Pereosnastka.ru

Welding alloy and carbon hardenable steels

TO

category:

Metal welding

Welding alloy and carbon hardenable steels

Steels that are intensively hardened during welding with the formation of martensitic and intermediate structures include the following groups of steels: – structural low- and medium-alloy medium-carbon steels with a carbon content of up to 0.5%.

These steels are distinguished by high strength combined with satisfactory ductility due to complex alloying. These include pearlitic steels 35Kh, 40Kh, 35G2, 50G2, ZOKHGT, ZOKHGSA, 35KhGSNA and martensitic steels ZZKHZNVFMA, 30Kh2NMFA, etc.

; – heat-resistant and heat-resistant steels 15X5, 15Kh5MA, 15Kh5VF, 20KhZMVF, ZOKHMA, 38KhMYuA, 25Kh1M1F, etc.; – medium and high carbon steels 30, 35, 40, 45, 50, 60, 25G, 35G, 45G.

High-carbon steels are, as a rule, not used in welded structures. The need for their welding arises during surfacing and repair.

Characteristic general difficulties in welding these steels are: – formation of hardening structures during cooling after welding and, in connection with this, a tendency to cold cracks; – danger of hot cracks; – softening of the weld joint metal compared to the base metal.

Depending on the degree of alloying and carbon content, these steels are classified as satisfactory, limited, or poorly weldable steels (see Table 2).

The difficulty in welding these steels is the formation of hardening structures and cold cracks, therefore the main metallurgical and technological measures to ensure the quality of welded joints are based on eliminating this difficulty and are common to most of the steels under consideration.

Basic measures to ensure a high-quality welded joint. Pre-welding - when developing a technology, the main attention should be paid to the rational choice of materials: base and filler metal, protective equipment. The base metal with a reduced content of carbon and impurities (sulfur, phosphorus) has higher resistance to cold and hot cracks.

To increase the ductility of the weld and increase crack resistance, the carbon content in the filler metal should be less than 0.15%; It is advisable to provide a wider groove of the edges in order to ensure the formation of the weld mainly due to a more ductile filler metal. High technological strength of the weld is achieved by limiting the content of alloying elements in the filler wire to the following limits,%: 0.15 C; 0.5 Si; 1.5 MP; 1.5 Gr; 2.5 Ni; 0.5 V; 1.0 Mg; 0.5 Nb.

As protective agents, it is necessary to use coatings and fluxes of the basic type, as well as inert gases (for alloy steels). To reduce welding stresses, which are one of the causes of crack formation, it is necessary to avoid rigid nodes, clusters of seams, intersecting and closely spaced seams during design.

During welding, the following technological measures are provided: 1. Careful preparation and assembly for welding, minimal displacement of edges (less than 10-15% of thickness), minimal clearance, high-quality tack welding and edge cleaning;2. Regulation of the thermal cycle of welding to ensure the required cooling rate of the weld and heat-affected zone.

The cooling rate is regulated by changing welding modes (current value, welding speed, heat input), using special technological methods (welding in short and long sections, applying an annealing bead, welding in a slide, cascade, etc.) and using heating, which can be preliminary or accompanying and subsequent ones.

Heating is the most radical way to regulate the cooling rate and is used when regulation of welding modes and special technological methods fail to ensure the required cooling rate and structure of the welded joint. The higher the content of carbon and alloying elements, the higher the heating temperature.3.

Reducing the hydrogen content in the weld, since hydrogen is one of the main reasons for the formation of cold cracks.

This is achieved by using electrodes with calcium fluoride coatings and basic fluxes, protective gases with low humidity; welding on direct current of reverse polarity; thorough preparation for welding of the welded and filler metal (cleaning, dehydration) and protective materials (drying, calcination).

4. Rational sequence of sutures in order to reduce residual stresses and deformations.

After welding, to prevent cold cracks, high tempering is immediately performed to relieve residual stresses and stabilize the structure.

To ensure equal strength of the welded joint, after welding, a complete heat treatment of the product is carried out, which consists of hardening and subsequent high tempering or normalization.

If the dimensions of the product and the available equipment allow complete heat treatment, then the chemical composition of the weld metal should be close to the chemical composition of the base metal.

