Production process

Steel is produced by smelting. The raw materials are cast iron, scrap steel or cast iron itself, pellets, fluxes and ferroalloys.

Cast iron itself, by nature, is not a sufficiently hard and brittle material, and therefore has limited use.

However, it is indispensable as a raw material for steel production. The essence of smelting is, in the case of using pig iron, to reduce the percentage of carbon in it to the required level.

Impurities not included in the final formulation are removed. The traditional composition of the charge is 55% cast iron and 45% steel scrap (scrap). There is also an ore process where ore material is added to components or a scrap process to recycle waste from engineering production.

To make it easier for impurities and carbon to be removed from the components during the smelting process, they are converted into gases and slag. First of all, when cast iron reacts with oxygen, iron is oxidized, forming iron oxide FeO.

At the same time, C, Si, Mn and P are oxidized, and oxygen is released from iron oxide to chemically active impurities. Flux is added to the charge mass to better dissolve the metal: limestone or lime, bauxite. Coal dust, liquid fuel oil, natural or coke oven gas are used as fuel.

Materials for the production of metals and alloys

For the production of cast iron, steel and non-ferrous metals the following is used:

- ore;

- fluxes;

- fuel;

- fireproof materials.

Industrial ore is a natural mineral formation containing a metal or several metals in concentrations at which their extraction is economically feasible.

Fluxes are materials loaded into a smelting furnace to form slags - low-melting compounds with gangue ore or fuel concentrate and ash.

Fuels are combustible substances, the main component of which is carbon; They are used to obtain thermal energy when burned. In metallurgical furnaces they use: coke, natural gas, fuel oil, blast furnace (top) gas. Coke is obtained from coking grades of coal by dry distillation at T = 10000C.

Refractory materials are materials and products primarily based on mineral raw materials that have a fire resistance of at least 15800C. They are used for the manufacture of the internal facing layer (lining) of metallurgical furnaces and ladles for molten metal.

Process Features

The steel production process occurs sequentially in three stages.

The first stage is the melting of the rock. At the stage of its implementation, a melt is formed in the bath and the metal is oxidized, simultaneously giving oxygen to silicon, phosphorus and manganese.

One of the main tasks of this stage is phosphorus removal. Its implementation requires a relatively low temperature and the presence of a sufficient amount of FeO. When the ingredients interact, phosphorus anhydride forms an unstable compound (FeO)3 + P2O5 with iron oxide.

The presence of the more stable base CaO in the slag causes the replacement of FeO. As a result, it binds phosphorus anhydrite into another compound (CaO)4 x P2O5 + 4 Fe, which is what was required to be achieved.

Pure Fe was released in the melt, and phosphorus formed slag, which is removed from the metal surface and disposed of as unnecessary. Since phosphorus anhydride transforms the composition of the slag, the process must be continuous.

Therefore, FeO must be continuously replenished by loading new batches of iron ore and scale, which introduce ferrous slag into the melt.

Features of the second stage

The second stage of steel production technology is called steel boiling. The main purpose is to reduce the carbon content by percentage due to oxidation. FeO + C = CO + Fe.

The oxidation reaction occurs more intensely during boiling and is accompanied by heat absorption. Therefore, it is necessary to create a constant flow of heat into the bath, as well as to equalize the temperature in the melt.

During this oxidation reaction, carbon monoxide gas CO is intensively released, which causes rapid boiling in the liquid aggregate state, for this reason the process is called boiling. To ensure that excess carbon is more intensively converted into oxide, the production of high-quality steel involves injecting pure oxygen and adding scale to the molten structure. This is why the quality of raw materials for steel production is so important. All source materials undergo scrupulous testing.

It is important at this stage to remove sulfur, which improves the quality of the final steel. The sulfur used in the components is not present in direct form, but in the form of iron sulfide FeS.

At high temperatures, the component also reacts with CaO oxide, forming calcium sulfide CaS, which dissolves in the slag without combining with iron. This allows the sulfide to be easily removed outside the bath.

Converter steel production

Deoxidation

The third stage is metal deoxidation. After adding oxygen (at the previous stage), it is necessary to reduce its content in clean steel. Using O2, it was possible to achieve oxidation of impurities, but its residual presence in the final product reduces the quality characteristics of the metal. It is necessary to remove or convert FeO oxides by combining oxygen with other metals.

There are two deoxidation methods for this:

- diffusion;

- besieging.

With the diffusion method, additives are introduced into the molten composition: aluminum, ferromanganese and ferrosilicon. They reduce iron oxide and convert it into slag. In the slag, the oxide disintegrates and releases pure iron, which enters the melt. The second released element, oxygen, evaporates into the environment.

The precipitation method involves the introduction of additives that have a greater affinity for oxygen than Fe. These substances replace iron in the oxide. They, being less dense, float and are removed along with the slag.

The deoxidation process continues as the ingot solidifies, in the crystal structure of which iron oxide and carbon interact. As a result, it is removed along with nitrogen and hydrogen bubbles.

The more inclusions of various metals are removed during deoxidation, the higher the malleability of the resulting steel. To check, a hot piece of metal is forged; cracks should not form on it. This sample check indicates that the deoxidation process is being carried out correctly.

Depending on the degree of deoxidation, specialists can obtain:

- calm steel of complete deoxidation;

- boiling, not completely deoxidized steel, when the process of removing bubbles of carbon monoxide CO continues in the ladle and mold.

To obtain alloy steels with the addition of certain metals, ferroalloys or pure metals are added to the molten metal. If they do not oxidize (Ni, Co, Mo), then such additives can be introduced at any stage of smelting. Metals Si, Mn, Cr, Ti, which are more sensitive to oxidation, are added to the ladle or, as usually happens, to the mold for casting the metal.

There are basic methods for producing steel in steelmaking.

Iron and steel production

Materials used in blast furnace production and their preparation for smelting.

Iron ores, fuel, and fluxes are used to smelt cast iron in blast furnaces.

Ores: Iron ores contain (55...60%) iron in various compounds (oxides, hydroxides, carbonates, etc.), as well as waste rock.

Manganese ores are used for smelting an alloy of iron and manganese - ferromanganese, as well as pig iron. Chromium ores are used for the production of ferrochrome, chromium metal and refractory materials - chromium magnesites. Complex ores are used for smelting naturally alloyed cast iron. These are ferromanganese ores, chromium-nickel ores, and iron-vanadium ores.

Fuel: coke - to obtain the required temperature and create conditions for the recovery of iron from ore; In order to save money, part of the coke is replaced with natural gas, fuel oil, and pulverized fuel.

Fluxes: this is limestone CaCO3 or dolomitized limestone containing CaCO3 and MgCO3. This is necessary to remove sulfur from the metal into which it is transferred from coke and iron ore during smelting. For normal operation of a blast furnace, the slag must be sufficiently fluid at a temperature of 14500C.

Preparation of ores for blast furnace smelting.

The purpose of this preparation is to increase the iron content in the charge and reduce harmful impurities in it - sulfur, phosphorus, as well as increase uniformity in lumpiness and chemical composition:

- crushing and sorting of ores by size serves to obtain pieces of optimal size for smelting;

- ore beneficiation: gravity (jigging) is the separation of ore from gangue by passing a stream of water through the bottom of a vibrating screen on which the ore rests. Magnetic separation is based on the difference in the magnetic properties of iron-containing minerals and gangue particles;

- agglomeration is carried out to process concentrates obtained after enrichment into lump materials of the required size;

Two methods of agglomeration are used.

- Agglomeration is the sintering of a fine charge and the removal of sulfur and arsenic. The result is a piece of porous fluxed material - an agglomerate.

- Pelleting is the rolling of a charge from crushed concentrates, flux, fuel, all of this is moistened, and when processed in rotating drums, pellet balls with a diameter of up to 30 mm are obtained.

Iron smelting.

Cast iron is smelted in shaft-type furnaces - blast furnaces (Fig. 1). The essence of the process of producing cast iron in blast furnaces is the reduction of iron oxides included in the ore with carbon monoxide, hydrogen released during combustion of fuel in the furnace and solid carbon released during combustion of fuel in the furnace. In Fig. — photograph of a mine-type blast furnace.

