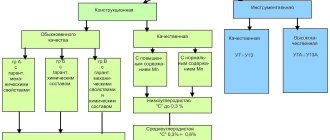

Steel 60 structural carbon steel

Substitutes

Foreign analogues

Decoding

The number 60 means that the average carbon content in steel is 0.60%.

Chemical composition, % (GOST 1050-88)

Chemical composition, % (GOST 1050-2013)

| steel grade | Mass fraction of elements, % | |||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | |

| no more | ||||||||

| 60 | 0,57-0,65 | 0,17-0,37 | 0,50-0,80 | 0,030 | 0,035 | 0,25 | 0,30 | 0,30 |

Characteristics and description

Steel 60 refers to structural unalloyed special quality steels with a high carbon content (0.60%) and normal manganese content, has high strength and high elastic properties.[1]

Steel is prone to cracks when quenched in water.

Purpose

Steel 60 is used for the manufacture of parts that require high strength and wear resistance, for example:

- Eccentrics,

- solid-rolled carriage wheels,

- tires for rolling stock of broad gauge railways,

- working rolls of sheet mills for hot rolling of metals,

- spindles,

- bandages,

- clutch discs,

- shock absorber spring rings,

- lock washers,

- adjusting washers,

- shims,

- work rolls of sheet mills for hot rolling of metal.

Temperature of critical points, °C [81]

Heat treatment

Small parts made of grade 60 steel (up to 10-12 mm in diameter) are hardened in oil at a temperature of 820-860 ° C, larger parts in water at a temperature of 800-820 ° C, tempering is carried out at different temperatures depending on the required mechanical properties.

Dependence of mechanical properties of steel 60 on tempering temperature

Hardness HB (GOST 1050-2013)

| steel grade | Hardness HB, no more | |||

| hot rolled and forged | calibrated and with special surface finishing | |||

| without heat treatment | after annealing or high tempering | hard-worked | after annealing or high tempering | |

| 60 | 255 | 229 | 269 | 229 |

Mechanical properties of metal products for steel 60 (GOST 1050-2013)

| steel grade | Mechanical properties, no less | |||

| Yield strength σ0.2, MPa | Tensile strength σв, MPa | Relative elongation δ5, % | Relative narrowing ψ, % | |

| 60 | 400 | 680 | 12 | 35 |

Rules of care

There are several rules:

- The metal surface after heat treatment is black. A layer of oxides is formed, which protects the tool from corrosion. You cannot remove blackening with grinding wheels “for beauty”. Only the working edge of the blade should shine after sharpening.

- Before long-term storage, the head is lubricated with oil. Experienced carpenters do not recommend using machine lubricants for this purpose. They use castor, linseed or vaseline oil. After lubrication, wipe the head - a thin film is enough to protect against rust.

- The tool should not lie on the ground, on a concrete floor or stand near a wall for a long time. The geometry of the ax is disrupted. That's why they hang him up. The wooden part is impregnated with oil so that the wood does not dry out.

How to sharpen an ax correctly

In production, cutting edge geometry is developed using a grinder. This is a belt sander. On an abrasive of this shape, a convex cutting edge is more easily formed.

- While working with an axe, it is enough to regularly adjust the cutting edge with a fine abrasive stone. The angle specified during sharpening in production is not violated.

- For universal axes, the sharpening angle is 20-30 degrees, for carpentry tools - 35 degrees. The steel is hard enough to hold an edge for a long time.

- If you need to restore the cutting edge and eliminate chips, use an electric sharpener. A grinder is not suitable for this purpose.

- It is very important to maintain the sharpening angle. They operate at low speeds to avoid beating of the blade and strong heating of the metal. As the temperature rises, the structure of the hardened steel changes and the blade loses its hardness.

- To cool, add water or take breaks from work.

Ax sharpening technology.

Sheet steel K60

Rolled thick sheet K60 TU 14-1-5474-2009 from low-alloy steel is used for the manufacture of electric-welded straight-seam gas pipes for operating pressures up to 9.8 MPa inclusive.

BMK STEEL LLC sells sheets of steel grade K60 from a warehouse in Chelyabinsk. Sheets are supplied from stock in thicknesses from 8 to 50 mm.

If you have specific requirements for metal products, send your application on letterhead. The company's specialists will respond in writing about delivery times, capabilities and prices for metal products.

If you have questions about purchasing K60 steel grade or its equivalent, you can contact us by phone +7. This email address is being protected from spambots. You must have JavaScript enabled to view it. .

Types of axes

Based on the shape of the head and ax head, axes are divided into universal and special. The universal ones include:

- Economic. A small ax with an almost symmetrical head.

- Army and tourist. Lightweight tools, the head and ax handle are often made from one piece of metal.

