What is the root of the problem?

It is necessary to warn that if you are determined to independently study the metalworking process, then you should pay special attention to the purchase of a welding machine. A qualified specialist can work without any problems with any device, with transformers that do not have a mode setting function, with inexpensive inverter models. A beginner in this business is recommended to purchase a modern model, which is more expensive in cost, but prevents the element from sticking.

If you don’t have the financial means to buy or you inherited an old modification, then study the reasons for sticking, which we described below.

Conclusion

Select the correct electrode diameter and current strength depending on the thickness of the metal being welded. Clean the surfaces to be joined. Observe storage and baking conditions. Use the “strike” method for ignition and maintain the optimal arc length.

Don't skimp when purchasing a welding machine. The ideal option would be equipment with additional functions “Hot start” and “AntiStick” . “Hot start” will provide an increase in welding current at the moment the arc is ignited, and “Anti-sticking” automatically reduces the current when sticking. But remember, an inverter with these functions will avoid most causes of sticking, but will not be able to completely eliminate it. Read about how to choose electrodes for welding here.

Electrode coatings: what are they?

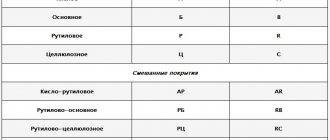

To understand the problem of why the consumable sticks, you need to consider the types of electrode coatings. Most often on the market there are products with rutile and basic coatings. In practice, the difference in the use of these treatments is significant.

The base coating is used to create an even seam. Electrodes with a basic coating can guarantee the creation of a durable seam that will be resistant to corrosion and various loads. Even if the finished metal product needs to be operated at low temperatures, this will be possible with the creation of a seam using an electrode with a basic coating. Piercing is recommended before using the conductor. Don't forget to clean the metal base and remove dirt.

Rutile-coated conductors are often used by beginners because they are easy to weld. With their help, it is possible to create strong connections even on a contaminated base. If it is possible to clean the metal, do so, but even otherwise it will be possible to make a reliable connection.

Rutile consumables are designed for welding with direct or alternating current. The work produces little dirt, which is why they are popular in welding circles. When choosing the type of coating, it is important to determine the parameters of the future seam. For example, the characteristics include permissible tensile strength, ultimate fluidity, viscosity indicators and other parameters.

Why don't they weld Uoni electrodes?

In order to understand what prevents you from cooking with UONI electrodes

on straight polarity, you need to know how the choice of polarity affects the welding process.

... But the specificity of the physical processes lies precisely in the fact that when welding with reverse polarity, an anode spot is formed on the electrode

, and a cathode spot is formed on the product.

Interesting materials:

How to use cycloferon in ampoules? How to accept an invitation to Yandex Disk? How to accept registration through Egov? How to participate in the green card? How is it customary to classify steel by purpose? How were you received in the Zaporozhye Sich? How to take coconut oil internally? How to take turmeric on an empty stomach? How to take medicine a c d fraction 2? How to take Omega 3 How many capsules per day?

Main causes of sticking

First of all, you should pay attention to the welding inverter. If it is of low power, it will not be able to produce enough current to weld thick parts. There are many other reasons why the electrode sticks during welding, these include:

- raw electrodes;

- chipped coating or its low quality;

- the core material is not suitable for the metal being welded;

- large voltage drops in the network can lead to low welding current or its sharp surges;

- a welder with low qualifications, for fear of burning a hole, sets a very low current on the welding machine;

- failure of device or inverter settings;

- When connecting, the phases are reversed, welding is carried out with a current of reverse polarity. This rule does not apply when welding aluminum and its alloys;

- the integrity of the welding cable may be compromised;

- pay attention to the heating of the welding holder, at a very high temperature, it is necessary to connect it to the cable;

- poor quality of preparatory work, parts are not cleaned of grease or rust;

- the possible reason is the low qualification of the welder and the inability to maintain a normal level of electrode combustion;

- The reason may be that the electrode is heavily soiled.

As you can see, the electrodes stick either due to non-compliance with the technology, or due to some defects in them themselves.

Raw electrodes

The welding electrode consists of a steel core and powder coating. The coating material is quite hygroscopic and, when stored in high humidity conditions, absorbs water vapor from the air.

If stored for a long time, even in a moderately humid room, the coating may also become damp.

If the electrodes were sealed in vacuum plastic packaging at the manufacturer's factory, they will not be exposed to moisture. But if the film is even slightly torn during transportation, the electrodes will inevitably become damp.

The damp coating begins to conduct electric current, as a result the arc does not ignite, and the electrode sticks to the workpiece.

