Sorbitol - hardening

Hardened sorbitol is more clearly visible in an optical microscope (Fig. 189) than hardened troostite.

Hardening sorbitol Compared with tempering sorbitol, it has lower ductility and viscosity.

| Steel (0 5% C after hardening at 840 C in oil. Structure. |

Hardening sorbitol is revealed more clearly in an optical microscope (Fig. 203) than hardening troostite.

Quenched and tempered sorbitol under an optical microscope is revealed more clearly than troostite due to the larger size of cementite and ferrite particles.

Hardening sorbitol is a mixture of ferrite with very small cementite plates (Fig. Under an electron microscope, cementite plates are clearly distinguishable (Fig.

There are also hardening sorbitol and tempering sorbitol. The structure of hardening sorbitol is lamellar, while tempering sorbitol is granular.

Quenched troostite and sorbitol have a lamellar structure of cementite, while troostite and tempered sorbitol have a granular structure. Quenched and tempered troostite consists of extremely crushed particles of cementite and ferrite and is therefore almost undetectable under a microscope. Due to increased morbidity, troostite is revealed by microanalysis in the form of dark formations. Under an electron microscope, the lamellar structure of hardened troostite is clearly visible.

| Microstructure of quenched martensite. X. 500.| Crystal lattice of martensite. |

Cementite in hardening sorbitol has a fine-plate structure; The hardness of sorbitol is higher than the hardness of pearlite.

The structures of perlite, hardening sorbitol and hardening troostite differ from each other only in the fineness of the cementite platelets; in essence, they are one family of pearlite platelet structures.

| Change in grain size during recrystallization. |

There are two types of sorbitol: hardening sorbitol and tempering sorbitol. Hardening sorbitol consists of alternating plates of ferrite and cementite, but the cementite plates in it are much thinner than in pearlite. Sorbitol is harder than perlite, but has less viscosity. In tempered sorbitol, the cementite particles are spherical in shape. Troostite, like sorbitol, is of two types: hardening troostite and tempering troostite. Troostite is a mechanical mixture of ferrite and cementite plates, but thinner than in sorbitol. Troostite has greater hardness compared to sorbitol, but lower viscosity. In tempered troostite, cementite is in the form of spherical particles.

I Gardin): and - hardening sorbitol (X20,000) (A.

Therefore, the resulting transformation products - troostite and hardening sorbite - differ from the equilibrium structure - pearlite - in a more dispersed structure: the plates of ferrite and cementite and the distance between them are smaller compared to that observed for pearlite.

Laxative effect of sorbitol (sorbitol)

Dispensing steel

Sorbitol has a pronounced laxative effect, increasing in proportion to the amount taken into the body. The recommended daily dose is 30-40 grams per day (determined individually). Doses within 30-50 (determined individually) grams cause flatulence. Doses over 45-50 grams (determined individually) lead to a strong laxative effect, accompanied by flatulence.

Sorbitol is used as a medicine to combat constipation in laxative preparations in the form of chocolates and candies.

Sorbitol can be used as a laxative when taken orally or as an enema. Sorbitol works as a laxative by drawing water into the colon, stimulating bowel movements. [ source unspecified 73 days

]

Tempered martensite

Martensitic transformation in steel

When martensite is removed from the quench bath, it is called freshly quenched martensite. The hardness data in Figure 4 refers specifically to freshly quenched martensite. The big problem with this "fresh" martensite is that if the carbon content is more than 0.2-0.3%, then the steel in this state is very brittle. This brittleness can be eliminated by some loss of hardness if the hardened steel is slightly heated. This process is called vacationing.

Therefore, hardened steels are almost always tempered to increase the toughness of the steel. The resulting martensite is called tempered martensite. The increased tempering temperature allows the carbon atoms that are “trapped” in the bct structure to move a little. This movement of atoms gives two effects: – allows the bct structure to change into a bcc structure; – enables the formation of very small carbide particles.

Expanded perlite

Steel tempering

Perlite is also called acidic volcanic glass with a fine structure, along which it splits into small balls, sometimes having a pearly luster. The composition of such expanded perlite,%: SiO2 65-75; Al2O3 10-15; Fe2O3 1.5-2.5; CaO 1.5-2.5; MgO 1.5-2.0. Expanded perlite

contains up to 3-6% constitutional (bound) water. When heated quickly, the water contained in this perlite evaporates, swelling the rock with an increase in volume up to 10-20 times. Swelling temperature 850-1200°C. Expanded perlite has a volumetric mass of 70-600 kg/m3, which allows it to be used as a lightweight filler in thermal insulation products.

