Cutting, cleaning and grinding are the three main functions of an angle grinder. The technology involves performing work while holding the tool in your hands. To reduce the load, stationary devices for various purposes are made on the basis of the grinder. They are obtained through design refinement and modernization, which significantly expands the functionality of the tool. Special devices for grinders and attachments are sold in retail chains, but most craftsmen perform them themselves. They allow the tool, which is in demand in production and at home, to be used to perform diverse operations on materials for various purposes during installation and construction work. The modified design can work as a cutting, trimming, milling, sharpening, grinding machine, wall chaser, pendulum saw, miter box, etc. To manufacture the device, you need to purchase the necessary attachments, components and fasteners from the retail chain. You can make a device with your own hands if you set such a goal and understand the intricacies of the design that you plan to create. This will expand the capabilities of the grinder, make it easier to work with the tool, reducing the load on your hands, and make the process of performing many operations more productive. On the Internet you can find a large number of drawings, photographs and videos that will help you realize your plans. It all depends on the capabilities that a person has, his thinking and flight of fancy. Let's consider the nuances of converting an angle grinder into the machines, devices and devices presented below.

Basic information

Using a conventional angle grinder is not always convenient. After all, at least you have to hold it with your hands. However, a properly selected angle grinder attachment will allow you to use the tool more conveniently and get the maximum benefit from it.

Important! The rotation speed of the grinder is 12,000 rpm. Therefore, regardless of its use, all safety measures must be observed.

The use of specially designed and created additional structures allows you to expand the functionality of the power tool. At the same time, the grinder always remains the main working mechanism, and the devices are accessories. They are available in specialty stores. Their production is even ordered from specialists.

The grinder is a non-volatile tool for installation, construction and repair work. It was originally designed to cut, grind and deburr various materials.

Reliable grinder from a Russian manufacturer Source zubr-russia.ru

Additional accessories allow the angle grinder to be used for trimming parts and performing milling work. The improved design is used for sharpening operations, creating grooves, making even cuts at the required angle and as a pendulum saw.

Important! Any well-thought-out attachment for an angle grinder allows you to increase the productivity of the work performed.

The choice of a specific additional accessory for an angle grinder depends on the area of use of the tool. The scope of its application affects the type of working disks. After all, manufacturers produce them in various designs for working with metal, concrete, and wood. Moreover, there are separate discs for grinding and polishing operations. However, they differ in grain size.

Discs for working with metal Source stroy-market63.ru

Store-bought accessories allow you to quickly improve your angle grinder. However, not every factory-made accessory has the necessary quality, which will ensure, for example, cutting accuracy. Therefore, it is not always advisable to purchase ready-made options. Sometimes the best solution is to order a so-called device from craftsmen who not only know all the intricacies of manufacturing, but have also personally tested the effectiveness of its use.

Of course, you can buy a grinder machine in a specialized store. After this, there is a possibility that it will turn out to be of poor quality and will not be able, for example, to firmly fix a power tool. Next, all that remains is to throw it away or give it to a specialist so that he can improve the device. With any of the options, a person will lose a certain amount of money.

Not all shop machines for angle grinders are of high quality Source 24aul.ru

DIY SOLE for an angle grinder with your own hands / DIY. SOLE for the Grinder with your own hands

@Your hobby is fishing and homemade crafts.

I will say, as I understand it, people come to the channel to see what you are constructing there, and you can listen to music on the music channel. Some light background is fine. Although the channel is yours, your rules! There is no desire to visit such channels a second time, this is my opinion, but good luck to you! Buy an angle grinder with a speed controller, set the speed above the average 5-6 thousand revolutions, and everything will be fine

The grinder is an incredible instrument. He'll saw off your fingers in no time! We need a handle for the eyepiece and hold it tightly with both hands! And there is a disc on wood for the Bulgarian. I also make the sole. I will do it with a connection to a vacuum cleaner.

The disk for wood, the tooth should go in from below, then it will attract the pad to the material, but on the contrary, it will pop out.

Yes, I know, thank you.

The device is certainly good. But the video shows how the Bulgarian breaks forward out of her hands. Then you need to make a cut in the other direction so that the disk rotates downwards. It's much safer. And on the box of this disc it is written very boldly what speeds this disc is designed for. And for the grinder there is a special three-pronged disc. I use it perfectly. He even hit a nail and at such speeds he did not notice the piece of iron. Well done. Good luck and like.

Thank you✊, I’ve already taken everything into account!

