Home / Product catalog / Components of ventilation systems / Vibration isolators /

Vibration bearing material: natural rubber, neoprene, silicone and other materials based on natural rubber intended for use in aggressive environments. Material hardness 55 Shore (other hardness of vibration mounts available on request). The material of the studs and support plates of the vibration mounts is galvanized steel, or can be made of stainless steel. Vibration mounts are used for vibration isolation of industrial equipment (machine tools, fans, refrigeration equipment, etc.). Versions of rubber-metal vibration supports: with two studs on both sides, with a stud and a threaded hole, with two threaded holes, with a stud on one side and with a threaded hole on one side of the support. The diameter of vibration isolators is from 6 to 200 mm, height is from 7 to 100 mm. In addition to standard sizes, it is possible to manufacture vibration isolators of any configuration.

Vibration mount data order type - 20.15 B

The first parameter is the type of vibration support - A, B, C, D, E

The second parameter is diameter (20)

The third parameter is height (15)

Vibration support 30.20D — 196 rub. as of January 2014 (background information)

Vibration isolator 5030VV28 — 690 rub. as of December 2013 (background information)

Vibration support 200.100D — RUB 5,594. as of January 2014 (reference information) Vibration support 40.40A - 338 rub. as of March 2014 (background information)

Non-standard designs

Why make a full-fledged vibrating machine to process a dozen other tiles?

If you need to make your own vibrating table not for constant work, then you can pay attention to simplified designs that can be assembled within an hour and will complete their task at a fairly high level. The video shows an example of how one of them works: The video shows an example of how one of them works:

You can make sides around the perimeter of the shield so that the forms do not fly off. The solution is poured, the forms are placed on the shield and by tapping with a hammer it is caused to vibrate, the strength of which is regulated in the full sense of the word “manually”. The shield, if necessary, can be screwed to the tires with a couple of screws.

The design can be complicated if the farm has an electric motor. It is screwed to the shield, an eccentric is attached to the shaft... And the hammer can be put aside.

From a hammer drill or impact drill

A steel plate is attached to the edge of a wooden panel or iron sheet (perpendicular to the surface). Something elastic is attached to the other end (rags, a piece of rubber) and it all rests against the wall. A hammer drill is connected to the steel plate and the vibration is no worse than with the tire method.

Instead of a drill, you can use a piece of pipe - the thickness is selected depending on the capabilities of the hammer drill chuck.

In this simple way you can quickly make a vibrating table for molding and for removing tiles from molds.

The production of paving slabs, as well as products made of concrete, gypsum or building mixtures involves compaction of the working composition. Under the influence of vibration, the working solution fills the corner areas of the mold, acquiring increased strength and the necessary structure. To make concrete products intended for domestic use, you can make a vibrating table with your own hands. This inexpensive and easy-to-manufacture equipment is not inferior to industrial designs in terms of operating efficiency.

DIY vibration table

Vibrating table - design features

The platform intended for vibration molding is a mechanism consisting of the following elements:

steel frame. It is a massive metal structure made of vertical posts, to which jumpers are rigidly welded; work plate. It is a horizontal base with a collar along the upper contour, limiting the mobility of the forms; vibration motor

When installing a motor for a vibrating table with your own hands, you need to pay attention to the mass of the eccentric that transmits vibrations to the plate; movable fastening unit. It provides connection between the plate and the frame

It consists of four spring elements installed in glasses; starting machine. It performs the functions of supplying and disconnecting voltage to the vibration motor, and also protects against thermal overloads.

When deciding how to make a vibrating table yourself, you should pay attention to its performance characteristics. What does a vibrating table consist of?

What does a vibrating table consist of?

The main parameters influencing the efficiency of compaction and the quality of manufactured products:

- amplitude of oscillatory movement;

- vibration motor shaft rotation speed.

To ensure optimal performance you must:

- choose the right eccentric design;

- select a mounting location for the vibration drive;

- equip the site with an electric motor of calculated power.

The selection of optimal modes is carried out experimentally.

Purpose in production

The cause of vibrations in most cases is the operation of workshop equipment. Waves of various frequencies can be generated by the working fluid supply system, ventilation or power plants.

All this affects the operation of the equipment. This phenomenon is negative, so the task of the engineering department is to minimize it. A good solution in this matter would be to install compensation elements that will dampen vibrations, preventing their further spread and helping to get rid of vibrations. It is for such purposes that vibration supports are intended.

To select the required model, the following factors should be taken into account:

Vibration direction. In most cases, a base needs to be installed. Less often it is necessary to reduce oscillatory processes in the upper or lateral parts. Weight of equipment. A vibration support for machine tools must not only dampen vibration waves, but also withstand its weight. At the same time, its performance characteristics cannot deteriorate. A mistake is made when, when choosing a vibration support, the mass of the material that you are going to load into the equipment is not taken into account. Characteristics of vibrations. First, decide what kind of vibrations you will be dealing with, as well as what vibrations may occur on the purchased equipment. This parameter includes periodicity of occurrence and frequency. Operating environment

Particular attention should be paid to the conditions in which the machine will be operated. You cannot use supports that, under the influence of aggressive chemical substances or low temperatures, will begin to collapse or, due to increased humidity, the metal elements of the support will suffer from corrosion.

These parameters are general when choosing a support type. The possibility of influence of external factors on the material, as well as manufacturing - aggressive elements, humidity, temperature changes is also important.

Installing a vibration support for equipment will have a positive impact not only on the quality of its work, but also on the safety of the floor in the workshop. Without constant repair work, it will last much longer.

Operating principle of vibration mounts

Their main function is to prevent the spread of vibrations in all directions - both from the protected object (power plant, pressing machine, liquid transfer system) into the premises where it is located, and to suppress return waves from the walls of the room to the protected object. Simply put, vibration absorption is the same as reducing noise levels, which in both cases are variations of vibration isolation.

In total, there are two options for vibration isolation:

- Active - represents counteraction to oscillations that are created by the equipment itself, for which they are opposed to the same oscillations, only reversed in phase. At the same time, active insulation is divided into shock absorbing insulation and periodic vibration insulation. Any equipment, be it a machine or a press, is certainly a source of vibrations of the two above-mentioned types - mechanical drives and their various types of mechanical action are capable of creating shock and vibration loads that spread in all directions and at the same time “hit” the location itself. Building codes and regulations No. 2.07.01 of 1989 regulate the degree and types of permissible vibrations in industrial premises, however, in some cases, limits may be based on the specification of the equipment used or the general arrangement of the production premises (for example, proximity to high-precision machines and similar precision devices);

- Passive – this protection is the protection of machines from destructive vibrations from the outside and does not use potential additional energy sources. This type of vibration is characterized by the fact that the frequency of their excitation is indefinite, and their formation itself is polyharmonic in nature. In this case, the equipment itself (measuring stand, machine tool, feeding system) becomes the object of destructive influence, and at the same time its accuracy decreases, simultaneously deteriorating other performance indicators. When using passive vibration isolation, it is necessary to avoid dry contact (friction) that may occur between the foundation and the protected object, bypassing the protective element.

