Updated: 02/21/2021 14:11:48

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

If anyone has tried plucking a chicken by hand, they know how long and tedious it is. The carcass must be soaked in hot water and each feather must be pulled out with your own hands. At the same time, clothes and hands are stained with fine fluff. To simplify the process, a feather removal machine was invented, which has a drum and punching fingers. The latter have a ribbed structure and capture feathers well. The carcass comes into contact with them due to the rotation of the rotor and is gradually cleared of feathers. Such a device makes it easier for the housewife to prepare a delicious dinner, and in commercial activities one cannot do without it at all. Our experts looked into which feather removal machines deserved the title of the best among numerous options.

What is a feather removal machine?

Before you decide to make such a device yourself, you need to study this issue and understand the principle of operation of the machine.

The feather removal machine is a container with rubber pins. These fingers have a special surface that grabs feathers and pulls them out. Thus, without much effort you can process several carcasses in a few minutes.

Feather removal machines are available in several versions:

1. With a centrifuge. Such a device looks like a round or triangular vertical container, inside of which the striking fingers are located.

The bottom of this container with the same elements unwinds at high speed. The carcass is rotated and processed with your fingers. This is how she is freed from feathers.

To make the machine more efficient, water is added to the machine. It protects carcasses from damage and washes away excess feathers.

You can load not very large birds into it. For example, you can pluck quails, chickens and ducks. Feather removal machines for geese take up more space and are more energy intensive. Such devices are used mainly in small farms. It is not economically profitable to use them at home. Therefore, for large birds in the household, other feather removal machines are used.

2. With a drum. Here the drum rotates with the help of a motor. The hitting fingers are located outside. The operator holds the carcass against the rotating rotor and adjusts the clamping force.

This machine allows you to pluck birds of any size. Of course, it is inconvenient to pluck small carcasses in this way.

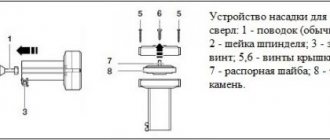

3. Special attachments for power tools. This tool is universal (you can pluck birds of any size), but not very convenient to use. Here you will have to hold the carcass with one hand, and the tool with the other. The inconvenience is justified by the low cost.

Of course, mechanization of the process has many advantages, but there is also one significant drawback - the high price. Therefore, only farms and peasant households that sell livestock regularly buy feather removal machines.

When using at home, you still want to minimize costs as much as possible. It is for this reason that the DIY feather removal machine has become so popular today. Here are several options for such machines.

Advantages and disadvantages of feather removal machines

Like any other, this method has its pros and cons compared to hand plucking. The main advantages are:

- A large number of processed carcasses at a time. In different models of drum machines, in one run you can pluck a couple of dozen quails, 5-6 broiler chickens, one goose or a medium-sized duck.

- Very high performance. If manual cleaning of feathers from a medium-sized bird carcass can take up to half an hour, then in feather photography this, depending on the model, takes from 30 seconds to 1 minute.

- Cleanliness of work. After removal from the car, if successful, the bird looks impeccably smooth - exactly the way we are used to seeing them on store shelves.

Of the minuses, perhaps, we can only note the complete lack of autonomy of such devices, as well as some risk of damage to the bird from strong rotation and the impact of whipping attachments.

Making a screwdriver attachment

The easiest option is to make an attachment for a screwdriver. And just a piece of advice: it is not recommended to make fingers for a pen removal machine with your own hands, since they are so cheap that there is no point in wasting time on them.

To make a screwdriver attachment, you will need a blank in the form of a tin can (the can itself will not work here, since it is made of thin tin, which wrinkles quickly). The workpiece can be made from a thick-walled light-alloy metal pipe. On one side, you need to secure the bottom with screws. A hole is drilled in the center of the bottom, in which a pin is secured with nuts (it should be the size of the drill chuck). Holes for the striking fingers are drilled in the cylinder itself, after which the rubber bands are tucked into the holes - and the device is ready.

