform composition and non-uniform mechanical characteristics.

- Burnout. Occurs due to the penetration of oxygen molecules into the metal surface. As a result, oxides are formed that change the performance characteristics of the surface layer. This defect occurs due to the burning of carbon from the steel caused by excess oxygen in the furnace.

- Water entering the oil cooling bath. This violation of the technical process leads to the appearance of cracks in the product.

All of the above defects are irreparable.

How to drill through hardened metal

First of all, we list the main features of drilling workpieces and products made of hardened metal. For successful processing you need:

- choose the right drill;

- prepare a workpiece or product;

- use cutting fluid.

Which tool to choose for drilling hardened metal

For drilling hardened metal, tools made from the following grades of steel are best suited.

- P18. Tools made from steel of this brand are the best choice. These drills for hardened metal appeared back in Soviet times. The material contains up to 18% tungsten. This gives the steel high strength. The surfaces do not overheat and wear out slowly.

- R6M5K5. This grade of steel contains 6% tungsten and 5% each of molybdenum and cobalt. These hardened metal drills can withstand maximum heat loads when machining hardened parts and products.

- HSS-Co. This is a foreign analogue of the previous steel.

Hardened metal drill made from HSS-Co steel

Craftsmen choose drills made from these steel grades because of the optimal combination of price and efficiency in processing high-strength hardened metals.

Note! Before drilling, it is necessary to thoroughly clean the workpiece or product from oils, grease and other contaminants.

Tips for using coolant when processing hardened metal

- Add coolant to tool cutting edges. During processing, the liquid scatters and evaporates. The lubricant must be updated promptly.

- Before processing a part or product, it is also necessary to apply coolant to the target surface.

- When drilling hot metal, take short breaks to allow the workpiece and tool to cool.

Characteristics of steel

In the context of this topic, steel has two important characteristics.

Hardenability

This characteristic reflects the fact how capable the steel is of becoming hard after undergoing the hardening procedure. There are alloys whose properties practically do not change as a result of this heat treatment, that is, the hardness remains at an insufficient level. They say about such a metal: “does not accept hardening.”

Metallurgy explains the high hardness of carbon-containing martensite by the distortion of its crystalline cells. This factor makes plastic deformation of the material difficult. The hardness index increases with increasing amount of carbon. In numbers it looks like this: the value of this parameter, established using the Rockwell method with the content of the element carbon (C) in steel at the level:

- 0.1%, equal to 30HRC;

- 0.7% is 64HRC.

But a further increase in the amount of carbon in the alloy does not lead to a significant increase in the hardness index. All this is displayed on the graph.

The following designations are used on it:

- pos. “1” – the heating temperature exceeds the Ac3 point;

- pos. “2” – the heating temperature of the product is 770°C, which is higher than only point Ac1;

- pos. “3” is an indicator of martensite hardness.

Typically, alloys with a carbon content of less than 0.3% are not subjected to the hardening procedure due to their low degree of hardening.

Hardenability

This characteristic indicates the depth of hardening of the steel. During this process, the core of the part cools more slowly than its surface. This phenomenon is explained by direct contact of the outer layer with a cooling substance that absorbs thermal energy. The situation is different with the central fragment of the product. Its heat is transferred through the thickness of the metal to the surface area, and there it is absorbed by the same cooling substance.

Hardenability is a characteristic derived from the critical hardening rate. This is understood as the lowest rate of supercooling of all austenite to the martensitic structural transformation. The depth of hardening is inversely proportional to this parameter. That is, the lower the speed of the above process, the deeper the hardening of the metal occurs. This is clearly manifested in alloys with large and small grains. The former are calcined to a greater depth than the latter, since they have a low critical speed.

Hardening temperature

The main criteria on the basis of which hardening modes are divided into types are the heating temperature and the speed of the technical process. There are also differences in such parameters as:

- time interval of exposure at certain temperature indicators;

- speed of the cooling procedure.

In general, based on the “heating temperature,” hardening can be of two types. Let's look at them briefly.

Complete hardening

Hypoeutectoid steel is processed by complete hardening. It is heated so that the final temperature exceeds the critical point Ac3 by 30°-50°. Then the mixture of ferrite and cementite is completely transformed into austenite. With further cooling, a predominantly martensitic structure is formed.

Hardening is incomplete

Tool steels are most often subjected to the incomplete hardening procedure. Carrying out heat treatment of this type has the goal of heating the product until the process of formation of excess phases begins. In this case, the following temperature range must be observed:

Ac1≤Т≤ Ac2, where

- T – heating temperature;

- Ac1, Ac2 – critical points. In the first (+727°C), recrystallization begins - pearlite is transformed into austenite. In the second (+768°C) α-Fe transforms into β-Fe and the steel loses its magnetic properties.

If this temperature range is maintained, the martensite structure will retain a certain amount of ferrite after quenching the steel.

Incomplete hardening of a hypereutectoid alloy is of the highest quality if the product is heated to a level exceeding Ac1 by 20°C-30°C. Then, during the process of heating and cooling, cementite will not be transformed. Because of this, the hardness of martensite will increase. If the heating temperature of the part goes beyond the above range, this characteristic may, on the contrary, worsen.