Taking a theoretical look at both of these types of vibration isolation, they are almost indistinguishable, therefore the level of their measurement is similar and is determined for both types in the same way. In general, it can be represented as a transmission coefficient, which will show what part of the vibration energy is transmitted through the vibration support.

Purpose in production

The cause of vibrations in most cases is the operation of workshop equipment

All this affects the operation of the equipment. This phenomenon is negative, so the task of the engineering department is to minimize it. A good solution in this matter would be to install compensation elements that will dampen vibrations, preventing their further spread and helping to get rid of vibrations. It is for such purposes that vibration supports are intended.

To select the required model, the following factors should be taken into account:

Vibration direction. In most cases, a base needs to be installed. Less often it is necessary to reduce oscillatory processes in the upper or lateral parts. Weight of equipment. A vibration support for machine tools must not only dampen vibration waves, but also withstand its weight. At the same time, its performance characteristics cannot deteriorate. A mistake is made when, when choosing a vibration support, the mass of the material that you are going to load into the equipment is not taken into account. Characteristics of vibrations. First, decide what kind of vibrations you will be dealing with, as well as what vibrations may occur on the purchased equipment. This parameter includes periodicity of occurrence and frequency. Operating environment

Particular attention should be paid to the conditions in which the machine will be operated. You should not use supports that, under the influence of aggressive chemical substances or low temperatures, will begin to collapse or, due to increased humidity, the metal elements of the support will suffer from corrosion.

These parameters are general when choosing a support type. The possibility of influence of external factors on the material, as well as manufacturing - aggressive elements, humidity, temperature changes is also important.

Installing a vibration support for equipment will have a positive impact not only on the quality of its work, but also on the safety of the floor in the workshop. Without constant repair work, it will last much longer.

Types of vibration supports

Types of vibration supports

One of the advantages of using compensation components is the reduction of costs for setting up a production line. There is no need to make a separate foundation for each machine, to take into account its mass and the characteristics of oscillatory processes during operation.

But for normal operation, it is necessary to correctly select the design of the vibration pads and the material for their manufacture. Currently, several types of these components are produced, which differ in technical characteristics:

- rubber. One of the most common materials for manufacturing. Both natural and synthetic rubber are used. It is important to pay attention to its specific gravity. Does not lose its characteristics at low temperatures, but if the exposure exceeds +60°C, rapid destruction occurs;

- rubber-metal. To increase the maximum load, a metal support is additionally installed. With its help you can adjust the height and control the level. Partially performs protective functions, preventing premature destruction of the elastic material;

- all-metal. Area of application – damping vibrations with a significant mass of the machine. Significant deformations may occur without loss of performance. The disadvantage is the transmission of high-frequency vibrations. Springs or springs can be used as a shock-absorbing element.

Bases made of felt and cork are less common. They perform the functions of adjusting the height of the machine, but the elimination of vibrations is insignificant. Lead-asbestos gaskets are the least common.

All parameters of dynamic vibration dampers must first be calculated. For this purpose, a special computing technology is used, which depends on many external factors.

The video shows an overview of rubber-metal vibration mounts for equipment:

The use of vibration mounts will improve the quality of parts processing

Vibrations that occur during equipment operation affect product quality, increase wear of components, and have a destructive effect on materials. Runouts are especially noticeable when grinding. Protection will be the installation of each unit on vibration supports that prevent the machines from acting on each other, on a solid base, and reverse reaction forces. Various types of such supports have been developed for individual processing mechanisms. The widespread use of vibration support OB is due to the fact that it provides protection in the axial and longitudinal direction.

Rubber-metal supports OB for metal-cutting machines

Designed to protect against passive (coming from outside) and active (arising in the nodes and spreading to surrounding objects) vibration. The principle of operation is compression.

Such supports make it possible to install equipment without an anchor foundation. Reduces costs when preparing a workshop, allows you to move or replace a machine with a different frame. Allows ergonomic use of space. Reducing vibration transmitted through floors makes metalworking possible in the workshop without significant noise impact on other areas of the building.

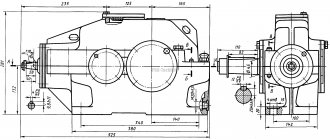

Designed for machine tools with increased or normal accuracy characteristics, TU2-024-5997-87. Visually presented in 3d drawings.

The supporting part will not require regular technical maintenance or revision, and will retain its performance characteristics in the absence of significant aggressive effects on the rubber.

Design

The constituent elements are:

- stud with a turnkey square;

- lid;

- top and bottom nut;

- washer – 2 pcs;

- rubber-metal shock absorber (rubber element + flange).

All metal parts, clearly presented in the 3d drawing, have an anti-corrosion coating.

The operating conditions for rubber are the same as those established by the standards for industrial premises where people constantly work. Heating above +60°C has a destructive effect on the elastic parts. Freezing causes rubber to crack under load.

Criterias of choice

The technical specifications indicate the minimum and maximum load at which the support operates effectively. The weight of the metalworking machine must be distributed over the appropriate number of 3D points of one model (for example, 70 meters) or choose a more powerful one - 31 meters. In addition, they differ in height adjustment.

Purpose of adjustment

The length of the thread on the stud is not intended to equalize sudden changes in 3D floor levels. Its purpose is to set, by adjusting the fit of the nut, an even distribution of the weight of the machine on the base. Therefore, the optimal combination of the following conditions will be:

- The shortest distance from the vibration support cover to the frame, the maximum passage of the nut;

- Equal compression of all rubber pads, uniform tightness.

Several vibration sources in the same room may at some moments coincide in frequency. The device ov 31m, ov 70 is a low-resonance device that does not allow large amplitude 3d movements of the frame.

Installation of vibration-isolating inserts for pressure pumps: 1.6 MPa with a diameter of 300 mm

LOCAL RESOURCE STATEMENT GESN 18-05-002-09

| Name | Unit |

| Installation of vibration-isolating inserts for pressure pumps: 1.6 MPa with a diameter of 300 mm | 10 inserts |

| Scope of work | |

| 01. Fitting and welding flanges to the ends of pipes. 02. Installation of flexible inserts with flange connections using bolts and gaskets. |

PRICE VALUES

The price list shows the direct costs of the work for the period of March 2014

for the city of Moscow, which are calculated on the basis of

2014 standards with additions 1

by applying indices to the prices of the resources used.

2000

federal prices .

The following indices and hourly rates from the “Union of Cost Estimating Engineers” were used: Index to the cost of materials: 7.485

Index to the cost of machines:

11.643

Hourly rates used: The monthly wage at a given hourly rate is indicated in parentheses.

Hourly rate 1st category: 130.23 rubles. per hour ( 22,920

) rub.

per month. Hourly rate 2nd category: 141.21 rubles. per hour ( 24,853

) rub.

per month. Hourly rate 3rd category: 154.46 rubles. per hour ( 27,185

) rub.

per month. Hourly rate 4 categories: 174.34 rubles. per hour ( 30,684

) rub.

per month. Hourly rate 5th category: 200.84 rubles. per hour ( 35,348

) rub.

per month. Hourly rate 6th grade: 233.96 rubles. per hour ( 41,177

) rub. per month.