Homemade pen removal attachments for power tools

The DIY drill attachment, which can also be used in conjunction with a screwdriver or sharpening machine, is easy to make. The main element of such a device is the drum, which must have sufficiently high rigidity. To make your own nozzle for plucking poultry, you can use the following algorithm.

- A bottom is attached to a section of a thick-walled pipe made of light metal using screws or welding, in the central part of which a hole is pre-drilled.

- A pin is inserted into the hole in the bottom of the drum and secured with two nuts. When selecting the diameter of such a pin, it should be taken into account that it must be securely fixed in the chuck of the power tool used to operate the pen removal attachment.

- Several rows of holes are drilled on the side surface of the drum along its entire circumference. They should be performed at the same distance from each other.

- Rubber strikers are inserted into the resulting holes.

If you have a suitable engine lying around on the farm, then it can be used to create a more powerful plucking device.

Such a feather plucking attachment, despite the simplicity of its design, can be used to process chickens, quails, ducks, geese and even turkeys. This attachment for plucking birds is also useful for hunters, who are also often faced with the need to process a large number of bird carcasses.

The simplest nozzle for plucking poultry can be made with your own hands from a piece of polyethylene pipe with a diameter of 100–120 mm. The two bottoms for such a nozzle can be made not of metal, but of hard plastic or plywood. In the center of both bottoms, holes are drilled through which a pin will be passed, intended not only for installing the attachment on a power tool, but also for tying the entire structure. As in the previous model of a homemade nozzle, holes are drilled on the surface of the pipe of this device into which rubber punching fingers are inserted.

The most affordable option for a homemade nozzle

Feather drum

Let's talk about how to make a do-it-yourself feather removal machine with a drum. It works like a drill attachment, only this attachment is longer. The drum is located on the support axis. During production, you can get by with a low-power electric motor and a simple pulley gearbox. This pinching machine can process any number of carcasses, and the size does not matter.

Read also: Molar mass of zinc g mol

The drum itself is installed on the frame, a bag is hung from below to collect feathers, after which you can clean as many birds as you like.

How to make a poultry plucking attachment with your own hands

Improving such a unique tool as a drill has no limits. Every year its capabilities only expand, thereby making life easier for people. Attachments for drills are sold in specialized tool stores, but it is almost impossible to find feather removal devices there. Such devices can be purchased in agricultural stores or online.

The easiest and cheapest way to use feather removal attachments on a drill for plucking poultry is to make them yourself. The advantage of this solution is ease of manufacture and low investment. You only need to buy one important part - the pins. Their number and length are selected depending on the type of bird. You can buy them separately in any quantity, and their price varies from 15 rubles per piece.

Accessories for making your own nozzle

Making feather attachments for drills and screwdrivers with your own hands is done as follows:

- The nozzle is based on a piece of plastic sewer pipe. The diameter of the pipe does not play a big role, but the optimal value is 60 mm

- You need to drill holes in the pipe, the diameter of which depends on the size of the fingers (usually 20 mm). You can drill holes in a chaotic sequence or three after two

- The end parts of the pipe must be covered with wooden circles. After cutting them out according to the pipe template, you need to drill a hole in the center with a diameter of 8 mm.

- The central hole is necessary in order to place the rod inside. A bolt with a length of 10 cm is used as a rod. Its length depends on the size of the pipe used as a drum

- Using a bolt with nuts, the wooden bases of the nozzle are secured. First you need to install the fingers on the pipe in the drilled holes.

- To prevent the plastic pipe from falling off the wooden circles while the drill is running, you need to additionally secure it with self-tapping screws

- The protruding part of the bolt is the shank, which is fixed in the tool chuck. For convenience, you can remove the threads using an emery machine.

Homemade device on the instrument

The result is a homemade device that can be used to quickly pluck a chicken or duck at home.

Similarly, you can make from available materials not only an attachment for a drill, but also a stationary machine for plucking poultry. A drum from a washing machine is used as the base, and the device can be driven into rotation by an old medium-power electric motor in the arsenal.

This is interesting! When making a plucking machine with your own hands, you must definitely select the optimal number of engine revolutions, since rapid rotation of the drum will lead to damage to the carcass.

