Any production related to metal cannot do without welding. However, traditional methods are not always cost-effective and applicable. For example, creating a strong connection between parts of large structures requires lengthy preparation, and in the field there are no power sources and gas welding equipment. An alternative in such cases is thermite welding.

Technology

When connecting parts, a special powder mixture is used as a consumable material, which includes elements such as aluminum, magnesium and iron oxides. These powders are called termites. When they burn, energy is released. This energy is enough to transform the edges of the parts being joined into a semi-liquid state. The metal is mixed with the mixture material and subsequent crystallization occurs.

To carry out the welding process, at the initial stage it is necessary to ignite the mixture. Its combustion temperature reaches 1350°C degrees. Several effective methods of arson have been developed. The specified temperature can be achieved by receiving an electric discharge, exploding a squib, or burning a special cord.

When thermite burns, the temperature inside the mixture rises to 2400-2700°C degrees. Most metals have a melting point below this value.

What is noteworthy about this technology is that combustion does not require the supply of atmospheric oxygen. There is enough oxidizing agent inside the mixture itself. If necessary, thermite welding can be carried out in an inert gas environment.

Sequence of work:

Preparatory stage

A significant role in how to weld a rail seam is played by preparation, which involves the following actions: near the joint, the rail fastenings must be loosened, and those located at the joint area must be completely removed. Next, using a burner, the rails are heated and also cleaned of rust. At the next stage, using wedges, they must be straightened both horizontally and vertically. The rails must be installed maintaining a gap of 2.5 mm, then a cutter is brought to them.

Alignment

Initially, you need to get rid of the gaskets of all fasteners, wedges are installed in their places, using a hammer they need to be adjusted to the required condition. Then you need to check how accurately the rails are laid; to do this, use a meter ruler.

Installation

At this stage, it is important to select the desired sealed form, then the burner must be placed in the middle in the area where the seam is expected to appear. You also need to seal the gaps; to do this, the mold must be pressed as tightly as possible against the seam; a spatula is also used here, which ensures a clean edge between the seam and the sand.

Heating and welding

Pre-heating of the rails is carried out with a burner at the following parameters: propane pressure – 1.5 bar, oxygen pressure – 5 bar. The flame is supplied for 1.5 - 2 minutes. When heating is complete, the burner is removed, the core is inserted and the crucible is turned. Then, at the site of the intended joint, a special barrel filled with charge is installed. In order to ignite the charge, a high-temperature fuse is used, then the liquid metal is placed in a mold and held for 4-5 minutes.

Sanding and quality control

At the end of the procedure, the joint is processed along the edges to a smooth state: while it is hot, the sagging is cut off.

Application

If aluminum powder is used as thermite, then the welding procedure involves fusing the ends of the parts. It is suitable for joining workpieces made of cast iron and other brittle alloys. In the railway transport industry, thermite welding is in demand when repairing or joining rails. GOST R 57181-2016 specifies all the requirements for the welding process. Thermite welding is used in mechanical engineering; it is indispensable in the production of propellers for marine transport or crankshafts for automobiles.

This type of welding has also found application in metalworking enterprises. It is often necessary to repair rolling mills, rotor shafts, various presses or buckets. All of the above are considered large equipment, so only one type of welding is possible. It must be emphasized that it is thanks to the combustion of thermite that high-quality connections of wires on power and communication lines are possible. In this case, compositions containing magnesium are used.

Kinds

There is a classification that distinguishes two types of thermite welding: muffle and crucible. They are used depending on the external conditions. Crucible welding is most often called aluminothermic welding and is used when connecting elements of grounding loops, as well as other metal structures that require repair by surfacing. Thermite contains aluminum powder and iron oxide. The approximate ratio of the proportion is 23 to 70. When the composition burns, scale is formed, which in molten form connects the parts.

An important advantage of aluminothermic welding is the ability to connect cast iron workpieces without noticeable joints. But aluminum parts are connected in a different way - muffle welding. Due to the evaporation of aluminum at high temperatures, magnesium is used as thermite in muffle welding. The molten composition is absorbed into the surfaces without spreading over them. But when working with aluminum, it is necessary to remove the oxide film. To do this, add a special flux.