By clicking on this link, you can see this standard calculated in 2000 prices. The basis for applying the composition and consumption of materials, machines and labor costs are GESN-2001

LABOR COSTS

| № | Name | Unit Change | Labor costs |

| 1 | Labor costs of construction workers Grade 3.7 | person-hour | 59,19 |

| 2 | Labor costs for drivers (for reference, included in the price of the EV) | person-hour | 0,55 |

| Total labor costs for workers | person-hour | 59,19 | |

| Workers' compensation = 59.19 x 168.38 | Rub. | 9 966,18 | |

| Payroll for drivers = 171.54 (for calculating invoices and profits) | Rub. | 171,54 |

How much does it cost to renovate an apartment? The cost of apartment renovation per hour.

OPERATION OF MACHINES AND MECHANISMS

| № | Cipher | Name | Unit Change | Consumption | St. unit.Rub. | TotalRub. |

| 1 | 021141 | Truck-mounted cranes when working on other types of construction 10 t | mach.-h | 0,55 | 1303,9 | 717,15 |

| 2 | 040502 | Installations for manual arc welding (DC) | mach.-h | 15,54 | 94,31 | 1 465,58 |

| 3 | 400001 | Flatbed vehicles, load capacity up to 5 tons | mach.-h | 0,63 | 1014,92 | 639,40 |

| Total | Rub. | 2 822,12 |

CONSUMPTION OF MATERIALS

| № | Cipher | Name | Unit Change | Consumption | St. unit.Rub. | TotalRub. |

| 1 | 101-1522 | Electrodes with a diameter of 5 mm E42A | T | 0,023 | 77559,57 | 1 783,87 |

| 2 | 101-2576 | Bolts with nuts and washers for sanitary works with a diameter of 16 mm | T | 0,0224 | 111002,55 | 2 486,46 |

| 3 | 301-1156 | Vibration-isolating inserts for pressure 1.6 MPa (16 kgf/cm2), diameter 300 mm | set | 10 | 12552,34 | 125 523,40 |

| 4 | 507-1008 | Steel flat welded flanges made of steel VSt3sp2, VSt3sp3, pressure 1.6 MPa (16 kgf/cm2), diameter 300 mm | PC. | 10 | 3511,74 | 35 117,40 |

| 5 | 509-0971 | Gaskets made of paronite grade PMB, 1 mm thick, 300 mm in diameter | 1000 pcs. | 0,02 | 114301,19 | 2 286,02 |

| Total | Rub. | 167 197,15 |

TOTAL BY RESOURCES: 170,019.27 RUB.

TOTAL PRICE: RUB 179,985.45.

You can see this standard calculated in 2000 prices. by following this link

The price is compiled according to the standards of GESN-2001 as amended in 2014 with additions 1

in prices

of March 2014.

To determine intermediate and final price values, the DefSmeta program was used

Estimate for the construction of a house, renovation and decoration of apartments - DefSmeta

Rental

The program provides an assistant who will turn the preparation of estimates into a game.

We construct a homemade vibration table with our own hands - simple solutions

When planning to make a universal molding vibrating table with your own hands, you must purchase the drawings in advance or draw them yourself

It is important to determine the design features of the vibration unit. The following types of vibration compactors are used:

- molding equipment. It is used for vibratory compaction of concrete mortar poured into molds;

- unmolding device. Designed for removing hardened products from molds using a special device;

- non-standard design options. Used to make a limited number of products at home.

The simplest options:

- based on automobile ramps. To assemble the tamping device, you need 2-3 slopes, a hammer, and a wooden board, the size of which allows you to place the molds. The compaction process occurs when the molds are placed on a wooden board located on the tires. When tapped with a rubber hammer, the concrete composition is compacted;

- using a drill or hammer drill. The design uses a slab made of metal sheet or plank board. The tabletop is placed on a horizontal base and rests against the wall with a damper made from a piece of rubber. When the hammer drill, connected to the opposite side of the base, is turned on, the material is compacted.

We develop a drawing of a vibrating table

When developing a drawing for a vibrating table, you need to know how to do it correctly.

To do this you need:

- use verified documentation according to which the vibration platform was previously manufactured;

- independently develop a sketch using a working sample.

Please note the following recommendations:

- the optimal dimensions of the tabletop are 50x100 cm;

- the distance from the floor to the work surface should not exceed 80 cm.

How to make a vibrating table yourself

When developing a drawing, it is important to consider the following requirements:

- the engine should not touch the base or elements of the metal structure;

- the desktop surface is horizontal;

- the legs of the frame must be of equal length to ensure stability;

- Stiffening ribs are installed in the corners to increase stability.

Before developing working documentation, you must first determine the dimensions of the unit and the mounting location of the motor. It is advisable to place the vibration motor in the center of mass of the entire metal structure.

General information about vibration supports

The supports, as well as the equipment on which they are mounted, must comply with certain technical characteristics, the first of which can be called the weight of the machine (also known as the static load)

Other parameters must be determined individually for each specific case, taking into account all the operating features of the equipment, and even more so - the requirements established by its manufacturer regarding vibrations

To integrate supports, the equipment must have standard fastening points - the so-called “paws”, which have holes of the required diameter. The machines on which the supports are mounted must meet stability requirements, since such an integration method eliminates rigid coupling to the base. This is relevant for frame-truss and column structures, as well as for equipment that is subject to wind blowing.

It is worth noting that the use of vibration supports does not guarantee 100% vibration absorption - such a result can only be achieved using a whole range of measures aimed at eliminating sources of destructive vibrations.

General conditions for the use of vibration mounts

These include:

- The obvious presence of oscillations with destructive characteristics, formed periodically and having their own frequency;

- Directionality of vibrations - destructive waves are clearly directed and pass through the base of the machine or its working elements;

- The presence of characteristic vibrations during the production process, reflected on the surface of the base (floor, foundation), and in the worst case, the occurrence of obvious cracks;

- The proper ratio of the weight of the machine equipment and the support - the latter must not only withstand the weight of the machine, but also not cause harm to it on its own.

Advantages

With the right choice of supports, you will receive such positive qualities as:

- There will be no need to set up a separate place for each machine. After all, installing a compensator is much easier than organizing a separate foundation. After all, you will have to take into account the nuances of vibration, mass characteristics and other parameters. Standard foundations may not be able to cope with the loads. Compensators are much stronger in terms of performance characteristics.

- Avoid frequent repair work caused by the negative effects of vibration on equipment components.

- Improve working conditions for operators who operate machines.

- Protect your flooring from damage and wear.

- When operating the units, you will significantly reduce the noise level that is created around.

- Provide favorable operating conditions for the machines.

- Extend the life of your devices.

Advantages of using vibration pads

With proper selection of vibration supports, the protected equipment can be provided with the following preferences:

- There is no need to equip protection for each machine - by installing the compensator once, it will cover the entire foundation of the room;

- The number of repairs, the need for which will be caused by exposure to negative vibrations, will decrease significantly;

- Working conditions will improve directly for equipment operators;

- The floor covering will be less subject to wear and destruction;

- The noise produced by the devices during operation will be significantly reduced;

- The quality and accuracy of the devices will increase;

- The service life of the equipment will be significantly extended.