If complete heat treatment is not possible, then the problem of equal strength is solved by selecting welding modes and alloying through a filler wire.

When welding hardening steels, the main types of fusion welding are used - manual arc, submerged arc, shielding gas, electron beam, electroslag using welding materials that provide the specified strength and chemical composition of the weld.

Read more:

Welding of high alloy steels

Source: https://pereosnastka.ru/articles/svarka-legirovannykh-i-uglerodistykh-zakalivayushchikhsya-stalei

Choosing a method

For home use, when the product will not bear much responsibility, the simplest method is used - arc welding. After all, this is the cheapest method that does not require special preparation. To weld 40x steel, electrodes specially designed for this purpose are required. In industry, electric arc welding with argon is used for critical facilities. Despite the high cost, this is one of the most reliable methods that ensures a long service life of the structure. To make the process cheaper, you can use gas welding using acetylene. The result will be very similar, and in terms of creating ceiling and vertical seams, it will also be more convenient. Other types and methods of metal welding are used quite rarely.

Welding steel 40X with argon

Regardless of the method chosen, the surface should be carefully prepared before welding.”

Weldability of 40X steel and its properties

Metal does not weld well. If the process of melting and the formation of a weld pool occurs relatively normally, since only increased viscosity is manifested here, but the whole series of problems that arise on the seam after completion often lead to its unsuitability for use. Welding 40xn steel perfectly demonstrates its temper brittleness properties. During the welding itself, as well as after it, cracks and other defects, including deformations, may appear. This occurs due to sudden changes in temperature that are caused by an electric arc, which is especially noticeable when welding thin metal with an electrode. This also occurs when voltages are generated due to insufficient protection. Thus, additional steps are needed both before and after welding.

Welding steel 40X

Tool selection

There is exactly one criterion when choosing a welding wire or electrode material. Their metal should correspond as closely as possible to the composition of that used in the blanks. You just need to pay attention to the thickness so that it matches the thickness of the parts, since the welding depth should be maximum due to the difficulties in the flexibility of this grade of steel. A more important parameter is protection. Welding 40x steel semi-automatically must be supported by a shielding gas environment, and when manually welding, the electrodes must have a coating designed to work with this grade of steel. Electrodes of the E85 brand are suitable here, which have a reduced hydrogen content in the coating, and are also resistant to cracking when working with complex metals.

Modes

To improve the quality of the joint, you should use already proven parameters, which are calculated for each workpiece thickness and the corresponding weld position. This will greatly facilitate the work process.

Welding medium and high carbon steels

Medium carbon steel structures can be welded well if the welding rules and the following additional guidelines are strictly observed.

In butt, corner and T-joints, when assembling the elements being connected, the gaps provided by GOST should be maintained between the edges so that welding transverse shrinkage occurs more freely and does not cause crystallization cracks.

In addition, starting from a steel thickness of 5 mm or more, edges are cut in butt joints, and welding is carried out in several layers. The welding current is reduced.

Welding high carbon steel

Welding high-carbon steels of grades VSt6, 45, 50 and 60 and cast carbon steels with a carbon content of up to 0.7% is even more difficult. These steels are mainly used in castings and tool making.

Their welding is possible only with preliminary and concomitant heating to a temperature of 350-400 ° C and subsequent heat treatment in heating furnaces.

When welding, the rules for medium carbon steel must be followed; we will discuss this process below.

Welding technologies for high carbon steels

Good results are achieved when welding narrow beads and small areas with cooling of each layer. After welding is completed, heat treatment is required.

Steel grade 40X: characteristics, hardening, GOST standards and industrial use

Mechanical engineering, instrument making, machine tool building and other areas of industry in the production process use a huge amount of materials, both classical, known for decades and hundreds of years, and completely new, modern ones.

Steel is one of the classic and widely used materials.

The classification of steels by chemical composition provides for their division into alloyed (with the introduction of alloying elements that provide the alloy with the necessary mechanical and physical properties) and carbon.

Steel 40x is a structural alloy alloy. The word “structural” indicates that the material is used for the manufacture of various mechanisms, structures and parts used in mechanical engineering and construction, and has a certain set of chemical, physical and mechanical properties.

