Looking into a hardware store, you can be amazed at the variety of tools displayed on the shelves of retail establishments. Especially many devices are offered for carrying out installation work of a narrow specialization. A gun for driving dowels is quite popular among them.

Of course, there are people who are against using the latest achievements of progress to facilitate the implementation of individual operations in construction and do everything the old fashioned way. However, this approach is only partly correct, since in each specific case everything is individual: the volume and speed of work will be different.

But people who want to effectively carry out the tasks facing them in construction or repair do not miss the opportunity to purchase and use a construction gun, since its use can significantly speed up the execution of manipulations, as well as improve their quality. Driving nails and dowels using this tool is much faster, the work process is noticeably faster, and in addition, the physical effort of the worker is reduced.

Features and Specifications

Among the large variety of properties and parameters that are typical for dowel gun models, the following important parameters can be noted:

- Cartridge supply. According to this parameter, semi-automatic and manual tools are distinguished.

- Weight of pistols. Depending on the model, it can vary from 3.1 to 5 kg.

- Nutrition. It can be provided by a battery, gas powder or an electrical network.

- Fixing elements supply system: modern models of construction pistols can be used single-shot or multi-shot.

- Gun length. This parameter varies from 345 to 475 mm.

- Trunk diameter. It varies from 8.2 to 12.5 mm.

- The optimal temperature for work is from -31 to +53 degrees.

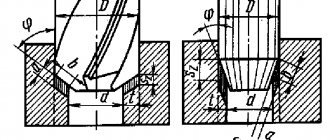

Gunpowder tools

A construction powder pistol drives the piston due to the explosion of gunpowder located in the cartridge. Dowels are driven into various surfaces. Advantages of this type:

- small size;

- the greatest power in comparison with other types;

- there are no connected cylinders, hoses, cables to electricity;

- works with various types of fasteners;

- the dowels fall exactly into the right place.

But there are also some disadvantages:

- in each individual case you need to select the appropriate cartridges;

- parts require cleaning from gunpowder residues and may require complete replacement;

- cannot be used in conditions of fire hazard;

- permission required.

A prominent representative of this category is the PC-84 construction pistol.

Scope of application

In principle, the purpose of this tool can be learned from its name. It is used mainly for driving dowels and nails into various surfaces. When performing manipulations, the fixative used is usually hammered into a solid material: concrete, plastic, brick, stone.

It is more reasonable to use a construction tool for dowels when it is necessary to carry out large volumes of work. Quite often it is used for:

- Laying various communications inside the building. The quality of the installation work carried out will depend mainly on the speed of driving in the fasteners. So, if the aligned fixing parts are driven in slowly, a situation may arise where they are skewed, which will subsequently negatively affect the functioning of the electrical network, Internet cable or antenna wire. If you quickly fix the fasteners using an installation tool, then the evenness and accuracy of the laying of communications is ensured. Of course, it is necessary to ensure accurate calculations and high-quality markings.

- Fastening siding to building facades. When performing work on the installation of siding panels, it is secured with special nails. In the process of this work, it is necessary to fix a large number of elements on the wall. The process of installing this finishing material will be incredibly long if this work is done manually. If the wall that needs to be upgraded with siding is made of monolithic concrete, then such work becomes practically impossible. When using a construction gun, it becomes possible to quickly and efficiently complete finishing work.

- Soft roof fastenings. This kind of work is not hard work. However, it should be considered incredibly complex. Its implementation requires significant time investment. In addition, there is a human factor that can negatively affect the quality of the work performed.

Types of mounting guns for dowels

Construction gun , used for driving dowels, is offered in stores in various variations. The varieties of this tool differ from each other in the system that creates force, thanks to which the fastening element is fixed in solid material. Depending on such a parameter as the principle of operation, the following types of construction guns can be distinguished:

- gas;

- pneumatic;

- powder;

- electric.

Next we will look at each of these types in more detail.

Gas pistol

The peculiarity of this type of instrument is that its design includes an impact piston mechanism, which is activated by the explosion of a small portion of gas. The latter is supplied from a special cylinder connected to the gun. The force generated during the explosion is transferred to the dowel, and this energy is quite enough to drive the metal fastener into solid material.

If we talk about the advantages of this type of construction gun, we can highlight the following:

- Light weight of the pistol, even when loaded.

- The tool does not have hoses, wires and cables, as well as the independence of the gas installation tool from electricity.

- Simplicity in operation.

- High impact power, thanks to which they can effectively perform installation work.

- Multifunctionality. A specialist can use a gas installation tool not only for driving dowels into solid material, but also use it as a screwdriver or use it as a hammer drill.

Pneumatic tool

This type of installation tool is a device whose operation is based on the expansion energy of compressed air. It is pumped by a special compressor. Currently, this option for mounting devices is quite popular.

It should be said that using a pneumatic device is somewhat inconvenient, since a dense hose is connected directly to it, through which pressure is injected. It is its presence that somewhat limits the possibilities for a specialist in moving and moving with a tool during work. However, we note that modern models do not have such inconveniences. The air ducts that fit the gun are flexible and lightweight.

A small disadvantage of this tool is that it depends on the availability of a source of electricity. If there are no working sockets near the work site, then it will not be possible to perform the work using a pneumatic gun. But many modern models offered in tool stores are equipped with rechargeable batteries, which make it possible to use the devices for an hour.