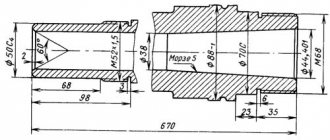

Vibration support OV-31-M

This type of vibration support is used for medium and light machines. Light crushers, milling and grinding equipment, turning and drilling equipment will be reliably installed in the allocated space. The characteristic features of the OV-31-M are:

- Weight is 1.56 kilograms.

- The adjustment limits are 12 millimeters.

- The assembled height is 13.2 centimeters.

- The diameter of the rubber cushion is 14.2 centimeters and the height is 6.

- The pin has a diameter of 16 millimeters.

- The permissible load ranges from 0.25 to 4.5 tons.

Such a product will have 4 support points, equipment weighing from 1 to 18 tons. For lighter units, the shock absorber does not work due to rigidity. And a heavier load will squeeze it into the lid body until it reaches the floor. The number of OV-31-M should be increased.

Pump installation errors

Up to 90% of problems with the failure of modern high-quality pumps in a short period of time are associated with installation and commissioning errors. In this case, the pumps fail within 2-4 months from the date of launch. Let's look at these errors using the example of cantilever-type pumps. These pumps are considered classics of pumping production and yet with their installation and commissioning errors are the most common.

In this publication, we will examine the three most common causes of pump failure due to improper installation:

- Errors in making the foundation

- Errors in installing vibration damping elements

- Incorrect alignment of pump and motor shafts

When considering installation errors, we will use the experience of the Service Center specialists, the regulatory documentation of the pump manufacturer and the Service database regarding calls for service specialists to real objects.

Here is an example of a typical installation error of a cantilever pump, in this case Grundfos:

Places of installation errors that are immediately visible are circled:

- The foundation does not meet installation requirements

- Vibration inserts are not installed correctly

Let's read what the manufacturer Grundfos says about vibration inserts in the installation instructions:

Below, from the installation instructions, is a diagram of the pump with rules for installing the vibration insert.

The figure clearly shows how the vibration insert is installed. The one and a half distance from the pump at both ends is clearly visible. The diagram clearly shows a concrete foundation under which vibration damping supports are installed.

Now let's look at another type of error that led to pump failure. In this case, the pumps did not have a foundation, vibration supports were installed incorrectly, alignment was not performed, and commissioning was not carried out, which should have revealed all this before the equipment was put into operation.

Regarding the foundation, the regulatory requirements of the pump manufacturer are also simple and clear:

But what happens when, during installation and commissioning, the pump and motor shafts are not ALIGNED

Here are the requirements for aligning pump shafts:

ATTENTION! All the pumps shown in the photo failed in a short period of time: from several days to several months. All of them were under official warranty service

However, due to non-compliance with the installation rules of the pumps recommended by the manufacturer, the warranty was canceled and repairs were carried out by the operating organization on a paid basis!

If you have questions or doubts about the correct installation or commissioning of the equipment, contact the Service Center and clarify all the necessary information.

GENERAL PROVISIONS

Upon completion of the main civil works, the construction site is being prepared for the installation of building elements associated with the ventilation device: arrangement of platforms and foundations for ventilation equipment, laying of underground ducts, openings in walls, ceilings and partitions for installation of air ducts or ventilation equipment, intake shafts, premises for placement of supply and exhaust chambers, etc.

Red marks for clean floors are painted on the walls with indelible paint.

The installation of ventilation devices begins when the object is accepted for installation according to the act. Lifting and transport, installation and rigging devices are prepared according to the work plan before installation begins. Tools and mechanisms are delivered to the construction site the day before the start of work based on the number of workers employed in the installation team. Ventilation equipment and air ducts are delivered to the on-site warehouse before work begins.

Installation of ventilation devices is carried out from components and parts, prepared in advance and fully equipped. Air ducts associated with process equipment are installed after installation of the process equipment; general ventilation air ducts - regardless of process equipment.

Installation method

The pin is inserted into the hole in the frame from below. The machine is lifted using a mechanism of the required lifting capacity and installed on a temporary base made of timber or I-beam. The height is sufficient for a threaded rod of 31 m (70) to pass through the equipment arm. Usually from 7 cm, depending on the width of the hole.

Installation of vibration mounts on the machine

The horizontal position of the equipment is set by level. The lower nut is held with an open-end wrench, and the stud is rotated by the square. When finished, tighten the top nut.

It is important to check all supports in 3D. The plane is formed by 3 points, the 4th may, unnoticed, remain underloaded and manifest itself later

Vibration supports 30m, 70, vertical action. They do not compensate for the tilt of the floor; the device slips from the installation site under the influence of mechanical vibrations.

The presence and adjustment of rubber shock absorbers may not give the desired result in terms of cleanliness of processing if the reason is internal to the equipment itself. Runouts of the lathe chuck, increased play in the rotation units, wear of the rubbing surfaces of the gears must be eliminated by repair.

Adjustment options

It is always worth leveling the base on which equipment with compensators is installed - all sudden changes in floor level must be leveled. Thus, a uniform distribution of the weight of the equipment will be set, which can always be adjusted by tightening the nut on the vibration support. As a rule, technical data sheets for pillows indicate the minimum and maximum number of loads in exact values that the support can withstand without serious damage. From here, the mass of the protected equipment should be distributed over a certain number of support points.

Causes of vibration

Noise level is one of the characteristics by which an air conditioner is selected. The indoor unit operates in the range of 26-36 dB. The outdoor module produces more noise - up to 56 dB. Loud noise comes from moving parts - the fan and compressor. The hum is often accompanied by vibration. An unpleasant situation arises for various reasons:

- unbalanced fan impeller;

- poorly secured bolts on brackets;

- mounting the block on a weak surface;

- lack of vibration support for the air conditioner.

An increased level of vibration accompanies the operation of not only budget, but also expensive models. If it is caused by defects in the installation of the outdoor unit, they can be corrected.

Rubber-metal supports

They are intended to protect devices from active (which occurs in the nodes and spreads to surrounding objects) and passive (which comes from outside) vibration. The principle of its operation is based on compression. Such supports make it possible to install equipment without an anchor foundation.

It allows you to replace the machine with another one with a different type of frame, move it, and reduces costs when preparing the workshop. It allows you to use space ergonomically. The reduced level of vibration, which is transmitted through the floors, makes it possible to work in the workshop without the strong influence of noise on other rooms in the building.

They are intended for machine tools with normal or increased accuracy characteristics, TU2−024−5997−87.

In the absence of strong aggressive influences on the rubber, the supporting part will not require inspection and regular maintenance, and will also retain all its performance characteristics.

Design

The constituent parts are:

- Rubber-metal shock absorber (flange and rubber element).

- Washer - 2 pieces.

- Bottom and top nuts.

- Lid.

- Hairpin with a square turnkey.

All parts made of metal have an anti-corrosion coating.

For rubber, the operating conditions are the same as for production facilities in which people constantly work. Temperatures above 60 degrees have a destructive effect on elastic parts. Rubber cracking under stress can be caused by freezing.

Criterias of choice

Technical data sheets indicate the exact maximum and minimum load that the support can withstand without being damaged.

