Forging chisel PICARD. Photo ForgingPRO

A chisel (a cleaver with a handle) is one of the oldest tools for processing cold or hot metal . Scientific and technological progress has made very minor improvements to this tool, offering high-strength materials for use and formalizing the sharpening angles of the blade. However, the appearance and methods of working with a chisel have not changed for many centuries. This article provides complete information about blacksmith tools for chopping metal, types, the possibility of making it yourself or purchasing a factory-made cleaver.

Bench chisels

The blade and head of a bench chisel are hardened and tempered . The length is usually 10-20 cm, and the width of the blade is 5-5.2 mm. The sharpening angle of the blade depends on the metal for which this chisel will be used - the harder or more brittle the metal, the more obtuse the sharpening angle should be. Standard sharpening angles for cutting various metals are as follows:

- hard steel, bronze, cast iron – 70 degrees;

- medium hard steel – 60 degrees;

- copper, brass – 45 degrees;

- zinc, aluminum alloys – 35 degrees.

The tool is also widely used for more specialized tasks, such as cutting grooves and narrow grooves. This instrument is called a crossmeisel .

Material

In the manufacture of metal chisels, different grades of carbon tool steel are used:

- 9ХС;

- U8A;

- U8;

- U7A;

- U7.

If the working part is equipped with carbide steel plates, it is made of structural steel grade 45 or 40X.

Surfaces must be covered with a protective decorative coating. According to GOST 9.306, 9.032, it can be of several types:

- Chrome plating with nickel sublayer (13 microns).

- Oxide with oiling (9 microns).

- Standard chrome (9 microns).

- Phosphate with oiling (9 microns).

- Galvanized with chromating (15 microns).

- Phosphate, which will be coated with paint (15 microns).

- Cadmium with chromation (21 microns).

If we talk about the hardness of steel, for grades such as 8ХФ, 7ХФ the optimal value will be from 56 to 60 HRC, and for grades 8ХВ, У7А - from 54 to 58 HRC.

Processing a blank for a chisel (Photo: pixabay.com)

Blacksmith chisels

The main design difference between a blacksmith's chisel and a mechanic's chisel is the hole in its middle part for mounting on a wooden handle. The cutting part of a forging chisel is called a knife, its length is from 30 to 50 mm. The length of the entire tool for cutting cold metal is 16-19 cm, for cutting hot metal – 18-24 cm.

Cold cutting forge chisel

Recommendations for selection

If you go to any specialized store, you will find a wide selection of attachments such as chisels for a rotary hammer. Because of this, beginners may have some difficulties with their choice.

This is an important undertaking, on which the ability not only to select a high-quality attachment, but also to effectively complete the task assigned to the chisel largely depends.

The choice of hammer chisel is influenced by various factors:

- type of work;

- make and model of hammer drill;

- type of shank and chuck;

- working surface dimensions;

- diameter;

- processed material;

- weight;

- design structure for processing.

The most popular and widespread is the SDS-Plus type chisel with a 10 mm shank diameter. There are also SDS-Max models, where the shank has a larger diameter. They are already aimed at the professional category of rotary hammers.

When choosing a chisel attachment, take into account the types of work to be done:

- peaks are suitable for removing old coatings, and are also useful for cutting channels and forming recesses in concrete;

- channel chisels are relevant in cases where it is necessary to make fairly even channels;

- shovels will become indispensable to remove tiles or old layers of plaster;

- Round and curved attachments are useful for wall chasers because they do a better job than a regular wall chaser.

Chisels differ from each other not only in appearance and shape, but also in the range of length and diameter.

To make the hole made more even and neat, it is recommended to choose nozzles that have a centering spike.

First, the spike enters exactly along the markings, and then the main cutting part does its part of the job.

What types are there: intrinsically safe with a wooden handle and others, photo

There are several types of blacksmith chisels:

- Non-sparking tools are designed for use in potentially explosive areas. The head of such chisels is made of bronze alloys, which ensures antimagnetic properties and a high level of corrosion resistance, and the handle is made of wood.

Blacksmith chisel. Photo ForgingPRO

- Chisels with a thin blade are designed for chopping hot metal, while those with a thicker blade are designed for separating cold workpieces.

- The shape of the working part can be straight or round.

Device and characteristics

A chisel is a metalworking tool that is used for chopping and creating recesses in hard materials. It is a steel rod, one of which is blunt, the other is sharpened at two edges. On the blunt side (butt), the master strikes with a hammer.

There are two types of chisels available for sale. Some are designed for manual work, others are installed in special equipment.