Chemical composition

The number 40 in the marking indicates that the percentage of carbon in the alloy ranges from 0.36 to 0.44, and the letter x indicates the presence of the alloying element chromium in an amount of no less than 0.8 and no more than 1.

1 percent. Alloying steel with chromium gives it the property of resistance to corrosion in an oxidizing environment and atmosphere. In other words, steel acquires stainless properties .

In addition, chromium determines the structure of the alloy, its technological and mechanical characteristics.

The remaining chemical elements are included in steel x 40 in the following quantities:

- no more than 97% iron;

- 0.5 - 0.8% manganese;

- 0.17 - 0.37% silicon;

- no more than 0.3% copper;

- no more than 0.3% nickel;

- no more than 0.035% phosphorus;

- no more than 0.035% sulfur.

physical characteristics

Almost all physical properties of metals depend directly or inversely on temperature . Indicators such as resistivity, coefficient of linear expansion and specific heat capacity increase with increasing temperature, while the density of steel, its modulus of elasticity and thermal conductivity, on the contrary, decrease with increasing temperature.

Another physical characteristic, called mass, does not depend on practically anything. The sample can be subjected to heat treatment, cooled, processed, given different shapes, and the mass will remain unchanged.

The physical characteristics of all known grades of domestic steels and alloys, including the grade described, are summarized in tables and placed in reference books on metal science.

Effect of heat treatment on quality

Steel in its original state is a fairly plastic mass and can be processed by deformation. It can be forged, stamped, rolled.

To change the mechanical properties and achieve the required qualities, heat treatment of the metal is used.

The essence of thermal or heat treatment is the use of a set of operations for heating, holding and cooling hard metal alloys.

As a result of such processing, the alloy changes its internal structure and acquires certain properties necessary for the manufacturer and consumer.

Critical points

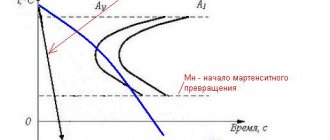

Critical points are temperatures at which the structure of steel and its phase state change. Calculated in 1868 by Russian metallurgist and inventor Dmitry Konstantinovich Chernov , which is why they are sometimes called Chernov points.

Such points are designated by the letter A. The lower point A1 corresponds to the temperature at which austenite turns into pearlite when cooled or pearlite into austenite when heated. Point A3 is the upper critical point, corresponding to the temperature at which ferrite begins to separate during cooling or its dissolution ends when heated.

Characteristics of high-strength steel made in Russia!

Steel is one of the most important materials that is used in almost all industries. Depending on the application, high-strength steel has different requirements. Steel grades differ in structure, chemical composition and in their properties (physical and mechanical).

Steel is a deformable alloy of iron with carbohydrate (no more than 2 percent) and admixtures of other elements: manganese, silicon, phosphorus. Special requirements are placed on high-strength fasteners. Therefore, to obtain steel that will ideally meet all characteristics, special impurities are added - alloying elements. These are chromium, tungsten, vanadium, titanium, manganese or silicon.

Regular quality carbon steel.

This type of steel is in greatest demand in construction. The reason for this popularity is manufacturability, durability and an attractive price. Another advantage of this alloy is the ability to make products from it that can withstand heavy loads and have good impact resistance.

Technology and features of steel welding

In modern industry, a wide variety of steel is used for welded structures.

It can be stainless or ordinary, high or low carbon, heat resistant and so on.

Various technologies are used for welding them, but the simplest is welding with a semi-automatic machine or inverter. In this article we will talk about the features of popular types of steel and how to weld them.

Welding tool steel

Tool steel is a type of steel containing less than 1% carbon. This steel is hard and durable, but not wear-resistant, so it is used only in the manufacture of tools. In addition, it has a low purchase price, which makes production profitable.

It is recommended to weld tool steel with a special electrode and using an inverter. Electrodes must be designed specifically to work with this type of steel. We recommend UONI-13/NZh/20X13 rods and a mid-price welding inverter. Be prepared for the fact that welding tool steel will require a lot of effort and patience from you. This is due to the low carbon content.

