It is known about the hammer drill that it is a highly specialized tool that is designed to perform percussion work. To do this, a corresponding nozzle is attached to the tool chuck, which has a special shape of the tail section. If you need to use the impact tool in question, but there is no drill in the package, then only an adapter for a hammer drill for a drill, into which you can install any type of cylindrical attachments, will save you. More details about the design of this device are described in the material.

Device for securing a drill in a hammer drill

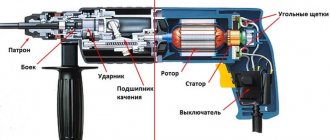

There is no better tool for drilling concrete and reinforced concrete than a hammer drill. The tool differs from the drill not only visually, but also in the design of the chuck mechanisms. If the drill design uses chucks with a collet mechanism, then rotary hammers use special devices of the SDS design. The installation of working attachments is carried out using a special clamp, which is presented in the form of slots for centering and balls for fastening. This is done so that the nozzles in the cartridge of the impact devices have some play. This play is needed so that the drill and other types of attachments make reciprocating movements when drilling concrete materials.

Often there is a need not only to drill concrete, but also to drill holes in wood, metal and other materials. For such purposes, you can use a hammer drill, but only in drilling mode. In addition, you must insert an attachment into the tool chuck - a drill for metal or wood. It is irrational to buy such drills for a hammer drill, especially if drills of the required diameter are available for a drill. To combine the tool with a regular drill bit, you will need to buy an adapter. This device is also called an adapter for a hammer drill, which is popular.

This is interesting! Having a special adapter, you can drill holes in durable materials with ordinary drill bits for concrete. This will allow you to save on the purchase of drills, which, unlike concrete drills for a drill, are somewhat more expensive.

While a drill with a special shank design can be installed in the collet chuck of a drill, it is impossible to secure a cylindrical drill in a hammer drill without a special device (connector). However, it is not recommended to use drills and other types of attachments in the chuck of a drill or screwdriver, since the collet mechanism does not allow the attachment to be centered. As a result, it turns out that when working with a drill with a drill from a hammer drill, the load on the tool increases due to the low straightness of the nozzle.

So, knowing why you need to insert drills with cylindrical shanks into powerful power tools, let’s figure out what the device for such attachments is.

How to insert a drill

To install the drill in the chuck, lightly press on the casing: the spring will compress and the slots in the shank will fit into the slots.

When the casing is released, the spring moves the ring, the locking balls enter the closed slot of the tail section. In the case of quick-release chucks, you can insert drills into hammer drills without any difficulty. But a screwdriver attachment or ordinary drill bits for drills cannot be installed in fasteners of this type.

To use a tool with smooth round shanks, you need to purchase an additional element - a collet chuck with a special holder with grooves.

The element is placed on a hammer drill, after which it is possible to use conventional drills.

What kind of hammer drill do you use? Is it possible to use a regular drill with a round shank in your model? Please share your experience in the comments.

How a regular drill is inserted into a chuck

If there is a need to make a hole in metal or wood, but the drill is not working, then there is a way out - take a tool, a drill and an adapter. Of course, many will think that it is easier to buy the appropriate SDS metal drill for a hammer drill, but that was not the case. Even if you manage to find such a drill of the appropriate diameter, it will cost at least 1.5 times more than a regular drill.

This is interesting!

Manufacturers produce sds plus , which are designed for drilling metal and wooden structures.

However, due to the special design of the shank, the cost of such devices differs from the price of drills with ordinary cylindrical shanks. As a result, it turns out that it is much more profitable to buy an adapter for a hammer drill for a drill, and use a nozzle of the appropriate diameter, than to buy a drill with a special shank shape. Many people don’t even know what an adapter or adapter for a drill to a hammer drill is, so let’s look at the design of the device.

Structurally, the adapter consists of two parts:

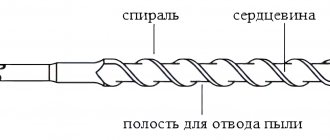

- The shank is the part that is inserted into the chuck of the unit. The tail part has a similar design as drills and other sds plus type attachments

- Threaded part - a collet chuck from a drill and screwdriver is screwed onto it. At the end of such an adapter there is a screwdriver bolt for fixing the devices. When choosing adapters, you need to take into account the size of the thread onto which the chuck from the drill and screwdriver is screwed.

The thread on the tip of the adapter is not right-handed, but left-handed, that is, in order to secure the cartridge to the adapter, you will need to rotate it to the left. The chuck from the drill is installed on the adapter for the hammer drill, and after that all that remains is to insert the corresponding drill into it and use it on the hammer drill.

This is interesting!