Homemade plucker from a washing machine with your own hands

How to make a feather removal machine with your own hands from a washing machine

For the manufacture of such a device, an old washing machine with a cylindrical stationary container, a ready-made bottom drive for rotating the bottom and an installed oil seal is ideal.

The main idea of the remodel is to make maximum use of the factory design. You need to drill holes in the walls for the pen removal fingers, and install a round plate of hard metal above the bottom. The bottom of an old frying pan or saucepan will also work here. This base needs to be attached to the axle.

You also need to drill holes in the bottom for the hammer fingers.

The rotating part should be smaller in diameter than the tank (approximately 5 cm). There is no need to leave a very large gap to prevent bird limbs from getting in there.

There should be a drain at the bottom of the tank for water with feathers. Important: the rotation axis must be sealed enough to prevent water from getting onto the electric motor.

This feather removal machine is capable of processing both large and small birds.

Poultry plucking process

A feather removal machine can pluck birds based on certain rules.

- After the goose has been slaughtered, you need to put the bird in a cool place for several hours so that the carcass cools down a little.

- Heat the water to a temperature warmer than room temperature. It is best if the temperature is 70-80°C: this way the feathers will steam better and will be pulled out better.

- Place the goose in water for a few minutes. The main thing here is not to overexpose the animal. Water should seep into all the feathers on the carcass.

- Turn on and warm up the device. It is important to ensure that all attachments are in place. Now you can put an animal carcass in it.

- While the device is operating, boiling water must be poured onto the geese.

- Remove the animal and wash it. Turn off the device so that it cools down and rinse the pen attachments. Now you can look carefully at the carcass and, if there are remnants of feathers, remove them manually.

Owners of a small flock of geese, turkeys, chickens or ducks do not have to spend money on such equipment; it is quite possible to pluck the birds with your own hands. However, purchased equipment is also perfect for removing feathers from broiler chickens. The remaining fluff can be removed using a soldering iron or blowtorch. It is necessary to remove the remaining burnt fluff with a knife, after which the carcass must be washed in warm water.

Barrel skimmer

A feather removal machine, made with your own hands from a barrel, works on the same principle as a device from a washing machine.

Initially, you will need a plastic or metal round barrel (about 1 meter high, about 70 cm wide). This barrel must be strong enough not to bend from blows from the carcass.

At the bottom of the barrel and at the bottom you need to make holes for the rubber strikers. the resulting drum must be placed in the frame. The frame can be made from wooden boards or metal corners. The first option is easier to do, but the second will be more reliable.

To the first layer of the bottom you need to add another one, which will be attached to the rotating mechanism.

In order to mechanize the machine, you will need an electric motor with a power of about 1.5 kW. To protect the motor, it is better to place it on a stand and take it to the side.

In this way, without extra costs, you can make a feather removal machine with your own hands. We discussed above how to do it in different ways.

The big advantage of such a unit is the cost. After all, it is made from scrap materials. A factory feather removal machine is quite expensive.

Article: 0011 Manufacturer: Novital (Italy) Description:

| Packaging dimensions (LxWxH): | 45,5×61,5×31 |

| Weight: | 24.5 kg |

Price: 39000 29000 rub.

Article: 1853 Manufacturer: Novital (Italy) Description:

| Packaging dimensions (LxWxH): | 45,5×61,5×31 |

| Weight: | 24.322 kg |

Price: 39000 32000 rub.

Feather removal machine T500mm – description and characteristics

Description:

A household electric drum-type feather removal machine is designed to automate the process of removing the feathers of broilers, roosters, turkeys, geese and other farm species of birds. The machine is made of high quality stainless steel. This type of machine works on the principle of a centrifuge. The lower disk rotates while the drum is stationary. The stylus fingers are easily replaced without the use of special tools. The high productivity and reliability of feather removal machines greatly reduces the processing time of poultry carcasses in small farms and private farmsteads. The working tool of the machine is rubber fingers; you can purchase additionally and replace them yourself as they wear out. Thanks to the use of a machine, poultry plucking becomes a convenient and quick process.

