Polymer structure

Polymers are made up of many monomers. They can exist in the form of several structures.

- Linear - links are connected in series (cellulose).

- Branched - the links are arranged randomly (starch).

- Reticular - linear molecules connected to each other (rubber).

Macromolecules can consist of both identical and different units.

- Homopolymers are a chain of identical monomers.

- Copolymers are a chain of different units.

Polymers are made up of structural units that are repeating groups of atoms. The number of units in high molecular weight compounds is determined by the degree of polymerization. In the formula (-CH2-)n, the degree is indicated by the letter “n”.

Peculiarities

The materials under consideration consist of monomers represented by repeating fragments of a structure of several atoms. They are connected into three-dimensional structures or chains of branched or linear shape due to polycondensation or polymerization. They are often clearly visible in the structure.

It should be said that the term "polymers" refers mainly to organic options, although inorganic compounds also exist.

The principle of naming the materials under consideration is to attach the prefix poly to the name of the monomer.

In addition to macromolecules, most polymers include other substances that serve to improve functional characteristics by modifying properties. They are presented:

- stabilizers (prevent aging reactions);

- fillers (inclusions of different phase states that serve to impart specific properties);

- plasticizers (increase frost resistance, reduce processing temperature and improve elasticity);

- lubricants (allows you to avoid sticking of metal elements of equipment used in processing);

- dyes (serve for decorative purposes and to create markings);

- flame retardants (reduce the flammability of some polymers);

- fungicides, antiseptics, insecticides (give antiseptic properties and resistance to insects and fungal mold).

In the natural environment, the materials in question are formed in organisms.

In addition, there are compounds close to polymers in structure, called oligomers. Their differences consist in a smaller number of units and a change in the initial properties when one or more of them is removed or added, while the parameters of the polymers are preserved. In addition, there is no clear opinion regarding the relationship between these compounds. Some consider oligomers to be low-molecular-weight variants of polymers, while others consider them to be a separate type of compound that is not high-molecular-weight.

Classification of polymers

In modern industry there are several dozen varieties of polymers that can be classified according to several criteria.

By origin

- Natural ones are found in natural conditions (cotton, linen).

- Synthetic polymers are produced using polymerization and polycondensation reactions (nylon).

- Artificial macromolecules are the result of modification of natural polymers (viscose is the result of transformation of cellulose).

By chemical composition

- Polyesters include the carboxyl group –COO (lavsan).

- Polyamide ones contain peptide bonds and the functional group –CO–NH2 (nylon).

- Organoelements include various elements from the periodic table D.I. Mendeleev (organosilicon polymers).

Borazon

Elbor, borazon, cyborite, kingsongite, cubonite are superhard inorganic polymers. Examples of their application: production of grinding wheels, abrasive materials, metal processing. These are chemically inert substances based on boron. Hardness is closer to that of other materials than diamonds. In particular, borazone leaves scratches on diamond, which also leaves scratches on borazone crystals.

However, these NPs have several advantages over natural diamonds: they have greater heat resistance (withstand temperatures up to 2000 °C, while diamond is destroyed at temperatures in the range of 700-800 °C) and high resistance to mechanical loads (they are not so fragile). Borazon was obtained at a temperature of 1350 °C and a pressure of 62,000 atmospheres by Robert Wentorf in 1957. Similar materials were obtained by Leningrad scientists in 1963.

Methods for producing polymers

Polymers can be obtained as a result of polymerization and polycondensation reactions.

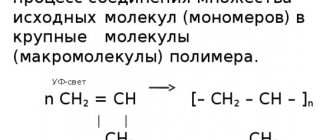

Polymerization

Polymerization is an addition reaction. This is a chain reaction consisting of three stages - initiation, growth and chain termination.

n CH2=CH2 + n CH3-CH=CH2→ [(-CH2-CH2-)x-(-CH2-CH(CH3)-)y]n

Sodium, peroxides, and complex compounds act as reaction catalysts. As a result of polymerization, important compounds are formed.

Polycondensation

Polycondensation is a displacement reaction that releases low molecular weight by-products. Polycondensation is a stepwise reaction. Polymers are formed by the sequential interaction of monomers, dimers or n-mers.

n C6H12O6→ (-C6H12O5-)n + n H2O

As a result of polycondensation, the most important high-molecular compounds are formed.

Main group trunk[edit]

Traditionally, the field of inorganic polymers has focused on materials in which the backbone consists solely of main group elements

Homocycle polymers

Homochain polymers have only one kind of atom in the main chain. One member is polymeric sulfur, which is reversibly formed upon melting of any of the cyclic allotropes such as S8. Organic polysulfides and polysulfanes contain short chains of sulfur atoms capped with alkyl and H, respectively. Elemental tellurium and the gray allotrope of elemental selenium are also polymers, although they cannot be recycled.