I made myself something similar. I have an angle grinder not only with a regulator, but also with speed stabilization, so the speed for a wood saw is all normal. But the disk should rotate in the other direction, like a manual circular saw, then it won’t break out. I will redo it)))

Well, what can you do?

@Your hobby is fishing and homemade crafts. Yes, and the button will be at the bottom..

Everything is much simpler. You just need to turn the grinder over and everything will be fine

Don’t invent bullshit, you can buy a hand-held circular saw and that’s it, but a grinder is for metal

If you put an emphasis, then you need to rotate the disk in the other direction

Great video! Even though I couldn't understand what was being said, the video gives clear instructions on how to make this useful tool !

Circular is much cheaper than life

I completely agree with you. Any tool, be it a hand tool or a power tool, is dangerous.

And so it will fly towards you. She should fly away from you if she bites

Everything is not bad here, but for some reason the music in such videos is always worthless and annoying. It’s better not to have it or somewhere quieter back in the background

@Your hobby is fishing and homemade crafts. The music always bothers someone in the videos ️

Maybe you are right about something

Grinder and wood are incompatible things. Suicide device.

In this option, the cut turns out smoother than if you saw with an electric jigsaw.

@Your hobby is fishing and homemade crafts. Isn’t it easier to cut with an electric jigsaw at home?

This is essentially the same circular hand saw, only in a smaller form.

It’s a good device, I just made it too, it’s convenient to saw and the grinder doesn’t jump and it’s even.

Salom where to buy a homemade metal cutter from a grinder

ali.pub/568iav you can buy

Interesting. I'll take it into service.

@Your hobby is fishing and homemade crafts. Agreed!

First of all, remove the saw blade - it is not designed for such speeds! There are special saw blades for grinders - two or three teeth, with carbide tipping! Secondly, your grinder is attached to a plastic body - if there is an impact, it can crack, spin, jump off the slot and, at best, jam the disc! But there are wonderful threaded holes on the body! Third - thexvid.com/video/9E42eiIJE2I/video.html pay attention to the shape of the handle. With such a handle, the grinder is fixed in your hand much more reliably! Good luck with your experiments! And trouble-free operation!

Cutting machine

To conveniently, quickly and efficiently cut various steel parts, rolled products, etc., use a grinder attachment for cutting metal. This additional design to the angle grinder will allow you to perform precise cutting. With its help, it will be possible to prepare the necessary workpieces of the same size, make the required cuts, which will have the required depth. When you install a disc for concrete or wood on a grinder, it will be possible to cut ceramic tiles or lumber.

Specialized retail chains offer ready-made machines. However, they cannot be purchased at a low price. Such a device can be made by an experienced craftsman from an angle grinder with a power of at least 0.9 kW. In this case, the costs will be less than purchasing a high-quality machine in a store. A custom-made jig will allow you to make precise cuts. They will be no worse than a high-quality factory model.

Professionally manufactured machine for angle grinders Source pinimg.com

Before manufacturing a cutting machine, its design must be carefully thought out. It should ensure reliable fastening of the angle grinder. To do this, first determine the dimensions of the machine, and to fix the angle grinder, think through the location of the fasteners. Usually the tool is clamped in 2 or even 3 places. It must be securely fixed to prevent its slightest displacement during cutting operations.

The angle grinder is secured on top of the worktop of a special table. It is also possible for the tool to be fixed from below. In this case, it will be possible to use a grinder attachment for an even cut not only of metal products, but also of lumber.

Machine for cutting wooden blanks Source texnotoys.ru

Important! Using a stationary machine is a safer way to cut various materials than carrying out operations when the angle grinder is held by hand.

Builders, finishers and other craftsmen use a simple or complex device for cutting metal with a grinder. The first version of the machine is an angle grinder attached to a workbench. This minimalist design implies the additional use of only fixing elements.

The second option is a machine of a more complex design. It is made to order or purchased ready-made if you plan to carry out large-scale work. Often the design includes a guide for an angle grinder for cutting sheet metal. It is also used when working with other materials. Thanks to this element, precise cuts of various workpieces and parts are made.

Machine of complex design Source ad-cd.net

On a note! When manufacturing a machine, it is important to contact a specialist who will use a welding machine, high-quality fasteners, and reliable rolled metal to create individual parts and assemble devices from them.