The weight of metalworking equipment must be distributed over the number of points of one model - OV-70, or choose a more powerful one - OV-31-M. These models also differ in the height of adjustment.

Purpose of adjustment

The length of the thread on the stud is not intended to equalize sudden changes in the floor level in the room where the equipment is located. Its purpose is to set the uniform distribution of the weight of the equipment on the base by adjusting the fit of the nut.

The following conditions are considered the most optimal:

- Uniform fit and equal compression of all pads made of rubber.

- Maximum nut passage and minimum distance from the frame to the vibration support cover.

To eliminate the critical influence of resonance, the machine is lowered along the stud as low as possible.

At some moments, several sources of vibrations located in the same room may coincide in frequency. The OV-70 and OV-31-M devices are low-resonance. They do not allow large amplitude movement of the frame.

Issues of proper selection of vibration support

These devices must be selected taking into account many individual characteristics of the units being protected. To do this, you need to decide on the following questions:

- Available types of vibrations that can threaten the protected equipment - frequency of their occurrence, frequency and average and maximum strength;

- Weight of the protected unit - the heavier it is, the more powerful compensator it will require. To obtain more accurate indicators, the weight of the device should be taken into account along with the weight of the workpiece (material) installed in it;

- Direction and nature of vibrations - the summed vector of the direction of the resulting vibrations should be taken into account. As a rule, the vibration isolation product is mounted under the base of the protected unit, however, in some cases the vibration cushion must be placed vertically on the wall;

- Ambient conditions in the room - you should always take into account the endurance of the vibration support, because it can be “afraid” of very high or very low temperatures;

- The possibility of unintentional contact with aggressive substances and stability when the vibration cushion comes into contact with them without loss of performance properties - this means chemical acids, molten substances, industrial oils, etc.

IMPORTANT! You should also take into account the issue of safety of the vibration mount itself - with a high draft, vibrations at low frequencies will be optimally isolated, however, the influence of external forces in the form of, for example, hydro-electric connections will be quite noticeable.

Professionals consider the following operating conditions for vibration pads to be the most optimal:

- All pads, made on a rubber base, are equally and evenly covered and compressed;

- The nut has a maximum passage and a minimum distance from the vibration pad cover to the frame;

- The machine is lowered along the stud as low as possible in order to eliminate the critical impact of resonance.

Installation option

The pin is placed in the hole in the frame from below. The machine is lifted using a mechanism for the necessary lifting of the load, and placed on a temporary base made of timber or I-beam. The height is sufficient for a threaded rod of 31 m (70) to pass through the equipment arm. In most cases from 7 cm, depending on the width of the hole.

Installation of vibration mounts on the machine

The horizontal position of the equipment is set by level. The lower nut is held with a wrench and the pin is rotated by the square. When finished, tighten the top nut.

It is important to check all supports in 3d. The surface is formed by 3 points, the 4th may, unnoticed, remain underloaded and show itself later

Vibration supports 30m, 70, vertical action. They do not compensate for the slope of the floor; the device appears to slip from the installation site under the influence of mechanical vibrations.

The presence and adjustment of rubber dampers may not give the required result in terms of cleanliness of processing, if the reason is in the middle of the equipment itself. Runouts of the lathe chuck, very high backlash in the rotation units, wear of the rubbing surfaces of the gears must be removed by repair.

If you find an error, please select a piece of text and press Ctrl+Enter.

Standard rubber-metal vibration mounts

Vibration bearing material: natural rubber, neoprene, silicone and other materials based on natural rubber intended for use in aggressive environments. Material hardness 55 Shore (other hardness of vibration mounts available on request).

The material of the studs and support plates of the vibration mounts is galvanized steel, or can be made of stainless steel. Vibration mounts are used for vibration isolation of industrial equipment (machine tools, fans, refrigeration equipment, etc.).

Versions of rubber-metal vibration supports: with two studs on both sides, with a stud and a threaded hole, with two threaded holes, with a stud on one side and with a threaded hole on one side of the support. The diameter of vibration isolators is from 6 to 200 mm, height is from 7 to 100 mm.

In addition to standard sizes, it is possible to manufacture vibration isolators of any configuration.

Vibration mount data order type – 20.15 B

The first parameter is the type of vibration support - A, B, C, D, E

The second parameter is diameter (20)

The third parameter is height (15)

Vibration support 30.20D – 196 rub. as of January 2014 (background information)

Vibration support 200.100D – RUB 5,594. as of January 2014 (background information)

Vibration support 40.40A – 338 rub. as of March 2014 (background information)

Specifications

Show

NameD, mmH, mmLoad, NM, mmh, mm...Price, rub.

| Products / Machine tools, machine equipment / Vibration mounts and wedge supports Vibration mounts for machine tools, fans, pumps and other industrial equipment are designed to prevent the spread of vibrations from operating equipment and machinery to the load-bearing structures of the building. The most common of them are vibration mounts OV-31 and OV-70, rubber-metal vibration mounts. Vibration supports (or vibration dampers) perform the function of a damping element that absorbs the resulting mechanical vibrations. Vibration supports OV 70 and OV 31 have proven themselves and are widely used in all industrial enterprises where they are needed, and their low cost is an additional argument for their use. Vibration support series OV available. Vibration support OV-31M, OV-70 is used as active and passive vibration isolation of metal-cutting machines and other industrial equipment. Anti-vibration mounts are easy to install and do not require additional maintenance. No foundation preparation is required during installation. The characteristics of vibration-isolating supports are stable over a long service life. |

Silentflex - vibration supports, shock absorbers, vibration isolators, dampers

Silentflex offers a wide range of vibration mounts, dampers, shock absorbers and vibration isolators for use in industry, transport, energy, construction, and electronics. The company was founded in 1989 in the north of Spain in Bilbao and began its activities as a distributor of various anti-vibration products. In 2006, we launched our own production, which is how the now well-known Silentflex® brand of anti-vibration products appeared, which combines the best characteristics of modern vibration supports and the company’s own innovative developments.

Silentflex is one of the most experienced companies in its field, with over 30 years of experience in dealing with noise, vibration and shock, ensuring the best quality on the market. Silentflex produces all types of vibration supports: all-metal, rubber-metal, elastic joints, floating floors, etc. Silentflex is an international company that does business in countries around the world, in the USA, China, Canada, Italy, Russia and ships ordered products as quickly as possible, providing a complete guarantee of safety.

Official website of Silentflex (Spain) - www.silentflex.ru

INCOL is Silentflex's partner in Russia. Delivery times and product prices are specified upon request.