If you plan to install a concrete drill into the collet chuck structure and work with it in a hammer drill, then it is not recommended to do this for a long time.

The impact actions performed by the unit mechanism are quite strong, so collet keys and quick-release chucks can quickly fail. The adapters are made of tool steel, so they can withstand heavy loads. The cost of such an adapter does not exceed 150-200 rubles, while for that amount you can buy only one attachment. An adapter for a hammer drill is a universal device that significantly expands the capabilities of the tool. Moreover, in a collet chuck from a drill, which is fixed in the power tool chuck through an adapter, you can fix not only drills, but also crowns, mixer attachments for mixing mixtures, as well as polishing and other types of working attachments.

Double clutch chuck

Compared to a key jaw chuck, this device does not have teeth or a stop. The rings are quite smooth. In this regard, a removable holder is well suited for removing equipment. Modern drills are increasingly equipped with the appropriate device. That is, the holder is included. Plus, arm yourself with a hammer up to 1 kg.

If the attachment is stuck and firmly held in the hammer drill, which makes it impossible to remove it in the usual way, try the following:

- using the holder, grasp the upper coupling, which is located closer to the drill, and clamp tightly;

- grab the drill itself using your own hands, feet, or a vice or clamps;

- strike the holder handle with force in the direction in which you want the clutch to unwind.

Usually one solid blow is enough to move the ring. After this, the drill is removed from the hammer drill without any problems.

The effect of this method will be even greater if you first add a little grease or oil into the gap between the cams or under the clutch.

This makes it easier to glide. Due to this, the clutch unwinds more easily.

Why is it better to drill metal with a hammer drill?

Not only drilling concrete, but also drilling metal or wood is best done with a powerful power tool, which is a hammer drill. This tool copes with any complex tasks, which is associated with the use of more powerful electric motors. Power ratings range from 700 W and above, while drills use electric motors with a power of 300 W or more.

In addition, the unit has great torque, so there are no difficulties with mixing dry mixtures. If you have a hammer drill, then you don’t need to buy a specially low-speed drill or mixer, because this power tool will cope with the task of mixing the solution.

The reasons why it is better to choose a rotary hammer for drilling than a drill are as follows:

- Greater power, which will allow you to achieve positive results faster than using drills

- Great torque force - this indicator is very important when using power tools for mixing dry mixtures and drilling wood with a large diameter drill

- High rotation speed - for this purpose, special regulators are used in the design of straight or pistol units. When the chuck rotation speed decreases, the torque increases, and when it decreases, on the contrary, the torque decreases, but at the same time the number of revolutions of rotation of the actuator increases

Now that you know why it is necessary to buy and use drill adapters for hammer drills, you should immediately order them or purchase them at your nearest tool store.

This is interesting!

Manufacturers also produce special collet chucks for rotary hammers, however, this option is irrational to purchase, since the time for replacing devices takes at least 15 minutes, while installing the adapter is done in a matter of seconds.

Drill or auger stuck in surface

It also happens that during the drilling process the nozzle breaks off and a fragment remains inside the wall, ceiling or floor, or gets stuck entirely, falling out of the chuck.

In this case, you can apply several different solutions.

- Reverse mode. The simplest situation is when the nozzle remains clamped in the socket, does not break, but does not want to come out of the wall. Turn on the reverse mode and begin to gradually pull the hammer drill back.

- Metal chain. This is relevant if part of the drill or auger was outside and you were drilling the ceiling. In this case, you can wrap a chain around the shank, tie on a heavy weight, and let gravity do the work. Just don't stand under the weights so they don't fall on your head.

- Vise. Using a portable vice, you can clamp the protruding part of the drill, and then use a lever to start swinging and turning the attachment. The help of a partner will not hurt here.

- Impact mode. You need to turn off the rotation and leave only the impact mode. At the same time, the hammer drill should be pulled in different directions. This will break up the concrete around the area where the bit is stuck. The drill will then come out easily.

- Gas key. You need to screw the nozzle onto it, and then turn it in the opposite direction with the key. Due to the long lever, you don’t have to put in much effort.

- Additional holes. If there is nothing to grab onto, you should try to drill or gouge the wall from above, below or on the sides of the stuck drill or auger. Although you end up with a large hole, it can easily be filled with mortar.

- Magnet. When a piece of a hammer drill attachment remains in the wall, but dangles freely in the hole, and you cannot grab the edge manually or with tools, try using a magnet. It will attract the metal and the drill will come out.

As a last resort, if the nozzle cannot be removed, you should use a grinder to cut it flush with the wall, and then cover it with mortar. It is also advisable to fill the hole with an anti-corrosion agent for metal so that a rusting drill does not lead to damage to the finish coating.

Have you ever had to pull a drill bit out of a wall or a hammer drill? What method did you use? Have nozzles been left in the walls?