Low quality

Why does the electrode stick if it is dry? It may not be of sufficient quality. Welding materials purchased in random places or from hand are often manufactured in violation of technology, the material of the rod does not meet the requirements of the standards, and the coating does not adhere well to the core and crumbles. In this case, sticking will also be frequent. It happens that the rod material is not suitable for the alloys being welded. Incorrect selection of consumables leads to constant attenuation of the arc or even the impossibility of igniting it .

Experienced welders check the quality of suspicious materials this way: they drop a rod from a height of 1.5 meters onto a flat concrete floor. If the coating has crumbled or peeled off, it is clearly not worth using such products.

In searching for the cause of electrode sticking, you can go through all the options. But quite often welders are faced with basic low-quality consumables. Even if you set the welding mode correctly and comply with all storage conditions, low-quality electrodes will stick. This cannot be corrected, so when choosing consumables, pay due attention to the choice of manufacturer.

The market may offer counterfeits under brand names. The only way to prevent the purchase of such electrodes is to check the documentation. If you are purchasing products to create strong seams in structures for which you are responsible for the integrity and safety, be sure to check compliance with GOST.

To make sure that there is lubricant on the tip, you can throw the electrode flat from a height of about 2 meters. If a chip in the coating is visible, this indicates low quality. Such electrodes should not be used when welding with an inverter.

Damp electrodes are another obstacle to creating a strong seam. High humidity compromises the stability of the connection. Since the arc is short, you will have to press the conductor against the metal base. Consequently, electrode sticking will occur. And over time, cracks form on the surface of the seam.

Effect of current

Novice welders are often afraid of burning through the workpiece, especially if it is small in thickness. Therefore, they underestimate the welding current values found in the tables, mistakenly thinking that with a low current they will slowly weld everything without defects. Unfortunately, this approach doesn't work.

If the current is insufficient, the melting of the workpiece and core to the metal stops before it has even begun, since the current strength is not enough to maintain the arc. The tip of the rod is immersed in the unformed and rapidly cooling weld pool and is seasoned with it.

It is necessary to set the current strength according to the tables and learn how to properly ignite an arc and make a seam.

Incorrect machine settings

This is also a fairly common cause of sticking during arc striking. At the beginning of the welding process, you need to accurately estimate the thickness of the metal that will be welded, select the appropriate diameter of the consumable and set a certain power.

The low current does not ignite the arc, but only slightly melts the tip of the rod, which sticks to the surface.

Mains influence

Why else might the electrode stick? The stability of the electrical network parameters has a strong influence on the ignition and maintenance of the electric arc.

This happens especially often when using outdated models of welding machines - AC transformers and rectifiers. The voltage on the secondary winding of the transformer in such units directly depends on the voltage in the network. If the voltage is unstable, then its surges also lead to the inability to ignite the arc; the secondary voltage is not enough for the discharge.

If the power of the local network is insufficient, then the very switching on of the welding transformer causes sudden voltage drops in the network, and the newly ignited arc dies out, and the tip of the electrode sticks to the cooling weld pool. This happens especially often when there is a lack of practical experience.

The use of welding inverters allows you to get rid of this dependence.

Lack of experience

Why does a dry electrode stick when welding with an inverter? In addition to underestimating the current, there is another typical mistake of novice welders. This is an attempt to keep the electrode too close to the workpiece . An air gap that is too short leads to a breakdown in the arc, the beginner tries to save the matter by bringing the tip even closer - and sticks it into the weld pool, where it can stick.

Errors occur both in the trajectory of the electrode during ignition and in guiding it along the seam. With a lack of experience and an attempt to use professional electrodes, such as UOSI, they also stick, most often due to excess welding current

It is necessary to get better at training preparations; once you gain enough experience, this effect ceases to appear. It is better to train on simple structural steels, and only then switch to alloy or stainless steel. Training should be conducted on inverter welding machines.

Uncleaned metal and improper arc ignition

The contaminated surface of the parts does not facilitate proper contact of the mass holder with it, and indeed the electrode itself. When you try to light an arc, it may go out and the coating may begin to fall off. Further actions will lead to sticking of the tip of the rod. Often, in the absence of experience, sticking occurs due to improper ignition of the arc. By tapping the tip of the rod on the workpiece, the electrode lingers on the surface for too long. A short circuit occurs, the metal at this point quickly heats up and solders the rod to the surface.

For novice welders, it is best to learn how to ignite an arc not by tapping, but by striking the consumable rod on the surface.

These are the main causes of sticking during welding. How can they be avoided?

