Characteristics of cartridges

There are quite a few modifications of cartridges for direct mounting. For ease of selection, additional markings are provided.

The construction chuck is precisely selected for specific work:

1. D 1 (marking color white) - made from environmentally friendly materials, does not contain heavy metals, and is used in enclosed spaces.

2. D 2 (yellow color) - used for fastening steel building structures with a thickness of 2 to 4 mm in a stone or concrete base.

3. D 3 (blue color) - used for fastening steel, aluminum or wooden structures to a concrete base.

4. D 4 (red color) - considered the most powerful, used for fastening building elements on surfaces made of concrete, brick and low-carbon steel, has an energy output of 700 J.

Packaging types

Construction cartridges are supplied in tape and ring plastic cassettes.

One package can contain 10-20 rounds.

Cartridges marked “D” can be supplied in boxes of 100 and 80 pieces marked “K”.

Handling construction cartridges requires some caution. Cartridges are explosive when heated, impacted or loaded.

Notes

- The data is for cartridges D1-D4 with a height of 22 mm. In cartridges with a height of 18 mm, there is less weight: in D4 22 mm gunpowder 0.43 g, in D4 18 mm - 0.36 g; in D3 22 mm - 0.38 g, in D3 18 mm - 0.33 g. In 22 mm, the gunpowder is non-graphitized, greenish-green in color with a silver tint, in 18 mm it is black, graphitized.

- [www.gun.ru/oxota0408.htm Salyut brand gunpowder.]

- [www.freepatent.ru/patents/2254313 Gunpowder for construction and assembly and pistol cartridges (RF patent No. 2254313).]

- Igor Boechin: “Trunks” for concealed carry” // “Weapons”. - 1995. - No. 12. - P. 50.

- [56.mvd.ru/news/item/500729/?print=1 Website of the Office of the Ministry of Internal Affairs of Russia for the Saratov Region.]

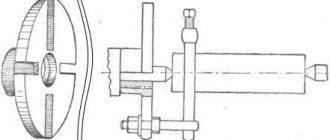

Tool for driving construction cartridges

Construction chucks are used for direct installation. Special mounting guns of various brands and designs are produced for construction cartridges.

Mounting guns (PMT-1 and PC-84) are classified as powder tools. They are specially designed for driving fastening building structures to brick and concrete foundations using direct shooting with construction cartridges and dowel-nails. Using mounting guns, it is easy to obtain permanent fastenings by direct shooting to a concrete or brick surface. You cannot use construction cartridges in firearms!

Source

Differences from combat [edit | edit code]

Despite the external similarity with small arms cartridges, changes have been made to the design of some construction and installation cartridges that prevent their conversion into combat ones. Thus, some construction cartridges have a very thin case bottom, which is not able to withstand the pressure of powder gases. [ source not specified 1842 days

] MPU cartridges use a less sensitive primer compared to a combat cartridge, which does not fire when used in military weapons. Cartridges of the D and K series are similar in case design to small-caliber rimfire cartridges, but in comparison with them they have different geometric dimensions and thicker case metal, in accordance with more severe operating conditions: the loading density and, accordingly, the mass of the powder charge in construction cartridges is much higher higher than that of bullets with the same volume of the internal cavity; accordingly, when they are triggered, a greater pressure of powder gases develops. The latter feature makes their use without modification for bullet shooting very dangerous, especially the more powerful variants.

The gunpowders used in construction and installation cartridges of the MPU series are similar in type to fast-burning hunting gunpowders for smooth-bore weapons (such varieties as “Salyut”, “Bars”), and are close in characteristics to the gunpowders used in small-caliber rimfire cartridges or some quick-burning pistol (P-45, P-125). They have a fine single-channel cylindrical grain, a very high burning rate and high power. They are not suitable for safe use in long-barreled rifles; Even with the normal use of gunpowders of this type, special care and high (up to 0.01 g) weighing accuracy are required.