When the furnace is operating, the charge materials, having been melted, are lowered, and new portions of the charge are fed into the furnace through the loading device in such quantities that the entire useful volume of the furnace is filled. The useful volume of the furnace is the volume occupied by the charge from the bottom to the lower edge of the large cone of the filling apparatus when it is lowered. Modern blast furnaces have a useful volume of 2000...5000 m3. The useful height H of a blast furnace reaches 35 m.

The operating efficiency of a blast furnace is characterized by the residence time of the charge in the blast furnace (5–6 hours) and the duration of the operation (5–6 years or more of continuous operation).

Physico-chemical processes of blast furnace smelting.

Conventionally, the processes occurring in a blast furnace are divided into:

- fuel combustion;

- decomposition of charge components;

- iron recovery;

- carburization of iron;

- recovery of manganese, silicon, phosphorus, sulfur;

- slag formation;

Fuel combustion . Near the tuyeres, the carbon of the coke interacts with oxygen in the air and burns. At the same time, in the furnace slightly above the level of the tuyeres, temperatures above 20,000C develop.

Iron recovery . The charge (sinter, coke) falls towards the gas flow, and at a temperature of 500...5700C the reduction of iron oxides begins. The reduction of iron from ore in a blast furnace occurs as the charge moves down the furnace shaft and the temperature rises in several stages - from the highest oxide to the lowest:

Fe2O3 → Fe3O4 → FeO → Fe.

Carburization of iron . In the blast furnace shaft, along with the reduction of iron, its carburization also occurs when interacting with carbon monoxide (CO2), coke, and black carbon. This leads to the formation of a liquid melt, which begins to flow in drops into the furnace.

Thus, as a result of the process of reduction of iron oxides, part of the oxides of manganese and silicon, phosphates and sulfur compounds, dissolution of C, Mn, Si, P, S in iron in a blast furnace, cast iron is formed.

Slag formation . Slag formation actively occurs in steam after the completion of iron reduction processes by fusing fluxes added to the blast furnace to ensure sufficient fluidity at a temperature of 1400...15000C, waste rock oxides and coke ash. The slag flows into the furnace and accumulates on the surface of the liquid cast iron due to its lower density.

Cast iron is released from the furnace every 3...4 hours, and slag every 1...1.5 hours. Cast iron is transported to oxygen-converter or open-hearth shops for conversion into steel. Cast iron not used in liquid form is poured into the molds of a casting machine, where it solidifies into ingots weighing 45 kg.

Rice. 1. Construction of a blast furnace : 1 – hearth; 2 – air duct; 3 – shoulders; 4 – steam; 5 – shaft; 6 – fire pit; 7 – receiving funnel; 8 – filling device; 9 – trolley; 10 – small cone; 11 – bowl; 12 – bridge; 13 - large cone (prevents the release of gases from the blast furnace into the atmosphere).

To ensure uniform distribution of the charge in the blast furnace, the small cone and the receiving funnel after the next loading are rotated through an angle that is a multiple of 60°.

Rice. Mine type blast furnace

Blast furnace products.

Cast iron is the main product of blast furnace smelting:

- Pig iron is smelted to convert it into steel in converters or in open-hearth furnaces. It contains 4...4.4% C, 0.6...0.8% Si, 0.25...1.5% Mn, 0.15...0.3% P and 0.03...0.07% S.

- Foundry cast iron is used in machine-building factories in the production of shaped castings. In addition to cast iron, ferroalloys - alloys of iron with silicon, manganese and other elements used for deoxidation and alloying of steel;

- By-products of blast furnace smelting are slag and blast furnace gas. Slag wool and cement are made from slag, and blast furnace gas, after purification, is used as fuel to heat the air blown into the blast furnace.

In Fig. Figure 3 shows the release of cast iron from a blast furnace.

Rice. 3. Release of cast iron from the blast furnace into ladles

Steel production.

The essence of the process. The essence of any metallurgical processing of cast iron into steel is to reduce the content of carbon and impurities by selectively oxidizing them and converting them into slag and gases during the smelting process.

The main materials for steel production are pig iron and steel scrap ( scrap ). The content of carbon and impurities in steel is significantly lower than in cast iron.

Steel smelting processes are carried out in several stages. The first stage is melting the charge and heating the liquid metal bath.

At this stage, the temperature of the metal is low; The oxidation of iron occurs intensively, the formation of iron oxide and the oxidation of Si, P, Mn impurities. The most important task of this process is to remove phosphorus (one of the harmful impurities in steel).

The second stage - “boiling” of the metal bath - begins as it warms up to higher temperatures than in the first stage. The boiling bath is the main thing in the steel smelting process.

During the same period, conditions are created for removing sulfur from the metal. The higher the temperature, the greater the amount of FeS dissolves in the slag, i.e. more sulfur passes from the metal to the slag.

The third (final) stage - steel deoxidation - involves the reduction of iron oxide dissolved in the liquid metal.

When melting, an increase in the oxygen content in the metal is necessary for the oxidation of impurities, but in finished steel oxygen is a harmful impurity, as it reduces the mechanical properties of steel, especially at high temperatures.

Steel is deoxidized in two ways:

- besiegers;

- diffusion.

Precipitating deoxidation is carried out by introducing soluble deoxidizers (ferromanganese, ferrosilicon, aluminum) into liquid steel. As a result, iron is reduced, and the resulting oxides of manganese, silicon and aluminum are removed into slag.

Diffusion deoxidation is carried out by deoxidation of slag. Ferromanganese, ferrosilicon and other deoxidizing agents in finely divided form are loaded onto the surface of the slag.

Depending on the degree of deoxidation, calm , boiling and semi-quiet steels .

Calm steel is obtained by complete deoxidation in the furnace and ladle. Boiling steel is not completely deoxidized in the furnace. Its deoxidation continues in the mold as the ingot solidifies due to the interaction of FeO and carbon contained in the metal. Gases are released in the form of bubbles, causing it to boil. Boiling steel does not contain non-metallic inclusions - deoxidation products, therefore

has good ductility.

Semi-quiet steel has an intermediate deoxidation between calm and boiling.

Alloying of steel is carried out by introducing ferroalloys or pure metals in the required quantity into the melt.

Alloying elements (Ni, Co, Mo, Cu), whose affinity for oxygen is lower than that of iron, practically do not oxidize during melting and casting, and therefore they are introduced into the furnace at any time during melting (usually along with the rest of the charge). Alloying elements whose affinity for oxygen is greater than that of iron (Si, Mn, Al, Cr, V, Ti, etc.) are introduced into the metal after deoxidation or simultaneously with it at the end of melting, and sometimes directly into the ladle.

Technological processes of steel production.

Steels are produced in metallurgical units of various operating principles: oxygen converters, electric and induction furnaces, etc.

Steel production in oxygen converters.

The oxygen-converter process is the smelting of steel from liquid cast iron in a converter with a main lining (magnesite and dolomite) and blowing oxygen through a water-cooled mold (Fig. 4.).

Before melting, the converter is tilted (Fig. 4.1), scrap is loaded through the neck using filling machines, and cast iron is poured at a temperature of 1250 - 1400 ° C. After this, the converter is turned into a vertical working position, a water-cooled form is inside it, and oxygen is supplied through it at a pressure of 0.9 - 1.4 MPa. Simultaneously with the start of blowing, lime, bauxite, and iron ore are loaded into the converter (Fig. 4.2). Oxygen jets penetrate the metal, cause it to circulate in the converter and mix with the slag. Due to the intense oxidation of cast iron impurities when interacting with oxygen, a temperature of up to 2400°C develops in the area under the tuyere.

The oxygen supply is stopped when the carbon content in the metal corresponds to the specified value. After this, the converter is turned and the steel is released into the ladle (Fig. 4, 3).

When steel is released from the converter, it is deoxidized in a ladle using the precipitation method with ferromanganese, ferrosilicon and aluminum; then the slag is drained from the converter (Fig. 4.4).

Converter capacity is 70 – 350 tons of molten cast iron.

Figure 4. Sequence of technological operations when melting steel in oxygen converters

The charge materials of the oxygen converter process are:

- liquid cast iron;

- steel scrap (no more than 30%);

- lime for removing slag;

- iron ore;

- bauxite (Al2O3) and fluorspar (CaP2), to liquefy the slag.