- Plotnitsky. Differs in sharpening angle for easy removal from dense wood.

- Russian. Can be used for woodworking and as a throwing weapon

Special axes are used to perform a certain type of work. Examples:

- A splitting splitter for splitting sawn logs along the grain. The head is massive and hardly sharpens.

- Myasnitsky with a short ax and a wide head.

- Lumberjack's axe. It has the longest ax handle, which increases the impact force.

- Firefighter. All-metal with a spike on the butt and heat-protective linings on the axe.

- Roofing. The butt has the shape of a hammer.

- Adze. Designed to remove layers of wood.

Main types of axes.

SHEET G/K K60

| NAME | PRICE | |||

| Hot-rolled sheet K60 8x2150x11800 mm | 63 000,00 | |||

| Hot-rolled sheet K60 10 x 2200 x 11800 mm | 63 000,00 | |||

| Hot-rolled sheet K60 12 x1876x11570 mm | 63 000,00 | |||

| Hot-rolled sheet K60 14 x1877x11700 mm | 63 000,00 | |||

| Hot-rolled sheet K60 16 x1575x12000 mm | 63 000,00 | |||

| Hot-rolled sheet K60 18 x2450x12000 mm | 63 000,00 | |||

| Hot-rolled sheet K60 20 x 2100 x 10500 mm | 63 000,00 | |||

| Hot-rolled sheet K60 24 x1550x8100 mm | 63 000,00 | |||

| Hot-rolled sheet K60 25 x2050x6200 mm | 63 000,00 | |||

| Hot-rolled sheet K60 30 x1800x8100 mm | 63 000,00 | |||

| Hot-rolled sheet K60 32 x 2200 x 6500 mm | 63 000,00 | |||

| Hot-rolled sheet K60 36 x2050x10700 mm | 63 000,00 | |||

| Hot-rolled sheet K60 40 x 2400 x 7800 mm | 63 000,00 | |||

| Hot-rolled sheet K60 45 x 2150 x 6000 mm | 63 000,00 | |||

| Hot-rolled sheet K60 50 x 2130 x 6500 mm | 63 000,00 | |||

Availability, sheet sizes, price please check with the sales department.

Available sheets:

thickness 8mm-18mm width 1500-2500mm length 4500-12000mm

Chemical composition in % of steel 60G and GOST standards for rental

The alloy of this grade has a relatively high carbon content, as well as manganese as the main alloying element:

- Fe – about 97%

- C – 0.57-0.65%

- Mn – 0.7-1%

- Si – 0.17-0.37%

- Ni – no more than 0.25%

- Cr – no more than 0.25%

- Cu – no more than 0.2%

- S – no more than 0.035%

- P – no more than 0.035%

60g steel enters the workshops of industrial enterprises in the form of shaped long products, manufactured in accordance with GOST standards:

- GOST 1051-73, 7417-75, 8559-75 and 8560-78 – calibrated rods

- GOST 14955-77, 7419.0-78 and 7419.8-78 – ground rods and silver

- GOST 1577-93 – thick sheets

- GOST 2283-79 – tapes

- GOST 4405-75 and 103-2006 – stripes

- GOST 1133-71 – forged blanks and forgings

Steel grade K60 interpretation:

K60 means steel with strength class K60; it includes the following steel grades: 10G2FBU 10G2FB 10G2SB 10G2SFB 08G1NFB 08G1NFB 09GNFB

Delivery of sheets 16D, 15HSND, 10HSND GOST 6713-91 by special transport:

Sheet K60 10mm, 12mm, 16mm, 20mm, 25mm, 32mm, 40mm, 45mm, 50mm delivery to Surgut:

Sheet K60 12mm, 14mm, 18mm in Omsk:

Sheet K60 12mm, 14mm, 18mm in Omsk:

Source

Application of steel 60g

The main area of application of low-alloy structural spring steel 60g is the industrial production of springs, springs and other spring-type products. The wear resistance and high elasticity of the alloy are used by technologists in the manufacture of parts such as brake drums, bushings, bandages, and brackets. In general, this alloy is used as a raw material by a variety of heavy engineering enterprises.