See also: Catalog of construction companies that have their own production of materials and components for the construction of houses

Pendulum saw

This version of the so-called angle grinder accessory allows for high-speed cutting of various materials at the desired angle. This device is called a pendulum saw. A tool with a power of 0.9-2.5 kW is usually fixed in its frame. In this case, the dimensions and other design features of the pendulum saw depend solely on the model of angle grinder used.

This option is the perfect attachment for an angle grinder for cutting at 45 and 90 degree angles. After all, the instrument will be fixed motionless. This will allow you to make precise cuts at the required angle.

Pendulum saw from a grinder Source ad-cd.net

The pendulum saw has a not very complex design. It includes a metal platform. It has a slot that allows the angle grinder disc to go deeper. A metal corner is fixed on the platform. The workpiece to be cut is pressed against it. To securely fasten it, another element is used, which has a thread that allows you to clamp the part with the necessary force.

The design also includes the pendulum hinge itself. It is fixed on a stationary frame. The tool is fastened by using holes that are designed for installing a handle on an angle grinder. The angle grinder is fixed in a special bracket and using additional pins and bearings. The parts allow you to secure the power tool in the desired working position.

Such a device for an angle grinder for cutting metal is usually placed on a table, which can be made of wooden or steel parts. It is important that it is a stable and durable structure. Some craftsmen even use a workbench as the basis for an angle grinder attachment.

A pendulum saw made from an angle grinder is placed on a stable base Source ad-cd.net

On a note! The cutting element of the pendulum saw must fit exactly into the slot of the platform or pass as close as possible to the end of the workbench or table if the angle grinder is mounted on a hinge directly near the edge of the supporting structure.

The mount for an angle grinder can also take the form of clamps. They are fixed on a pendulum handle. The clamps, which are tightened with bolts, are designed to attract the body of the angle grinder.

If the fastening is in the form of a rigid connection through the use of holes in the angle grinder, then it becomes possible to accurately position the power tool in space. You can even order a craftsman to make a device that will additionally include a protractor. It will allow you to make the most accurate cuts of various workpieces at the required angle. In this case, the protractor can be placed on the support platform or directly on the pendulum.

Variant of a pendulum saw from an angle grinder Source ad-cd.net

Lawn mower (trimmer)

Taking care of the area with the help of an angle grinder is not a utopia, but a completely useful life hack. Especially if you have an old angle grinder at hand, which you don’t really feel sorry for. The Kulibins take different paths. Some build quite serious devices on two to four wheels, obtaining a stable and fairly productive lawn mower.

Sometimes modern cordless tools are even used as a drive for equipment. And sometimes everything is limited to creating a compact and maneuverable trimmer with one wheel or without one at all. In order not to overload a tired grinder and for safety reasons, metal knives are usually not used here. A fishing line is used, which is attached directly to the nut. You can also secure the line to a plastic sanding disc.

Milling machine

It is often necessary to process flat and shaped surfaces of various workpieces. For this purpose, special cutters are used. They are part of the machine of the same name. Such a device for an angle grinder can have one of the following designs:

- An angle grinder is rigidly mounted vertically on a moving element of the machine, which allows the tool to move relative to the workpiece being processed.

- The angle grinder is fixed motionless in the device. Therefore, during milling, only the workpiece being processed moves, and the tool remains in place.

Any of the options requires a reliable frame. If the device is made to order, then the design will usually be suggested by a specialist, based on his experience and knowledge.

Of course, the customer can provide drawings that were developed by another specialist or simply downloaded from the Internet. In any case, the master will prepare all the necessary materials for the manufacture of a milling machine. You will also need to purchase a cutter holder. This is a collet device. At the same time, some craftsmen are able to make it from a hexagon.

Option for a milling machine made from an angle grinder Source pic.rutube.ru

Trimming tool on stand

Mobility is one of the most valuable qualities of an angle grinder. But sometimes you need to make some preparations - that is, you can use a workbench while in a comfortable stationary position. In such cases, an excellent option would be to fix the angle grinder in a “rack”.

There are a lot of constructive solutions. For example, in addition to traditional pendulum ones, there are vertical configurations. The most interesting homemade products are equipped with return springs, a massive dimensional plate, adjustment of cutting angles, and a reliable multi-position clamp for the workpiece.

In this case, the tool becomes much more stable, which has a positive effect on the speed of work, as well as on the cutting accuracy. This “trimming” will be safer.

Machine for ceramic granite

Only an experienced craftsman can cut porcelain tiles efficiently with a grinder held in the hands. After all, the material has a special structure that is highly durable. Therefore, it takes effort to cut it. At the same time, you also need to hold the tool level. Otherwise, you will get a crooked cut, which in most cases is not required.