Silentflex products:

All-metal vibration mounts

| Vibration supports for a machine with height adjustment Height-adjustable machine vibration mounts, or anti-vibration feet, are the most sought-after vibration isolators in the industrial market. They not only help isolate any vibrations caused by the operation of industrial machines, but also allow you to easily adjust the height of production equipment thanks to a special nut for ease of work. Static load: 25 - 7000 kg Resonance frequency: 15 Hz Detailed description |

| All metal pad The Silentflex® all-metal pad is made from stainless steel reinforcing wire, evenly distributed and highly compressed to obtain the specific geometric shape, required size and maximum vibration isolation properties according to your order. Static load: 0.01 - 3000 kg Resonance frequency: 10 - 35 Hz Detailed description |

| Shockproof cable shock absorber Anti-shock cable shock absorber refers to all-metal anti-vibration mounts. It is made of stainless steel cable, which is wound on strips made of light alloy. Great for equipment up to 400 rpm, fans, compressors, pumps, motors, telecommunication racks, electronic and electrical equipment on board trains, ships, aircraft, etc. Static load: 5 - 1000 kg Resonance frequency: 7 - 15 Hz Detailed description |

| Vibration supports for server cabinets, racks and data centers Silentflex® vibration mounts for server cabinets, telecom racks and data centers are specifically designed to absorb vibration and shock in information and telecommunications equipment typically located in data centers. The effectiveness of vibration isolation is achieved due to a durable elastic anti-vibration spring, inside of which there is a stainless steel damping all-metal pad. Static load: 100 - 1000 kg Resonance frequency: 4.5 Hz Detailed description |

| Axial stainless steel vibration isolator Axial Inox The axial stainless steel vibration isolator Axial Inox Silentflex® is an all-metal damper capable of isolating vibration in a wide range of industrial and on-board equipment. The elastic element of the all-metal vibration mounts of the Axial Inox series is made of 100% stainless steel wire. Static load: 300 - 1950 kg Resonance frequency: 15 - 20 Hz Detailed description |

| Vibration mounts 954201 Equal frequency vibration mounts of the 954201 Silentflex® series are capable of both compression and tension, and consist exclusively of metal elements that are resistant to oxidation, aggressive environments and extreme temperatures (from - 70 °C to + 300 °C). The damping element is a stainless metal pad AISI 304. The bowl, axle and base are made of machined steel. Static load: 50 - 900 kg Resonance frequency: 18 - 25 Hz Detailed description |

| Vibration supports 954202-954203 Series 954202-954203 Silentflex® vibration mounts consist of a top plate, a base with four mounting holes and a threaded rod. The damper is made of cast iron with a special high-strength protective layer of paint applied, which prevents the negative effects of aggressive environments. Static load: 50 - 7000 kg Resonance frequency: 11 - 22 Hz Detailed description |

| Vibration mounts S402 The S402 Silentflex® vibration mounts consist of a cast stainless steel top bowl and base and an aluminum alloy central shaft, making the vibration isolator particularly strong and reliable. All steel elements of the damper are coated with a special durable protective layer of paint. The elastic element is represented by an anti-vibration metal pad made of 100% stainless steel. Static load: 30 - 700 kg Resonant frequency: 15 - 20 Hz Detailed description |

| Vibration mounts S120 – S125 All-metal vibration mounts of the S120 - S125 series are flat vibration isolators that work in compression and can withstand very high dynamic loads. They consist of a top and a base made of steel, and the elastic element inside the support is a metal pad made of stainless steel reinforcing wire (AISI 304). Anti-vibration supports can be attached directly to the floor. Static load: 120 - 7000 kg Resonance frequency: 13 - 20 Hz Detailed description |

| Vibration mounts 954412 Vibration mounts 954412 Silentflex® consist of an upper body and a base made of steel and coated with a protective layer of paint. Inside there is a central aluminum axis and an elastic element in the form of a metal pad made of stainless steel wire. This shock absorber can withstand the same loads in both compression and tension at a natural frequency of 15 - 20 Hz. Static load: 1000 - 3000 kg Resonance frequency: 15 - 20 Hz Detailed description |

| Vibration mounts for electronics and aviation Vibration mount for electronics and aviation Silentflex® is an all-metal stainless damper that works on compression and provides a gradual stop using a kind of buffer, represented by a metal pad made of stainless pressed steel reinforcing wire and a high-strength metal spring. Static load: 0.25 - 60 kg Resonance frequency: 6 - 12 Hz Detailed description |

| Spring vibration isolator The Silentflex® spring vibration isolator consists of one or more springs that form a single anti-vibration mechanism. Each elastic element is a high-strength metal spring, inside of which there is an all-metal cushion made of stainless steel wire. Static load: 25 - 7000 kg Resonance frequency: 15 Hz Detailed description |

| Double spring vibration isolator with amplitude limiter Silentflex® spring vibration isolator with double-acting vertical amplitude limiter Service life is equal to the service life of the damped machine. It is a low-frequency damper in the Z axis and has significant rigidity in the XY plane. This shock absorber works on compression. Static load: 80 - 1460 kg Resonance frequency: 7 - 9 Hz Detailed description |

| Anti-vibration support for the press The Silentflex® Anti-Vibration Press Mount is a low-frequency isolator that has excellent anti-vibration properties and is ideal for all types of industrial presses. Static load: 800 - 14000 kg Resonance frequency: 10 - 25 Hz Detailed description |

| Vibration mounts for transformer Silentflex® transformer vibration mounts are effective vibration isolators specifically designed for low, medium and high voltage static electrical machines. They demonstrate excellent shock-absorbing properties and are particularly reliable and durable Static load: 50 - 1120 kg Resonance frequency: 3 - 4 Hz Detailed description |

| Pipe shock absorber The VR-126 Silentflex® Pipe Absorber is a flexible vibration mount made from high strength insulating springs with a damping metal pad inside. Ideal for anti-vibration support of hot and cold pipes. Static load: 12 - 45 kg Resonant frequency: 5 - 7 Hz Detailed description |

| Shock absorber for exhaust pipes The S501 Silentflex® Exhaust Pipe Damper protects fragile components during transport and is also capable of isolating most of the vibrations that occur in on-board systems during operation of exhaust, drain and sewer pipes. The vibration damper is specially designed to support hot engine exhaust pipes. Widely used in shipbuilding, shipping and industrial sectors. Static load: 20 - 7000 kg Resonance frequency: 10 - 25 Hz Detailed description |

Rubber-metal vibration mounts

| Shock absorber for electronics The shock absorber for Flextronic electronics has a very small size and weight (about 6 cm and 10 g), two through mounting holes in the steel base and an upper threaded hole. The shock absorber is made of vulcanized NBR and NB rubber. Vibration mounts are specially designed to absorb vibration and soften shock in electronic equipment, computers, GPS navigation devices, radios, small engines, gyroscopes, etc. Ideal for both stationary equipment and sensitive on-board equipment of trucks, airplanes, trains, ships, special equipment and commercial vehicles. Static load: 10 - 224 kg Resonance frequency: 5 Hz Detailed description |

| Spherical damper for electronics Low-frequency spherical vibration mount for aviation electronics belongs to a series of rubber-metal vibration isolators. All metal parts of the damper are made of aluminum: both the oval base with two smooth through holes for mounting from below, and the top mount with one smooth through hole. The vibration support has a very small size (about 4 cm in length) and very light weight (about 6 g). The inside and bottom of the spherical rubber body is empty. Ideal for shock absorption of light equipment such as avionics and aircraft instruments, computers, fans, hard drives, medical instruments, compressors, pumps, etc. Static load: 1.9 - 7 kg Resonant frequency: 4 - 6 Hz Detailed description |