In an oxygen converter, due to the presence of slags with a high content of CaO and FeO, and the mixing of metal and slag, conditions are created for removing phosphorus from the metal at the beginning of purging the bath with oxygen, when its temperature is not yet high. Cast iron processed in converters should not contain more than 0.15% P and 0.07% S.

In oxygen converters they smelt: structural steels with different carbon contents, boiling and calm.

It is difficult to smelt steels containing easily oxidizing alloying elements in oxygen converters, so low-alloy steels (up to 2–3% of alloying elements) are smelted in them. Alloying elements are introduced into the ladle, melting them in an electric furnace, or hard ferroalloys are introduced into the ladle before releasing steel from it. Melting in converters with a capacity of 130 - 300 tons ends in 25 - 30 minutes.

Steel production in electric furnaces.

Electric melting furnaces have advantages over other melting units, since they can produce a high temperature of the metal, creating an oxidizing, reducing, neutral atmosphere and vacuum, which makes it possible to smelt steel of any composition, deoxidize the metal with the formation of a minimum amount of non-metallic inclusions - deoxidation products. Therefore, electric furnaces are used for smelting structural, high-alloy, tool, and special alloys and steels.

Arc and induction furnaces are used for melting steel (Fig. 5).

Figure 5 . Diagram of an electric arc melting furnace

The arc melting furnace operates on three-phase alternating current. Electric current from a transformer with a power of 25 - 45 kV *A. Operating voltage 160 – 600 V, current 1 – 10 kA. During operation of the furnace, the arc length is adjusted automatically by moving the electrodes. In Fig. 6 shows an arc melting furnace.

Rice. 6. DC electric arc melting furnace

Rice. 7. Production of steel from an electric arc melting furnace

The capacity of these furnaces is 0.5 - 400 tons. In metallurgical shops, electric furnaces with a basic lining are used, and in foundries - with an acid lining.

To determine the chemical composition of the metal, samples are taken and, if necessary, ferroalloys are introduced into the furnace to obtain the desired chemical composition of the metal, after which the final stage of deoxidation is performed, steel is made with aluminum and silico-calcium and the metal is released from the furnace into the ladle (Fig. 7.

When smelting alloy steels in arc furnaces, alloying elements in the form of ferroalloys are introduced into the steel.

Induction crucible melting furnace (Figure 8).

Single-phase alternating current passes through the inductor (4) from an industrial frequency generator (50 Hz) or from a high frequency generator (500 - 2500 Hz). The current creates an alternating magnetic flux that passes through the pieces of metal in the crucible. The alternating magnetic flux induces powerful Foucault eddy currents (1) in them, heating the metal until it melts and reaches the required overheating temperatures. The crucible is made from basic or acidic refractories (5). Crucible capacity 60 kg – 25 tons. (2) – roof of the crucible furnace. (3) – neck for draining metal.

Figure 8. Diagram of an induction crucible melting furnace

Induction furnaces have advantages over arc furnaces: they do not have an electric arc, which makes it possible to smelt steel with a low content of carbon, gases and low waste of elements; during melting, electrodynamic forces arise in the metal, which mix the metal and contribute to the equalization of the chemical composition and the floating of non-metallic inclusions; The small size of the furnaces allows them to be placed in chambers where any atmosphere or vacuum can be created.

However, these furnaces have low lining durability, and the temperature of the slag in them is insufficient for metallurgical processes to occur between metal and slag.

In induction furnaces with a main lining, high-quality alloyed steels with a high content of manganese, nickel, titanium, and aluminum are smelted, and in acid-lined furnaces, structural, alloyed steels are smelted.

During vacuum induction melting, an inductor with a crucible, a batch dispenser and molds are placed in vacuum chambers. Melting, introduction of alloying additives, deoxidizers, and casting of metal into molds are carried out without breaking the vacuum in the chamber. In this way, high-quality alloys with a low content of gases, non-metallic inclusions, and alloys alloyed with any elements are obtained. In Fig. 9. shows an induction crucible melting furnace.

Rice. 9. Induction crucible melting furnace

In Fig. 10 recorded the working torque of steel melting in an induction crucible melting furnace.

Rice. 10 . Melting steel in an induction crucible melting furnace

Steel casting (Fig. 11; 12; 13).

The smelted steel is released from the melting furnace into a ladle, from which it is poured into the molds or crystallizers of a continuous casting machine (CCM). In molds or crystallizers, steel hardens, and ingots are obtained, which are subjected to rolling and forging.

Rice. 11. Scheme of pouring steel from above directly from the ladle

Rice. 12. Siphon casting of steel : where 1 - ladle, 2 - center sprue, 3 - siphon bricks, 4 - pallet, 5 - molds, 6 - slag catchers, 7 - refractory mass

Large weight ingots (up to 200 tons) are cast on top, as well as some types of alloy steel (high-speed, ball bearing, etc.), in which a minimum content of non-metallic inclusions is permissible.

Using the siphon method, from ladle 1 through center sprue 2, depending on the weight of ingots, from two to 60 are simultaneously poured.

100 molds. In this case, the metal, passing through the center sprue 2, enters through a system of channels formed by special siphon bricks 3 in a cast iron pan 4, to each mold 5. Advantages of the siphon method: a large number of ingots can be cast in one stream, the surface of the ingots is clean due to the reduction in height and the volume of the shrinkage cavity, you can obtain high-quality ingots weighing up to 20-30 g of steel. The disadvantage of siphon casting is the labor-intensive work of assembling molds for casting and the high consumption of metal on the gates. Therefore, this method is not used when casting expensive steels.

A progressive method is continuous casting of steel (Fig. 13).

Metal from the ladle is poured in a continuous stream into the intermediate device, and from it enters water-cooled crystallizers, into which steel blanks are preliminarily placed to form the bottom. When liquid metal comes into contact with these workpieces

(seeds) and the walls of the crystallizers, its rapid solidification begins, further intensifying when passing through the secondary cooling zone. The hardened billet is pulled out by rollers operating from a special mechanism to the carts of the gas cutters, cut into pieces, and then transported along a conveyor to the rolling shop. The use of the method of continuous casting of steel makes it possible to reduce metal waste from 15-20% during conventional casting to 3-5%, i.e. 5 times.

Rice. 13. Diagram of a continuous casting machine (CCM) Molds - cast iron molds for the production of ingots (square,

rectangular, round or polyhedral cross-sections). Square ingots are converted into rolled products (I-beams, channels, angles, etc.). Rectangular ingots are converted into sheets. Pipes and wheels are made from round ingots. Multifaceted ingots are used for forgings.

For rolling, ingots weighing 200 kg - 25 tons are cast; for forgings – weighing 300 tons or more. Typically, carbon calm and boiling steels are poured into ingots weighing up to 25 tons, alloy and high-quality steels into ingots weighing 500 kg - 7 tons, and some types of high-alloy steels into ingots weighing several kilograms.

Continuous casting machines can have several crystallizers, which makes it possible to simultaneously produce several ingots, which can be rolled on section mills, bypassing blooming and slabging.

Ingot structure.

The steel poured into the molds transfers heat to its walls, so the solidification of the steel begins at the walls of the mold. The thickness of the crystallized crust continuously increases, while between the liquid core of the ingot and the solid crust of the metal there is a zone in which there are simultaneously growing crystals and liquid metal between them. Crystallization of the ingot ends near its longitudinal axis.

The steel hardens into tree-shaped crystals called dendrites.

The sizes and shapes of dendrites depend on the crystallization conditions (Fig. 14).

Rice. 14. Scheme of the structure of steel ingots : a, d – mild steel; b, d – boiling steel; c, d – semi-quiet steel;

A – thin outer crust of fine-grained crystals; B – zone of large columnar crystals (dendrites); B – zone of large unoriented crystals; D – fine-crystalline zone at the bottom of the ingot.

Calm steel hardens without the release of gases, a shrinkage cavity is formed in the upper part of the ingot, and shrinkage axial looseness is formed in the middle.

Steel ingots are heterogeneous in chemical composition. Chemical heterogeneity, or segregation, occurs due to a decrease in the solubility of impurities in iron during its transition from a liquid to a solid state. Liquation is of two types - dendritic and zonal.

Dendritic segregation is the heterogeneity of steel within one crystal (dendrite) - the central axis and branches. For example, during the crystallization of steel, the sulfur content at the boundaries of the dendrite compared to the content in the center increases by 2 times, phosphorus by 1.2 times, and carbon decreases by almost half.