The gray allotrope of selenium consists of helical chains of Se atoms.

Polymer forms of group IV elements are well known. The main materials are polysilanes, similar to polyethylene and related organic polymers. They are more fragile than their organic counterparts and, due to their longer Si–Si bonds, carry larger substituents. Poly(dimethylsilane) is prepared by reduction of dimethyldichlorosilane. Pyrolysis of poly(dimethylsilane) produces SiC fibers.

To some extent, heavier analogues of polysilanes are also known. These include (R 2 Ge) n

and polystannans (R 2 Sn)

n

.

Based on Si

Heterochain polymers have more than one type of atom in the backbone. Typically, two types of atoms alternate along the main chain. Of great commercial interest are polysiloxanes, the main chain of which consists of Si and O centers: −Si − O − Si − O−. Each Si center has two substituents, usually methyl or phenyl. Examples include polydimethylsiloxane (PDMS, (Me 2 SiO) n

), polymethylhydrosiloxane (PMHS (MeSi(H)O)

n

) and polydiphenylsiloxane (Ph2SiO)

n

). Siloxanes include polysilazanes. These materials have the main chain formula -Si-N-Si-N-. One example is perhydridopolysilazane PHPS. Such materials are of academic interest.

P-based

A related family of well-studied inorganic polymers are polyphosphazenes. They have a -PNPN- line. Having two substituents on phosphorus, they are structurally similar to polysiloxanes. Such materials are prepared by ring-opening polymerization of hexachlorophosphazene followed by replacement of P-Cl groups with an alkoxide. Such materials find specialized applications as elastomers.

General structure of polyphosphazenes. Gray spheres represent any organic or inorganic group.

Based on S

Polythiazyls have the stem -SNSN-. Unlike most inorganic polymers, these materials have no substituents on the backbone atoms

Such materials have high electrical conductivity, a discovery that attracted much attention during the discovery of polyacetylene. It is superconducting below 0.26K

Ionomers

Generally, charge-neutral inorganic polymers do not include ionomers. Phosphorus-oxygen and boron-oxide polymers include polyphosphates and polyborates.

Physical properties of polymers

Polymers are characterized by two states: crystalline for stereoregular macromolecules and amorphous for high-molecular compounds with a random arrangement of units. All high molecular weight substances have the following properties.

- Low thermal conductivity (when a metal pan is heated, plastic handles do not melt).

- Flexibility (applying a polymer layer to metal plates).

- Rapid ignition (on an open fire, plastic quickly melts and releases toxins).

- Electrical insulating properties (socket plugs are made from high molecular weight compounds).

Based on their special thermal properties, high-molecular compounds are classified into two groups.

- Thermoplastics return to their original shape after exposure to high temperatures.

- Thermosetting materials are destroyed when heated.

All polymers are in liquid and solid aggregate states. They can be liquids (lubricants, varnishes, adhesives, paints), elastic materials (rubber, silicone, foam rubber) and hard plastics (polyethylene, polypropylene).

Polymer flooring materials

Now let's consider one of the options for the practical use of polymers, revealing the entire possible range of these materials. These substances are widely used in construction and repair and finishing work, in particular in floor coverings. The enormous popularity is explained by the characteristics of the substances in question: they are resistant to abrasion, have low thermal conductivity, have low water absorption, are quite durable and hard, and have high paint and varnish qualities. The production of polymer materials can be divided into three groups: linoleum (rolled), tile products and mixtures for creating seamless floors. Now let's briefly look at each of them.

Linoleums are made on the basis of different types of fillers and polymers. They may also contain plasticizers, processing aids and pigments. Depending on the type of polymer material, there are polyester (glyphthalic), polyvinyl chloride, rubber, colloxylin and other coatings. In addition, according to their structure, they are divided into baseless and with a sound- and heat-insulating base, single-layer and multi-layer, with a smooth, fleecy and corrugated surface, as well as single- and multi-colored.

Tile materials made on the basis of polymer components have very low abrasion, chemical resistance and durability. Depending on the type of raw material, this type of polymer product is divided into coumaron-polyvinyl chloride, coumaron, polyvinyl chloride, rubber, phenolic, bitumen tiles, as well as particle boards and fiberboards.

Materials for seamless floors are the most convenient and hygienic to use, they are highly durable. These mixtures are usually divided into polymer cement, polymer concrete and polyvinyl acetate.