Expanded perlite is used primarily in construction: in the production of effective plaster, bricks and blocks from artificial perlite stone (the advantages of which are low weight and ease of processing), as a soundproofing filler, insulation, etc. In addition, expanded perlite is used in agriculture and more.

Lit.:

Gulyaev A.P. Metallurgy. - M.: Metallurgy, 1977. - UDC669.0 (075.8)

Ivanov V.N. Dictionary-reference book for foundry production. – M.: Mechanical Engineering, 1990. – 384 p.: ill. ISBN 5-217-00241-1

Zimmerman R., Gunter K. Metallurgy and materials science. Reference ed. Per. with him. M.: Metallurgy, 1982. 480 p.

See also Iron-carbon alloys and Isothermal transformation of austenite.

Sorbitol - vacation

| Influence curves. |

Basic non-ferrous metals and alloys

As a result of tempering at 600 C, tempering sorbitol is formed, a ferrite-cementite mixture larger than troostite. Hardness is further reduced.

When tempered at high temperatures, a structure is formed which is called tempering sorbitol. Tempered sorbitol consists of a ferrite base penetrated with cementite particles. The diameter of cementite particles in sorbitol is N0 - 5 mm.

When tempered at high temperatures, a structure is formed which is called tempering sorbitol. Tempered sorbitol consists of a ferrite base penetrated with cementite particles. The diameter of cementite particles in sorbitol is 1 10 - 5 mm.

| Change in grain size during recrystallization. |

There are two types of sorbitol: hardening sorbitol and tempering sorbitol. Hardening sorbitol consists of alternating plates of ferrite and cementite, but the cementite plates in it are much thinner than in pearlite. Sorbitol is harder than perlite, but has less viscosity. In tempered sorbitol, the cementite particles are spherical in shape. Troostite, like sorbitol, is of two types: hardening troostite and tempering troostite. Troostite is a mechanical mixture of ferrite and cementite plates, but thinner than in sorbitol. Troostite has greater hardness compared to sorbitol, but lower viscosity. In tempered troostite, cementite is in the form of spherical particles.

| Long-term strength of the cast housing of the PT-60 turbine stop valve made of 15Х1М1ФЛ steel. 1 - initial state. 2 - metal of the stop valve body after 150 thousand hours of operation. |

On the other hand, reducing the length of sub-boundaries and converting fragmented tempered sorbitol into a structureless ferrite-carbide mixture increases the long-term ductility of steel.

To produce lightweight structures of high strength and obtain a tempered sorbitol structure, machine parts are subjected to heat treatment in the form of hardening and high tempering (improvement) or surface hardening by heating with high frequency currents. The steels used in these cases contain from 0.30 to 0.65% carbon. Carbon steels are used for the manufacture of small cross-section parts; For the manufacture of parts with large sections, due to the low hardenability of carbon steel, it is necessary to use alloy steels.

The martensite decomposition product obtained during high tempering, called tempering sorbitol C0), has the maximum viscosity for steel, combined with satisfactory strength indicators. This complex is ideal for machine parts subjected to dynamic and cyclic loads. Due to this advantage, heat treatment, combining hardening and high tempering, has long been called an improvement.

With such heat treatment, as a rule, a tempered sorbitol structure with a fairly good set of mechanical properties is obtained.

| Destruction of the disk of the first stage of the medium pressure rotor of the K-500-240 turbine after 83 thousand hours of operation. |

Metallographic examination of the destroyed disk established that the microstructure of the disk is tempered sorbitol, both needle-shaped and structureless, i.e. has a structure typical for the initial state of the disk. An electron microscopic study revealed the initial stage of the recovery and recrystallization processes with the appearance of recrystallization nuclei formed as a result of coalescence of subgrains inside bainite plates and migration of subboundaries. Thus, observation of the structure of steel through a transmission electron microscope shows that processes characteristic of high-temperature creep occurred in the metal.

In cases where the stable metal structure of the pipes under study is tempered needle sorbitol and ferrito sorbitol (points 1 or 2 - 6, respectively, on the microstructure scale of TU 14 - 4 - 450 - 75), average grade durability estimates can be used as permissible stresses .

When heated to 600 C, carbides coagulate and a tempered sorbitol structure is formed. The structure of sorbitol consists of ferrite and small grains of cementite.

Is it possible to temper steel at home?

