In terms of its functionality, an engraver is very similar to a conventional drill or grinder, but its main purpose is to process parts of miniature size. Using such equipment and special working attachments for the engraver, you can effectively perform various technological operations, which include drilling, milling, grinding, engraving, etc.

Cutting a steel pipe with a cutting disc for a drill

The list of materials that can be processed using an engraver is also quite extensive. These are soft and malleable wood, hard steel, fragile glass or ceramics, various types of plastic and even bone. Naturally, to process different materials with an engraver, different working attachments are used, differing in both design and material of manufacture.

What are engraver attachments?

Working attachments or tools used to work with an engraver are presented in a wide variety on the modern market. Their design includes two main elements:

- a shank with which the tool is fixed in the chuck of the equipment used;

- the working part, which performs the main functions, interacting with the material being processed.

The working part of these nozzles is designed for processing metal surfaces

The choice of working attachments for an engraver is influenced by the following factors: characteristics of the material being processed and the list of technological tasks that need to be performed. Those home craftsmen and specialists who work with an engraving machine on a regular basis try to immediately purchase a set of attachments for the engraver, which includes tools of various sizes and purposes. Depending on the needs and financial capabilities of a particular engraving artist, this may be a more modest set, including several dozen necessary tools, or a professional set, which includes attachments for performing various works on metal, wood and other materials.

When choosing working tools for an engraver, you should take into account that some of its models can be equipped with collet chucks that are suitable for attachments only of a certain brand. To use such equipment in conjunction with any type of attachments, you will have to purchase universal collets for the engraver, which are also sold in whole sets.

Diamond burs for engraving work

The most popular types of working attachments used to complete engraving installations include diamond burs for engravers. The base of such a tool is made of tool steel, and diamond powder is applied only to their working part. The mechanical characteristics of diamond powder make it possible to successfully use the attachment for processing hard materials such as steel, ceramics, glass, artificial and natural stones.

Expensive dental diamond burs have a long service life

Diamond burs (or cutters) are used primarily for finishing shaped holes. As a rule, diamond consumables for engravers are sold in whole sets of 10–20 tools of various shapes and sizes. When working with them, you should strictly follow the rules of their operation so as not to damage the diamond coating. The standard shank diameter of diamond-type engraving bits is 3 mm.

Abrasive tools

The most budget-friendly option for use in conjunction with a drill or engraver are attachments, the working part of which is made of rubber and abrasive material. The diameter of their shank is 2.3 mm, and they are used mainly for work on metal, including stainless steel. Abrasive tools are usually sold in sets of 6 pieces and have different working part configurations.

Abrasive cutters (aluminum oxide) for processing steel and non-ferrous metals

Some manufacturers (in particular,) produce abrasive engraving attachments in various colors, which allows the user to easily determine the category of the tool. Thus, red abrasive wheels, intended for working on metal, are made of aluminum oxide, and green ones, made of silicon carbide, are used for processing stone, glass and ceramic products. For the convenience of performing various technological operations, diamond cutters are made with different shapes of the working part, but their shanks always have the same diameter.

Using abrasive attachments for an engraver, operations such as boring holes, grinding surfaces, etc. are performed. These attachments are optimal for use at home; for a professional, their capabilities will not be enough.

Nozzles can be in the form of removable working heads mounted on the corresponding shank

Master class for a beginner wood carver

First, the wood is selected. Experienced craftsmen do not recommend using pine because it is layered: a soft layer is combined with a hard one.

Description of the procedure for artistic carving.

- First they draw a sketch. Or they select a photograph or picture from other sources, for example, from the Internet.

- Place copy paper on a working wooden surface, and place a drawing on top. Secure with clamps.

- Using cutters, the outline of the future image is manually made.

- The drawing and background are polished. Sanding is a labor-intensive and painstaking task.

- Cover with stain. Apply varnish. But not all craftsmen like varnish coating. They use drying oil, which does not give unnecessary glare, the product remains matte.

This is what the work of novice carvers looks like.

Working attachments for grinding and polishing

An engraving machine, as mentioned above, can be successfully used for fine grinding and polishing of products made from various materials. A roller cutter made of felt is used as a working attachment to perform such technological operations. Since felt does not have outstanding abrasive qualities, such a tool is used only in conjunction with special polishing pastes.

Polishing discs can be used for roughing or finishing, as well as for finishing irregularly shaped surfaces

The choice of polishing pastes of a certain type, which differ significantly from each other in their characteristics and chemical composition, depends primarily on the properties of the material that will be processed with their help. Thus, grinding of hard metal surfaces is performed using pastes based on paraffin and polishing powder. Special polishing pastes based on diamond powder of various fractions are intended for work on wood and glass. With their help, you can not only effectively remove scratches from the surface of wood and glass, but also bring the product into a perfectly smooth state. Experts recommend giving preference to those in which diamond powder has a fraction size of 3/2 and 5/3.