Material

When choosing a chisel, special attention is paid to the material from which it is made. The alloy must be shock-resistant and not crumble from physical impact. There are two options for manufacturing the working parts of the tool:

- Tool steels.

- Carbide plates made of structural steels.

Sharpening chisels, angle

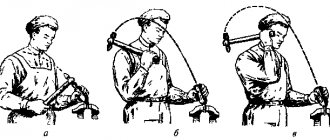

Sharpening is performed on a special sharpening machine. The chisel is placed on the tool rest and, pressing slightly, slowly moved along the entire width of the rotating abrasive wheel, alternately sharpening one or the other edge. In this case, the blade should be often immersed in cold water to prevent overheating of the metal, during which it loses the necessary hardness.

After sharpening is completed on the grinding wheel, the burrs are removed from the chisel, and then the cutting edge is threaded on the abrasive wheel.

Hot forging chisel with a sharpening angle of 70-80 degrees

The sharpening angle of the chisel knife for hot cutting is no more than 50 degrees, and for cold cutting - at least 60 degrees.

Important! The wooden handle on which the forging chisels are mounted is not wedged (to avoid kickback and breakage).

Finally, the correct sharpening angles of the blade are checked with a special template . As such a template, a metal block is used, in which grooves are cut. The angles in these grooves have the required values, therefore, by inserting a sharpened chisel blade into this groove, you can visually determine the correct sharpening.

Varieties

This attachment, like a chisel, designed for a hammer drill, is offered in several versions.

They differ from each other in shape. In total there are 4 varieties.

- Flat. Externally, such attachments look like screwdrivers, but with a pointed tip. The most common type of hammer drill chisel. It is a pioneer in this field. Already on the basis of a flat chisel, all other varieties appeared. The cutting edge has a length less or slightly greater than the width of the body of the product. Sizes generally range from 10 to 40 mm. But sometimes you can find tools where the edge length is greater than the specified values. The longer the length, the less force you need to apply when chiseling.

- Spike-shaped. They differ in cone shape. They also resemble a pointed pyramid. They are used to make holes in concrete and brick foundations when there is no suitable crown. After processing, the edges of the hole remain torn. Therefore, such a chisel cannot be considered a full replacement for a crown.

- Shoulder blades. The shape of the chisel resembles a spatula. Resembles the flat variety. But here the cutting edge is thinner and wider. Used to remove old coating in the form of tiles or plaster layers. To make it more convenient to work with a spatula, the shape is made slightly curved. Thus, the spatula lifts the layer and removes it easily. That's why such attachments are usually called tile chisels. There are also chisel blades that look like an ordinary shovel used in the garden.

- Semicircular. This is a special form of chisel for a rotary hammer. Like the spade attachments, they also have a slightly curved shape. This is a channel chisel designed for a rotary hammer. They need to be used to perform certain tasks. We have developed products for making channels for wiring. In fact, this is a substitute for a wall chaser. To make the tool work more efficiently and conveniently, wings were provided along the body of the nozzle. When the chiselling process begins, these wings support the chisel on the wall, which allows you to adjust the depth of the grooves made in the material.

So the hammer chisel must be selected based on the tool used, as well as the type of work that the device will perform.

Requirements

The main requirement for a blacksmith chisel is its serviceability . Safety of using the tool includes several characteristics that the chisel and its individual parts must have:

- The strikers must have a smooth surface , without chips, cracks, burrs, or deformation.

- The handle, necessarily made of hardwood or synthetic materials, must have an oval shape with a thickening towards the free end and a smooth surface, without cracks. Metal handles are also used, which also do not fit tightly, and rope handles.

- The length of the chisel should not be less than 150 mm.

- When working with a chisel, individual parts of the metal may fly off to the sides, so it is necessary to wear safety glasses.

Open-end wrenches

Traditional open-end wrenches are becoming hopelessly outdated, and it is not always convenient to store or carry a complete set with you. In addition, some key numbers are almost never used.

Every craftsman or motorist had such sets. PHOTO:

An excellent alternative are adjustable wrenches or “toads”, which are used by plumbers. Instead of a full set of approximately 10-12 units, no more than 4 keys with different size ranges are enough.

With this wrench you can unscrew a nut of any size PHOTO:

Malfunctions

Among the most common breakdowns of a forging chisel are:

- break;

- dullness;

- the appearance of notches;

- deformation, curvature of the striker;

- cold hardening on the striker, which is fraught with chips and flying fragments.

Chisel striker broken

Malfunctions arise in the event of incorrect cutting, during prolonged use of the tool, or in the presence of manufacturing defects. Periodically (at least once a quarter) it is necessary to inspect the chisel for any damage to the striker or handle. Faulty tools that have defects must be removed from service.