Why does the electrode stick when welding with an inverter?

When working with a welding machine, especially when welding work is carried out using a welding inverter, cases of electrode sticking are extremely rare. Much more often when using an AC welding machine or, more simply, a conventional welding transformer.

However, it should be recognized that an inverter welding machine is not immune to this problem. And here, in addition to the usual disappointment in work, with such equipment the other side of the coin is also revealed - an insufficiently strong connection of parts.

And although there are many hypotheses regarding this unusual phenomenon for welding with an inverter, there are only three main ones that have a real explanation:

- electrode that does not match the parameters;

- incorrectly set welding current on the device;

- poor-quality electrode coating material.

A detailed consideration of each of the mentioned cases will help you quickly and correctly find a solution to the problem and also quickly eliminate it.

Features of the use of welding equipment and electrodes for electric arc welding

As is known, a welding inverter is a direct current device for welding metals of different thicknesses and qualities using a fusible electrode with a steel core and a special coating as a working element. For work with the inverter, electrodes are used that are classified as “universal” and intended only for working with direct current.

The use of electrodes that have a specification for working with devices that produce only alternating current leads to unstable ignition of the arc, the arc does not work stably, and great effort is felt to hold both the arc itself and the weld itself. Most often, in this case, the electrode simply does not have time to warm up, the metal forms a large drop and then the unheated electrode tightly sticks to the surface to be welded.

To solve this problem, if it has already arisen, is quite simple, you need to replace the electrode with one that is intended for welding with direct current.

This is the most effective and reliable method, neither increasing the current power nor changing the polarity will help at all, the result will be predictable, the adhesion of large drops, an unstable seam, sticking of the electrode and a high probability of failure of the welding machine itself, especially when working with a large diameter electrodes.

Selection of the appropriate welding current when welding with an inverter machine

Experience with various welding machines and various welding technologies allows us to weld with an even, durable and beautiful seam.

In this case, experience, as a rule, plays a major role, because mastering basic welding skills implies a certain level of theoretical training.

At the same time, quite often, when a welder with little experience works, sticking of the electrode still occurs.

One of the reasons for this phenomenon, even if the electrode is selected correctly, is the discrepancy between the parameters of the welding current and the parameters of the electrode. Ignition of the arc for each specific electrode diameter requires the correct adjustment of the device.

Too much current supplied by the device “pulls the electrode” and requires some effort in order to hold the arc; the ignited arc at a high current strongly attracts the electrode.

At a low current that does not correspond to the diameter of the electrode, on the contrary, igniting a stable arc is somewhat problematic; it is necessary to keep the electrode too close to the surface of the metal, and the weld pool is formed too small, it does not allow the metal to melt.

At low current, even the smallest movement can open the arc and stop the electrode melting process. The coating of which will most likely simply break off from the rod. And the next time you touch it, the electrode will stick again.

In order to correctly select the value of the welding current, you need to use a simple formula, which, although approximately, will allow you to begin selecting the required welding current - 30A = 1 mm of electrode diameter.

An incorrect choice of welding current will not allow a normal connection to be made in a vertical plane, both when the seam is directed from bottom to top and from top to bottom, and welding from the bottom position of a horizontal ceiling plane is out of the question.

The influence of high-quality electrode material on the quality of the seam

Ignition and formation of the weld pool are largely ensured not only by the correctly selected current, but also by how well the electrode itself is made. Indeed, almost the majority of stuck electrodes are either low-quality or inappropriate rods.

Most often, sticking is associated with rapid solidification of the metal during welding, due to the lack of a sufficient amount of spar coating on the electrode itself or its complete absence. A crumbled coating or a layer that is too thin or does not sufficiently meet the requirements for the proportions of fillers is guaranteed to cause welding with such an electrode to stick.

The problem here is that it is the coating that forms the necessary gas cloud around the weld pool and displaces oxygen from the weld pool, becoming covered with slag, such a connection forms a strong seam of molten metal.

The absence of such a gas shell does not allow the metal to displace oxygen and, accordingly, the pool itself is formed in a shorter time and the loss of control over the seam within a few moments makes the electrode motionless, captured at the site of arc formation by the liquid metal.

Coating can crumble for various reasons:

- due to manufacturing defects;

- substandard storage conditions for electrodes;

- mechanical stress, kinks, impacts, caking due to improper storage;

- when the electrodes become damp.

Electrode sticking is also characteristic of high humidity of the coating itself. An overly moistened coating does not ensure the proper level of combustion of the coating, resulting in multiple chips and cracks from the heated metal rod.