Chemical properties

The reactions of high molecular weight compounds are determined by the functional group. If the compound contains a hydroxyl group-OH, then the polymer undergoes the same reactions as alcohols. If the macromolecule contains a carboxyl group –COOH, then the polymer is characterized by the same reactions as carboxylic acids.

Reactivity increases in the presence of double bonds and functional groups. They also determine the ability of individual macromolecules to be cross-linked. Examples of cross-linking include vulcanization and the transfer of linear macromolecules of thermosetting polymers into network structures.

Main group trunk

Traditionally, the field of inorganic polymers has focused on materials in which the backbone consists solely of main group elements.

Homochain polymers

Homochain polymers have only one kind of atom in the main chain. One member is polymeric sulfur, which is reversibly formed upon melting of any of the cyclic allotropes such as S8. Organic polysulfides and polysulfanes contain short chains of sulfur atoms capped with alkyl and H, respectively. Elemental tellurium and the gray allotrope of elemental selenium are also polymers, although they are not recyclable.

The gray allotrope of selenium consists of helical chains of Se atoms.

Polymer forms of group IV elements are well known. The main materials are polysilanes, similar to polyethylene and related organic polymers. They are more brittle than their organic counterparts and, due to their longer Si–Si bonds, contain larger substituents. Poly(dimethylsilane) is prepared by reduction of dimethyldichlorosilane. Pyrolysis of poly(dimethylsilane) produces SiC fibers.

To some extent, heavier analogues of polysilanes are also known. These include polygermanes (R 2 Ge) n

and polystannans (R 2 Sn)

n

.

Based on Si

Heterochain polymers have more than one type of atom in the backbone. Typically, two types of atoms alternate along the main chain. Of great commercial interest are polysiloxanes, the main chain of which consists of Si and O centers: -Si-O-Si-O-. Each Si center has two substituents, usually methyl or phenyl. Examples include polydimethylsiloxane (PDMS, (Me 2 SiO) n

), polymethylhydrosiloxane (PMHS (MeSi(H)O)

n

) and polydiphenylsiloxane (Ph2SiO)

n

). Siloxanes include polysilazanes. These materials have the main chain formula -Si-N-Si-N-. One example is perhydridopolysilazane PHPS. Such materials are of academic interest.

P based

A related family of well-studied inorganic polymers are polyphosphazenes. They have a -PNPN- line. Having two substituents on phosphorus, they are structurally similar to polysiloxanes. Such materials are formed by ring-opening polymerization of hexachlorophosphazene followed by replacement of P-Cl groups by an alkoxide. Such materials find specialized applications as elastomers.

General structure of polyphosphazenes. Gray spheres represent any organic or inorganic group.

S-based

Polythiazyls have the stem -SNSN-. Unlike most inorganic polymers, these materials have no substituents on the backbone atoms

Such materials have high electrical conductivity, a discovery that attracted much attention during the discovery of polyacetylene. It is superconducting below 0.26K.

Ionomers

Generally, charge-neutral inorganic polymers do not include ionomers. Phosphorus-oxygen and boron-oxide polymers include polyphosphates and polyborates.

Application of polymers

The first polymer materials appeared at the beginning of the twentieth century. Paints and films were produced by processing cellulose and oil refinery waste. Thanks to this discovery, cinema began to develop. Now children's toys, synthetic fabrics, rubberized shoe soles, sports equipment, computer equipment, etc. are made from plastic.

It is impossible to imagine civilization without polymers. Each of them is special and is used in many areas.

- Polyethylene – packaging, insulation of electrical wires, automotive parts, corrosion protection of oil pipelines.

- Polystyrene – toys, equipment parts, interior lining of car and airplane interiors, fittings, external electronics parts, dishes.

- Polyvinyl chloride – automobile parts, chemical industry equipment, artificial leather.

- Polycarbonate – parts for electronics and automobiles, materials for construction.

- Epoxy resin – decorative decorations, varnishes, glue, laminate.

- Polyester – lamps, masts, protective equipment, aircraft and machine bodies.

Space industry scientists have created flying rockets and satellites based on polypropylene. In laboratory tests, it turned out that the low mass of this raw material helps overcome the Earth’s gravity without much effort, and the plastic does not deform under large temperature changes in an aggressive environment.

Food industry

In the food industry, polymer materials are used for the manufacture of containers and packaging. May take the form of hard plastics or films. The main requirement is full compliance with sanitary and epidemiological standards. We cannot do without polymers in food engineering

Their use makes it possible to create surfaces with minimal adhesion, which is important when transporting grain and other bulk products. Anti-adhesive coatings are also needed in bread baking and semi-finished food production lines.