In construction and installation rimfire cartridges, very fast-burning varnish powders of the MSSN 15/4.85 and MsSN 17/4.85 brands, which are spheroid-shaped grains with a graphite surface, are also used; they are also used in some cartridges for firearms of limited destruction (“ traumatic").

In order to save money, gunpowder from construction and assembly cartridges is quite widely used by owners of short-barreled and traumatic weapons for training shooting - in Ukraine this is within the legal framework, as well as by reenactors for simulated shooting. Forensic scientists know a large number of homemade weapons chambered for construction and installation cartridges of the K and D series, or made on their basis.

Mounting chucks are an indispensable item in construction and finishing work. Their use allows for quick installation of structures, communications, finishing of premises and other operations. It is used for driving dowel-nails into bases made of brick, lightweight concrete and reinforced concrete, as well as into bases made of low-carbon steel up to 12 mm thick.

Wood, plywood, aluminum, steel and other materials are used as materials for mounted elements. The work uses automatic and semi-automatic mounting guns from domestic and foreign manufacturers - such as PC-84, PMT-1 and others. offers long and short construction cartridges, which you can buy with delivery to your region in a batch of the required volume.

Mounting chucks. Characteristics and color coding

Powder construction pistols require mounting cartridges, the explosion energy of which ensures impact driving of dowels into concrete or metal surfaces. In this article we will talk about the types and markings of such cartridges.

Classification

Since a mismatch in the capabilities of the mounting cartridge can cause damage to the powder pistol, the classification of these consumables is carried out simultaneously according to several parameters:

All types of mounting chucks used in construction work have a standard design and consist of the following parts:

Select the one you need

Mounting cartridges of the bulletless type fire according to the same principle - when the striker of the pistol strikes the primer, the impact composition located in the cartridge is ignited sequentially. The explosion energy of the gunpowder released in this case accelerates the piston of the mounting gun to values that provide the dowel-nail with the necessary speed of penetration into the material.

There are five conventional gradations in power, which is released when the mounting cartridge is triggered:

For 5.6 caliber cartridges, mounting cartridges with the number D6 are additionally produced, the kinetic energy of impact of which, in comparison with similar consumables of the D5 series, is increased by 30...35%. Thus, the operational capabilities of mounting cartridges are determined by their height and diameter, which must be consistent with the corresponding parameters of powder pistols.

Security measures

Since the cartridges for the mounting gun contain an explosive substance, the degree of danger of which, according to GOST 19733-74, is fourth, special precautions should be taken when using them. They boil down to the following:

Why is this being done?

But the main purpose of the mark, coloring of elements and labels is that they together form a system of symbols, which contain the information necessary to distinguish between the types and purposes of cartridges. Although there may be additional properties. For example, the coloring of cartridges is used to provide a distinctive feature of one type that is easily perceived, or to quickly communicate the purpose of cartridges. At the same time, it is also a means of protection against corrosion processes.

In the domestic tradition, the color of the bullet head (its tip) is used. This decision has been made since the times of the Russian Empire. For example, an armor-piercing incendiary bullet is painted red and black. Green is selected for tracer cartridges. Ordinary cartridges do not have a distinctive color. This is observed in a number of foreign armies.

Sometimes you can see the color of the primer at the junction of the bullets with the barrel of the cartridge case. In this case, it is used not only to obtain a distinctive feature, but also for tightness. True, this approach causes certain inconveniences when creating cartridges and visually determining the nomenclature. What information can be gleaned by examining bullets? In short, the main information is:

- For Soviet (Russian) ones: year of manufacture and designation of the manufacturing plant.

- Australian, Canadian, English: type (brand) and name of the creator company.

- French: time (quarter and year), designation of the metal supplier for the sleeve.

- German: the manufacturer, material, batch number, and also when it was produced are indicated.

- Italian: for private enterprises only the year of manufacture and the name of the company that created the product. For government officials: manufacturer, time of manufacture, inspector’s initials.