Manufacturers of cutting and piercing tools are also interested in the characteristics of 60g steel: knives, axes, cleavers - in such products, 60g alloy is most often used to form the core of the working part of the tool.

physical characteristics

| Temperature | E, GPa | G, GPa | r, kg/m3 | a, 10-6 1/°С | C, J/(kg °C) |

| 204 | 81 | 7810 | — | — | |

| 20 | 204 | — | 7810 | — | — |

| 100 | — | — | — | 116 | 483 |

| 200 | — | — | — | 119 | 483 |

| 300 | — | — | — | 129 | — |

| 400 | — | — | — | 129 | 487 |

| 600 | — | — | — | 138 | 529 |

| 800 | — | — | — | 146 | 575 |

Description of mechanical symbols

| Name | Description |

| Section | Section |

| sT|s0.2 | Yield strength or proportional limit with tolerance for permanent deformation - 0.2% |

| σB | Short-term strength limit |

| d5 | Elongation after break |

| d4 | Elongation after break |

| d10 | Elongation after break |

| y | Relative narrowing |

| H.R.C. | Rockwell hardness (diamond indenter, spheroconic) |

Mechanical properties of steel 60 depending on the section

| Section, mm | Sample cutting location | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (J/cm2) |

| Quenching 780-830 °C, oil. Vacation 560 °C | ||||||

| 30 30 | K C | 590 540 | 920 880 | 19 — | 50 — | 24 49 |

| Quenching 780-830 °C, oil. Vacation 610 °C | ||||||

| 10 30 60 60 | Ts K K Ts | 600 540 480 390 | 860 880 730 680 | 20 20 25 27 | 58 50 60 56 | 73 49 49 49 |

Description

Steel 60 G is used : for the manufacture of flat and round springs, springs, spring rings and other spring-type parts that require high elastic properties and wear resistance; tires, brake drums and bands, brackets, bushings and other parts of general and heavy engineering; knives of earth-moving machines (bulldozers, scrapers, graders and motor graders, as well as for knives of bulldozer and grader equipment of excavators, rollers and other earth-moving machines); measuring tapes.

Note

Alloy spring steel.

Mechanical characteristics

| Section, mm | holiday t, °C | sТ|s0.2, MPa | σB, MPa | d5, % | d4 | d10 | y, % | Brinell hardness, MPa | H.R.C. |

| Cold rolled strip 0.1-4.0 mm according to GOST 2283-79 in delivery condition | |||||||||

| 0.1-4 | — | — | 740-1180 | — | — | — | — | — | — |

| Sample with a cross section of 34.0x9.5 mm. Quenching in oil from 950 °C + Tempering | |||||||||

| — | 400 | ≥1460 | ≥1710 | ≥2 | — | — | ≥5 | ≥440 | — |

| Cold rolled strip 0.1-4.0 mm according to GOST 2283-79 in delivery condition | |||||||||

| 0.1-1.5 | — | — | ≤640 | — | ≥15 | — | — | — | — |

| Sample with a cross section of 34.0x9.5 mm. Quenching in oil from 950 °C + Tempering | |||||||||

| — | 500 | ≥1270 | ≥1460 | ≥4 | — | — | ≥10 | ≥420 | — |

| Cold rolled strip 0.1-4.0 mm according to GOST 2283-79 in delivery condition | |||||||||

| 1.5-4 | — | — | ≤740 | — | ≥10 | — | — | — | — |

| Sample with a cross section of 34.0x9.5 mm. Quenching in oil from 950 °C + Tempering | |||||||||

| — | 600 | ≥1120 | ≥1240 | ≥7 | — | — | ≥16 | ≥380 | — |

| Cold rolled strip 0.1-4.0 mm according to GOST 2283-79 in delivery condition | |||||||||

| 0.1-1.5 | — | — | ≤620 | — | ≥15 | — | — | — | — |

| Sample with a cross section of 34.0x9.5 mm. Quenching in oil from 950 °C + Tempering | |||||||||

| — | 700 | ≥980 | ≥1130 | ≥5 | — | — | ≥22 | ≥350 | — |

| Cold rolled strip 0.1-4.0 mm according to GOST 2283-79 in delivery condition | |||||||||

| 1.5-4 | — | — | ≤620 | — | ≥12 | — | — | — | — |

| Hot rolled sheet. Normalization | |||||||||

| 80 | — | ≥390 | — | ≥11 | — | — | ≥35 | ≥229 | — |

| Rolled sheets according to TU 14-1-4118-2004 | |||||||||

| — | — | 540-780 | — | ≥12 | ≥14 | — | — | — | |

| Long products. Quenching in water from 790-810 °C + Tempering at 360-400 °C, air cooling | |||||||||

| 20 | — | ≥1180 | ≥1370 | ≥5 | — | — | ≥10 | — | 42-47 |

| Long products. Quenching in water from 800-820 °C + Tempering at 530-600 °C, air cooling | |||||||||

| 40-60 | — | ≥640 | ≥830 | ≥9 | — | — | ≥37 | — | 30-35 |

| Long products. Steel categories: 3, 3A, 3B, 3B, 3G, 4, 4A, 4B. Quenching in oil from 830 °C + tempering at 470 °C | |||||||||

| — | ≥785 | ≥980 | ≥8 | — | — | ≥30 | — | — | |