Accessories such as felt grinding attachments for working on wood, metal, glass and other materials are successfully used not only in conjunction with a specialized engraving unit: they can be equipped with a dental drill and simple hand-held devices.

Replaceable sanding attachments

What products can be made

Carving has been practiced since ancient times, as evidenced by the found rock paintings, ornaments on dishes and other household items. People carved images on different materials: stone, glass, bone.

Wood carving with an engraver is a fascinating activity. With the invention of electrical assistants, decorative processing became simpler, and designs became more complex and elegant.

Wood carving has become popular not only in Russia, but in many countries around the world. For example, Canada, rich in forests, is famous for its architects.

They began to decorate with engraving:

- panels, paintings;

- carved balusters;

- icons, iconostasis;

- headboards of beds, furniture fronts;

- platbands for wooden log houses, baths;

- icon cases, frames.

Key rings, knife handles, corner decors - there’s just so much that wood craftsmen don’t decorate.

For reference! An engraver is a tool that replaced manual drawing on wood. In addition, the device can grind, polish small parts, and perform a long series of actions.

Artistic carving on the butt of a gun

Working attachments for professional engravers

A separate category of working attachments that engravers are equipped with are professional series tools. Specialists for whom working with an engraving machine is their main activity, as a rule, have at their disposal entire sets of various attachments that differ in the material of manufacture, design and shape of the working part. If we talk about the most typical composition of such a set, then it necessarily includes:

- cutters for engravers of various shapes, sizes and designs;

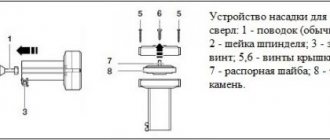

- drills that turn the engraving machine into an effective drill;

- diamond, abrasive and felt rollers;

- wire nozzles, with the help of which they clean the treated surfaces from traces of corrosion and other contaminants;

- cutting discs for engravers, which are quite difficult to purchase individually.

For professionals, each attachment is designed for a specific operation.

The presence of such a capacious set of tools for a specialist who uses an engraver in his professional activities is explained very simply. Often, high-quality and accurate work on the smallest details on the surface of the workpiece is not possible only with a milling cutter, a cutting disc for an engraver, and other tools of the same size. That is why, even within the processing of one product, tools often have to be changed, choosing attachments suitable for performing a certain technological operation.

In addition, the presence of a specialist set of tools, which includes drills, cutters, cutting wheels for engravers and cutters of many other types, is an indicator of professionalism and indicates that this is an experienced person who is good at his job. Craftsmen who constantly work with engraving devices choose expensive sets of tools from the professional series for another reason that it is quite difficult to purchase individual tools from such sets (in particular, a cutting wheel for an engraver).

Special holders allow you to quickly change the necessary attachments

Purpose of attachments by type of operation

- Milling is carried out with attachments in the form of a milling cutter made of hard material.

- Ball-shaped attachments are used for tongue and groove work.

- The material is cut using prefabricated forms.

- Polishing is carried out with nozzles of varying degrees of roughness based on the surface texture: the most common are wheels coated with sandpaper, leather and felt.

- When creating grooves, cone-shaped burs are needed.

- For drilling, steel or carbide nozzles are used.

- Clean the surface from corrosion and dirt using a brush.

- The final processing is carried out with diamond cutters. They are used for metals, alloys, and ornamental stones.

The use of nozzles is clearly shown in the table:

| Nozzle | Type of operation |

| Sharoshka | Engraving |

| Multi-format cutting discs | Material cutting |

| Steel and carbide drills | Drilling |

| Cone-shaped burs | Creating grooves |

| Circles made of felt, felt, sandpaper, leather and holders for self-winding | Polishing |

| Ball burs | tongue and groove |

| Diamond rings, sandpaper circles, grinding stones of various shapes, rubber cylinders | Grinding |

| Milling cutter | Milling |

| Brush made of wire, fabric, thread | Surface cleaning |

| Diamond cutter | Finishing |

Video - DIY engraver attachments

Brief overview of brands

Today, finding engravers and working attachments to equip them on the domestic market does not present any problems. At the same time, the variety of equipment and tools available for free sale allows you to choose them to suit your needs and financial capabilities.