- Japanese: year of creation (according to the local calendar) and quarter, abbreviated name of the company.

Information is usually applied by indentation. Although sometimes you can find convex relief.

Industrial construction powder cartridges D2;3;4;5 and K – price, photos and videos, reviews

Operating temperature from minus 30°С to plus 50°С.

Delivery forms and packaging:

Cartridges D1-D5 6.8x18 in bulk are supplied in cardboard boxes of 5000 pieces. Primary packaging for consumers – cardboard boxes of 100 pcs. The products comply with the requirements of regulatory documents GOST R 50530-2007.

K series cassette construction and installation chucks

Fast mounting technology

In various fields of industry and construction, it is often necessary to install structures without resorting to preparatory operations. The so-called direct installation technique involves fastening individual parts to each other using construction guns, steel dowels and blank industrial chucks.

This cartridge is fired from a mounting gun, pressing it tightly against the surface to be fastened. Due to the impact force generated when the cartridge ruptures, the dowel fits tightly into concrete, brick or metal (with a thickness of no more than 6 mm). In this way, you can fasten elements without pre-drilling holes.

You can find areas of application for such connections everywhere: for fastening the equipment of plasterboard boards, metal mesh for finishing walls with marble or tiles, etc. and so on. Loads, differences in mechanical tasks and proposed circumstances determine a certain approach to the selection of consumables.

It is clear that the base into which the dowel fits has a different density, so construction cartridges of different power are used for such installation.

K series mounting chucks on cassette

Description and designations

Mounting cartridges are used as a source of energy for driving dowel-nails into concrete, steel and brick building structures when installing equipment, utility fasteners and hanging elements made of metal up to 6 mm thick.

They are designated by the codes D (long) and K (short) and marked with two numbers 6.8x18 or 6.8x11. The first number indicates the caliber, the second the length of the cartridge case.

In cartridges with code D (length 18 mm), the shock composition is located in the annular part of the bottom of the case; with code K (length 11 mm), the shock composition is distributed over the entire area of the bottom of the case.

Cartridges with indices D and K are divided into 5 groups according to the mass of the powder charge and, accordingly, according to energy, measured in Joules (J). To facilitate classification by power, the crimped end of the sleeve (star) is painted a certain color.

Cartridge designation – 6.8*18 (6.8*11). Diameter Ø, mm – 6.8.

The table shows the classification of cartridges for the PTs-84 mounting gun of varying power.

| Caliber 6.8 x 18 mm | |||

| Cipher | Color | Energy, J | Material of construction |

| K3D | Green | 165-224 | |

| K4D | Brown | 224-293 | |

| D1 | White | 293-370 | Brickwork, concrete |

| D 2 | Yellow | 370-457 | Brickwork, medium strength concrete |

| D3 | Blue | 457-574 | Brickwork, medium strength concrete |

| D4 | Red | 574-703 | High strength concrete |

| D5 | Black | 703-846 | High strength concrete |

| Caliber 6.8 x 11 mm | |||

| Cipher | Color | Energy, J | Material of construction |

| K1 | Grey | 105-154 | |

| K2 | Brown | 154-212 | |

| K3 | Green | 212-278 | Brickwork, medium strength concrete |

| K4 | Yellow | 278-354 | Medium Strength Concrete |

| K5 | Red | 354-458 | |

| K6 | Black | 439-534 |

For soft materials such as wood, plywood or chipboard, “white” cartridges are used, and then, the stronger the base structure, the “darker” the paint on construction and installation cartridges.

Precautionary measures

In accordance with GOST 19433-81, mounting cartridges belong to class 4 according to the degree of danger, subclass 4.1 - flammable solids. During transportation, storage and use, the manufacturer's recommendations and safety regulations must be strictly followed.

Despite the fact that mounting cartridges belong to the blank class, it is necessary to follow safety regulations and allow trained workers to work.