In addition, damp electrodes cannot be properly ignited, since it is the high humidity of the coating that is unable to properly facilitate the melting process of the electrode itself. The arc arising in the damp electrode shell will not have a stable appearance; the height of the bath will constantly fluctuate and, as a result, sticking of the electrode.

A coating saturated with moisture forms an insufficiently dense gas dome around the weld pool, which naturally affects the quality of the weld; even if it is possible to apply a seam without sticking the electrode, such a connection will still be unreliable due to the high content of the hydrogen component in the metal.

The only way out of this situation is to dry the electrodes. Removing excess moisture will allow you to continue working within a few hours with consistently high results.

Thus, sticking of the electrode to a greater extent is still the result of a lack of quality components of the welding electrodes, and not the welding technology itself using a welding inverter.

Troubleshooting

Let's add a few words about how to diagnose malfunctions in the device.

If you smell burning or smoke from the inverter housing, this is a signal of a very serious breakdown. We do not recommend diagnosing the device yourself in such a situation; it is better to take it to a service center. Eliminating such malfunctions requires many years of experience and understanding of all the nuances of the operation of the device.

If the breakdowns are less critical, you can do the diagnostics yourself. To do this, remove the housing and visually inspect all components of the device. Sometimes manufacturers produce models with poor-quality soldering or low-quality wires. In such cases, you can simply re-solder individual sections and the device will work properly.

Types of coated electrodes

Many, especially beginner welders, are concerned about the problems of correctly selecting consumables. So what kind of electrodes are needed for welding with an inverter, and which ones are better suited for different materials? To answer this question, you need to talk about the types of coatings and which electrodes to choose for welding specific metals or alloys. The coating serves the following purposes:

- With the help of carbon oxides, it protects the weld pool from the action of atmospheric oxygen.

- Stabilizes the arc discharge.

- Helps remove oxygen from the metal or alloy, deoxidizing the seam.

- With the help of impurities it has an alloying effect on the seam.

Based on the thickness of the coating, these materials are thin (M), medium (C), thick (D) and extra thick (G). This parameter is regulated by GOST 9466-75 and affects the welding process, enhancing the effect of the coating on the seam and stabilizing its properties. Based on the chemical composition of the coating, electrodes are divided into the following types:

- for direct current, a base coating is used, which provides a plastic seam;

- coating with iron powder, which increases welding strength;

- type with an acid coating, providing speed of work and ductility of the metal being welded;

- for vertical joints, a cellulose coating with low slag formation is more suitable;

- type with rutile content and the presence of ferromanganese and magnesium carbonate.

To make the correct selection in relation to the metal being welded and to avoid sticking of the electrodes, you need to know which of them are most suitable for the workpieces being joined. Technical characteristics of the coating and metals and alloys recommended for welding correspond to different brands of electrodes, namely:

- to work with structural low-alloy, carbon steels, it is necessary to use UONI-13/55, OMA-2, OZS-30, MR-3M, Vi-10-6, ANO-21 and VSF-65U;

- alloyed high-strength steels are welded EA-981/15, EA-395/9, NIAT-5, OZSh-1 and NIAT-3M;

- for heat-resistant and heat-resistant steels, ANZHR-2, TML-3U, TsL-39, IMET-10, KTI-7A and OZL-35 are used;

- stainless and corrosion-resistant alloys are welded using NZh-13S, NIAT-1, UONI-13NZH, TsT-15, and EA-400/10T;

- dissimilar alloys and steels are welded EA-391/15, TsT-28, OZL-32, ANZHR-2, NII-48G, IMET-10, V-56U and VI-IM-1;

- OZL-44, ANV-20, EA-112/15 and NII48G are suitable for special steels;

- cast iron is cooked using OZZHN-1, OZCh-2, MNCh-2, TsCh-4;

- for aluminum alloys you need OZA-2, OZANA-2, OZA-1 and OZANA-1;

- copper and its alloys are well welded ANTs/OZM-2, OZB-2M (bronze), Komsomolets-100, OZB-3;

- for nickel and alloys use V-56U, OZL-32;

- metal cutting is carried out by ANR-2M, OZR-2, OZR-1.

When welding without errors, by matching the metal of the workpiece with the brand of electrode, you will most likely be able to avoid sticking when working with inverter devices.

It is very important to know in as much detail as possible the properties and name of the metal of the workpiece, because the quality of the welded seam depends on this.

How to eliminate electrode sticking

Eliminating the sticking phenomenon is quite simple. To do this, you need to use high-quality consumables, set the desired mode and prepare the parts before welding. And, of course, you will need a little experience in lighting an arc.