Zonal segregation is the heterogeneity of steel composition in different parts of the ingot. In the upper part, due to the convection of the liquid metal, the content of sulfur, phosphorus and carbon increases several times, and in the lower part it decreases. Zonal segregation leads to metal rejection due to deviation of its properties from the specified ones. Therefore, the profitable and profitable parts of the ingot, as well as its bottom part, are cut off during rolling.

In ingots of boiling steel, no shrinkage cavities are formed: the shrinkage of steel is dispersed throughout the cavities of gas bubbles that arise during boiling of the steel in the mold. When the ingot is rolled, gas bubbles are welded.

Semi-quiet steel retains the advantages of calm and boiling steels and does not have their disadvantages.

Semi-quiet steel is partially deoxidized in the furnace and ladle, and partially in the mold. An ingot of semi-quiet steel has the structure of calm steel in the lower part, and boiling steel in the upper part. The segregation in the upper part of the semi-quiet steel ingot is less than that of the boiling steel, and is close to the segregation of the calm steel, but the semi-quiet steel ingots do not have shrinkage cavities.

Methods for improving the quality of steel.

The development of mechanical engineering and instrument making places increasing demands on the quality of the metal: its strength, ductility, and gas content. These indicators can be improved by reducing harmful impurities, gases, and non-metallic inclusions in the metal.

To improve the quality of metal use:

- processing of metals with synthetic slag;

- vacuum degassing of metal;

- electroslag remelting (ESR);

- vacuum arc remelting (VAR);

- metal remelting in electron beam and plasma furnaces, etc.

Processing metal with synthetic slag is as follows: liquid slag is mixed with liquid steel,

a reaction in which the content of sulfur, oxygen and non-metallic inclusions in steel decreases. Its ductility and strength increase. Such steels are used for the manufacture of critical machine parts.

Evacuation of steel is carried out to reduce the concentration of oxygen, hydrogen, nitrogen and non-metallic inclusions. Various methods are used for evacuation, for example, evacuation in a ladle, circulation and flow evacuation, jet and batch evacuation, etc.

Electroslag remelting (Fig. 15). ESR is used for smelting high-quality steels for ball bearings, heat-resistant steels for turbine disks and blades, compressor shafts, and aircraft structures. Metal melted in an arc furnace and rolled into round rods is subjected to remelting. The source of heat in ESR is a slag bath, heated when an electric current passes through it. An electric current is supplied to the remelted electrode, immersed in a slag bath, and to a tray installed in a water-cooled metal crystallizer in which the seed is located. In Fig. 16. shows an installation for electroslag remelting of steel.

Rice. 15. Scheme of electroslag remelting of a consumable electrode : a – crystallizer; b – switching on the installation 1 – electrode; 2 – slag bath; 3 – drops of metal; 4 – metal; 5 – crust; 6 – ingot; 7 – crystallizer; 8 – seed; 9 – pallet.

Rice. 16. Installation of electroslag remelting of steel

Vacuum arc remelting (VAR) is used to remove gases and non-metallic inclusions from metal. The process is carried out in vacuum arc furnaces with a consumable electrode. In Fig. 17. The diagram in Fig. is shown. 18. Installation of vacuum-arc steel remelting.

Rice. 17. Scheme of vacuum-arc remelting: 1 – body; 2 – water-cooled rod; 3 – electrode-cathode; 4 – drops of liquid metal; 5 – liquid metal; 6 – mold; 7 – ingot; 8 – seed-anode

Depending on the requirements for the resulting metal, a consumable electrode is produced by mechanical processing of an ingot smelted in electric furnaces or in ESR installations.

VAR ingots contain little gases and non-metallic inclusions, are characterized by a highly uniform chemical composition and improved mechanical properties. They are used to make critical parts of turbines, engines, and aircraft structures. The weight of the ingots reaches 50 tons.

Rice. 18. Installation of vacuum-arc steel remelting

Melting in electron beam furnaces (Fig. 19) is used to obtain pure and ultra-pure refractory metals (molybdenum, niobium, zirconium, etc.) and for the smelting of special alloys and steels.

The vacuum inside the furnace, high overheating caused by an electron beam directed at the metal, and high cooling rates of the ingot help remove gases and impurities, producing metal of particularly high quality. However, when remelting a charge containing easily evaporating elements, the chemical composition of the metal is changed.

Rice. 19 Diagram of an electron beam furnace

Melting steel in plasma-arc furnaces (Fig. 20) is used to produce high-quality steels and alloys.

The heat source is low-temperature plasma (30,000°C) produced in plasma torches. In these furnaces it is possible to create a neutral environment of a given composition (argon, helium). Plasma-arc furnaces make it possible to quickly melt the charge, and in a neutral gas environment the smelted metal is degassed; the volatile elements included in its composition do not evaporate.

Rice. 20. Installation of a plasma-arc furnace

Open hearth method

This method is used to produce high-quality steels used in critical machine parts and precision mechanisms.

At one time, it replaced the labor-intensive and low-productivity crucible and pulding melts that had been used previously.

The loading capacity of one reverberatory furnace used in this method reaches 500 tons. A special feature of the open-hearth method is the ability to remelt not only pig iron, but also metallurgical waste and scrap metal.

The heating temperature of liquid steel reaches 2 thousand degrees. This result is achieved by the special design of the open hearth furnace:

- the use of additional heat from regenerators obtained by burning coke oven or blast furnace gas in a stream of hot air;

- reflections from the roof of the injected gas as a result of fuel combustion in it occurring above a bath of metal, which contributes to the rapid heating of the contents;

- using reversal of the heating flow.

An open hearth furnace consists of the following elements:

- working space with fire-resistant lining of walls and filling windows;

- hearths (bases) made of magnesite brick;

- furnace roof;

- furnace heads;

- slag for removing dust;

- regenerator with changeover valves.

The smelting process takes from 4 to 12 hours. In order to speed up the smelting process, the volume of pumped oxygen exceeds the requirements, which increases smelting productivity by 20–30%.

There are several ways to make steel:

Oxygen converter process.

Scrap steel is loaded into the converter (melting unit), filled with molten cast iron (more than 70% by weight of the melt) and purged with oxygen from above. In this metal cocktail, C, Si, Mn and other impurities are intensively oxidized. The result is steel with a specific composition. Oxygen consumption is 2 – 5 m3 per 1 ton of metal. Exposure time is from 10 to 30 minutes. The higher the oxygen consumption, the shorter the purge time.

The purity of technical oxygen should range from 99.5 to 99.7%. This ensures a low content of hazardous impurities in the finished alloy.

Figure 1. Diagram of an oxygen converter with a diagram of the movement of metal when blown with oxygen. 1: 1 – converter casing; 2 – reinforcing layer of magnesite brick; 3 – resin-dolomite packing; 4 – fireclay brick; 5 – tap hole for draining steel; 6 – lance for oxygen injection; 7 – metal. 2: 1 – nozzle; 2 – oxygen stream; 3 – reflected jet; 4 – metal movement.

During the purging process, iron, carbon and other impurities are oxidized. Toward the end of smelting, carbon oxidation slows down. This makes it easier to produce steel of a given composition. The duration of the smelting determines the final carbon content of the steel.

When carbon oxidizes, CO bubbles are released, which remove nitrogen, phosphorus and sulfur from the metal.

Silicon is almost completely oxidized during blowing, manganese is approximately 70% oxidized at the beginning of the process, and 95–98% of phosphorus disappears, turning into slag. But sulfur is removed worse than phosphorus, so for the production of steel in cast iron it should not be more than 0.06 - 0.07%.

During oxygen-converter smelting, iron is also oxidized and evaporated. Its loss is up to 2%.

Deoxidation of steel.

Regardless of the production method from cast iron and scrap, oxidation reactions occur in steel. At the end of smelting, the alloy contains oxygen, which remains in the hardened steel. It degrades steel strength, ductility and toughness. Deoxidation of steel is necessary to reduce the amount of oxygen to acceptable values.

Types of steel deoxidation:

• Deep (precipitating).

Particles are added to the alloy which deoxidize it. Substances that appear during oxidation are less dense than steel. They settle into a layer of slag and then float to the surface.