| Vibration isolator with square and oval base Axial vibration isolator with square and oval base Silentflex® is a vibration support consisting of a rubber ring attached to two metal frames in the shape of a truncated cone. The elastic element is rubber. Static load: 42 - 5000 kg Resonance frequency: 15 - 20 Hz Detailed description |

| Shock absorber type B The Type B tensile shock absorber is made of a cylindrical stainless steel spring, a galvanized material support, an acoustic elastomer, and one or two axial threaded rods, one or two hook rods, depending on the model. Type B shock absorbers are specially designed to insulate suspended ceilings, air conditioners and pipes and significantly reduce noise levels in rooms. Static load: 5 - 420 kg Resonance frequency: 3 - 5 Hz Detailed description |

| Toroidal damper Silentflex® toroidal dampers are rubber-metal vibration mounts with a frame made of galvanized steel to increase the wear resistance of the mount. Toroidal vibration isolators have a structural resistance corresponding to a constant acceleration of 10 g at maximum load. The stability of the fastening can be increased by tilting the support at an angle of 45° relative to the center of gravity of the insulated system. Static load: 1 - 28 kg Resonant frequency: ~ 9 Hz Detailed description |

| Shock absorber buffer The shock absorber buffer can be made of rubber and metal or only rubber. It is possible to select the type of rubber in accordance with the characteristics of the further operation of the buffer (for example, if resistance to chemicals and extreme temperatures is required). A shock absorber buffer is used to reduce noise levels and absorb large amounts of kinetic energy released during impacts, thereby reducing the stress and forces exerted on the equipment or structure that receives the impact. The buffer is also used as a vibration support for production equipment with or without height adjustment. Static load: 2 - 30,500 kg Resonant frequency: depends on model Detailed description |

| Shock absorber buffer empty The empty buffer shock absorber consists of two thick conical membranes united by a common axis and connected by a large base to create a kind of elastic washer. Static load: 0.1 - 3 kg Resonant frequency: 10 - 25 Hz Detailed description |

| Cylindrical rubber damper Silentflex® cylindrical rubber damper consists of a cylindrical rubber element to which metal plates, also cylindrical, are attached on both sides. If the anti-vibration mount is used as a stop, the metal plate is attached to only one side. Static load: 1 - 1100 kg Resonance frequency: 8 Hz Detailed description |

| High-strength vibration isolator type T The high-strength vibration isolator type T is a rubber-metal vibration support, available in a wide range of models. It is made in the form of a rubber ring, which can be either with or without internal reinforcement with a metal axis. Static load: 1 - 28 kg Resonance frequency: 9 Hz Detailed description |

| Axial rubber damper The Silentflex® axial rubber damper is made of special anti-vibration rubber attached to a metal frame in the shape of a truncated cone. The vibration mount limits axial movements by gradually stopping with a rubber buffer. The elastic element is made of high-strength rubber, resistant to oils, fuel and other aggressive substances. Static load: 40 - 135 kg Resonant frequency: 5 - 8 Hz Detailed description |

| Axial rubber damper BF The axial rubber damper BF, made of special anti-vibration rubber, is a vibration support consisting of a rubber ring attached to two metal frames in the shape of a truncated cone. The rubber buffer creates a gradual stopping effect, limiting axial movements. Fastening to the machine occurs using the upper threaded hole inside the central metal axis. The diamond-shaped base of the vibration support also has two holes for fastening to the floor. Static load: 80 - 114 kg Resonance frequency: 5 Hz Detailed description |

| Equal frequency vibration isolator The equal-frequency vibration isolator belongs to a series of rubber-metal vibration mounts. It is a standard, easily adjustable shock absorber for both equipment and surfaces (floors, walls). It consists of an upper frame with a smooth through or threaded hole (welded nut), a base with fastening using lugs and a rubber element. Static load: 4 - 3125 kg Resonance frequency: 2 - 8 Hz Detailed description |

| Anti-vibration support vertical Vertical anti-vibration support Silentflex® are vibration isolators that allow you to create an anti-vibration interface (from the English “interface” - connection, common boundary) between inclined and vertical planes. Static load: 2.5 - 35 kg Resonance frequency: 5 - 8 Hz Detailed description |

| Compression and tension vibration mounts Silentflex® compression/tension vibration mounts for airborne systems are composed of anti-vibration elastomer for highly effective shock absorption and work in both compression and tension. The frame, washer and vibration support axis are made of steel. Vibration mounts are used to protect electronic, navigation and measuring instruments, vehicle generator sets and on-board control panels from vibration and shock. Static load: 10 - 70 kg Resonance frequency: 15 - 25 Hz Detailed description |

| Sandwich type vibration supports Sandwich vibration mounts are created by layering one or more layers of elastomer and thin metal strips on top of each other. All of them are contained between two metal bases. Sandwich vibration mounts can have different thicknesses, rigidity and number of layers of metal and rubber, and can also be manufactured for different load ranges and frequencies. Static load: 2500 - 25,000 kg Resonance frequency: 10 Hz Detailed description |

| Vibration mounts FLEXAMOR FLEXAMOR vibration mounts are made of a durable vulcanized natural rubber layer on the outside and steel layers on the inside, which give high strength to the entire small structure. FLEXAMOR vibration mounts have many applications, especially in industrial applications. They are used to insulate motors, ventilation equipment, generators, presses, cutting equipment, etc. Static load: to order Resonant frequency: to order Detailed description |

Elastic connections

| Elastic sleeve An elastic bushing (the most widely used type of vibration mounts and shock absorbers) is an elastic joint made of a high-strength elastomeric material sandwiched between two cylindrical metal bushings. Used in place of lubricated metal bearings when it is necessary to reduce vibration, friction and noise in mechanical joints. Resonant frequency: 8 Hz Inner diameter: 6 - 136 mm Outer diameter: 16 - 230 mm Load capacity: axial, radial, conical (torsion) Detailed description |

Floating floor

| Anti-vibration floating floor The Silentflex® anti-vibration floating floor is a patented technology that is a concrete floating floor with durable and high-strength metal containers that allow you to adjust the height of the floor and withstand the loads thanks to the springs located inside them, filled with all-metal stainless steel cushions. Our anti-vibration flooring can be installed easily and quickly on any surface that requires insulation and can be adjusted to any load using special lifting screws. Resonance frequency: 1- 4.5 Hz Noise isolation: 55 dB Detailed description |

Other

| VIBRALOCK wedge washers Vibralock wedge washers do not become loose due to vibration because they are a bolt-on system that uses advanced technology to provide a more secure locking system. Vibralock wedge locking washers prevent self-loosening by locking the bolted connection using tension rather than friction, in accordance with DIN 25201. Unlike traditional locking methods, Vibralock locking technology applies a pre-tightening force to the connection. Size: M3 - M130 Inner diameter: 3.4 - 133.4 mm Outer diameter: 7 - 178 mm Detailed description |

Rubber-metal supports

They are intended to protect devices from active (which occurs in the nodes and spreads to surrounding objects) and passive (which comes from outside) vibration

It allows you to replace the machine with another one with a different type of frame, move it, and reduces costs when preparing the workshop. It allows you to use space ergonomically. The reduced level of vibration, which is transmitted through the floors, makes it possible to work in the workshop without the strong influence of noise on other rooms in the building.