Polymers are used in various fields of human activity, which makes them highly in demand. It is impossible to do without them. Natural materials cannot provide a number of characteristics necessary to meet specific conditions of use.

The future of polymers

High molecular weight compounds are the future of humanity. But they can be not only useful, but also dangerous for people. At the moment, the world faces a problem with the disposal of plastic, which takes a long time to decompose and releases toxins. The inhabitants of the seas and oceans feed on garbage, which negatively affects nature.

Scientists are tackling the problem of discarded plastic by developing “smart high molecular weight compounds” that can change their structure and properties depending on the environment. Polymers are the object of research by scientists. The following developments are currently underway.

- Biodegradable films containing corn starch.

- Packaging that changes color depending on the shelf life of the product and decomposes without harm to nature.

- Eco-soil with hydrogel for dry areas of natural agriculture.

- Polymer liquids that change properties depending on the environment.

- Pharmaceutical packaging for delivering medicines directly to a diseased organ inside the human body.

Humanity can no longer develop without polymer products. Now the question is about its safety for the environment and the transition to a new level of interaction. It is impossible to give up plastic, but it is possible to reduce its consumption and switch to products made from natural materials.

Main characteristics

At the moment, there are many types of inorganic polymeric materials, both natural and artificial, which have different compositions, qualities, areas of use and state of aggregation.

The current level of development of the chemical industry makes it possible to produce inorganic polymer materials in significant volumes. In order to obtain a material of this kind, it is necessary to create conditions of very high pressure and high temperature. The raw material for manufacturing is a pure substance that is amenable to the polymerization process.

Inorganic polymer materials are characterized by the fact that they have very high strength, flexibility, are difficult to attack by chemical-based substances and are resistant to high temperatures. However, some types may be fragile and lack elasticity, but are very durable. The most popular of them are graphite, ceramics, asbestos, mineral glass, mica, quartz and diamond.

The most popular polymer materials are based on chains of elements such as silicon and aluminum. This is due to the popularity of such elements in nature, especially silicon. The most popular among them are inorganic polymer materials such as silicates and aluminosilicates.

Properties and characteristics vary not only depending on the chemical polymer composition, but also on molecular weight, degree of polymerization, atomic structure and polydispersity.

Most inorganic compounds differ by the following criteria:

- Plastic. A characteristic such as plasticity shows the ability of a material to become larger in size under the influence of an external force and return to its original state after the load is removed. For example, rubber can expand seven to eight times without changing its structure or causing any damage. Returning the shape and size is possible by maintaining the location of the polymer molecules in the composition; only some of their sections move.

- Crystal structure. The properties and specifics of the material depend on the spatial arrangement of the constituent components, which is called the crystal structure, and their mutual actions. Based on these parameters, polymer materials are divided into crystalline and amorphous.

Crystalline ones have a stable structure in which a certain arrangement of polymer molecules is carried out. Amorphous ones consist of short-range order polymer molecules, which have a stable structure only in some zones.

The structure and degree of crystallization depends on certain factors, such as the crystallization temperature, molecular weight and concentration of the polymer material solution.

- Glassiness. This property is distinctive for amorphous polymer materials, which, when the temperature decreases or the pressure increases, acquire a glassy structure. In this case, the thermal movement of polymer molecules ends. The temperature ranges at which the glass formation process occurs depends on the type of polymer material, its structure and the parameters of the structural components.

- Viscous flow state. This is a property in which irreversible changes in the shape and volume of a material occur under the influence of extraneous forces. In a viscous flowing state, structural parts move in a linear direction, which turns out to be the basis for changing its shape.

Structure of inorganic polymer materials

This property is extremely important in certain industrial sectors. It is most often used in the processing of thermoplastics using options such as injection molding, extrusion, vacuum forming and others.

In this case, the polymer material melts at very high temperatures and high pressure.

Popular message topics

- Peoples of the Volga region

Many different peoples live on the territory of our country. There are about 190 of them in total. There are large nations, such as Russians, Tatars, Chechens, and there are also very tiny ones, of which only a few hundred people remain. - Ussuri Nature Reserve

In the Primorsky Territory, not far from the city of Ussuriysk, the famous Ussuri Nature Reserve is located. Huge, diverse forests occupy a large area here, which are perfectly complemented by high mountains and rivers flowing nearby. - Money

Nowadays, people cannot imagine life without money. We are surrounded by many shops where we can buy everything we need for our existence. But it was not always so. Previously, people did not know what “money” was. How did they live? Everything is very simple:

Literature

- Vinogradova S. V., Vasnev V. A.