The use of sighting tools and construction cartridges significantly reduces the installation time of metal structures on concrete and brick foundations, and also eliminates preparatory operations (drilling, countersinking holes, etc.), and completely eliminates the use of power tools.

The use of a special cassette (tape) of 10 pieces allows the use of semi-automatic analogues from foreign manufacturers, for example, such as WALTE PT-450V.

How does an electrical cable work?

The cable design consists of two elements:

- Current-carrying conductors - copper or aluminum, single or consisting of several conductors, coated with a dielectric material. Conducting conductors can be collected in packages, which, in turn, have a sheath made of dielectric, lead or aluminum.

- External dielectric shell.

Single conductors are used in cables whose current strength does not exceed 25 amperes. Stranded wires have greater electrical strength with a smaller cross-sectional area due to mutual compensation of surface currents, which lead to heating, melting and subsequent physical breakage. In addition, a package of multiple conductors is more flexible and easier to lay, since the permissible bending radius of the cable (without leading to destruction of the internal insulation layer) is smaller.

Aluminum has a higher resistivity than copper (0.028 versus 0.017 Ohm/mm2) and a lower melting point (660 and 1085 0C, respectively). Therefore, to obtain the same electrical strength, aluminum conductors must be twice as thick, which is not particularly significant for currents up to 16 A and is a decisive fact in favor of choosing copper conductors for heavy loads in the network.

In addition, practical experience in installing electrical wiring shows that wires made of this material tend to break when repeatedly twisted or subject to significant vibration loads. However, cables with aluminum conductors are cheaper and weigh less, so they were widely used during Soviet times.

The cable screen - the outer sheath - plays the role of not only dielectric, but also physical protection. Therefore, those that are used in unfavorable conditions, for example, are laid in the ground or where they can be damaged by mechanisms or tools, are wrapped with metal tape on the outside and are called armored. Their screen consists of three layers:

- Cushion – fibrous materials impregnated with bitumen. Serves to protect against damage to the insulation of current-carrying conductors by the edges of the armor tape.

- Metal (steel or copper) tape - armor protection.

- Cover - bitumen compounds or polyethylene protective hose.

Ammo questions

Precautions when using starting flare pistols and 5.6mm revolvers.

Some unprepared citizens are connoisseurs of starting (signal) pistols and revolvers (usually pistols),

They do not know about such a feature of side firing cartridges as loose rolling of the cartridge. This happens regardless of the size and manufacturer in 5.6mm cartridges.

This can affect the performance of the pistol as follows:

When a pistol is fired, burning powder gases and sparks can penetrate the holes in the top of the remaining cartridges, causing the remaining cartridges in the clip to ignite and detonate. Which can lead to several bricks being deposited in the “shooter’s” pants.

In this regard, I recommend that you don’t be lazy and take any available tool, such as PVA glue.

Particular importance should be attached to this when shooting with Hilti cartridges (especially red ones).

Long cartridges are much louder than short ones.

The flash from a shot is much stronger with long cartridges than with short ones.

shoot short cartridges?

shoot long cartridges?

Is it possible to buy less ammo than in a pack?

We sell cartridges only in packs of 100 pcs.

In rare cases, we can pour zhmenka free of charge (to the buyer we like).

Why is the caliber written 6mm but in reality 5.6mm?

5.6mm or 6mm which is correct?

The “small thing” has a bullet and cartridge caliber of 5.6mm.

Blank cartridges have exactly the same case caliber of 5.6 mm. I measured it myself.

although the real caliber is 5.6mm. The same is often written on cartridges. My final and factual verdict: There is no 6mm caliber in nature! There is an inscription, but not in nature =).

What is the joule capacity of your Umarex 5.6mm long cartridges?

There is no concept of power for starter cartridges, so I definitely won’t answer this question. I guess they are a little weaker than the brown Hilties.

On Hansa they wrote about 50-80 J (but this is not verified information).