They are intended for machine tools with normal or increased accuracy characteristics, TU2−024−5997−87.

In the absence of strong aggressive influences on the rubber, the supporting part will not require inspection and regular maintenance, and will also retain all its performance characteristics.

Design

The constituent parts are:

- Rubber-metal shock absorber (flange and rubber element).

- Washer - 2 pieces.

- Bottom and top nuts.

- Lid.

- Hairpin with a square turnkey.

All parts made of metal have an anti-corrosion coating.

For rubber, the operating conditions are the same as for production facilities in which people constantly work. Temperatures above 60 degrees have a destructive effect on elastic parts. Rubber cracking under stress can be caused by freezing.

Criterias of choice

Technical data sheets indicate the exact maximum and minimum load numbers

The weight of metalworking equipment must be distributed over the number of points of one model - OV-70, or choose a more powerful one - OV-31-M. These models also differ in the height of adjustment.

Purpose of adjustment

The length of the thread on the stud is not intended to equalize sudden changes in the floor level in the room where the equipment is located. Its purpose is to set the uniform distribution of the weight of the equipment on the base by adjusting the fit of the nut.

The following conditions are considered the most optimal:

- Uniform fit and equal compression of all pads made of rubber.

- Maximum nut passage and minimum distance from the frame to the vibration support cover.

To eliminate the critical influence of resonance, the machine is lowered along the stud as low as possible.

At some moments, several sources of vibrations located in the same room may coincide in frequency. The OV-70 and OV-31-M devices are low-resonance. They do not allow large amplitude movement of the frame.

Structural components of vibration support

Due to the fact that the most common type of vibration supports are rubber-metal, it makes sense to identify its main working elements:

- Shock absorber made on the basis of metal and rubber (rubber element plus flange);

- Two washers;

- Nuts – upper and lower;

- Tire;

- Hairpin with a square hole for a key.

As a rule, all parts made of metal have an anti-corrosion coating. The operating conditions for these products are the same as for industrial premises in which people work. However, it should be noted that rubber parts are adversely affected by exposure to high temperatures - from +60 degrees Celsius. At the same time, they can crack when the ambient temperature drops sharply.

What you need to prepare - tools and materials

If your workshop has all of the above, then you can make a vibrating machine for making blocks:

- Welding machine. You can assemble a vibrator for shaking blocks with your own hands and using bolted joints, but welding is much faster.

- Grinder with cutting and grinding wheels.

- Drill and drill bits of required sizes.

- Bolts, nuts, washers and wrenches for them.

- Tape measure and ruler for measuring and marking.

- Metal sheet - the lid for the vibrating table will be made from it. At home, you can also use a wooden one, but only for low-power devices, otherwise the vibration will very quickly loosen the fastenings.

- Metal corners or channels for the frame or tabletop edging, with a cross-section of 5-10 mm. Their number and length depend on the calculated dimensions of the table. Metal pipes are also suitable for a do-it-yourself vibrating table, but they are more difficult to process.

In the video, a vibration table assembled from scrap parts:

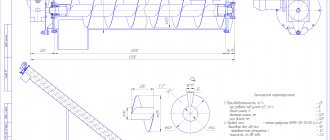

The main components and the materials required for them are as follows:

bed

It consists of four vertical supports connected at the top and, if necessary, reinforced with jumpers at the bottom. It must be heavy enough to support the entire structure, plus the weight of the molds with concrete. A factory or homemade vibrating machine is most often made from angles with a metal thickness of 5-10 mm.

Tabletop

This is a perfectly flat surface with edges curved up so that forms with concrete do not jump out of it during work. Depending on the size and weight of the blocks a vibrating table is needed, the thickness of the tabletop and the material from which it will be made are selected. Most often, a sheet of iron with a thickness of 3 mm or more is chosen for it. If you plan to work with large, heavy tiles, then the tabletop can be reinforced with metal corners along the perimeter and in the inside. Depending on the design chosen, a vibration motor may be attached to the tabletop.

Springs

Provide the necessary amplitude of movement of the tabletop relative to the fixed frame. If the weight of the table top is correctly calculated, they do not need any kind of fastening - they are simply installed in glasses specially fixed for them. Good vibration machines are obtained if springs from moped springs are used in the design. The length is selected in such a way that the tabletop can vibrate, but not sway from side to side.

Cups for fixing springs

They are made from scraps of metal pipe with dimensions slightly larger than the diameter of the springs. If the internal size is selected small, then the springs will be difficult to remove, for example, to replace the tabletop with a molding one. If the diameter is too large, the tabletop will “play” strongly under the influence of vibration and the weight of the building blocks and may simply fly off the frame. A good result is also obtained if the glasses are inside the springs.

Vibrating table without springs

Instead of steel springs, without compromising the quality of the structure, it is possible to use ropes, chains or tight strands. In this case, the tabletop is made slightly wider than the frame and is attached to it with a belt shock absorber. To do this, instead of glasses, guides are welded to the corners of the tabletop surface, connected by belts to the frame, as shown in the diagram.

Vibro block

Depending on the chosen design, the vibrating table may consist of one or two elements.

If a factory-made vibration motor is available, it is installed directly on the surface of the tabletop. Such an engine has a specific design - eccentrics are mounted on both sides of its shaft. They are made in the form of two semicircles, which can move relative to each other, thereby adjusting the strength of vibration. The factory vibration motor is specially designed to work in conditions of constant vibration, so placing it on a tabletop is not dangerous.

How to make your own machine and an example of its operation in the video:

All of these designs make it possible to obtain an acceptable result from the operation of the device - the choice between them is made based on what required material is available. The engine power of factory vibrating tables is in the range of 0.75-2.2 kW. For homemade ones, it is selected experimentally. The following diagram is approximate drawings of a homemade vibrating table, which you can use as a guide during manufacturing.

Purpose in production

The cause of vibrations in most cases is the operation of workshop equipment. Waves of various frequencies can be generated by the working fluid supply system, ventilation or power plants.

All this affects the operation of the equipment. This phenomenon is negative, so the task of the engineering department is to minimize it. A good solution in this matter would be to install compensation elements that will dampen vibrations, preventing their further spread and helping to get rid of vibrations. It is for such purposes that vibration supports are intended.

Why does vibration occur?

The cause of vibration can be microdefects in parts and moving elements, uneven weight distribution, and all kinds of distortions due to wear.

Any fan, like a ventilation unit, naturally has moving elements that, during operation, create noise and vibration in the system. The main drivers of vibration are the fan blades, the electric motor and the motion transmission shaft. When the fan is new and just installed, it creates little noise and operates quietly and without shaking. After a certain period, the parts of the equipment in use wear out and become bent, which leads to a redistribution of the mass of these parts and heterogeneity. In this case, it becomes clear that vibration effects occur at a fan blade speed of 1900 rpm.

As mentioned above, vibration is closely related to noise; moreover, in engineering systems it is vibration that is the structural component of noise and causes its occurrence in more than 60 percent

This confirms the importance of carrying out acoustic calculations in your projects.