Polycondensation processes and polymers. : M.: MAIK “Nauka/Interperiodika”, 2000, 372 p. - Korshak V.V., Vinogradova S.V.

Equilibrium polycondensation. , M.: Nauka, 1968. - Korshak V.V., Vinogradova S.V.

Nonequilibrium polycondensation. , M.: Nauka, 1972. - Krivoshey V.N.

Containers made of polymer materials, M., 1990. - Makhlis F.A.

Fedyukin D.L., Terminological reference book on rubber, M., 1989. - Tager A. A.

Physico-chemistry of polymers, M.: Scientific world, 2007.; - Sheftel V. O.

Harmful substances in plastics, M., 1991. - Encyclopedia of Polymers, vol. 1 - 3, ch. ed. V. A. Kargin, M., 1972-1977.

Styrene

Synthesis

Polymer materials

Polymerization is the process of combining many small molecules, known as monomers, into a covalently linked chain or network. During the polymerization process, some chemical groups may be lost from each monomer. This occurs during the polymerization of PET polyester. The monomers are terephthalic acid (HOOC - C 6 H 4 - COOH) and ethylene glycol (HO - CH 2 - CH 2 - OH), but the repeating element is OC - C 6 H 4 - COO - CH 2 - CH 2 - O -, which corresponds to a combination of two monomers with the loss of two water molecules. The individual fragment of each monomer that is included in the polymer is known as a constituent unit.

Laboratory synthesis methods generally fall into two categories: step-down polymerization and chain polymerization. The significant difference between them is that in chain-growth polymerization, monomers are added to the chain only one at a time, for example, in polyethylene; whereas in step polymerization, the monomer chains can be connected to each other directly, for example in polyester. More modern methods, such as plasma polymerization, do not fit into either of these categories. Synthetic polymerization reactions can be carried out with or without a catalyst. Laboratory synthesis of biopolymers, especially proteins, is an area of intense research.

Notes

- V. A. Rabinovich, Z. Ya. Khavin.

Brief chemical reference book. - Leningrad branch: "CHEMISTRY", 1978. - 356 p. - Shulpin G.

These different polymers (Russian) // Science and life. - 1982. - No. 3. - P. 80-83. - ↑ Staudinger G. High-molecular organic compounds. Rubber and cellulose. Die hochmolekularen organischen Verbindugen, Kautschuk und Cellulose. lane from German, - Leningrad, ONTI, 1935

- Napalm. [www.xumuk.ru/encyklopedia/2/2747.html Concise chemical encyclopedia. Volume 3 (Maltase-Pyrolysis)] Ed. N. L. Knunyants. Directory in 5 volumes - M., “Soviet Encyclopedia”, 1967. p.360-361

- ↑

- ↑ Discovery. - 2022. - No. 5 (130). — P. 9.

OPERATING PRINCIPLE

Treatment of the test resin sample with a certain volume of one sodium chloride solution, previously neutralized to pH 7.0 ± 0.2. After stirring and decanting, measure the potential difference between glass and standard calomel electrodes immersed in the liquid phase of the mixture at (23 ± 2) ° C, and read this difference, expressed in pH units, directly on the pH meter scale. It is possible to measure the potential difference in millivolts with subsequent conversion into pH units. Before the measurement, the measuring system is calibrated and plotted daily.

DETERMINATION METHOD

Before all pH measurements of the aqueous extract are carried out, a control test is carried out with a sodium chloride solution. This solution can be used if its pH (determined by testing) is in the range of 6.8-7.2. Otherwise, neutralize the solution again, as indicated in point 3, and carry out control until the required results are obtained. If the pH value is in the range of 6.8-7.2, carry out the determination in accordance with the procedure described below. In the flask (point 4.4), pre-rinsed with a solution of sodium chloride (tested in the above manner), place the following substances: (10 ± 0.5) g of resin, (50 ± 2) ml of sodium chloride solution. The flask is stoppered and placed on a mechanical shaking device (p .4.5). Stir the contents for (60±5) minutes. Then hold the flask for 5-10 minutes so that the resin can separate (under or on the surface of the liquid). Then, using a pipette (section 4.2), transfer approximately 30-40 ml of the liquid located under or above the resin into a glass (section 4.3), pre-rinsed with sodium chloride solution. (If a large amount of foam forms, the liquid should be filtered before pipetting). The pH of an aqueous solution is measured at a temperature of (23±2) °C using a pH meter (clause 4.1). The determination is carried out in two stages. The measurement result is expressed in pH units with an accuracy of one tenth. If the results of these repeated determinations differ by more than 0.2 pH units, then further measurements are carried out until results are obtained that differ by no more than 0.2 pH units.