Most often, steel is deoxidized with manganese, silicon and aluminum.

Manganese is the weakest deoxidizing agent. Silicon and aluminum are more energetic. Based on the degree of deoxidation, boiling, calm and semi-quiet steel are distinguished.

• Diffusion.

The oxygen concentration in steel is reduced using special slag - white, carbide, siliceous, aluminous. With this type of steel deoxidation, there is no carbon boiling, because the O content in the steel quickly decreases.

Steel smelting in open hearth furnaces.

Figure 2. Open hearth furnace.

1, 2 – gas and air regenerators; 3, 4 – gas and air channels in the furnace head; 5 – working chamber of the furnace; 6 – under the stoves; 7 – furnace roof; 8 – filling windows.

An open hearth furnace is a flame regenerative device.

Smelting steel requires high temperatures. The “food” for an open-hearth furnace is a mixture of blast furnace, coke oven and natural gases, fuel oil or natural gas. Mixed gas is used where there is blast furnace and coke production. The bulk of steel is smelted in furnaces that run on fuel oil or natural gas. Natural gas does not contain sulfur, burns without ash, is easy to transport, and is cheaper than fuel oil, which is why a significant number of large open-hearth furnaces are heated with it.

To smelt a small amount of steel, 30–80-ton furnaces are used. At large metallurgical plants, 250-500 devices are common. The bath dimensions of such furnaces are up to 20x6 m, and the hearth area is up to 115 m2. Some industries operate furnaces of 900 tons or more. The larger the oven, the greater the economic efficiency.

The duration of melting in small and medium-sized furnaces is from 3 to 6 hours, in large ones - up to 12 hours. Open-hearth furnaces operate without interruptions until they are stopped for overhaul (400 - 600 melts).

As a rule, steel is melted from pig iron grades M1, M2, M3 and steel scrap. Limestone, iron ore and other additives are added to the composition. Ferromanganese is used for deoxidation and alloying.

Open hearth furnaces are divided into basic and acidic.

The underside and walls of the main furnace are lined with magnesite bricks. The vault is made of chromium-magnesite brick. Magnesite or dolomite powder is layered on the bottom. In the steel making method, limestone is added as a flux in the main furnace so that the main slag is formed with more lime. Using this technique, sulfur and phosphorus are displaced from the alloy.

In an acidic furnace, the bottom and walls are made of silica brick, and a layer of quartz sand is welded onto the bottom. During smelting, acidic slag is formed, which contains a lot of SiO2. Here it is impossible to get rid of sulfur and phosphorus during smelting. This open-hearth process is rarely used.

The main open-hearth process is divided into scrap process and scrap ore process.

The basic scrap process is usually used in furnaces with a capacity of up to 100 tons for the production of high-quality steel in mechanical engineering and small metallurgical enterprises where there is no pig iron production.

In order to accelerate the oxidation process of impurities, iron ore is used, and ferroalloys are used for deoxidation and alloying.

During smelting, the formation of slag is of great importance, because its chemical composition, properties, quantity and temperature determine the entire course of smelting.

In addition to carbon steels, many alloy alloys are produced by the main scrap process.

The scrap ore process is used where there is iron production. Large open-hearth furnaces produce the bulk of open-hearth steel.

Only carbon steels are smelted using this method. They are of lower quality than those smelted by the scrap process because cast iron, limestone and iron ore, used in large volumes, introduce unnecessary sulfur, phosphorus, non-metallic contaminants and gases into the alloy. However, the scrap ore process is more economical.

Double bath ovens.

Figure 3. Diagram and principle of operation of a two-bath furnace.

The main advantage is that their productivity is higher than conventional open-hearth ones. For example, the productivity of 400-ton open-hearth furnaces is from 0.2 to 0.6 million tons per year, and two-bath furnaces (2 × 200 tons) are from 0.8 to 12 million tons per year. In addition, they have a simpler design and 4–6 times less fuel consumption.

Acid open hearth scrap process.

This method in small furnaces produces steel with higher performance than open-hearth steel. Here they use high-quality cast iron, pure in sulfur and phosphorus. The duplex process is widely known: first, the steel is melted in the main furnace using a conventional charge to remove sulfur and phosphorus, and then the steel is poured into an acid furnace and the melting is completed. This approach reduces productivity and increases the cost of the metal.

Acid steel has good deoxidation; it contains practically no gases, sulfur, phosphorus and non-metallic oxide elements. It is used for particularly critical products: ball bearings, large turbine rotors, etc.

Steel smelting in electric arc furnaces.

A more advanced method. In an electric arc furnace, you can easily regulate the thermal process, create an oxidizing, reducing, neutral atmosphere or vacuum, and it is easier to alloy steel with easily oxidized elements. Electric steel contains a minimum amount of sulfur and phosphorus, non-metallic inclusions, and is well deoxidized.

Arc furnaces produce structural, high-alloy, corrosion-resistant, heat-resistant steels.

Steel production in induction furnaces.

Figure 4. Induction furnace for steelmaking.

1 – crucible for refractory materials; 2 – water-cooled inductor; 3 – chute for melt release; 4 – steel-pouring ladle; 5 – metal; 6 – eddy currents.

Induction steelmaking furnaces produce high-quality corrosion-resistant and heat-resistant steels. Furnaces can hold from several tens of kg to 30 tons of metal.

Non-domain methods for producing steel.

Approximately 80% of all cast iron is used for smelting into steel. There are several methods of smelting without blast furnaces: reduction in a fluidized bed and obtaining sponge iron in capsules.

Production of high-quality steels and alloys.

A sign of high-quality steel is the absence of harmful impurities, non-metallic inclusions and dissolved gases. To obtain the highest quality steel for parts and structures for special purposes, melting is used in vacuum arc and induction furnaces, as well as the electroslag remelting method.

Figure 5. Electroslag remelting diagram.

a – process diagram; b – installation diagram.

1 – remeltable electrode; 2 – slag bath; 3 – drops of liquid metal; 4 – metal bath; 5 – slag crust; 6 – ingot; 7 – water-cooled metal crystallizer; 8 – seed; 9 – pallet.

Figure 6. Diagram of an electric arc vacuum furnace.

1 – current-carrying rod with electric holder; 2 – electrode; 3 – working chamber; 4 – consumable electrode; 5 – liquid metal bath; 6 – ingot; 7 – water-cooled crystallizer; 8 – water-cooled tray.

Figure 7. Diagram of a plasma arc furnace.

1 – plasmatron; 2 – plasma arc; 3 – melting chamber; 4 – mechanism for feeding crushed charge; 5 – water-cooled crystallizer; 6 – ingot.

Converter method

Converters melt grades of steel for the production of automotive sheets, tool steel, welded structures and other steel blanks. They are inferior in quality to open-hearth ones and are used for the manufacture of less critical products.

They contain more impurities than in open-hearth production. Due to the high loading volume of one furnace, up to 900 tons, the method is considered the most productive, and therefore has become widespread.

The production of steel and other types of metal by this method is based on blowing liquid cast iron with air or oxygen under a pressure of 0.3–0.35 MPa, while the metal is heated to 1600 degrees. Melting is fleeting and lasts up to 20 minutes. During this time, oxidation occurs of carbon, silicon and manganese contained in the raw materials, which are extracted from the molten slag bath.

The converter is a retort-shaped (pear-shaped) vessel consisting of steel sheets with a lining on the inside. One hole is used to pour cast iron and release finished steel; cast iron and scrap are also loaded into it.

The Birth of Steel

MODERN MELTING METHODS

Steel is produced from cast iron and steel scrap. Cast iron contains about 4% carbon, as well as manganese, silicon and other impurities. Their quantity is higher than in the steel being smelted, therefore, before starting steel smelting, oxidative smelting is carried out to remove excess carbon and other impurities from the cast iron.

Alloy steels additionally contain chromium and nickel for strength. In order for steel to be of good quality, during its smelting, as many harmful impurities as possible are removed from the composition - sulfur, phosphorus, oxygen, nitrogen and non-metallic impurities.

Process Features

Together with them, slag-forming substances are loaded: lime and bauxite. The body is surrounded by a support ring attached to the pivot pins. With their help, the vessel is tilted and the finished steel is poured through this hole - the tap hole. Bottom blowing is carried out through through holes (tuyeres) made in the bottom of the furnace.