Price: 31900 on promotion 24800 rub.

Feather removal machine T550mm – description and characteristics

Description:

A household electric drum-type feather removal machine is designed to automate the process of removing the feathers of broilers, roosters, turkeys, geese and other farm species of birds. The machine is made of high quality stainless steel. This type of machine works on the principle of a centrifuge. The lower disk rotates while the drum is stationary. The stylus fingers are easily replaced without the use of special tools. The high productivity and reliability of feather removal machines greatly reduces the processing time of poultry carcasses in small farms and private farmsteads. The working tool of the machine is rubber fingers; you can purchase additionally and replace them yourself as they wear out. Thanks to the use of a machine, poultry plucking becomes a convenient and quick process.

Technical characteristics of the feather removal machine: Dimensions: 750 x 800 x 1000 mm Inner drum diameter: 550 mm Weight: 60 kg Electric motor: 1.1 kW, 220V, 1400 rpm

Price: 33900 on promotion 28800 rub.

Feather removal machine for geese and ducks T600mm – description and characteristics

Description:

The feather removal machine is used for plucking geese, ducks, and other types of poultry. The machine is made of high quality stainless steel. This type of machine works on the principle of a centrifuge. The lower disk rotates while the drum is stationary. The stylus fingers are easily replaced without the use of special tools. The high productivity and reliability of feather removal machines greatly reduces the processing time of poultry carcasses in small farms and private farmsteads. The working tool of the machine is rubber fingers; you can purchase additionally and replace them yourself as they wear out. Thanks to the use of a machine, poultry plucking becomes a convenient and quick process.

Read also: How to melt silver at home

Technical characteristics of the feather removal machine: Dimensions: 750 x 850 x 1050 mm Inner drum diameter: 600 mm Weight: 73 kg Electric motor: 2.2 kW, 220V, 1460 rpm

Price: 35900 on promotion 30800 rub.

We present in the table the recommended **** parameters for working with NT series machines:

| NT 500 | NT 550 | NT 600 | NT 600A | NT400/ NT400A** | |

| Loading: | PC | PC | PC | PC | PC |

| Quail | 5-15* | 8-18* | 10-20* | – | 3-10 |

| Broiler chicken | 1-2 | 1-2 | 1-3 | – | 1 (up to 1.8kg.) |

| Chicken | 1-2 | 1-2 | 1-3 | 1-3 | – |

| Turkey | – | – | 1 (up to 5 kg.) | 1(up to 7kg.) | – |

| Duck | – | – | – | 1(up to 7kg.) | – |

| Goose | – | – | – | 1(up to 7kg.) | – |

| Heat treatment modes: | С°/seconds | С°/seconds | С°/seconds | С°/seconds | С°/seconds |

| Quail | 62-66/15-30* | 62-66/15-30* | 62-66/15-30* | – | 62-66/15-30 |

| Broiler chicken | 64-67/20-40 | 64-67/20-40 | 64-67/20-40 | – | 64-67/20-40 |

| Chicken | 64-68/30-60 | 64-68/30-60 | 64-68/30-60 | 64-68/30-60 | – |

| Turkey | – | – | 66-70/30-60 | 66-70/30-60 | – |

| Duck | – | – | 72-76/40-60 | 72-76/40-60 | – |

| Goose | – | – | 75-82/40-90 | 75-82/40-90 | – |

| Processing modes: | seconds | seconds | seconds | seconds | seconds |

| Quail | 10-20 | 10-20 | 10-20 | – | 10-20 |

| Chicken broiler | 15-25 | 15-25 | 15-30 | – | 15-25 |

| Chicken | 15-35 | 15-35 | 15-40 | 15-35 | – |

| Turkey | – | – | 25-45 | 25-45 | – |

| Duck | – | – | – | 25-60 | – |

| Goose | – | – | – | 25-60 | – |

Article: 03400B000 Manufacturer: China

Feather removal machine for quail T400mm - description and characteristics

Description:

A household electric drum-type feather removal machine is designed to automate the process of removing the feathers of quails and other small birds. The machine is made of high quality stainless steel. This type of machine works on the principle of a centrifuge. The lower disk rotates while the drum is stationary. The stylus fingers are easily replaced without the use of special tools. The high productivity and reliability of feather removal machines greatly reduces the processing time of poultry carcasses in small farms and private farmsteads. The working tool of the machine is rubber fingers; you can purchase additionally and replace them yourself as they wear out. Thanks to the use of a machine, poultry plucking becomes a convenient and quick process.