Brown 100+-50JGreen 150+-50JYellow 250+-50JBlue 350+-50JRed 450+-50J

For comparison, the power of a live cartridge for a Makarov pistol (PM) is 300J.

How are your Umarex (Pobeda) cartridges better than Hilti mounting cartridges?

Is there a difference between Hilti cartridges and your cartridges?

I could write an entire dissertation on this topic.

If used to launch rockets, it is “very large.” If for shooting, “medium”

“Hilti” has a lot of power and produces too much gas. “Umarex” has lower power, lower gas formation rate, and lower power.

The Hilti does not have an even weight of gunpowder. In Umarex everything is like in a pharmacy.

(next to machine guns and other interesting things).

“Hilti” has a short, dull rumble and a small short flash. “Umarex” has a more biting and beautiful sound (like in a movie) and a big

a beautiful flash that is longer in time.

“Hilti” often swells from all sides and can even tear the sleeve or knock out the bottom. “Umarex” does not inflate after a shot. They are freely removed from the drum.

“Hilti” often give points, especially in some games. There are no such problems with Umarex.

How to properly store cartridges?

Store them in a dry place, preferably with a bag (or several) of silica gel. Well, make sure they don’t get eaten: children, wives, dogs, cats, moths, mother-in-law.

Can Hilti chucks and other mounting chucks be used? What kind of shots do you use?

As for other cartridges, I will say this. Initially, starting (signal) pistols and revolvers were made for the cartridges that I sell (umarex).

Everything else is not Feng Shui.

I shoot red Hilti cartridges, I’ve already shot half a pack. Why hasn't my Lom-S ruptured yet?

For a full test, you need to shoot a couple of hundred (or even thousands) and then speak with confidence.

What is the diameter of the rubber ball in the 9PA (9x22) traumatic cartridge?

Ball diameter 10mm.

What are the best 9PA (9x22) blank cartridges?

Of those that I brought, buyers praised me the most. YAS - Türkiye.

Titan (Perfecta) – Germany.

They say they are powerful and good for reloading. (The capsule in them is a 4.4mm boxer)

Mounting chucks

According to the current legislation in Russia (Resolution of the Plenum of the Supreme Court of the Russian Federation No. 5 of March 12, 2002), assembly cartridges do not belong to ammunition, therefore their use in the construction industry is permitted without restrictions.

We, ELECTRON LLC, offer mounting index (marking) cartridges D3 and D4 at prices starting from 1.5 rubles per unit. The cartridges sold by our company comply with the norms and standards adopted in Russia, and also have all the necessary documents confirming the quality of the products - GOST R 50530-2007.

Our warehouse capacity allows us to store and offer for sale virtually unlimited quantities of construction and assembly cartridges D3 and D4.

For questions regarding the purchase of industrial cartridges, as well as regarding the possibility of using them in mounting guns of various brands, please contact our company employees by phone and +8 (965) 760-77-77 or by email

The mass of the powder charge of D3 mounting cartridges is sufficient to completely drive a dowel into steel up to 4 millimeters thick and aluminum up to 5 millimeters thick.

In addition, using industrial D3 cartridges in mounting guns, you can drive dowels into lightweight concrete with porous filling, into heavy concrete with natural stone filler, as well as into unplastered and plastered brickwork.

The storage requirements for industrial D3 cartridges are less stringent than for military cartridges, because according to Russian legislation, D3 assembly construction cartridges do not qualify as ammunition.

To make it easier to determine the class of the cartridge, its rolled part is marked with red paint. The traditional form of production of industrial mounting chucks is a package of 100 pieces.

The D4 marking of the mounting cartridge means that the mass of gunpowder in it is 0.43 grams, and the energy output is 1174 J.

From us you can order everything you need for construction and more.

By phone

How to do it and what is needed for the work?