There are four ways to conduct thermite welding.

- The first method is characterized by a butt connection. But first, the ends of the parts are processed and cleaned. To avoid deformation from uneven heating of the metal, the welded areas are wrapped in thermal insulation film. After the thermite burns, the resulting liquid metal, located in the crucible, is poured into the gap left between the workpieces. After this, the blanks are pressed against each other and joined.

- Intermediate casting is considered less expensive and technologically easier. Molten metal from the crucible is poured into the gap. In this case, the parts are not prepared in advance, which greatly simplifies the process.

- Combined welding is characterized by the fact that it combines the technology of butt connection and intermediate casting. It is usually used when welding rails. The ends of the workpieces are cleaned, and a metal plate is placed between them. After the alloy is poured, the rails are pressed against each other. If possible, the seam around the perimeter is re-welded.

- The duplex method involves subsequent compression of the workpieces after pouring the alloy.

Briefly about the history of development

For the first time, thermal welding was used to repair rails in 1915, and already 8 years later in the capital, all tram overpasses were repaired only by this method, using imported thermite. In 1925, Russian engineer Mikhail Aleksandrovich Karasev patented domestic thermite and organized its production in Moscow.

Thanks to domestic thermite, which was much better than imported options, the rails were welded to a higher quality, and the seam lasted much longer. As a result, over 100 thousand joints on tram tracks were restored.

In those distant times, repairs were carried out in two ways: by wedging and by a combined method. The first option quickly failed under constant load, so they abandoned it and began to use duplex - intermediate casting with pressing of molten metal.

The quality was constantly improving - the number of burst joints over 10 years of operation did not exceed 0.8%, so similar methods began to be used during the construction of the Moscow metro. The original technique began to be used for welding joints of high-pressure pipes, where alloy steel of special strength was used. Thermites were used to repair large diameter shafts and other large metal parts.

Compositions

As mentioned above, iron-aluminum thermite welding has become the most popular. The bulk of thermite is iron oxide. There is only 25% aluminum in the mixture, but additional components can be found in the composition. Flux, alloying additives and iron trimming are added. Thermite combustion and melting of the mixture occurs in a magnesite crucible. In addition to aluminum, it is possible to combine the following elements:

- Magnesium (31%) and iron oxide (69%).

- Calcium (43%) and iron oxide (57%).

- Titanium (31%) and iron oxide (69%).

- Silicon (21%) and iron oxide (79%).

Depending on the welding application, different types of mixtures are prepared. Iron dross and aluminum powder provide an elemental mixture. Proportions must be strictly observed. For connection and repair on the railway, a special rail train is created. During aluminothermic welding, a steel filler is introduced into the charge, which consists of ferromanganese and graphite chips. Alloy steels are joined using a special composition. It contains ferrotitanium or ferrovanadium additives.

Cast iron products, as a rule, have special requirements for welding. Thus, thermite for cast iron must contain silicon. If you follow the technology, you can get a fairly high-quality and durable connection. Manganese is not used in such additives.

How to make thermite yourself

To make your own thermite mixture, you will need rust and aluminum powder. You can get rust at home; if it is wet, you should dry it using a stove. Then you should turn your rust into powder and heat it in a metal vessel. Making thermite yourself requires little effort and expense. Aluminum powder (you can buy it or extract it yourself using a file from a whole piece of aluminum) must be added to the iron oxide. The proportion of rust to aluminum will be 8 to 3.

Aluminothermic rail welding

The entire procedure can be divided into separate stages. First, the total amount of heat released is calculated. It should be sufficient for the welding process. The optimal composition of the thermite mixture is selected. The mixture should be uniform in composition. Use any available method to ignite the mixture. It is necessary to reach a temperature of 1350°C degrees.