A special cutting machine made from an angle grinder will allow you to perform straight movements with a power tool. Thanks to the device, it will also be possible to control the depth of the cut. Accurate execution of all movements will minimize damage to ceramic granite. Thanks to the smooth movement, fragments will not break off from the material and other defects will not appear on its front surface. This will reduce the number of defects when performing work. Therefore, it will be possible to reduce overall costs.

Factory machine for angle grinders for cutting tiles Source i-tiler.ru

One of the main parts of a machine for cutting ceramic granite is the guide element. Thanks to its presence, the power tool will always move clearly along a given line. Many craftsmen offer to quickly make such a machine using blocks and plywood. All these materials are easy to process. Therefore, manufacturing the device takes a minimum of time.

Protractor for angle grinder

A convenient option is when the machine for cutting metal from an angle grinder is additionally equipped with a protractor. This device allows you to make the most accurate cuts if a person is working, for example, with a metal profile. Thanks to the protractor, the required cutting inclination is set. High precision must also be observed when working with various finishing materials, including porcelain stoneware and other tiles.

Factory protractor for an angle grinder machine Source ebayimg.com

The design of conventional transport consists of a corner. This element is a guide part. It is better if it has a pad that prevents movement and scratches on the surface of the part being fixed. The design also includes hinges and a fixing bolt.

To use a protractor, you must first press the workpiece firmly. Only after this is the desired angle adjusted. At the last stage, the workpiece itself is cut directly using a power tool.

Types of devices

Adaptations for grinders exist with a wide variety of functions:

- for smooth cutting;

- for grinding;

- for cutting rods and pipes with a diameter of 50 to 125 mm;

- for stripping old layers from surfaces;

- for cleaning and grinding;

- for polishing;

- chain saw for cutting wood;

- for collecting and removing dust during work.

These devices are also called accessories. They are often purchased separately from the main unit. Some of them can be made independently from available material or old equipment.

Grinding machine

One of the adaptation options is a grinding machine, which will function due to the work of the grinder. The most complex type is the tape device. This design uses two or even three rollers. One of them is driven by an angle grinder. Therefore, it connects with the power tool.

The rollers are designed to accommodate the belt sanding element. They are housed in a housing, which can have different shapes. If the machine is made to order, then the master will select and make the best option, which will allow you to conveniently grind specific parts.

The machine body is mounted on the table. The grinder is also necessarily rigidly connected to the entire system, subject to all safety measures. There are also lightweight options for manual use.

A device for grinding from an angle grinder Source ytimg.com

Another version of the grinding machine allows you to fix the grinder more often in a vertical position. The fastening is carried out to the metal supporting elements of the device. Most often they are made of metal corner. The actual fastening of the tool to them is carried out with bolts into the holes that were originally intended for the handle.

Important! The support structure for the angle grinder must be stable and rigidly connected, for example, to a table.

The grinding process itself is carried out with a special wheel, which is fixed on the angle grinder. Its grain size is selected for a specific process depending on the properties of the material being ground.

Sandpaper is usually used as an abrasive surface. Instead, craftsmen also often use a felt circle in their work. It all depends on the specifics of the work being performed.

On a note! Before attaching the angle grinder, it is necessary to remove the handle and protective casing from the power tool.

How to make a homemade dust collector

The simplest dust collector for an angle grinder can be made from a plastic bottle of motor oil.

The nozzle is made as follows.

- Attach a disk of the diameter that will be used for cutting to the container and make a mark: place the disk so that its edges do not cling to the casing, and mark src=»https://tehnika.expert/wp-content/uploads/2017/ 11/image083.png" class="aligncenter" width="600″ height="429″[/img]

- Cut a square hole in the side of the bottle using a utility knife.

- You should also cut 2 holes opposite each other, in the place where you marked src=”https://tehnika.expert/wp-content/uploads/2017/11/image087.png” class=”aligncenter” width=”600″ height=”428″[/img]

- Screw the dust collector to the angle grinder using the standard holes for attaching the casing, and put the hose from the vacuum cleaner onto the neck of the bottle.

- Place a cutting disc on the angle grinder shaft.

- The hole, which is used for convenience when changing tools, can be closed with a small piece of plastic.

After these simple steps, you can use the grinder to process materials that create a lot of dust when cutting.