Historically, it has been the custom that the method used everywhere is called the Thomas or Bessemer method. In the last century, the open-hearth process became predominant. The regenerator is heated by purging furnace gases, after which it heats the cold air entering the melt.

In modern designs, the top method is more often used, in which blowing at high speed is carried out through nozzles lowered to the metal surface. In Russia, it is primarily the top blowing of furnaces that is used.

Being under a stream of air, cast iron intensively oxidizes in the contact zone. Since its concentration is much higher than other impurities, iron oxide is predominantly formed. But it dissolves in the slag. Therefore, the metal is enriched with the released oxygen.

C, Cr and Mn are oxidized, reducing the percentage in the metal structure. Oxidation is accompanied by the release of heat. Due to the presence of slags CaO and FeO before heating, phosphorus is removed at the very beginning of blowing.

The slag is merged with it and a new one is created. Steel production is accompanied by express analyzes and monitoring of current changes using control devices installed in the furnace. The phosphorus content in cast iron should not exceed 0.075%.

History of iron[edit]

The Age Before Metals[edit]

It’s worth touching on that too. The main materials of Cro-Magnon stone tools were flint and quartz. Descendants accumulated vast practical experience in their manufacture and so carefully selected small pebbles with sharp edges, and the craftsmen very carefully chipped larger ones into them that they managed to assemble spearheads, arrowheads, harpoons from them, and a little later - table knives, awls and even needles. According to archaeologists, the best stone knives were not much inferior to modern ones in terms of sharpness and working qualities. In fact, many people still use ceramic knives - this is also stone, but artificial. This required skill and experience in selecting blanks on the verge of HIGH art and a huge amount of time searching for the blanks themselves. Sometimes these craftsmen, while searching, came across pieces of a strange reddish stone with a strange shine...

Copper and bronze[edit]

Copper is the first metal that ranks behind hydrogen in the activity series (that is, it does not lend itself to electrochemical corrosion). Copper salt comes into contact with any base metal (for example, iron) - iron forms salt, copper precipitates. What follows from this? And the fact that, by analogy with gold, there are copper nuggets. This is how forging was invented. Then they came up with the idea of heating copper to get rid of problem areas in nuggets, which resulted in copper smelting - due to its inactivity, copper was the only base metal that can be easily smelted from ores.

- From a purely chemical point of view, copper is

, but platinum and platinoids are not.

Copper made bad tools, but they could be repaired - unlike stone ones, which had to be hewn out again, for a long time and with difficulty. And if things are really bad, you can melt it and re-cast it in the mold. The Copper Age covers approximately the X-IV millennium BC. e.

Then they came up with [1] arsenic bronze, an alloy much stronger than copper, but with three major drawbacks:

- Melting is extremely harmful (remember the lame Hephaestus - he swallowed arsenic vapor).

- Scrap is not recycled - the melting point is lower than that of pure copper, but when melted, arsenic burns and evaporates.

- The alloy is strong but fragile. like tin bronze, the quality of the metal depends greatly on the proportions.

Later, in the first half of the 2nd millennium BC. e., switched to tin or antimony bronze. But there were only one or two deposits of tin and antimony in the ancient world, but the owners of these mines and resellers made wild profits from them.

You can (will) read more about how malleable oxidized ores gave copper to man and how recalcitrant sulfide ores were roasted in the main article.

Meteoric iron[edit]

Black iron stones are quite processed using technologies familiar with copper. Usually meteorites contain admixtures of nickel and precious metals

, giving iron hardness. The weapon turned out to be decent (at the level of modern kitchen knives), but due to its high cost, it ended up in the treasuries of kings rather than participating in battle.

Native iron is also found; the closest deposit now selected to the ancient world was in Germany. Significant deposits of it were and are in Sweden; less significant mines are and have been found throughout the Alpine region.

Cheese furnace and the technologies that arose around it[edit]

The oldest smelted iron began to be obtained along the shores of the Black Sea in the 2nd millennium BC. e. Ferrous sand was burned in a cheese furnace (a pipe built from earth and clay) with charcoal.

2C + O2 = 2CO 3CO + Fe2O3 = 2Fe + 3CO2

It is curious that due to the high melting point of iron (slightly below 1600°), the reduction process took place without melting it, in the solid phase. This prevented the resulting iron from getting rid of inclusions, slag and unreacted ore.

What happened was called kritsa - a mixture of iron and slag. To get rid of slag, the kritsa was forged with a hammer. The iron turned out to be crappy, worse than the bronze of that time. In addition, the cheese furnace was disposable; a new furnace had to be built for a new melt. Through repeated forging, combined with treatment with a good flux, especially advanced craftsmen obtained “white iron” that was almost free of slag - but it cost at least an order of magnitude more than usual.

At the turn of the 1st and 2nd millennia BC, the completely expected happened: the explored tin deposits were worked out, but no new ones were found. Someone began to pass on bronze swords by inheritance, someone switched to “junk metal”... In order to get “Tison, a sword worth a thousand marks”, and not a piece of iron from the Kukuev coat of arms, many problems had to be solved, and they were solved by unknown blacksmiths for a good millennium .

- How to get rid of silicon impurities - for this, flux (limestone) was added along with iron sand.

- How to control carbon content in iron. This was done by blacksmiths literally by eye, according to the color of the heat, and was passed on from one to another. The best products were made from blanks that had lain in the ground or water for a couple of years so that the worst parts would rust.

- Crystalline iron could only be obtained from a melt, and without it there was a choice: a lot of carbon is brittle, a little is ductile. I had to forge packages of blanks with different carbon contents - here you have the famous production technologies of Japanese katanas (although they did this everywhere). Plus hardening the edge of the sword. And if you fold and forge many times, you get damascus (not to be confused with damask steel).

It is not surprising that the blacksmith's profession had a magical touch. They usually forged in pairs: the blacksmith knocked with a small hammer, the big hammer hammer hit this place with a hefty sledgehammer! So the famous Russian toy “man and bear” had a very real prototype.

So the Iron Age crept up unnoticed for more than a millennium: by the 1st millennium BC. e. Basic technologies for iron were obtained; by the 1st millennium, in terms of price/quality ratio, iron surpassed bronze; in the first centuries of our era, mass-produced iron was obtained, superior to any bronze, and this made it possible, for example, to massively build houses from logs. One of the reasons for the emergence of the Middle Ages was iron: the sword, perfected by the 9th century, required iron, and good iron at that. Plus a challenging learning curve. And also armor, also iron. Together with the good nutrition inherent to the landowner, the result was a man-tank, who was difficult to kill, and not profitable to kill: it was better to take prisoner for a ransom. This is how feudalism turned out: we fight (and this business was not as dangerous as it seems), but we receive land for military service.

Iron was expensive, and the carpenter’s advertisement was that he built “without a single nail.” Nails were used in shipbuilding, but more often wooden, less often copper and bronze, because they did not know how to make stainless steel at that time, cast iron was rarely used, and iron and steel instantly corroded at sea. And although metal parts have been used in shipbuilding since antiquity, but exclusively tightening and through connections with their careful coating and protection from air: it was simply impossible to build large ships without the use of metal purely from wood for reasons of strength. Steel, bronze, cast iron so-called. “efficient things” in the form of eyelets, lanyards, carbines, etc. were used even before Columbus, and the ship’s blacksmith was an obligatory member of the crew long before Vasco da Gama’s squadron sailed to India.

But in carts, iron and other nails were used quite widely - all the same, the service life of those parts that were nailed together was lower than the service life of nails, but with iron nails the repair was faster.

Even now scrap metal is not garbage, but scrap, but then they reforged everything that was metal! Blacksmiths instantly appeared at the fire looking for nails. Before wire nailing appeared, forged nails looked like a tetrahedral pyramid - this is how railway crutches still look (because they are huge) and horseshoe nails (it’s more convenient to bend).

Attention, error!

In one of the mobile games I saw a quest: help the gnomes find a coal deposit so that they don’t burn the trees. I don’t remember, for fuel or for iron, I’ll explain both. For fuel: coal has been known since ancient times (no high-tech is needed, remember the Donbass “kopanki”), but coal is mined in deposits and consumed everywhere. Only the railway (and sometimes river transport) made it possible to transport coal. On iron: Coal contains sulfur, which makes iron brittle. We need not just coal, but coke. Attempts began in the 15th century in England, when the burning of forests for coal began to take away resources from the growing fleet, and it was the invention of coke in the 17th century that saved the situation.