Technical characteristics of the feather removal machine: Dimensions: 560 x 560 x 850 mm Inner drum diameter: 400 mm Weight: 40 kg Electric motor: 1.5 kW, 220V, 1400 rpm

Price: 0 rub.

Article number: 0021G Manufacturer: Novital (Italy) Description:

Drum with 24 rubber fingers for feather removal machine .

Price: 11900 rub.

Article: 147G Manufacturer: Novital (Italy) Description:

Drum with 36 rubber fingers for feather removal machine .

Price: 11900 rub.

In poultry farming, one of the most labor-intensive operations is de-feathering poultry. To facilitate labor and speed up the process of plucking poultry, electric feather removal machines are used. The principle of operation of such machines is approximately the same, however, a feather removal machine for geese and ducks usually has a larger capacity, and a feather removal machine for quails and chickens has a smaller capacity. Nozzles with rubber fingers also differ.

For most poultry farmers and summer residents, it will be the best solution if the feather removal machine you decide to buy belongs to the universal class. The ESTERINA feather removal machine from the Italian manufacturer Novital, which you can purchase on our website, belongs to this class. It is reliable and effective, easy to clean. Thanks to special flexible, rubber pen removal fingers located close to each other, uniform and quick pen removal is ensured. This machine is suitable for all kinds of poultry. At the same time, working on it is comfortable and productive (80 chickens per hour). When processing manually, each bird takes up to 15 minutes. It’s easy to calculate how much time and effort you save from using the machine.

Article: PR144-50 Manufacturer: Italy Material: rubber Purpose: chickens, geese, ducks, turkey Hardness: SH50

Households very often breed poultry for meat (ducks, geese, broiler chickens, etc.). At the same time, the plucking process is not easy and not very pleasant. It is precisely in order to save owners from such an unpleasant task that a feather removal machine was invented. For use at home, you can make a feather removal machine with your own hands.

What are kicking fingers, and what types are they?

These are the main active elements of feather removal machines, due to which feathers and down are removed from the carcass after scalding. This is a consumable item that you will replace repeatedly as you use the machines. They are usually made of food-grade rubber, which does not peel off and does not leave any discharge on the carcasses even when exposed to high temperatures.

At the same time, it is important to know that the striking fingers are not at all the same, and differ from each other in such parameters as diameter, the presence and shape of notches, and rigidity. All this is very important to take into account before you start plucking, because if you don’t do this, you risk hopelessly damaging the carcass, or simply plucking it poorly. So, there are:

- Nozzles for large birds. They are suitable for ducks, guinea fowl, chickens. Their length reaches 98 mm.

- Nozzles for small birds. Can be used for quails, partridges, chickens. Their length reaches 60 mm, usually a horizontal notch is used.

- Universal. They have a medium level of hardness, horizontal notches, and are suitable for working with any type of poultry.

The general rule is that the shorter the striker, the smaller the bird it is intended for. Most models come with spare attachments suitable for plucking different carcasses. This material can also be ordered online.

How the devices work

Before you start making your own device, you need to understand the principle of its operation. A pinching machine is a container with rubber pins. These fingers have a special surface that can grab feathers and pull them out. Thus, without any effort, you can get several processed carcasses in a matter of minutes.

Read also: 78M05 pinout circuit diagram

Such devices are available in several modifications:

- With a centrifuge. Round or vertical triangular containers with punching fingers inside. The bottom unwinds at high speed, the carcass also begins to spin and gradually becomes free of feathers. To increase efficiency, a small amount of water is poured into the device - it will protect the carcasses from damage and wash away all excess. Small birds (quails, chickens, ducks) are loaded into it. It is not profitable to use them at home, so other types are suitable for households.