Subsequently, the temperature in the thermite mixture increases. Molten metal is obtained from thermite in 20-30 seconds. Its mass is approximately half the mass of the mixture. The remaining half is slag. The metal will settle at the bottom of the crucible, and the slag, due to its lower density, will float to the top.

The difficulty of repairing rails is that all work has to be done in the field. The rail welding machine is quite massive, but its use is the only opportunity to carry out repair work. The first step is to prepare the ends. They must be even, and the gap between them is 2-3 cm. The elements to be welded are aligned and fixed in one position. After installing the refractory mold, the welding itself takes place.

Every welder wants to get a high-quality result. Unlike manual arc welding, thermite welding requires precise calculations. It is necessary to correctly select the total amount of powder so that the resulting metal completely fills the gap. When preparing the mixture, it is important to thoroughly mix all the ingredients. The initial start of the process should occur at a temperature of 1400°C degrees. Lower values will not cause thermite fires.

Technological features

What is it: thermal welding is a method that uses powdered mixtures based on aluminum and iron scale, and other metal oxides are used instead of the first component. Thanks to a similar mixture, an instantaneous ignition reaction occurs at the welding site with the formation of a high temperature, and the molten components occupy free space in the joint - a single whole is obtained.

An intense flow with a temperature of 2.3-2.7 thousand degrees acts on the edges of parts in the same way as a welding arc, and an individual feature of this method is the independent ignition of the thermite cartridge due to the presence of oxygen molecules in the composition.

Important! As a result of thermite ignition, the edges of the parts melt, and the molten metal from it plays the role of an additive, filling the free space.

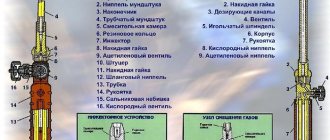

Equipment

Thermite welding technology seems elementary at first glance. However, it requires careful preparation and the availability of the necessary tools and equipment. Thermite is poured into a crucible; it must be made of a refractory material, for example, ceramic. The crucible is equipped with a special device that allows you to drain the molten metal.

To ensure that the casting turns out neat and fits the free space, matrices and molds are made. In some cases they can be reused, but often the forms are disposable. A special clay coating will not allow the metal to spread over the surface.

An important point in thermite welding is to ensure the immobility of the workpieces and their fixation. It is carried out using various devices and devices, which include a vice or clamps. The tool for surface treatment depends on the type of metal and the degree of its contamination. Usually they work with an abrasive wheel or a wire brush.

Additional work may be required after thermite welding. The welder's arsenal must include an oxygen torch, a torch and a hacksaw for metal.

The process in practice

The technology for welding railway rails is as follows:

- The two ends of the rails are aligned equally vertically and horizontally with their ends opposite each other. A gap of 25 mm is left between them for filling. To do this, a special plate of appropriate thickness is inserted.

- Both sides are clamped with small grips or clamps.

- The junction is lined with fireproof plates to direct the hot flow exactly between the rails. Small gaps between the mold and the metal are covered with paste.

- A crucible is installed on the mold - a small container with thermite powder. Or a funnel-like watering can is placed on top of which a store-bought barrel with the mixture is placed.

- The thermite is ignited with a ignition pencil through the top hole in the barrel or crucible.

- Burning lasts about 30 seconds. The increasing temperature melts the bottom plug and the mixture flows into the mold. The latter is filled in and a connection is created. High temperature promotes good fusion of iron and base metal. The slag flows onto the ground or into special pockets of the device.

- After the end of combustion, the pockets, crucible and mold are removed.

- The connection is crimped with a press to ensure complete formation. The product remains in this state for about 5 minutes.

- The slag deposits are broken off by tapping with a hammer.

- The seam on the rails is sanded on the working sides so that there are no protrusions in the area. The surface not touched by the train wheels is left without sanding.

https://www.youtube.com/watch?v=kuydZx-ckTs

Advantages and disadvantages of the method

Using thermite welding, it is possible to weld ferrous and non-ferrous metals without the use of expensive equipment. Compared to other welding methods, this technology is favorably distinguished by a number of qualities.