And the second mistake

, which has become a cliche - to draw some cool-looking weapon without thinking about combat techniques and forging technologies.

For the third error

there is a separate article: Cast a sword. However, the swords were cast from bronze and copper: it is useless to forge them due to the peculiarities of the crystalline structure, except to beat off the edge in a cold manner for the sake of hardening, and the melting point is quite low for ancient technologies.

Transition to industrial iron processing technologies[edit]

Somewhere in the 1st millennium, the Indians came up with a stukofen, or domnitsa - a permanent furnace for smelting iron with a high (4 m or more) pipe for draft. The bellows were pumped by several people, and even a water engine. In Stukofen, the Indians managed to make damask steel - but this required high-quality ore and graphite instead of charcoal. And the process of carburizing iron itself is not fast. Stukofen was already producing up to 250 kg of kritsa per day - but he converted a lot of ore into cast iron. (According to other sources, the ancient Romans were also able to obtain cast iron). This cast iron had no use and went to waste: it was possible to separate the iron from the slag only by forging, and cast iron cannot be forged.

It is not surprising that stukofen spread when other iron technologies were brought to standard - around the 14th century.

New oven, Blauofen (XV century). We made the pipe even higher and added preheating of the air. Iron became better, there was more cast iron, but it also became better - building blocks and cannonballs could be cast from it.

And then, around the 16th century, they made such a mechanism (a shouting horn). There is coal on the grate and cast iron on it. Under the grille is the air supply. The cast iron melts, flows down, and there the carbon oxidizes. The melting point of iron is higher than cast iron, a piece of iron thickened, they pulled it up with a crowbar - disgusting work, you know. When 50-100 kg of kritsa has accumulated, it is taken out for forging. This turned out to be a revolution: now iron can be made from cast iron (the so-called conversion process)! True, a problem arose - due to contact with burning coal, a lot of sulfur and phosphorus, harmful impurities, passed into the iron. They solved it a little later by creating a reflective forge: the coal burns separately, and the fireplace lies on the hearth separately, and hot air from the firebox passes over it, and the heat is reflected from the curved ceiling (see below about the puddling forge). From a chemist’s point of view, the method is absurd: fuse iron with carbon and then burn the carbon? [2] But there was no other technology. Here they no longer began to waste time on trifles: they blew harder and poured all the metal into the cast iron. What happened was called a blast furnace - from the word “to blow.” Hence “arrogant”, that is, “inflated”.

By the way, another common myth is that krits were folded and forged many times in order to obtain a kind of multi-layered super-duper metal, at the same time so hard that it could cut a falling hair, and so flexible that it could be wrapped around the waist instead of a belt. In fact, when steel is forged, it loses carbon from the surface due to oxidation, and forging of this kind was the only way to remove excess carbon at temperatures available at that time. Such iron was called “welding” (because the layers were welded together by forge welding), which is somewhat counterintuitive for contemporaries. The work was very labor-intensive and unproductive, so when it became possible to maintain iron in a molten state, they abandoned it, crossed themselves and switched to puddling - mixing molten cast iron with a poker with the addition of oxidizing agents.

- Iron was repeatedly welded not in order to burn off carbon - with the help of cheese reduction, obtaining high-carbon steel in sufficient quantities is still a hemorrhage. And in order to even out the chemical composition. In addition, in principle it was possible to increase the amount of carbon in the iron by heating it in the reduction zone of the forge flame.

To this day, cast iron is made in blast furnaces, descendants of the then

, the only fundamentally new ones are coke and operation on natural gas. But the conversion processes today are different, and now the whole history of ferrous metallurgy is about how they began to turn cast iron into iron and steel.

Coke

- almost pure carbon, obtained by burning coal without access to air - was invented by the ancient Chinese. Apparently, at first they used it to heat the houses of nobles, and then they used it in metallurgy. The history of coke in the West is similar: by the 17th century. There was a firewood crisis in England; the smelting of cast iron was banned (it was imported from Russia). But the question arose: how to heat the breweries (coal smoke harmed the booze). In the 17th century Coke was invented, and only by the 18th century. he was loaded into the blast furnace.

A water engine could pump bellows, but to replace a big hammerman with a machine, a steam engine was needed (early 18th century). The result was a forging press.

- Until the middle of the 19th century (or even until the end of it), hammers driven by a water wheel were used in the form of a sort of lever-driven mega-sledgehammer.

At the end of the 18th century. Henry Cort invented the puddling furnace - the main difference from the clarion forge was the insulation of cast iron from the fuel. The iron production process was equally nasty. (The same Cort, by the way, invented the rolling mill.)

Lyrical digression:

One of the attributes of steampunk is a pulley with crooked spokes. By that time, cast iron had become good enough that it was already possible to cast it, for example, into car frames - and these same pulleys. But cast iron remains fragile, it can break even from thermal expansion - therefore, in order to somehow spring back, the knitting needles began to be made crooked. And the number of spokes was made odd - so that when the casting shrinks, the round pulley would not be pulled into a polyhedron (the pressure from each spoke is distributed over two opposing spokes);

In 1856, Henry Bessemer developed the first furnace to produce real steel, the so-called Bessemer converter. This is a pear-shaped vessel with holes at the bottom. The converter is placed on its side, cast iron is poured in, the blast is turned on and the converter is placed vertically. The words “Bessemer steel” became a kind of brand: now what a blacksmith assembled from strips of different types of iron could be made, for example, by casting or rolling, in large quantities and cheaply. And since an ingot, unlike a forging, is quite homogeneous, such steel is convenient to process by cutting.

Modern technological processes of ferrous metallurgy[edit]

In 1865, Pierre and Emile Martin developed the open hearth furnace. It is based on a reflective arch, which reduces the contact of flue gases with metal, and regenerators that preheat the air to a high temperature. The latter made it possible to raise the temperature of the flue gases and melt the steel.

While the Bessemer converter could load scrap metal in very small quantities, the open hearth made scrap metal real scrap again. Open-hearth and Bessemer steel had slightly different properties, but because the open-hearth process was more repeatable, it long became the dominant technology for steelmaking. In 2018, the last open-hearth furnace was closed in Russia, and these furnaces remained only in India and Ukraine. Nowadays steel is melted in oxygen converters and electric furnaces.

Lyrical digression.

People often confuse recycling (using an item several times for the same or a different purpose in its original form), recycling (processing waste into something useful), decontamination (removing waste from harmful properties) and landfill (placing waste where it does not belong). will interfere).

Accordingly, scrap

, or

recyclable materials

, is waste that in a given technical and economic situation can be processed into something useful.

The steel was blown, of course, with air. And it contains 78% nitrogen, and it is harmful. In the 20th century they made cheap oxygen, and they began to put it into the open-hearth (the temperature in the converters developed such that it burned out). In moderate quantities, of course, the refractories melted there too. In 1952, the oxygen-converter process was mastered: oxygen was supplied from above through a pipe, and scrap was constantly added to it for cooling.

Good steel contains many alloying elements. But how can you make sure that they fuse with steel and not oxidize into slag? For this, at the beginning of the 20th century. invented electric furnaces - arc and induction. They can have any atmosphere: even oxidizing, even reducing, even neutral, even completely inert. First, the required amount of carbon was achieved in an oxidizing atmosphere, the slag was removed, ferroalloys with the required elements were added, and heated without access to air. In an arc furnace, an arc was created between cast iron and a graphite electrode, and in an induction furnace, they were heated with a high-frequency current.

Relatively new technologies include vacuum furnaces (reduce the amount of nitrogen and oxygen in steel), electroslag remelting (a method of purifying steel from sulfur and phosphorus) and direct reduction of iron, bypassing cast iron (if there is cheap electricity or large fines for emissions of harmful substances, it can be cheaper) .

[Someone write more about them]

Oxygen-converter method of steel production

Steel production today is carried out mainly in this way. BOF production recently accounted for up to 60% of global steel production.

However, this percentage is decreasing due to the advent of electric arc furnaces (EAFs). The furnaces are purged with pure oxygen (99.5%) under high pressure.