- With a drum. Here the motor drives the drum. The fingers are located only on the outside. The person must hold the bird close to the rotating rotor, constantly adjusting the pressure. You can clean carcasses of different sizes, but the smallest ones are inconvenient to process.

- Special attachments for power tools. They are distinguished by their versatility (you can pluck any bird), but they are not very convenient to work with: you have to hold the carcass with one hand and carry out processing with the other. The only justification is that such attachments are inexpensive.

Of course, mechanization of the process has many advantages, but there is also a significant disadvantage - high cost. , only farmers or individual business owners who regularly sell livestock buy such devices

But even when using at home, you want to minimize costs, which is why these days a self-made pen removal machine has gained popularity. There may be several options.

Drum pluckers

Common devices (including those for home use) are drum-type pluckers. They are a precisely centered drum, on the outer surface of which the beaters are fixed. During the plucking process, the poultry carcass is brought to a rotating drum, which can have different lengths. It should be noted that using drum devices for plucking small poultry is not entirely convenient.

A budget option for this type of device is a drum attachment for a drill for plucking poultry. Such attachments, although universal, are not very convenient to use. To process a poultry carcass using such a device, you have to hold it with one hand and use the power tool with the other to rotate the nozzle.

A simple plucking attachment consists of an aluminum body with holes for fingers and a shaft for mounting in a drill or screwdriver chuck.

It should be borne in mind that the drum-type feather removal attachment allows you to pluck only one poultry carcass at a time, so for farms where it is necessary to pluck several birds at once, it is better to purchase devices of other types. These are, in particular, feather removal machines operating on the principle of a centrifuge, or larger and more productive drum devices driven not by a power tool, but by a separate drive.

An even more budget-friendly device for this purpose is a drill attachment for plucking, the working part of which is not a drum with pins, but a sponge with a reinforced washing surface. Although this attachment looks primitive, it allows you to pluck poultry or wild birds quite effectively.

Serial feather removal equipment and special devices designed for plucking poultry are purchased mainly by farms and private entrepreneurs who regularly sell their products on the market or in retail chains. Many of those who breed poultry only for their own needs make such devices with their own hands from scrap materials, using only factory-made beating fingers, which today can be purchased at a low price. You can make your pen picker reliable only if you purchase high-quality strikers that will last much longer than those made by yourself.

Feather removal machine in the form of an attachment for a screwdriver

This option is one of the simplest. Important advice: you should not try to make fingers yourself, because their cost is low.

In order to make the nozzle, you will need a blank in the shape of a tin can. But the can itself will not work, as the thin tin will bend very quickly. Use thick-walled alloy metal pipe . Attach the bottom on one side using screws, drill a hole in the center, secure the pin in it with nuts (the diameter and dimensions must match the drill chuck). Drill holes for the hammer fingers directly in the cylinder, then insert the rubber bands there - the unit is completely ready for use.

The second economical option: take a sewer pipe made of polyethylene, the diameter of which does not exceed 12 cm. Any hard material is suitable for the bottom. The pin is threaded through, the “cheeks” are tightened using nuts. The fingers are inserted according to the same pattern as described above. To increase productivity and make work easier, the drill can be attached to the table.

A device with a drum works on a similar principle to drill attachments, differing only in its longer length. The drum is located near the supporting axis . For production, a low-power electric motor and a simple pulley gearbox are enough. A large number of birds can be processed, regardless of size. The drum is installed on the frame, a bag for collecting feathers is suspended from below, then you can clean an unlimited number of carcasses.

How to choose a feather removal machine

First, let's note the key parameters for choosing poultry plucking machines. This will help you evaluate the potential of the models presented in the review and decide what characteristics to look for for your own needs. Here are a number of important factors to consider when choosing:

- Power.

