Some housewives, avid hunters and farmers know that there is such a useful device as a nozzle for plucking poultry. This device, which can be used equally successfully for plucking both poultry and wild birds, greatly facilitates this process.

The attachments clean poultry carcasses fairly quickly and with minimal damage.

Those who have ever plucked poultry know how labor-intensive and tedious such a procedure is. It’s easy to imagine how exhausting the manual plucking procedure can be if several bird carcasses need to be de-feathered, which is often faced by farmers and hunters.

As you know, before plucking, the bird carcass must be scalded with boiling water and only after that all feathers and fluff must be removed with your fingers. After the first carcass plucked in this simple way, your hands get tired and productivity decreases.

The design of this device is so simple that you can think about making it yourself

For large poultry processing enterprises, whose workers have to pluck a large number of poultry carcasses every day, the issue of mechanization of this process was resolved quite a long time ago. At these enterprises, specialized feather removal machines are used for plucking poultry, but it is advisable to purchase and use such equipment for domestic purposes only if the volume of poultry carcasses processed daily is large enough.

To mechanize plucking at home, today you can purchase inexpensive plucking drums. Meanwhile, it should be noted that such devices are of low quality and are practically disposable devices for plucking.

Application area of the nozzle

Anyone who has tried to pluck a bird's feathers by hand has found that it is quite a troublesome task.

If you had to pluck two or three birds in a row, you will agree that this is quite a labor-intensive task. To begin with, the bird must be scalded with boiling water, then plucked by hand to remove fluff, feathers and newly growing feather stumps. After the second or third bird the fingers no longer obey. And if there are more than 10 pieces, this is work for a couple of days, no less. This applies to both hunters and small farms that raise chickens for sale.

Large poultry farms have resolved the issue of feather removal long ago; they use mechanisms for removing feathers on a conveyor belt, which were created relatively long ago. Small farms and hunters use special drill attachments, which are very effective in their work.

Of course, there are also special devices for plucking poultry on sale, but they are practically disposable. Therefore, the invention of such an attachment for a drill, screwdriver or lathe came in handy. Moreover, it is convenient to use it when plucking chicken or quail, as well as musky duck or goose.

Popular types of attachments for plucking poultry

Feather stumps are also plucked, regardless of the age of the bird. And this is a rather slow activity, which simply makes your fingers go numb. Imagine a bottle brush - this is a primitive prototype of an attachment. Only instead of a fishing line, rubber fingers are used, and the attachment is put on a drill.

If you take, for example, a chicken, it takes about 2 minutes to remove feathers without first scalding and with sufficient skill with the nozzle, and the carcass is practically not damaged. A large bird, such as a goose, can be plucked using a nozzle in 10 minutes.

It can also be used to process ostrich carcasses; here the processing time will be about 20 minutes. The most important thing is that steam treatment is not needed in this case.

What is needed for quality plucking?

Beginning of work.

To be effective, the procedure for plucking birds at home starts with the following:

- Place the attachment on one or another electrical appliance that contains a rotating structure.

- Fix the nozzle properly.

- Plug the device into a power outlet.

- Bring the carcass to the device.

How to pluck poultry correctly?

There is no need to perform any super complex tasks, you just need to adhere to the following rules :

- It is not recommended to pour boiling water over the carcass, as many poultry farmers are used to.

- The device should not be used on birds that are too wet.

- You should prepare containers for plucking in advance.

- The nozzle must be kept at a distance from the bird so as not to damage its skin.

In order not to harm the carcass, you must have experience working with such a device. On the Internet you can find many videos and training lessons on how to use this device. After looking at them, you can clearly understand and imagine how to properly use the plucking device.

Description of poultry plucking attachments

Why is the device called a nozzle? It’s just a working element that works when it is mounted on a drill chuck. The nozzle body is made of stainless metal, round in cross-section, and must be strictly centered. The fingers themselves, which are mounted on the body, are made of rubber, their size and number depend on the type of bird being processed. For example, for plucking the carcasses of small birds, fingers are taken measuring 5 cm; for a large goose, for example, fingers measuring 9 cm are taken.

Sizes and types of nozzles

The body is made of stainless steel and does not rust in a humid environment. It is usually made from medical grade stainless steel.

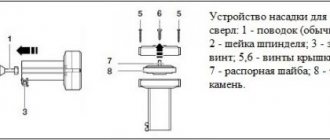

What does the nozzle consist of?

The fingers themselves do not damage the delicate skin of the bird and, at a good engine speed, clean the carcass carefully and completely.