Among the advantages of pneumatic tools for installing fasteners are:

- high rate of fire;

- compact dimensions;

- reliability of the tool and ease of operation;

- to use this type of tool, no special cartridges or gas mixture are required;

- ease of maintenance;

- high power level;

- light weight of the tool, which ensures ease of use;

- low noise level;

- You can use an air gun in absolutely any conditions;

- reasonable price tag for the tool;

- To use it, a specialist does not need to obtain special permission.

Devices using powder cartridges

To use this type of tool, you must have not only the gun itself, but also special cartridges that are filled with gunpowder . They differ in several parameters: diameter and color, which shows the power of the future shot.

Using a green K3 cartridge during operation, 250 J of energy is generated when fired. This is quite enough to drive a standard dowel into sand-lime brickwork or to fix fasteners in medium-strength concrete.

The cartridges used in such an installation tool are able to fix dowels:

- for metal;

- having threaded elements;

- for wood;

- with extended caps;

- intended for monolithic concrete.

Among the advantages of this type of construction tool are the following:

- compact dimensions of the tool;

- significant shot power;

- absolute precision of fastener supply;

- Autonomous operation of the tool. It does not require a gas cylinder, electrical power or air supply hose;

- the possibility of using various types of dowels during work;

- practicality when performing work, as well as the low weight of the device itself.

Electric nail gun

This version of the installation tool is the weakest. Specialists use such models mainly at the finishing stage, as well as when carrying out “finishing” work.

Electric pistols have the following advantages:

- low weight of the tool;

- ease of use;

- minimum cost of one shot;

- no gas emissions during operation;

- slight vibration and low noise level during use;

- low maintenance requirements for installation tools during operation.

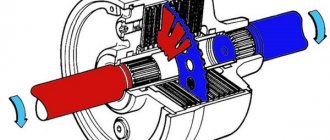

New technologies

A nailer has recently appeared in Russian stores, using the force of compressed nitrogen enclosed in a pneumatic cylinder to strike. The piston is driven by an electric motor powered by a battery.

This miracle of technology is called Senco Fusion F-18. Its advantages are already known:

- high rate of fire (3 shots per second);

- full mobility;

- cheap shot;

- battery charge for 500 shots;

- power of an average pneumatic nail gun.

Of the shortcomings of this pin hammer, only one is known so far - its cost is 35 thousand rubles, which makes its presence in the home workshop quite dubious.

We recommend other articles on the topic

Electric impact wrench - what are the advantages of the tool?

Malka - a tool for moving corners and arranging door slopes

Drill cutters for working on metal and wood

Adjusting the chainsaw carburetor, disassembling, searching for common faults

General operating principles

It should be noted right away that the metal dowels used in mounting guns have a special structure and configuration. They are very little similar to classic dowels. Outwardly, this type of fastener looks like a nail that has a washer located near the pointed end. It is its presence that guarantees high-quality and tight pressing of the fastener to the underlying surface.

The essence of the process of driving in fasteners using a construction tool is to fire a gun loaded with a dowel at a pre-designated location. Completion of this manipulation results in the fastener entering the material, and the washer moves to the top of the cap, which is subsequently fixed with it.

The fastening elements used when shooting with a mounting gun provide the ability to secure any materials on solid bases. It should be remembered that dowels should not be driven into highly porous material, otherwise the fastener will “go away” or the fastening will be fragile.

Tips for choosing

A construction gun should be considered as a convenient tool for driving dowels. Its use allows you to significantly speed up the installation process. The use of this tool ensures reliable fixation of the necessary fasteners. However, it should be understood that depending on the type of installation tool chosen, the range of actions that it is able to perform is limited.

Thus, electric guns, which have low power, can make it easier to carry out work at home. Gas and powder devices, due to the fact that gas is released when they are used, can only be used outdoors. The most multifunctional version of such a tool are pneumatic models.

To choose the right mounting gun for yourself, you need to familiarize yourself with its main advantages and, based on them, select a suitable solution. When choosing, you should take into account the tasks that you will solve with its help. If you have any difficulties choosing this device, then you should contact the seller at the construction tools store. He will tell you a suitable model that will allow you to effectively solve the problem facing you.

How to use it correctly

It is easy to work with a mains or battery model. When the tool is disconnected from the network, nails or other hardware are loaded into the drum. The impact force is adjusted taking into account the type of material and the length of the fasteners. After connecting the cable to the outlet, just place the tool in the desired location and pull the trigger.

When working, it is recommended to adhere to the following rules:

- Use only serviceable and certified tools.

- Before starting installation, wear protective clothing and safety glasses with side guards.

- When choosing powerful models, you need to wear earplugs or headphones, as some devices make a lot of noise when driving nails.

- Before starting the device, you should check the reliability of the connections of all structural parts. Attention is also paid to the quantity of hardware in the store. To start working, you need to put the nailer on its side and charge the clip, then close the lid.

- Don’t forget about adjusting the depth of driving nails; you need to adjust it before work.

- Sparks may fly out of the gun during operation. To maintain fire safety, it is recommended to remove flammable objects from the work area.

- During operation, it is necessary to monitor the rotation of the spring mechanism. After each blow it must return to its original position.

- The tool is positioned strictly in the direction of the surface being processed.

- After installation is completed, the magazine is emptied, the body is wiped with a dry cloth, after which the gun is placed in a case or box. It should be stored in a cool but dry place. To extend the service life of the tool, it is recommended to lubricate the holes after each use with machine oil.