Professional grade attachments

Those craftsmen who engrave wood, metal and other materials at a professional level and already have the appropriate equipment at their disposal should pay attention to working attachments produced under the Dremel and Dexter trademarks. The high cost of such equipment for an engraver is fully justified by its exceptional reliability and durability. Another important advantage that a milling cutter, cutting wheel, drill, as well as any other tool of these brands has, is high processing accuracy.

High-quality consumables are purchased by both professionals and home craftsmen who respect their craft.

When choosing Dremel or Dexter working attachments, keep in mind that one such tool can last as long as 10 Chinese-made attachments. The fact that in the assortment of these companies you can find nozzles of various purposes and standard sizes speaks in favor of purchasing fairly expensive but high-quality products from well-known manufacturers. So, these can be various cutters for a drill or engraver, drills of different diameters, disk tools, as well as any other types of cutters designed for working on wood, metal, ceramics, and glass.

Budget models

Cheap, but decent quality attachments are offered by the domestic manufacturer. At affordable prices you can purchase sets of attachments, including up to 180 tools of the most popular types, designs, sizes and shapes. These sets contain tools for drilling, cutting discs for a drill or engraver, milling attachments, diamond and abrasive cutters, and much more.

All attachments included in the Zubr brand set are placed in a plastic case, making it easy to both store and carry to the job site.

Nozzles from Chinese manufacturers

There are two opinions about Chinese-made nozzles. On the one hand, their quality and reliability are in question, on the other hand, they cost significantly less than branded equipment. A Chinese milling attachment for an engraver, a cutting disc or a drill bit for drilling will not last long, but it won’t be such a shame to throw them away, given their cost. If a professional works behind the engraver, then even a cheap Chinese cutter will not prevent him from doing the job efficiently (although he will have to change such a tool more often).

Chinese attachments for a drill or engraver can be recommended to beginning engravers, who can use them to acquire their first skills in this matter.

Affordable prices of Chinese attachments allow beginning engravers to purchase large sets “to try”

Rules for beginners

Engravers work not only on wood, but also on stone, leather, glass, metal, bone, and plastic. In order for the work to be of high quality, and for the carver to carry it out comfortably, you need to know how to work with an engraver and adhere to the rules. This is especially important for beginners.

It is advisable for beginning carvers to master the technique of carving with a hand engraver rather than an electric one.

To begin with, they “stuff” their hand. They learn to cut grooves, grooves, and simple shapes. Necessary tools for working as a hand wood engraver:

- gravers with thin steel rods (v-shaped, angular, flat);

- lamp with lens;

- punches (for dotted lines, dots);

- chisels;

- substrate for the workpiece.

It is advisable for a beginning carver to use a tutorial with ready-made drawings, ornaments and techniques, or take several lessons from professionals.

Note! When working as a wood engraver, the workpiece is placed on a small cushion so that the material does not slip. The pillow itself is fixed with double-sided tape.

Rules for wood carving with an engraver for beginning carvers:

- The desktop should be free, no unnecessary objects.

- A special lamp for soft illumination of the workplace.

- It is unacceptable to jerk the instrument in different directions, play around with it, or knock on the table.

- The engraver must not be left accessible to children.

- While the instrument is running, it is prohibited to remove or change the attachment.

- During operation, the device should be kept away from your face to avoid accidental injury.

All attachments, cutters, and tools necessary for work should be laid out on shelves and drawers so that they can be easily retrieved without being dragged anywhere.

Shelves with woodcarver's tools

Homemade attachments for engraving machines and drills

For simple engraving work in a home workshop, you can make a cutter, cutting disc, grinding and polishing wheels yourself. As a simple cutter to equip an engraver or drill, you can use a grooved wheel from a regular lighter or a dowel, on the head of which working teeth are cut. Making a working attachment for grinding or polishing is also quite simple: for this you can use a wooden drum with a shank, sandpaper glued to the side surface of it.

Many homemade attachments for an engraving machine (if they are used to perform not too complex work) perform well, and the cost of their production is minimal.

Drill carving technology

The work of a wood engraver consists of stages, at each of which the master uses different attachments.

Set of cutters

The first (rough) wood processing begins. Give shape, cut corners using rasp attachments: cone, barrel, mace, ball.

At this stage, the most popular attachment is the barrel.

The next stage is medium processing. Using attachments and discs of different diameters, the edges are removed and smaller parts are cut out. In this case, a different bur is used, with a narrower grip. For beginners, it is enough to have one drill.

Then they work with diamond nozzles (diamond-coated cutters): drop-shaped, peak-shaped.

Then the product is polished. You can use a nylon circle with long pile as a nozzle. It will penetrate into all bulges and depressions. The nozzle exposes the pattern, making it brighter.

The final stage is grinding with a grinding wheel.

After all stages of work, the product is painted, decorated with stones and metals