The product of an oxygen converter furnace is steel with specified chemical properties. It enters a continuous casting machine (CCM), where the material solidifies into a bloom or slab. To obtain certain stringent parameters, the metal is recycled.

Mini-metallurgical plants

Since the mid-80s. In the 20th century, the concept of “mini-metallurgical plants” became firmly established in the practice of metallurgical production, which began to successfully compete with full-cycle plants.

Currently, approximately 30% of all steel is produced at such plants. The modern content of the concept of “mini-plant” includes minimal production costs, minimal emissions of process waste into the environment, minimal downtime of equipment and units, a minimal production cycle with maximum productivity, sales, profitability, etc. Typically, this category includes plants with a production volume of 0.1...1.6(2) million tons of steel per year. According to various estimates, there are currently about 500-600 mini-factories in the world.

A mini-metallurgical plant is a complex consisting of the following units: an electric arc furnace, a steel finishing installation in a ladle-furnace ladle, a high-performance continuous steel casting machine and a group of rolling mills.

The basis for the successful operation of mini-metallurgical plants is the high economic efficiency of the main technological units included in their composition, as well as the high degree of their functional compatibility in a single production cycle. Essentially, the connecting element between the electric arc furnace and the continuous casting machine (CCM) is a “furnace-ladle” unit, in which a set of measures is carried out to refine the steel in terms of temperature and chemical composition, its refining, as well as holding it in time in accordance with the regime casting on a continuous casting machine. Particular attention should be paid to the fact that it is the units that allow regulated heating of steel in the ladle that provide in practice both the expansion of the functionality of out-of-furnace processing and the stabilization of the operation of the continuous caster when casting in long series with a usable yield above 96...97%, as well as significant energy - and resource-saving effect.

An extremely important feature of the new mini-plants is the desire to ensure the highest specific productivity of melting units and continuous casters producing long products.

Electric steelmaking method

Steel production by electric melting has a number of undeniable advantages. This method is considered the main one for the smelting of high-quality alloy steels.

The high temperature achieved in this case allows the smelting of steels containing refractory metals:

- molybdenum;

- tungsten;

- vanadium.

High quality is achieved by the virtual absence of phosphorus, sulfur and oxygen in steels. This method is also used to produce a wide range of construction steels.

The release of heat is not associated with the consumption of the oxidizer, but occurs as a result of the conversion of electrical energy into thermal energy. It is released during the passage of an electric arc or the induction of eddy currents. Depending on the principle of operation, furnaces are divided into electric arc and induction.

An electric arc furnace can simultaneously accept from 3.5 to 270 tons of raw materials:

- liquid steel from converters;

- scrap;

- iron ore.

It has several electrodes made of graphite-containing material, to which electrical voltage is applied. The melting time is up to 1.5 hours, while the arc temperature reaches 6 thousand degrees.

Heat treatment of steel[edit]

Basic types[edit]

- Annealing (heating until red-hot and slow cooling with the furnace, in hot ash, sand, etc.). Makes steel ductile and malleable. Known since ancient times (used for copper in the Copper-Stone Age)

- Normalization is the simplest option: heating until red hot and cooling in air.

- Hardening (heating red-hot and sharp cooling) was necessarily combined with subsequent tempering (moderate heating - the temperature depended on the purpose: low - 150-250°, for cutting tools; medium - 350-500°, for springs, armor, etc. , high - 500-700°, for critical metal structures).

Hardening was invented at the turn of the 2nd and 1st millennia BC. e. (the oldest find is the city of Idalion in Cyprus). This is the most critical of heat treatment operations: a small error in the heating temperature or the method of immersion in the quenching liquid can lead to cracks or severe deformations of the product. Moreover, whether the blade would be sharp or dull depended 90% on the hardening temperature!

Water was used as a traditional quenching medium (necessarily cool - 15-25 °), often taken only from strictly defined rivers (Jalon and Hiloka in Spain, Fur - in France, Derwent - in England), as well as solutions based on it, often very exotic - the urine of a three-year-old ram or a red-haired boy (by the way, it’s really much better than water: the salt present in the urine provides a sharper and more uniform hardening, and urea sharply reduces the risk of cracks), blood (really, it’s a worthless option: it instantly coagulates and a lump of protein forms on the product, preventing normal cooling), milk (produces a not very hard, but very sharp blade - just like the famous hardening in a stream of wind). For particularly capricious products, they used hardening in a wet cotton rag, in wet felt (and soaked not in water, but in a mixture of blood, vinegar and onion juice!), in the trunk of a banana tree (it is comparable in hardness to a potato), in freshly cut grass or wild berries, etc.

Of the non-aqueous quenching media, the most popular are different types of oils (in our time - industrial, in the old days - animal and vegetable; in Africa, of course, weapons hardened in human fat were especially popular).

More complex cases[edit]

- Nitriding

- exposure of steel to a layer of nitrogen or its compounds (salts of nitric acids, ammonia, but not nitric acid) dramatically increases the strength of its surface layer and resistance to corrosion even at room temperatures. Actually, the above examples of hardening in urine are actually nitriding. Native iron is usually found in the form of small nuggets, the size of a small pea or less, and the Iron Age Celts got the idea of feeding them to chickens or geese half and half with grain, and then washing out their droppings. This could be done repeatedly. This method was later adopted by the Germans. Simply soaking the finished product in a vat of boiling urine is also suitable; in some places it was actually used (India, China), but due to nausea, of course, it did not become widespread. In modern times, it has been replaced by baths of nitrogen salt solutions heated to 500 degrees, or by special furnaces and chambers with ammonia heated to 1000 degrees.

Features of electric induction furnaces

In electric induction furnaces, steel is smelted in small volume (4.5–60 tons) containers called refractory crucibles. Around the crucible there is an inductor consisting of a large number of turns of wire.

When an alternating current passes inside, high-power eddy currents are induced, causing the contents of the crucible to melt. Electromagnetic forces simultaneously stir the molten steel. The duration of smelting in such furnaces does not exceed 45 minutes.

The electric steelmaking method produces little smoke, dust and emits less light energy. However, the high cost of electrical equipment with low capacity limits the use of this method.

Diagram of an electric furnace

In addition to the options discussed, there are not only basic methods of steel production. Modern steelmaking uses smelting in vacuum induction furnaces and enrichment of the percentage of iron in pellets by plasma-arc remelting.

Types of steel produced by chemical composition

The steel produced by these methods is divided, depending on the chemical composition, into two large groups:

- carbon;

- alloyed.

Percentage of elements in carbon steel:

| Name | Fe | WITH | Si | Mn | S | P |

| Content in percentage | up to 99.0 | 0,05–2,0 | 0,15–0,35 | 0,3–0,8 | up to 0.06 | up to 0.07 |

In carbon steels, strength is not sufficiently combined with ductility. The disadvantage is eliminated by introducing additives of other metals; such steel is called alloy steel.

According to GOST 5200, there are three groups of alloy steels with permissible impurity content:

- low alloy no more than 2.5%;

- medium alloyed in the range of 2.5–10%;

- highly alloyed over 10%.

Every year, smelting methods are improved thanks to the commissioning of new high-tech equipment. This allows the steel industry to produce high-quality steels with the optimal content of additives and metals.

Steel marking

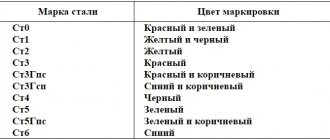

Depending on the purpose and guaranteed properties, ordinary quality steels are divided into groups A, B, C. Steels of these groups are guaranteed: A – mechanical properties; B – chemical composition; B – both of these parameters.

Ordinary quality steel is marked with the letters St and numbers from 0 to 7, indicating a serial number, with an increase in which the strength increases, but the ductility of the steel decreases. The steel’s belonging to groups B and C is indicated in the marking with the same letters. Marking examples: St2kp, BSt6sp, VSt3ps, BS6Gps. As the steel number increases, the carbon content also increases, but the figure does not correspond to its average content (St3 contains 0.14...0.22% C, St4 - 0.18...0.27% C, St6 - 0.38... 0.49% C, in StO – approximately 0.23% C).

Group A steels are used mainly in the as-delivered state without subsequent technological operations (welding, pressure treatment, etc.). Heat treatment is not recommended since steels have significant variations in chemical composition.