Miter box for grinder

Another useful device is a miter box. It allows you to quickly and accurately cut various workpieces at the required angle. This device will definitely come in handy when laying tiles, installing baseboards and many other finishing materials.

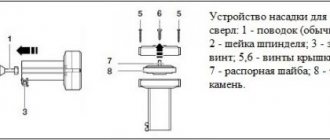

Often a miter box is used together with a special frame, which is a mount for an angle grinder for cutting at an angle of 45 and 90 degrees. This combination allows you to prepare blanks for assembling various frames. The miter box itself consists of a disk, which is placed under the angle grinder. It is usually put on a metal axle, which allows it to be rotated in any direction.

The disc has a slot. Thanks to the rotating design, it can be installed at any desired angle relative to the cutting element of the power tool. The slot is a guide. In accordance with its directions, the cut will be performed.

Important! The workpiece being cut must always be held motionless. The cutting angle on it is set in accordance with the slot on the disk.

Wall chaser from an angle grinder

This is another useful device that expands the scope of use of an angle grinder. After all, grooves are always made when building a house with stone walls. They are also created during major renovations.

Important! An angle grinder with a minimum power of 1200 W is suitable for use as a wall chaser. When installing discs for cutting concrete with a power tool, it will be possible to make furrows of the required width in the walls, ceiling and floor.

Each groove is created by cutting two parallel recesses in the building structures of the house. Therefore, a feature of the device is the installation of two working disk elements at once. They must have the same diameter. After all, the slots in concrete or brick must have equal depth.

On a note! Grooves are used for laying electrical cables and even pipes with a small diameter.

Grooves with already laid cables Source staffmasters.ru

To install two cutting disks on one shaft at once, specially made gaskets are used. They allow you to secure the working elements at the required distance from each other. Bushings are also used. They fit on the shaft, so they have the appropriate diameter. These elements also allow the installation of discs with a large bore diameter. In this case, they must have a suitable external cross-sectional size.

Additionally, a casing of a different design is installed on the grinder. It allows you to close two cutting discs at once. After all, the standard casing has inappropriate dimensions.

Often the protective element additionally has a pipe through which dust generated during gating is removed. A powerful construction vacuum cleaner is usually connected to it.

In addition, a wall chaser for an angle grinder may have roller mechanisms. Their presence allows you to reduce the load on your hands. After all, the tool has to be constantly moved across the surface.

On a note! The advanced design is equipped with an adjustment unit. With its help it is possible to change the cutting depth of the discs.

Factory-made device for an angle grinder Source imperia.md

All work with power tools is carried out in strict compliance with safety rules. Otherwise, harm to health is caused. In all honesty, electric shock may occur. In addition, dust harms the respiratory system, and sharp cutting elements can seriously injure a person.

Important! In addition to respiratory and eye protection, before starting work you need to check the operation of the electric tool at idle speed and the integrity of the electrical cable. It is also necessary to use working disks that are free of defects in the form of chips and cracks.

Manufacturers

The most common and popular attachments are cutting discs. Bosch also produces good wheels for metal. The best diamond bits are produced by Hitachi (Japan) - such discs are universal and can successfully cut any material.

Sanding attachments from DeWalt from America are highly valued. They differ in the material from which they are made; they can be: sponge, fabric, felt.

To work with stone and metal, special abrasive attachments are used. The highest quality specialists are considered to be products from DWT (Switzerland) and Interskol (Russia). The products of the latter company stand out due to their combination of price and quality. The above companies also produce good grinding discs that are coated with diamond.

In addition, DWT produces high-quality angle grinder attachments called cutters. They are used to remove old paint, cement, and primer.

It produces a variety of turbine nozzles of very good quality. Prices for nozzles from this appeared on the market relatively recently, but it has already gained a good reputation and authority.

from China (Bort) also makes good attachments for grinders. As you know, products from Chinese manufacturers are traditionally low in price.

Briefly about the main thing

The grinder is already called a universal electric tool due to the ability to use it together with various devices. They are the ones who expand the scope of application of angle grinders.

The devices are available in retail chains in factory-made versions or their production is ordered from craftsmen. Bolkarka can serve as the basis for a cutting, grinding, milling machine. An angle grinder is used in the same way as a pendulum saw or wall chaser. An angle grinder even allows you to cut porcelain tiles evenly and quickly.

For an angle grinder, a protractor or miter box is purchased in ready-made wine or made to order. They allow you to cut workpieces at the desired angle. Cutting machines for angle grinders often have guides in their design.

Ratings 0