The characteristics vary from 140 to 2200 W. The higher the number, the faster the rotor can rotate under load and not overheat. For professional activities, choose an indicator of 1500 W. - Productivity

. In an hour, one machine can pluck 120 carcasses, and another - 400 of the same size. Your choice depends on the volume of work, but more productive models are more expensive. - Capacity

. There are devices with drum sizes from 200 to 700 mm. The wider it is, the more carcasses it can accommodate at a time, which affects the speed of plucking a large number of birds. The size of the drum also determines what type of birds will fit in it. There are universal models for all types of birds (ducks, geese, turkeys, broilers, partridges, quails) and specialized ones for quails or laying hens only. - Material of the drum and other parts.

Equipment made from food grade stainless steel is stronger and more durable, but is more expensive. Plastic drums also do not rust, but are inferior in durability. But they are lighter, which reduces the load on the motor. - Number of fingertips.

The number varies from 90 to 200 pieces. The more there are, the faster the feathers are plucked. - Dimensions and weight.

If stationary use is intended, then the machine is installed once in a permanent place, after which it is not moved. Heavy weight of 30-80 kg provides good stability and low vibration. When you plan to regularly take the device outside, pluck the bird and return it to its storage location, look for small models weighing 10-15 kg. Although they bounce around a bit when spinning, they won't be difficult to wear.

Manufacturing a unit based on a washing machine

To make it, an old washing machine with a fixed cylindrical container, a ready-made drive in the lower part that rotates the bottom, and an installed oil seal is perfect.

The main point of processing is to make maximum use of the standard design. Holes are made in the walls for attaching fingers, and a round plate of hard metal is attached above the bottom (the bottoms of old pots or pans are suitable). The base is attached to the axis. Holes are also drilled in the bottom.

The part that rotates should have dimensions smaller than the tank (about 5 cm). If the gap is too large, bird limbs may get in. It is necessary to equip a water drain at the bottom of the tank, while simultaneously ensuring the tightness of the axle so that water cannot get into the electric motor.

With the help of such a unit you can process both small and large carcasses.

Removing feathers with your own hands is not difficult

In order to effectively remove feathers from chickens, geese, turkeys and ducks, you need to prepare gauze or bandage and an iron. You need to place a small piece of gauze or bandage on the area of the carcass. The cloth must be wetted with warm water in advance. Place a hot iron on top and hold for several tens of seconds. After the area has warmed up very well, you can slowly remove the feathers. They should be removed without problems, since the animal’s skin will be well steamed.

Using this process, you can not only speed up the performance, but also cause less damage to the bird’s skin. After all the manipulations have been carried out, you should burn the remaining fluff with a blowtorch and remove the burnt areas. The animal carcass should be washed under warm water and left to dry.

Under no circumstances should you throw away bird feathers, because they are so valuable that you can get good money for them. There are special collection points that accept feathers and down. A person tries to carry out plucking very carefully, because not only the quality of the meat, but also the quality of the fluff depends on this. Even meat from which feathers have been properly removed (even with your own hands) will cost much more. Profit directly depends on personal efforts.

Barrel skimmer

- A homemade feather scraper based on a barrel will work on the same principle as devices from washing machines. You need to take a plastic or metal barrel (height - 1 meter, width - 70 centimeters). It must be strong to withstand bird impacts against the sides.

- Holes for fingers are made in the lower part and on the bottom, and the drum is placed in the frame. It can be made from wooden beams or metal corners. The first option is easier to do, but the second is more reliable.

- Before the first layer of the bottom, another one should be added - for attachment to the rotation mechanism.

- To mechanize the product, you will need a 1.5 kW motor. To ensure proper protection, it is better to place the motor on a stand and move it to the side.

This is how you can make a plucking machine with your own hands without extra costs. A significant advantage of such a device is that it can be assembled from scrap materials.

Disc plucking machines for geese

These devices do not have broken pins. The principle of operation is similar to epilators - feathers are torn by movable steel discs, this has no effect on the skin. Two motors available. The first of them moves the disks, the second rotates the fan turbine, which ensures the operation of the blades.

The advantage of this equipment is the good quality of the carcass, without skin tears or bruises. There is no need to steam or wax the goose first. Since no water is used, the shelf life of the meat is increased. Feathers and down remain clean and dry - the material can be sold.