- Thermite welding is less time-consuming. If we take into account the massiveness of the parts being welded, this benefit is sometimes decisive.

- The quality of the seams reaches a high degree, since partial penetration of the metal of the workpieces occurs. In addition, the seam is quite aesthetic and neat.

- It should also be noted that the work is relatively low in labor intensity.

- A certain skill is required from the welder, but it rather concerns the preparatory stage and preparation of the mixture. The welding process itself does not require special skills, unlike electrode welding.

- The availability and low cost of consumables will significantly save money and simplify the task.

- Welding equipment can be used away from populated areas.

At the same time, thermite welding installation is considered quite dangerous. Precautions must be taken when using it. It is important to remember that termites are considered flammable. Liquids must not be allowed to enter the mixture, as this may lead to an explosion.

Thermite welding has not become as widespread as arc welding, but in some cases it is irreplaceable. In small workshops, repairs are carried out using a thermite pencil. A novice master should first master this tool, and only then begin to study the real equipment.

SAFETY INSTRUCTIONS

3.1.

Work on welding wires using thermite cartridges must be carried out in accordance with the “Safety Rules for the Operation of Electrical Installations” (K.: Energy, I960), “Fire Safety Rules for Welding and Other Hot Work” and “Rules for the Use of Tools and Devices, used in the repair and installation of power equipment" (P.: Energy, 1973).

3.2.

Specially trained persons who are at least 18 years old and have a qualification group for electrical safety of at least III, and when performing work at heights - at least IV, may be allowed to work on welding wires using thermite cartridges. Persons who are authorized to carry out wire welding work must be issued a coupon insert of the established form or an entry must be made in the knowledge test certificate.

3.3.

To carry out work on welding wires, a permit must be issued in the prescribed form, and when working in existing electrical installations, in addition, a work order must be issued.

Welding of wires using thermite cartridges without written permission may be permitted on construction sites, overhead lines and in places that are not fire hazardous, only to highly qualified specialists. The list of specialists allowed to independently weld wires using thermite cartridges without obtaining written permission is announced by order of the head of the enterprise (facility).

3.4.

Knowledge of this Instruction must be tested at least once every two years.

3.5.

Electricians welding wires using thermite cartridges must be provided with special clothing, special footwear (leather shoes or boots; felt boots in winter) and a headgear (helmet). In this case, it is necessary to ensure that strands of hair do not fall out from under the headdress.

3.6.

When lighting a thermite match and igniting a thermite cartridge, you must be at least 0.5 m away from the ignited cartridge.

Do not lean over a burning thermite stick.

3.7.

When lighting matches and igniting a thermite bomb, you must wear safety glasses with a light filter (blue glasses or TIS-1 glasses). After the thermite stick ignites, lower the protective cover of the welding device.

3.8.

When welding near combustible structures and materials (wooden supports, scaffolding, etc.), it is necessary to take measures to clear the workplace of flammable materials. To prevent the possibility of a burning thermite match or checker coming into contact with combustible structures and materials, it is necessary to lay asbestos sheets, steel sheets, etc.

3.9.

Spare thermite cartridges should be kept in a work bag, separate from thermite matches. Thermite matches should be stored in their original packaging. It should be remembered that they are easily ignited by friction against one another. To prevent this, the matches in the original packaging are wrapped in waxed paper, which cannot be removed unnecessarily.

3.10.

To avoid burns, it is prohibited to touch or adjust the burning or cooling thermocartridge with your hand.

3.11.

Burnt thermite matches must be placed in a special steel box suspended near the work site, or on a previously prepared fireproof area.

3.12.

After the thermite block has cooled (to a dark color), the resulting slag should be knocked away from you onto a previously prepared area.

3.13.

The welding area must be fenced off or an observer must be placed. It is prohibited to pass under the welding site until the work is completed.

3.14.

Do not use damp thermite cartridges. Care must be taken not to allow water to come into contact with the burning thermite cartridge, as this may cause an explosion and burns.