Drill and drill: what's the difference?

There are two main types of equipment for a rotary hammer. Drills are used in hammer drills. They make a hole with sharply sharpened ribs arranged in a spiral.

Drills of various diameters are used to pierce more durable foundations. Unlike simple rotational movements of the drill, this equipment also performs shock and vibration movements.

Drills are not suitable for use in a drill socket, and have their own design features:

- there is a landing shank at the end of the equipment,

- mounting grooves that fit only into the hammer drill socket,

- screw rod.

The latter feature allows the nozzle not only to make holes, but at the same time to remove the resulting debris out. The strength characteristics of the drill are added by a pobedite or diamond tip.

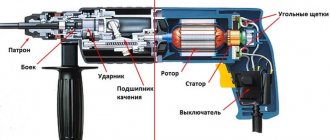

Device

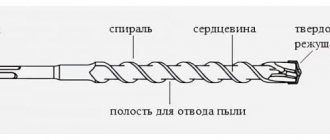

Regardless of the above-mentioned type, material and design features, drills for concrete hammer drills are built according to a standard principle. They are actually built from two parts: the shank and the working part. The latter, in turn, consists of 4 more zones:

- Spirals - spiral-shaped turns that help remove dust generated during the drilling process.

- The core is the main rod on which spiral-shaped turns and cavities are organized that remove dust.

- Channels for dust removal - peculiar cavities obtained due to the ribs of the spiral.

- The carbide cutting edge is the tip of the drill, which bears the main load during drilling. The effectiveness of work and the durability of the equipment depend on its quality characteristics.

How a drill for a hammer drill works Source redteh.ru

Important! When choosing a good concrete drill, pay attention to the location of the cutting plate. It should “sit” firmly in the saddle and be located strictly in the center.

Pobedite or diamond tip: which is better?

Which drills are best to choose are determined depending on what the surface being treated is made of. The rod of any equipment is crowned with a tip or solder. It has edges of various configurations and hard alloys are used for its manufacture.

The quality of drilling, wear resistance of the drill, and the speed at which it punches holes are determined by soldering. Therefore, it is better not to use a concrete drill bit for a hammer drill if you plan to work with marble tiles or masonry. But the diamond tip can handle both heavy and reinforced concrete.

Pobedit brazings are divided into three strength classes:

- soft ones are inexpensive, they can choose low-grade concrete and brickwork for the hole;

- medium-strength ones are most often used in everyday life for minor repairs and amateur construction. Tips of this hardness cope well with concrete floors;

- High-strength types of drills can compete with their diamond counterparts, but not on reinforced concrete bases.

All pobedit tips (if used as intended) are designed for repeated use without sharpening.

Diamond drilling price

The price of diamond drilling should also include depreciation of tools and equipment, as well as energy consumption

The price of drilling holes with diamond tools is influenced by the following factors:

- complexity of the work (drilling a wall in a hard-to-reach place or at an angle);

- type of building material for the supporting structure of the building;

- diameter, depth and number of holes made.

Diamond drilling of holes in concrete, price:

| Hole diameter, mm | Brick, foam concrete, aerated concrete | Reinforced concrete, monolith |

| 40 — 70 | 15 rub/cm | 22 rub/cm |

| 80 — 100 | 17 rub/cm | 24 rub/cm |

| 200 | 30 rub/cm | 37 RUR/cm |

| 300 | 45 rub/cm | 60 rub/cm |

Diamond drilling of holes in concrete is shown in the video:

What types of drills and drills are there?

If a home craftsman often needs to use a drilling tool, then it makes sense to look at sets of drills for a rotary hammer in the store. With such a purchase, the master will be ready to work with any surface.

The set contains nozzles with different types of shank and all shapes of the working part. Equipment can be divided into two broad categories: through and through.

The first ones choose the base material, gradually going deeper inside. The second type destroys (chips off, knocks off) an impressive part of the working surface. Within each group there is an additional breakdown into species.

How to remove a jammed drill bit from a hammer drill

There are several simple ways to remove a drill bit stuck in it from a hammer drill chuck.

- The free part of the drill, which is stuck in the hammer drill chuck, must be clamped in a vice, and then gently tapped on the cams of the clamping mechanism with a hammer, using a wooden spacer.

- If the method described above for removing a stuck drill does not help, then the cartridge can be placed in a container with gasoline, and then try to remove the drill in the usual way.

- If the drill is jammed in a key-type chuck, you should turn the key of such a mechanism counterclockwise, which will free the tool. If necessary, you can drop machine oil into the key type chuck in which the drill is stuck.

- — To remove a drill that is jammed in the keyless chuck, you can try to loosen the clamp of the fastening mechanism with gentle blows made counterclockwise.

- The last option for freeing a drill that is jammed in a hammer drill chuck is to completely disassemble the fastening mechanism.

To avoid the problem of a stuck drill, its shank should always be treated with a waterproof lubricant, which will facilitate the process of removing the tool from the hammer drill chuck.

Screw attachments

The category of the most used attachments is represented by auger drills. Their cutting edge is twisted into a spiral, and the tip is additionally hardened.

If you need to make a deep hole in a matter of seconds, these are the nozzles you use. They are purchased to hang a shelf, sconce or TV bracket.