Welding structural steel

Structural steel is used much more often than tool steel. Everything is made from it: from small parts to factory machines. It is this category that includes welding of 40x steel, 30xgsa steel, 35xgsa steel and other other grades.

What is structural steel? This is a very interesting metal in composition. It consists of various impurities, in particular phosphorus and sulfur. The more of these components there are in the composition, the more unreliable the steel will be, so you need to monitor this indicator. Structural steel can be ordinary, high-quality, high-quality and especially high-quality.

As you understand, the latter type of structural steel contains a minimum of impurities, due to which it is possible to obtain truly high-quality and durable metal.

Well, ordinary structural steel contains the most impurities; it is considered the most short-lived.

By the way, this classification also has separate subgroups (they differ in the presence of some additional chemical components). But we will not describe the classification in detail so as not to confuse you.

Tempering of hardened metal

Tempering of metal is the final stage of heating, used to reduce hardness, reduce brittleness and eliminate internal stresses. The technology involves heating the metal to a certain temperature and then cooling it. It can take place both in the open air and in various liquids (oil and molten media).

The phase states and structures of metals directly depend on heating temperatures. The higher it is, the lower the hardness and brittleness, but the higher the viscosity and flexibility.

Three types of tempering of metal during heating are actively used. The maximum heating temperatures are different.

- Low vacation. The maximum heating temperature is 300 °C. At this tempering temperature, materials with the highest possible hardness are obtained. At the same time, internal stresses are reduced and the viscosity of wear-resistant steels increases.

- Average vacation. The maximum heating temperature is +450°C. It is used for heating metal parts and products to obtain increased elasticity and strength. The viscosity remains at a certain specified level. Using this technology, spring and spring steels are produced. Cooling is usually done outdoors.

- High holiday. It is carried out in the temperature range from 450 to 650 °C. After such a vacation:

- hot metal becomes ductile;

the relative elongation and contraction of the workpiece or product increases;

- internal stresses are reduced by 95%.

Image No. 1: the influence of tempering temperature on the mechanical properties of metals and alloys

Steel 40X: characteristics, application, hardness and weldability of steel 40X

Steel grade: 40Х (substitutes 45Х, 38ХА, 40ХН, 40ХС, 40ХФ, 40ХР).

Class: alloy structural steel.

Industrial use: axles, shafts, pinion shafts, plungers, rods, crankshafts, camshafts, rings, spindles, mandrels, racks, sponge rings, bolts, axle shafts, bushings and other high-strength upgradeable parts.

Hardness: HB 10 -1 = 217 MPa

Weldability of the material: difficult to weld. Welding methods: RDS, ESW, heating and subsequent heat treatment are required. KTS - subsequent heat treatment is required.

Forging temperature, oC: beginning 1250, end 800. Sections up to 350 mm are cooled in air.

Flock sensitivity: sensitive.

Tendency to temper brittleness: prone.

Type of delivery:

- Long products, including shaped steel: GOST 4543-71, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006, GOST 10702-78.

- Calibrated rod GOST 7417-75, GOST 8559-75, GOST 8560-78, GOST 1051-73.

- Polished rod and silver GOST 14955-77.

- Thick sheet GOST 1577-93, GOST 19903-74.

- Strip GOST 103-2006, GOST 1577-93, GOST 82-70.

- Forgings GOST 8479-70.

- Pipes GOST 8731-74, GOST 8733-74, GOST 13663-86.

| Foreign analogues of steel grade 45 | |

| USA | 5135, 5140, 5140H, 5140RH, G51350, G51400, H51350, H51400 |

| Germany | 1.7034, 1.7035, 1.7045, 37Cr4, 41Cr4, 41CrS4, 42Cr4 |

| Japan | SCr435, SCr435H, SCr440, SCr440H |

| France | 37Cr4, 38C4, 38C4FF, 41Cr4, 42C4, 42C4TS |

| England | 37Cr4, 41Cr4, 530A36, 530A40, 530H36, 530H40, 530M40 |

| European Union | 37Cr4, 37Cr4KD, 41Cr4, 41Cr4KD, 41CrS4 |

| Italy | 36CrMn4, 36CrMn5, 37Cr4, 38Cr4KB, 38CrMn4KB, 41Cr4, 41Cr4KB |

| Belgium | 37Cr4, 41Cr4, 45C4 |

| Spain | 37Cr4, 38Cr4, 38Cr4DF, 41Cr4, 41Cr4DF, 42Cr4, F.1201, F.1202, F.1210, F.1211 |