What type of shank is on the hammer drill adapter?

A pertinent question is what type of shank has an adapter for drills for mounting in a hammer drill chuck. Manufacturers produce exclusively one type of adapters, which can only be installed in units with sds plus type cartridges. Manufacturers do not produce such adapters for units with sds max type cartridges, and the reasons for this are the following factors:

- Rotary hammers with sds-max chucks do not have a drilling option, so you cannot use ordinary metal or wood drills in such tools

- Tools with sds max chucks are quite powerful (from 1.5-2 kW and above), so using fragile drill bits in them is simply irrational. They will quickly heat up, wear out and break.

As a result, it turns out that adapters for hammer drills for installing drills are used only in household and semi-professional power tools. Such units have the following options:

- Chuck rotation speed regulator, which allows the tool to be used not only for drilling metal and wood, but also for mixing solutions

- Mode switch that allows you to turn on the drilling mode. It is in this mode that you can use drill bits from a drill in a hammer drill, installed through a special adapter

- Reverse is another useful option that allows you to free a jammed drill in a metal base or mix the solution in two directions

This is interesting!

If you have a barrel perforator or a straight one, but without a drilling mode, then buying an adapter for drills does not make sense, since using it in such tools is not only impossible, but also impossible.

Why does the hammer drill attachment jam?

It will be useful to know how to remove a replacement drill bit that is stuck inside the hammer drill or in the wall. There are 3 main reasons.

- Large diameter of the equipment used. When the hammer drill is working, due to the excessively large size of the drill, it begins to grind, as a result of which it can become thoroughly stuck.

- Low quality steel. If the steel is of mediocre quality, then during active work the material may become deformed. What most often happens is that the shank becomes wedged, like an anchor. Due to weak steel, attachments also break. This mainly occurs when working in impact drilling mode.

- Mismatch between chuck and attachment. This situation leads to the fact that the drill or drill begins to fall apart. Some element remains in the cartridge, or gets stuck in a hole in the wall, ceiling, or floor.

Separately, we can highlight such a problem as rust. When a power tool is used quite frequently, such problems may not occur.

And it’s a completely different matter if the nozzle was not removed from the problem hammer drill and left for long-term storage. As a result, the sting sours. Rust forms, which blocks the free exit of the element from the cartridge.

If a drill or drill suddenly gets jammed in your hammer drill or in the wall, then you will definitely need to pull it out. It is highly not recommended to leave pieces of metal fittings in the wall. This will cause rust to develop, which can affect the finish.

Adapter from sds max to sds plus

I know everything about the difference between sds max and sds plus cartridges. Situations often arise when your tool arsenal includes a hammer drill with an sds max chuck type. These are good and powerful units that are designed to perform serious work. For such units, corresponding attachments are produced, which cost 2 times more than drills, shovels, etc. for tools with sds plus chucks.

That is why, in order to save budget, manufacturers produce special adapters that allow you to install nozzles with sds plus type shanks in the sds max hammer drill chuck. This is not only profitable, but also very convenient, since it is very difficult to find a small-diameter sds max drill. The video shows in detail what the adapter from sds max to sds plus is and how the corresponding attachments are attached to it.

It is only worth noting one factor: the cost of such adapters, compared to those that allow you to attach a drill bit to a hammer drill chuck, is quite high. Their price starts from 1000 rubles and above, which depends on the quality of the steel used in their manufacture.

This is interesting!

attachments for SDS plus SDS max tools , it is necessary to take into account that they can quickly not only wear out, but also break under the influence of high impact force.

It is contraindicated to use drill bits for drills in the design of powerful units with sds max cartridges, using two types of adapters. The reasons for such contraindications are indicated above.

What to do if the tip of the nozzle in the chuck breaks

It's one thing to clamp a solid cartridge in a chuck. Here you have the opportunity to grab the tip, pull it out with pliers and use other methods of influence.

Another question is if the nozzle breaks and the shank remains inside the chuck. Here you won’t be able to grab the drill or drill with tools. We need to look for another way out of this situation.

As a standard, home craftsmen try to pick out the remains of the drill using an awl or a screwdriver. Some try to get it out using a magnet. Another common solution is to stick it to the drill using superglue and then pull it out. But in practice, all these methods show low efficiency. Of course you can try. But if the fragment is held tightly, then the superglue will not be enough to set. And a powerful magnet won't help.

In fact, if the drill cannot be pulled out of the hammer drill, there are two solutions to what to do: contact a workshop, where experienced specialists will disassemble your cartridge in parts, or install a new one, or still try to solve the problem on your own. Note that the first option is safer, but requires financial costs.