In order to create such a device, you will need the following elements:

During operation, this pistol model has the ability to automatically get rid of the used cartridge case, as the powder gases are released, and this, in turn, facilitates the reloading itself.

The sequence of loading a construction gun: a - putting on the tip, b - opening the gun, c - pushing out the wad, d - inserting the dowel into the barrel, e - inserting the cartridge, c - closing the gun.

So, the process of creating a homemade pistol is as follows:

Source

A few things you might encounter

In this gun, the role of an arc is performed by a bent nail. It accounts for most of the recoil when fired. The firing process is accompanied by a release of energy from the powder gases, as a result of which the bolt moves to the rearmost position, and the cartridge case flies out of the pistol at this moment. This process puts tension on the mainspring, which provides shock absorption.

The position of the construction pistol and the operator’s hands when firing a shot: a – pressing the button, b – placing the pistols along the markings and pressing the trigger, c – the dowel is hammered in and the gun is removed from the plane of the wall.

During this action, the handle itself hits this improvised arc, and this method stops the bolt, and after the gun gets rid of the cartridge case, the bolt returns to its original position. So, to prevent the arc from deforming and cracking on the surface, it is best to use 200 nails for this purpose. It is recommended to pre-harden the iron.

To ensure more convenient erection of the bolt, it is necessary to install a ring near the arc, on the bolt frame itself. It will help support the impact. It must be installed similarly to the shutter handle, that is, obliquely, otherwise interference will occur when aiming. At a short distance, 7 mm holes (2 pcs.) are made on both sides of the frame. They will serve as a patron to make it possible to more conveniently and quickly reload the pistol.

Along the entire body of the main frame, it is necessary to cut a semicircular hole, which is intended for the bolt frame.

To make the trigger, the nail is bent in an “h” shape, but only in such a way that the upper right leg is missing. After this, you need to make a hole in the frame for the pin, as close to the trigger as possible, and grind off the excess. A similar aperture is made for a spring, the location of which is in the middle of the trigger.

After the trigger is attached to the frame, they begin to fix the bolt frame with the barrel. For this, metal plates and screws are used. The first ones must be in the shape of the pistol frame, for which they are deformed accordingly. They are fastened on both sides, as well as in the center of the bolt and main frame.

Loading in such a pistol is as follows: first of all, the bolt is cocked all the way, and it is loaded with a cartridge, after which a shot follows. After each procedure, the steps must be repeated. To ensure that the cartridge case leaves the bolt freely, it is recommended to lightly coat each cartridge with machine oil.

Mounting chucks. Characteristics and color coding

Powder construction pistols require mounting cartridges, the explosion energy of which ensures impact driving of dowels into concrete or metal surfaces. In this article we will talk about the types and markings of such cartridges.

Since a mismatch in the capabilities of the mounting cartridge can cause damage to the powder pistol, the classification of these consumables is carried out simultaneously according to several parameters:

All types of mounting chucks used in construction work have a standard design and consist of the following parts:

| Video (click to play). |

Mounting cartridges of the bulletless type fire according to the same principle - when the striker of the pistol strikes the primer, the impact composition located in the cartridge is ignited sequentially. The explosion energy of the gunpowder released in this case accelerates the piston of the mounting gun to values that provide the dowel-nail with the necessary speed of penetration into the material.

There are five conventional gradations in power, which is released when the mounting cartridge is triggered:

For 5.6 caliber cartridges, mounting cartridges with the number D6 are additionally produced, the kinetic energy of impact of which, in comparison with similar consumables of the D5 series, is increased by 30...35%. Thus, the operational capabilities of mounting cartridges are determined by their height and diameter, which must be consistent with the corresponding parameters of powder pistols.

Since the cartridges for the mounting gun contain an explosive substance, the degree of danger of which, according to GOST 19733-74, is fourth, special precautions should be taken when using them. They boil down to the following:

There is no topical video for this article.

| Video (click to play). |

Moscow Engineering Construction Economic Forum.