| China | 35Cr, 38CrA, 40Cr, 40CrA, 40CrH, 45Cr, 45CrH, ML38CrA, ML40Cr |

| Sweden | 2245 |

| Bulgaria | 37Cr4, 40Ch, 41Cr4 |

| Hungary | 37Cr4, 41Cr4, Cr2Z, Cr3Z |

| Poland | 38HA, 40H |

| Romania | 40Cr10, 40Cr10q |

| Czech | 14140 |

| Australia | 5132H, 5140 |

| South Korea | SCr435, SCr435H, SCr440, SCr440H |

Steel 40X and its characteristics

In our company you can order a variety of metal products used in everyday life, construction and industry. Its qualities, properties and characteristics depend on the material from which rolled metal is made.

We invite you to familiarize yourself with the various types of steel. For example, steel grade 40X, which belongs to the structural alloy class, is especially popular. In this section you will learn more about this material.

If you have questions about products or want to place an order, then call our specialists! Company managers work around the clock.

This material contains 0.40 percent carbon and less than one and a half percent chromium.

This material is difficult to weld. You can weld using the manual arc method or the electroslag method, but first you need to preheat the steel and then perform heat treatment. Resistance spot welding also requires further heat treatment.

The hardness of steel 40X is as follows: HB 10 -1 = 217 MPa.

Substitutes for this material can be brands 45X, 38XA, 40XH, 40XC, 40ХФ, 40XP.

If you are going to forge this steel, then at the beginning of the process you need to heat it to 1,250 degrees Celsius, and at the end cool it to 800 degrees. If products with a cross-section of up to 350 millimeters were forged, they must be cooled in air.

You can find out more information from the tables located on the website.

Choosing a method

For home use, when the product will not bear much responsibility, the simplest method is used - arc welding. After all, this is the cheapest method that does not require special preparation. To weld 40x steel, electrodes specially designed for this purpose are required. In industry, electric arc welding with argon is used for critical facilities. Despite the high cost, this is one of the most reliable methods that ensures a long service life of the structure. To make the process cheaper, you can use gas welding using acetylene. The result will be very similar, and in terms of creating ceiling and vertical seams, it will also be more convenient. Other types and methods of metal welding are used quite rarely.

Welding steel 40X with argon

Regardless of the method chosen, the surface should be carefully prepared before welding.”

Weldability of 40X steel and its properties

Metal does not weld well. If the process of melting and the formation of a weld pool occurs relatively normally, since only increased viscosity is manifested here, but the whole series of problems that arise on the seam after completion often lead to its unsuitability for use. Welding 40xn steel perfectly demonstrates its temper brittleness properties. During the welding itself, as well as after it, cracks and other defects, including deformations, may appear. This occurs due to sudden changes in temperature that are caused by an electric arc, which is especially noticeable when welding thin metal with an electrode. This also occurs when voltages are generated due to insufficient protection. Thus, additional steps are needed both before and after welding.

Welding steel 40X

Tool selection

There is exactly one criterion when choosing a welding wire or electrode material. Their metal should correspond as closely as possible to the composition of that used in the blanks. You just need to pay attention to the thickness so that it matches the thickness of the parts, since the welding depth should be maximum due to the difficulties in the flexibility of this grade of steel. A more important parameter is protection. Welding 40x steel semi-automatically must be supported by a shielding gas environment, and when manually welding, the electrodes must have a coating designed to work with this grade of steel. Electrodes of the E85 brand are suitable here, which have a reduced hydrogen content in the coating, and are also resistant to cracking when working with complex metals.

Modes

To improve the quality of the joint, you should use already proven parameters, which are calculated for each workpiece thickness and the corresponding weld position. This will greatly facilitate the work process.