Tools for hot metal forging

Blacksmith hammer-smoother. Photo ForgingPRO

Each master creates a set of necessary equipment independently, depending on the level of skills and assigned tasks. The blacksmith's kit includes a different list of tools: basic and auxiliary:

- hammer, sledgehammer and anvil;

- pliers (tongs);

- nail shop;

- manual and lining forks;

- vice.

Using the listed tools, various operations for processing metal workpieces are performed: chopping, bending, giving the desired shape through deformation.

Hand tools for artistic forging have a simple design, so they are easy to make with your own hands.

We mechanize manual labor

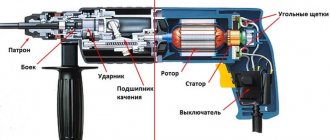

A real locksmith knows that working with a chisel is quite exhausting and hard work. What are the hammer blows alone worth when chopping metal, and how many blows does the master give... And you can’t count them! But with the advent of the hammer drill, it was possible to mechanize manual labor, due to the fact that the hammer drill has in its arsenal a striking device, no worse than a conventional hammer. This is how a special attachment for an electric jackhammer appeared, and it was called that - a chisel for a rotary hammer. This device greatly facilitated the work of not only the mechanic, but also the builder.

Now you don’t need to constantly swing the hammer and strike, just insert the attachment and press the button, and carry out the specified work only by directing the working part of the tool in the desired direction. Afterwards, a huge number of different attachments for hammer drills appeared, their main task is to chop and chip hard materials. For example, after a welder’s work, there may be a need to remove unnecessary tacks; of course, a hammer and chisel can easily handle this, but the mechanized method significantly saves time and effort.

There is a very convenient device for working with stone; craftsmen simply call it a “wall chaser.” The design of such a device is a working area in the form of a curved blade. If when installing a groove with a regular chisel we get an uneven groove, plus concrete fragments fly in different directions, then using a “wall chaser” we will get a high-quality, even recess for laying electrical wiring or other communications.

Of course, the mechanized method has one small drawback, namely: sound accompaniment of the work being carried out. If we periodically deliver dull blows with a hand tool, then a hammer drill does everything with precision, but vice versa. It produces a strong and loud noise, especially if metal processing is carried out, so in such cases it is better to use ear protection.

Where to buy or order, manufacturers (manufacturers) and suppliers

Not all craftsmen have the necessary skills to make their own chisels. In such cases, it is recommended that you familiarize yourself with the list of manufacturers and suppliers of this tool, which are collected in a separate section. Companies offer a wide range of tools: pliers, hammers, nails, etc.

Sections: Tools

Tags: Forging - basics

Previous article: Mini forge - how to organize a workplace Next article: Decorating forging

Manufacturing nuances

The main materials for the manufacture of hammer drill chisels are forged and hardened steel. The raw materials are characterized by increased strength and long service life.

In the production shops, the workpieces undergo a hardening procedure. The temperature can vary over a wide range, but is at least 800 degrees Celsius. It is important that the metal is heated evenly, affecting the entire working surface. Therefore, special high-temperature furnaces are used for production.

The best solution is considered to be uniform heating of the workpiece, followed by holding it in the oven for 30 minutes, rather than rapid heating 10 minutes to the maximum temperature, followed by sharp cooling.

When the metal has warmed up, it is placed in oil or water. This allows you to gradually cool the steel and thereby harden it, giving additional strength and resistance to stress. When cooling, the chisel is gradually rotated at low speed in a water or oil environment.

To create a chisel of increased strength based on a mixture of iron and carbon, a special technology is used. The metal is heated, then slowly cooled to 650 degrees Celsius, after which it is cooled sharply from 650 to 400 degrees. Touching the liquid coolant, the hot metal causes boiling processes. Steam is generated which envelops the workpiece. That is, there is no direct contact between the metal and the liquid. This effect in the form of a vapor film around the product is called a steam jacket. This helps the steel cool slowly.

Using this technology, the working surface is hardened, that is, the dynamic center is not affected. The shank is similarly hardened to give it the necessary strength.

Although many people believe that water and oil cooling have the same efficiency, there are still differences between them. This must be taken into account during production.

The difference between oil and water is that in the first case cooling occurs more slowly. This minimizes the likelihood of internal stress occurring in the metal. The oil is recommended for use in the manufacture of nozzles made of alloy and high-carbon steel. And water is for low-carbon raw materials.

The result is a balanced and highly durable tool that can be used to perform various types of work. It is enough just to install and secure it in the hammer drill chuck.