If you decide to take everything into your own hands, then there are 2 ways to solve the problem to choose from. This can be done using a welding machine or by pressing.

When using the welding machine, follow these instructions:

- Using a heavy-duty vice, clamp the hammer drill. The cartridge should face up.

- Remove the seal, retaining ring, washers, and nuts. Depends on the design. Or pull down the cartridge itself.

- When the cartridge is opened to its maximum, insert the insulating sheath into the cartridge. Take a fairly powerful wire, the cross-section of which will be at least 7 mm.

- Connect one terminal from the welding device to the body of the hammer drill. The second terminal should be used to grab a metal rod or welding tip of sufficient length. The cross-section should be smaller than that of the insulation.

- Connect the tip with a fragment of the nozzle. Using the device, give a short, low-power discharge.

- When the welder grabs the fragment, it is enough to pull it along with the rod out of the chuck.

If you have a welding machine and a vice, the procedure takes very little time.

But there are several disadvantages:

- Not everyone has the necessary equipment at home;

- after welding, adhesions may remain inside the cartridge;

- Welding joints form randomly on the chuck and hammer.

The danger of soldering is that they can disrupt the normal operation of the power tool and ultimately permanently damage it. Therefore, there is an alternative solution: extraction with pressure.

The meaning of the idea is as follows:

- remove the boot from the cartridge;

- pull back (down) the cartridge;

- turn on shock mode;

- At the same time, using some suitable device, press on the fragment of the nozzle.

This is a potentially dangerous method, because when pressed, a piece of the drill or auger flies out at high speed and in an unpredictable direction.

To minimize risks, install some kind of shield or panel at a short distance opposite the cartridge that can absorb the force of the impact. It should not be a metal sheet or anything hard. Otherwise, the fragment will ricochet and may hit you. Or something will be damaged in the room. It's not worth the risk.

As a result, you will end up with a broken drill or auger. Check the condition of the cartridge to make sure it can be used again.

How to choose the right adapter for a hammer drill for a drill

When choosing an adapter, no difficulties arise at all, since manufacturers produce only models that have sds plus shanks for a hammer drill. Shanks of this type have a diameter of 10 mm, as do the nozzles. It is not necessary to buy a drill chuck, since it can be removed from the power tool. Moreover, you can use cartridges not only from drills, but also from screwdrivers.

It is worth considering that it is much safer to use key-type clamps, since they firmly fix the nozzle, unlike quick-clamping ones. It is impossible to make the transition from sds plus to sds max, and there is no need to. After all, the most popular are rotary hammers with sds plus type cartridges. When purchasing, you need to take into account the diameter of the hole on the collet chuck. They are different, so first you need to clarify the diameter of the hole, and then order the appropriate adapter for the hammer drill for the drill.

This is interesting!

SDS this name from a German developer. The full decryption looks like this: “steck -dreh -sitzt ”.

Translated from German it means insert, turn and seat. In addition, there are also adapters for bits that allow you to install appropriate attachments in the hammer drill chuck for unscrewing or screwing fasteners. If there is an adapter for switching to a collet mechanism, then it is not necessary to buy such a device. What the device is is shown in detail in the video.

Knowing all the advantages and disadvantages of the considered device in the material, one can draw an appropriate conclusion about the rationality of their use. In a household where you have both a hammer drill and a hammer drill, the adapter will play an important role, so it is recommended to buy it before you need it. And be sure to consider the size of the thread the chuck is screwed onto, as they come in different sizes and buying at random "should fit" always comes down to the need to replace the device.

Keyless chucks

Sometimes it becomes necessary to pull out a nozzle that is tightly seated in a quick-release chuck. They can be used in the design of not only a rotary hammer, but also a drill and a screwdriver. There is no rotating clutch here. The attachments are held in place by a snap ring.

If we talk about how to get a broken drill out of your hammer drill or other power tool, then there are 2 solutions to solve the problem at home.

- First way. When faced with the fact that the drill bit is stuck and firmly seated in the quick-clamping chuck of your hammer drill, you can try the following. Remove the top o-ring, then pull the chuck back and use a metal wire and a screwdriver to pry the clamp ears off. Then you need to stretch and pull the cartridge in the opposite direction. Next, grab the nozzle using pliers or pliers. Start swinging and turning in different directions, gradually pulling the drill or drill outward

- Second way. Since the nozzle can jam quite tightly, there is another option. Remove the tube that leads to the cartridge (raster). This will give you access to the end of the drill. Using a regular drill with a metal drill bit, drill out the tip. This will allow the drill bit to come out of the keyless chuck easily. This option can be considered almost a non-alternative solution when the tip of the nozzle literally flattens. Otherwise, it is almost impossible to get the nozzle out of the hammer drill.