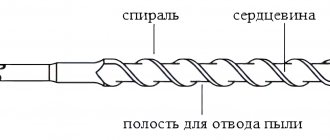

Spiral drills

This type of consumable is indispensable when you need to make a long passage of large diameter. If you need to stretch a cable through load-bearing partitions from one room to another, choose a spiral drill.

Voting for the best hammer drill

Which drill bit would you choose or recommend?

DeWalt EXTREME DT9571-QZ 14*600 mm

0.00 % ( 0 )

Granite 425100 25*1000 mm

11.11 % ( 1 )

DeWalt Extreme 2 DT7935B-QZ

22.22 % ( 2 )

Makita D-00050 6*100 mm

22.22 % ( 2 )

Granite Quadro-X 845570 45*570 mm

0.00 % ( 0 )

DS-MAX Bison 29350-340-12*340 mm

0.00 % ( 0 )

Bosch 2608833778 6*160 mm

22.22 % ( 2 )

Matrix 71098

0.00 % ( 0 )

CALIBER NB-13

11.11 % ( 1 )

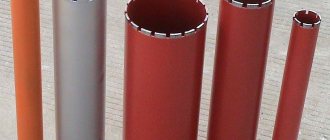

Crowns

When working with concrete foundations, it is often necessary to use crowns. Such equipment is needed when laying electrical wiring and engineering systems.

To select a round hole of large diameter (for example, for a socket), purchase a spiral-shaped rod with an attachment. The crown has incisors along the edges, making it easy to penetrate into concrete.

Scope of drilling with diamond tools

As a rule, diamond drilling equipment is powered by electricity, but manual drilling rigs can now be found on the market.

Diamond drilling is used to create holes:

- in the foundation. Holes in the foundation are sometimes necessary to connect water and electricity supply systems, heating, and sewage systems to city highways;

- in the walls for laying pipes for water supply, heating, sewerage;

- in ceilings for water supply, heating, and sewage riser pipes;

- in ceilings and walls for installation of air conditioning systems;

- in ceilings and walls for ventilation valves and air ducts;

- for installation of chimneys, connection of heating devices;

- for supplying communications to swimming pools;

- for installing internal roof drain risers;

- for installing fencing railings on flights of stairs;

- for installation of automatic fire extinguishing systems.

Diamond drilling of holes in concrete, prices and efficiency largely depend on the equipment used. Diamond drilling can be carried out using rotary hammers or special installations . The latter are used for large volumes of construction work. Directly drilling holes is carried out with diamond drills or crowns.

How are drills marked and what sizes of nozzles are there?

Before inserting a drill into a hammer drill, you should make sure that you purchased a consumable with the type of shank recommended by the manufacturer (that is, all holes and shapes match the mount). Professionals advise choosing shanks with SDS fastening. It makes it possible to quickly change equipment and comes in 5 types:

- SDS plus is distinguished by the presence of 4 grooves with a diameter of 10 mm. The drills themselves can have a diameter of at least 0.4 cm and a maximum of 2.6 mm. They work great on concrete bases;

- SDS has 2 grooves, diameter 10mm;

- SDS max has five slots and is used for fastening powerful drills in rotary hammers for professional work. The diameter of the equipment increases from 2 to 8 cm;

- SDS top is distinguished by the presence of 4 grooves with a diameter of 1.4 cm. The size of the nozzles for this mount varies from 1.6 cm to 2.5 cm. This equipment is used in medium-weight hammer drills.

- The longitudinal projections in the SDS quick mount seem to have affected their popularity. They are rarely found on store shelves.

In addition to the type of fastening, the type of work to be done should influence the purchase of a particular consumable. Drill sizes for simple household work are limited to 6-10 mm.

Choosing a blade for a hacksaw for metal: rating the best blades, choosing and using the best toolReview of diamond bits for concrete: subtleties of choosing and using tools for high-quality drilling

The best concrete drills for drills and hammer drills: tips for choosing, structure and types of tools

If you need to screw an anchor bolt into the wall, you will need to take equipment of at least 2 and no more than 20 mm.

Another indicator of the drill size is the length of the working part and the main length. For private construction, where thick partitions are almost always erected, both a modest 10 cm nozzle and professional meter-long equipment may be required.

The walls in apartments are much thinner, and for standard repair work a 6 mm drill with a length of 110 mm will be sufficient.

To summarize, we can say that the choice of consumables for a hammer drill is made after assessing the scale and complexity of the upcoming work.

Tools for drilling large diameter holes

To create cylindrical holes of large diameter, a special type of drill is used - crowns . The body of the drill bit has the shape of a hollow pipe. At one end of the housing there is a special mechanism for attaching the crown to the motor shaft, and at the other, diamond-containing segments are soldered. A drill with a small screw thread acts as a core. Its length is 1-2 cm greater than the height of the body. The core is used to center the hole being made.

Drilling concrete with a crown, the price of which is considered one of the disadvantages of this method, is performed using a heavy hammer drill or a special installation. The diameter of the crown can reach 1000 mm , and upon request it can be increased even more. In this case, the drilling depth is limited by the height of the housing.