Most often, heat treatment applies to various simple parts, household utensils - knives, forks, metal cups, car parts, and so on. However, home metallurgy has many limitations that the common man may not be aware of. Let's consider the main problems that a person may encounter during a steel holiday at home:

- Most home ovens cannot reach high temperatures. Therefore, at home you can only make a low or medium vacation. Theoretically, you can try to re-equip or “strengthen” your stove to increase the heating temperature, but this will be difficult for a person without experience.

- To carry out heat treatment, it is necessary to use a protective medium (oil, alkali, saltpeter). But each substance has its own temperature characteristics. A simple example: saltpeter-based compounds can explode when heated to high temperatures, which can be dangerous to the life and health of the home metallurgist.

- Tempering without the use of a protective environment can be fatal to the metal itself. The fact is that without the use of a protective environment, the metal will cool quickly, which can affect the quality of the steel (increased brittleness, bending, plastic deformation, rust).

- Also, do not forget about low-temperature brittleness of the first type (from 250 to 300 degrees). If the temperature is incorrect, the quality of the metal can be seriously affected, up to the complete destruction of the alloy.

Structure - martensite

The martensite structure is formed during rapid cooling as a result of the transition of the lattice of the solid solution of γ-iron (austenite) into the lattice of the solid solution of α-iron (ferrite) without the release of carbon from the solution. The transition of y-iron to a-iron is accompanied by a change in the volume of crystal lattices, which causes the appearance of internal, additional stresses. Martensite is a supersaturated solution of carbon in a-iron with a distorted crystal lattice. An alloy with a martensite structure has great hardness and strength.

| Scheme of bainite transformation. |

The structure of martensite after these types of transformation is different.

The structure of martensite in low- and medium-carbon steels has the shape of laths (lath martensite), elongated in one direction. In high-carbon steels, martensite forms plates that look like needles in the grinding plane.

The structure of martensite is unstable: when heated above 200 C, martensite tends to transform into a more stable structure - troostite-sorbitol, and, finally, at temperatures above 720 C - into the most stable structure - pearlite.

The structure of martensite consists of plates in the form of needles, oriented relative to the old austenite phase in parallel or at certain angles.

The martensite structure in a welded joint is not dangerous during welding and in operation if the welding method and filler material are chosen correctly, the optimal conditions of the welded product manufacturing technology are not violated, stress concentrators are eliminated by creating smooth transitions from the weld to the base metal, or favorable conditions are created in the welded joint , reducing sensitivity to stress concentrators: the use of austenitic additives or surface treatment by cold hardening. The welded joint is unreliable if the seam is made with low-alloy wire, which provides a martensitic-ferritic structure of the weld, or with austenitic wire of the type Sv - 06Kh18N9T, Sv - 13Kh25N18, Sv - 08Kh20N10G6 with a small margin of austeniticity. Such a weld has an austenitic-martensitic structure (high-carbon martensite), has low plasticity and impact toughness and is not reliable in operation under repeated static loads.

The structure of martensite is formed as a result of the transition of the lattice of the solid solution of y-iron (austenite) into the lattice of the solid solution of c-iron (ferrite) without the release of carbon from the solution. The transition of y-iron to a-iron is accompanied by a change in the volume of crystal lattices, which causes the appearance of internal additional stresses. Martensite is a supersaturated solid solution of carbon in a-iron with a distorted crystal lattice. An alloy with a martensite structure has great hardness and strength.

The structure of martensite is characterized by a small grain size and often has a needle-like structure.

The structure of martensite consists of plates in the form of needles, oriented relative to the old austenite phase in parallel or at certain angles.

The structure of martensite varies in appearance depending on the composition of the steel and the quenching conditions.

In this case, the structure of martensite transforms into trooste-sorbitol forms and then into austenite. The contact temperature of the cutter with the chips, when a significant amount of heat is released, is so high that molecular adhesion forces develop, especially from the chips, and melting of thin layers is observed. In this case, the softened surface layers of the machined surface and the crater are carried away by chips moving along the front surface of the cutter.

The structure of martensite, formed at temperatures above room temperature, has needle-shaped crystals without signs of internal twinning. The authors of this work believe that twins present in martensite plates reduce the number of possible slip systems and thereby increase the strength of martensite. I. N. Bogachev and his co-workers disagree with the last conclusion, who believe that twins do not additionally strengthen the martensite of transition-class steels.

| Dependence of steel hardness on carbon content in.| At the top is the greatest hardness of hardened steel depending on the carbon content in it (according to Burns, Moore and Archer. At the bottom is the change in the number of elementary cells of martensite, which each account for one carbon atom, depending on its content in the steel. |

The structure of martensite is characterized by a thin block structure, which largely determines the high resistance of hardened steel to plastic deformation.