Of course, they wear out in the process, but worn out fingers can be easily replaced by ordering a spare set from the online store or replacing, if necessary, with a different size.

To learn how to pluck correctly, all you need to do is watch a video on the Internet once on how to learn how to use a feather removal attachment on a drill for plucking poultry.

The domestic drill attachment Ruff for plucking poultry is also very popular. The Yorsh-2 modification has up to 40 fingers and a larger size of the nozzle itself - 100 mm. The rotor of the nozzle is made of polypropylene, which is very easy to clean and is approved for use in the food industry.

Nozzle Yorsh-2

Attachments from Ukrainian manufacturers have also proven themselves to be quite good, for example “Plaker”, which are made for both small and large birds, as well as “Perun”. Their body is made of food grade stainless steel.

Nozzle for processing poultry Perun 110

The only problem is that buying such an attachment for a drill for plucking poultry is quite problematic; it is ordered through an online store. When ordering any attachment, you need to make sure that it has a locking ring and a lock nut that prevents the attachment from coming off during operation. The price of the nozzle depends on the model. For example, Yorsh-2 costs 2,600 rubles, there are cheaper models for 1,200 – 1,600 rubles. Ukrainian nozzles cost around 1000 rubles. All prices do not include delivery. The cost of delivery is decided with each supplier separately.

Homemade do-it-yourself feather picker for plucking chickens, geese and ducks

Plucking carcasses is a long and unpleasant process.

To mechanize the procedure in the household, a feather removal machine was created, which can be purchased at a specialized store or made with your own hands from scrap materials.

What is a feather removal machine, how it works

The capabilities of the feather removal device are processing up to 30 carcasses in 60 minutes. The advantage is the preservation of the presentation of ducks and various birds.

Appearance of the structure:

- large capacity;

- a lot of rubber beaters on the bottom and walls of the tank (beaters are strong and elastic pins with threads located at the ends).

Operating principle of the device:

- Pouring a dead bird with boiling water.

- Throwing the carcass into the tank.

- Turning on the engine.

- Rotating a tank with a goose or other bird carcass.

- Contact of the product with the beaters (birds are thrown over the entire area of the drum).

- Feather removal process (duration: 2-3 minutes). It is necessary to periodically water the product (for faster and more thorough feather removal). In addition, water washes away unnecessary feather residues and protects carcasses from various damages.

- Taking cleaned birds from a homemade version of the device.

- Processing carcasses manually (after using the device, the plucking process takes a short amount of time).

Making a screwdriver attachment

The method is simple. It is not recommended to create fingers for the machine yourself.

Step-by-step creation of a nozzle:

- Design of the part (appearance – tin can). It is the used container that is not used (due to the thin and easily wrinkled sheet metal). For the workpiece it is necessary to use a pipe made of low-melting metal.

- Fastening the bottom part (screws are used).

- Drilling a hole in the central part.

- Securing the pin. This is done using nuts in the central part. The size of the pin is similar to the size of the drill attachment.

- Drilling a hole for the fingers (in the cylinder of the future machine).

- Inserting rubber bands into the hole made.

- Using a carcass plucking machine.

Do-it-yourself feather removal machine: making an economical option

Required parts:

- pipe blank (required diameter - 10-12 cm);

- material characterized by rigidity (for the bottom of the structure).

The initial stage is threading the pin and tightening the pipe. This is done using nuts. The final stage is equipping the structure with fingers.

Making a drum for removing feathers

To create a drum for a feather removal machine, it is necessary to have beaters.

The purpose of the parts is to remove feathers from carcasses. Making beaters at home is considered impractical. The only option is to purchase from specialized stores selling agricultural goods. You can purchase the part in online stores.

Reviews of drill attachments for plucking poultry

Judging by the reviews, the attachment really justifies itself. The most common manufacturers are China and Ukraine. There are both European and Russian manufacturers. Chinese baits are generally of very poor quality; they can only be purchased by hunters for small amounts of game. Basically, in terms of price and quality, Ukrainian and Russian nozzles are most used; European ones have excellent quality, but they are more expensive and more difficult to order.

Makita drill attachment

The service life of the metal part of the case itself is 10 years. The fingers themselves also have a good service life, and they can also be replaced. Judging by the reviews, up to 80-90 carcasses per season can withstand processing, after which some need to be replaced. Spare fingers can also be ordered through the online store. In addition, by purchasing such an attachment from a Russian or Ukrainian manufacturer, you can easily learn the plucking process using the instructions. Everything is described in sufficient detail, with drawings and photographs.