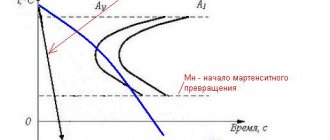

Critical transformation points

Figure 2 shows the cooling and heating curves of pure iron. As can be seen from these curves, during the process of restructuring one lattice into another, as well as during the melting and solidification of iron, temperature stops occur, which are the result of the release of additional heat during cooling and the absorption of additional heat during heating.

Rice. 2. Cooling and heating curves of pure iron.

Temperature stops at which lattice rearrangements occur are called critical temperatures or critical points and are designated Ar during cooling and Ac during heating. At points Ar2 and Ac2, the atomic lattice is not rearranged, but the magnetic properties of iron change. At temperatures above 768°, iron loses its ability to be attracted by a magnet. At a very low rate of heating and cooling, the critical points A c3 and Ar3 do not coincide with each other by 12°. As the cooling rate increases, the discrepancy between the critical points increases, since the temperature decreases significantly and the iron becomes supercooled. This phenomenon is called hysteresis.

When heating and cooling steel, a restructuring of the atomic lattice also occurs, but the temperatures of the critical points are not constant. They depend on the carbon content and alloying impurities in the steel, as well as on the rate of heating and cooling.

In Fig. Figure 3 shows a diagram of the state of carbon steel during slow cooling and heating.

Fig.3. State diagram of carbon steels.

What is temper brittleness

The release temperature affects the quality of processing - the higher the temperature, the higher the quality of processing. However, metallurgical scientists have found that this rule has 2 exceptions, when an increase in temperature does not lead to an improvement, but to a deterioration in the quality of the material. These two exceptions are often called temper brittleness islands in practice. Fortunately, several effective, safe ways to bypass these islands have been developed, so the issue of tempering ability is not significant in modern metallurgy. Let's look at each of the islands separately + learn how to get around them.

Irreversible low temperature embrittlement

Another name is fragility of the first kind. It occurs during prolonged processing of the material at temperatures from 250 to 300 degrees, and this fragility extends to all types of steel alloys. Explanation of the phenomenon: when heated in a given temperature range, carbon begins to actively distribute over the surface of the crystal lattice. However, the distribution of carbon is extremely uneven - this leads to disruption of the crystalline structure of the metal, which leads to a serious increase in fragility. As the name implies, this fragility is irreversible (that is, the islands remain stable for an unlimited time, and damaged material is only suitable for remelting). The method of dealing with this fragility is trivial - you need to use either low or medium heat treatment - but not “intermediate” between them.

Reversible high temperature embrittlement

Another name is fragility of the second kind. It occurs only when three factors are combined simultaneously. The first factor is that the metal is heated above a temperature of 500 degrees (that is, this fragility is characteristic of high tempering processing). The second factor is that steel is an alloy with a high content of chromium, manganese or nickel. The third factor is a very low cooling rate. Explanation of the phenomenon: with a combination of three factors, an uneven distribution of carbon, chromium, manganese and nickel atoms also occurs, which leads to disruption of the crystal lattice of the alloy. There are many ways to combat this fragility - let's look at two of them:

- Method No. 1: after the formation of brittleness, the material is reheated to a given temperature - only heating is carried out in an oil environment, and the metal is cooled after tempering very quickly.

- Method No. 2: during tempering, tungsten (about 1% of the total mass) or molybdenum (0.3-0.4%) is additionally added to the alloy - after this, high tempering is performed using standard technology.

Hardenability

The mechanical properties of structural elements depend on the homogeneity of the metal structure, which directly depends on through hardenability and the minimum diameter. This parameter characterizes the formation of more than half of martensite. So the table shows some indicators at which the critical diameter is maintained.

| steel grade | Carrying out hardening at temperature, °C | Critical diameter, mm | |

| Intensive cooling environment | |||

| water | oil | ||

| 45 | 840…850 | until 9 | up to 25 |

| 45G2 | 840…850 | before 18 | up to 34 |

| 40ХН2МА | 840…850 | up to 110 | up to 142 |

| 38Х2МФА | 930 | up to 72 | up to 86 |

As practice shows, alloying elements have a great influence on hardenability. This is especially noticeable in the presence of nickel. Its presence makes it possible to harden parts of large diameter. Thus, a critical part with a diameter of over 100 mm can be turned from steel 40ХН2МА and subjected to heat treatment while maintaining the given properties throughout the entire volume.

Troostit - vacation

Tempered troostite has a hardness of approximately HRC 40 - 45, which depends on the chemical composition of the steel, temperature and duration of tempering.

The structure of tempered troostite (Fig. 191, b), as well as quenched troostite, due to the significant dispersion of the formed ferrite and cementite particles, is poorly revealed by microanalysis; Troostite is observed in the form of heavily etched dark formations.

The structure of tempered troostite (Fig. 205, b) and quenched troostite due to the significant dispersion of the formed ferrite and cementite particles is poorly revealed by microanalysis; Troostitis is observed in the form of heavily etched dark formations.

Tempered sorbitol and troostite differ from the hardening structures of the same name in that tempered cementite has a granular rather than lamellar shape.

The martensite orientation preserved in tempered troostite in the form of a needle-like structure distinguishes it from quenched troostite.

| Steel after isothermal transformation at 700 C - lamellar pearlite (x500. pickling with 4% alcohol solution of nitric acid. | Steel after isothermal transformation at 650 C - sorbitol (x500. pickling with 4% alcohol solution of nitric acid. |

Thus, tempered troostite is a product of martensite decomposition. It is a highly dispersed mixture of ferrite particles, tiny round grains and short cementite plates.

Above 350 C, tempered troostite structures are formed, and with a further increase in heating temperatures, tempered sorbitol structures are formed.

As a result, the tempered martensite turns into tempered troostite, and the release of carbon from the solid solution (martensite base) almost ends and a significant part of the distortions of its lattice and internal stresses are removed.

As a result of tempering, the martensite obtained during normal quenching turned into tempered troostite (Fig. The structure of tempered troostite consists of dispersed particles of iron - Fig.

At higher strength (ab1300 MPa), medium-carbon steels with a tempered troostite or martensite structure are characterized by reduced resistance to crack propagation. In addition, the low ductility of high-strength steels increases their sensitivity to cuts in the most stressed areas of parts. As a result, fatigue cracks appear in places where stress is concentrated, quickly leading to parts failure. Due to the increased sensitivity to the notch, there is a significant scattering of the values of a and a decrease in a to ( 0 4 0 3) av. The load-bearing capacity of parts made of alloy steels in a high-strength state may be lower than that of hot-rolled carbon steels.

Quenched sorbitol and troostite have a lamellar structure and this differs from tempered sorbitol and troostite, which have a granular cementite structure.

Hardened steel, tempered at 300 - 400, acquires a structure called tempering troostite. This type of steel structure is needed for springs, springs, braids, wood saws, etc.

As a result of these transformations, hardened steel, heated to 350 - 500, receives the tempered troostite structure (Fig.

Average tempering involves heating the steel to a temperature of 350 - 500 C and cooling to obtain a tempered troostite structure. As a result of average tempering, the hardness of the hardened steel is reduced to HRC 40 - 50, while the elastic limit, which has the smallest value after hardening the steel, reaches its maximum value. Therefore, springs, springs and other elastic elements are subjected to medium tempering.

Methods for obtaining austenite

Austenitic steels are formed in the process of the appearance and growth of grains in the initial microstructure of a metal product.

Austenite is formed at the interface between the ferrite and carbide phases. Carbide particles gradually dissolve in the austenite solid solution. Austenite can also be obtained from the eutectoid modification of iron, consisting of ferrite and cementite. To do this, the original metal workpiece must be heated to a temperature of 900 °C

It is important that the alloy contains a minimum carbon concentration of 0.66%. During this process, ferrite transforms into austenite, and cementite is completely dissolved

The result is austenitic stainless steel.

When producing metal blanks from austenitic steels stabilized with titanium, it is necessary to remelt the metal in a vacuum induction furnace. The resulting melt is kept for a long period to denitrogenize it. The amount of time required for this process depends on the weight of the original product. After holding, a mixture of titanium and nitride-forming chemical elements is introduced into the molten austenite.

When adding chromium and nickel to the iron modification, the material must be kept for a longer time. Very often a mixture of molybdenum or phosphorus is added to the resulting solution. These chemicals increase the toughness and fatigue strength of the iron alloy. To reduce the wear of the resulting austenite, additional alloying materials and energy-intensive carbides are used.