Nozzle packaging with instructions

As always, there are consumers who saved money and bought products from a Chinese manufacturer. As a rule, although there are exceptions, the desired result cannot be achieved during application and another negative review appears on the Internet that the attachments are ineffective and spoil the appearance.

Excellent reviews are written about English, French and Italian devices. This, naturally, depends on the number of birds; the device must pay for itself, although you also need to spare your hands.

Types of nozzles

The attachments may vary depending on the size of the fingers and their number. The main factor influencing this is the type of bird. For small birds, fingers are 5 cm. For large birds, fingers are 9 cm. The number of fingers can be from 12 to 24. The length of the fingers and their number can vary, depending on the manufacturer of the device. Fingers come in soft and hard types. Soft type fingers are used for poultry. Hard ones are for wild ones.

Among the feather-plucking devices, Dakmaster is especially popular among poultry farmers. The device was produced by the Krasnodar company Grand, which has been selling plucking devices for more than five years; reviews of its products are easy to find on the Internet, on various thematic resources. In set you can find:

- Aluminum alloy nozzle.

- 16 rubber fingers.

- Detailed instructions for the product.

- A box.

different to process :

- Dove - 30 seconds.

- Chicken - 60 seconds.

- Broiler - 90 seconds.

- Duck - 120 seconds.

- Goose - 150 seconds.

- Turkey - 180 seconds.

- Ostrich - 300-420 seconds.

Thus, the smaller the bird, the less time it will take to process it.

The brush attachment, which is made of medical steel, has gained particular popularity among farmers. Their popularity is due to the fact that they are very convenient, reliable and lightweight. The ruff is suitable not only for poultry, but also for fish. This versatility makes the product popular in the plucking market.

How to choose a nozzle?

The device manufacturers are Russia, Ukraine and China. It is up to the poultry farmer to decide which manufacturer to choose. First of all, you need to familiarize yourself with the characteristics of the device and its instructions. If there are no instructions or they are very brief, then it is better to refuse such a product. In addition to the instructions, close attention should be paid to the material from which the device is made and the long-term warranty . It is better to choose a device made of stainless materials. You should also pay attention to the spare parts included in the kit. Typically, rubber fingers will be replaceable.

Pros of using the nozzle

The main advantage of this device is that it saves time and effort for the poultry farmer. Another advantage is the relatively inexpensive price of the device. It can be purchased for 2000-3000 rubles and used for necessary purposes.

Disadvantages of using an attachment

If the plucking rules are not followed, the skin of the carcass can be damaged and it will lose its presentation. Another problem with this device is that it is quite difficult to acquire . The nozzle is not sold in stores; you will have to resort to the Internet and find acceptable conditions for purchasing the product.

How to use the nozzle

Additional reasons to buy one include the following: Mechanical rubber fingers remove feathers, fluff and stumps gently without damaging the bird's outer skin. One of the conditions for using this attachment: the bird should not be wet. It is advisable to use the device in a room where fluff and feathers can be collected. Also wear clothes to which the fluff does not stick too much. It is better to pluck the carcass about an hour after slaughter, when the blood has drained, but it is better not to cool too much, although it can also be used for frozen poultry.

It is still advisable to pull out the large feathers on the wings and tail of a large bird by hand so that the plucked carcass has an attractive appearance. Then it is better to treat them with steam or boiling water. Users of attachments emphasize that for the drill to work best, it must be protected from fluff getting on the working parts, which disables it.

You also need to use a drill with a speed of at least 1300 rpm, otherwise the skin of the bird will be damaged. If you fix the drill to the table, your hands will be free and processing the carcass will be even easier.

As an advantage, the attachment can be used in any place where there is electricity or you can use a drill or screwdriver with a battery, if necessary.

After treatment, it is suggested to lower the nozzle into a container with a washing and disinfectant solution and turn on the engine for 3-4 seconds. The nozzle will be cleaned and disinfected. And ready to go again.

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: +7 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru

Advantages of plucking devices

The main advantage of the products in question is the ability to quickly and easily obtain finished carcasses without feathers. Such devices do not have a negative effect on meat, so they can be used for any type of poultry.

There is no need to specifically buy a drill or screwdriver if you need to remove feathers from poultry. Any rotating mechanism, such as an electric motor, is suitable for such purposes. The disadvantage of using an electric motor is that it cannot be moved. This disadvantage is also an advantage, since during operation the plucked carcass can be held with both hands.

Stationary type of plucker with electric motor

Making a pinching device is not difficult. If such a task is set, then you need to start implementing it by ordering a certain number of nails. It is recommended to order fingers with a reserve so that during operation of the nozzle they can be replaced if necessary.