Preparing materials

Items that were stored in a dry room with a good ventilation system do not need further processing, especially if the batch was taken in original packaging. If moisture gets on the surface, thorough drying is necessary.

Let's talk about the methods used at home if the kit becomes damp.

We offer “folk” remedies for heat treatment:

- Using an electric oven - a gas oven will not work, since heating is not recommended over an open fire. To do this, you need to raise the temperature to 200 degrees, place a bunch of rods inside the equipment, fry for 2 hours and leave there until it cools completely.

- Warming up with a construction hairdryer, where on models there is functionality for setting the temperature regime. Select a container whose diameter is comparable to the hole of the tool. Electrodes are placed there and then hot air is directed at them.

- Building a furnace takes more time, but for people who plan to work with welding on an ongoing basis, this provides a guarantee of effectiveness. We will not touch upon the construction process, since deciphering this topic will require writing a new article.

The above methods are quite suitable for electric welding of non-critical components. However, if a specialist wants to improve his skills and has the financial ability to achieve excellent results, we recommend purchasing special professional equipment, such as a thermal pencil case or a muffle furnace.

Let's start setting up the equipment

The effectiveness of the event will depend on how you can correlate the thickness of the welded material, the diameter of the electrode and the current power.

All these parameters are displayed in the table of the device’s technical passport. It is worth studying them carefully, but at the same time understanding that these are basic data and deviations from the norm are quite acceptable, provided that the specialist has extensive experience and keeps the device in perfect order. Each raw material has its own current parameters, for example, for plates 3 mm thick it is necessary to set 100/120 A. Not all devices are equipped with an adjustable transformer. For those using older models, it is important to move the cable connection to the level where the current stops burning through the weld point. It is important to know! To avoid burn-through (the formation of holes) on a structure made of thin-walled material or when working with car bodies, you should gain experience. To do this, take an unnecessary part and start welding, where by trial and error you will select the required power mode of the device, gradually increasing the current.

In addition, before starting work, it is worth checking the voltage in the network with a special tester. Once you make sure that the line is not overloaded, you can begin to implement the plan. Otherwise, you should wait until the problem stabilizes. If jumps are repeated time after time, then purchase a stabilizer; it will help you carry out the task uninterruptedly and calmly.

The correct combination of ground cable and holder is of no small importance:

- Sixteen-core copper wire with an outer diameter of 11.5 millimeters is suitable for thin-wall material.

- For welding a thicker sample, a 25-core cable with a 13.5 mm hole is suitable.

Learning how to properly create a plasma barrel

If you are new to the business, then we offer you a simple method, once mastered it will be easy for you to move on to the professional ignition method.

To do this, move the electrode like a match across a box, you will get a striking sound. In this case, try to keep the working element perpendicular to the workpiece. After the arc has flared up, you should tilt the consumable back at an angle of 15 degrees and quickly move the seam along the intended line. The main condition is continuity in work, since stopping even for a short time threatens combustion failure.

Modern devices have high-frequency ignition, which allows the formation of a plasma barrel without directly touching the material. That is, when the consumable approaches, an arc is created due to high-frequency currents, which is accompanied by a buzzing crackling sound.

We provide you with a visual aid, after looking at which you will understand why electrodes stick when welding on an inverter and what needs to be done to prevent this:

How to prevent electrode sticking

Now that we have found out why the electrode sticks when welding with an inverter, we will talk about simple methods for preventing errors. What can every welder do to prevent the electrode from sticking? The solution is not difficult to find based on the essence of the problem.

Solution #1: Prepare the electrodes and metal

Buy electrodes in sealed packaging from trusted manufacturers. These can be domestic Rotex rods or European ESAB rods. They meet quality standards and should not stick if you set up the device correctly and ignite the arc.

If the electrodes have been left unpacked for more than 8 hours, they need to be dried. This can be done in an electric furnace, taking into account the melting temperature of the electrode. The electrode itself cannot be dried more than three times, otherwise it will lose its properties.

Also, do not forget about preparing the metal. Thoroughly clean the surface of the parts from dirt, rust and paint.

Solution #2: Configure your hardware correctly

By setting the correct settings for the welding inverter, you will not only prevent sticking of the electrode, but also improve the quality of the weld. Below you can find the recommended settings that you should set on your device.

But keep in mind that these are approximate values and you need to rely not only on educational tables, but also gain your own experience. We recommend that all beginners start with a low current setting and increase it gradually. Over time, you will begin to understand what parameters are needed in each individual case.

Solution #3: Learn how to strike the arc correctly

To light an arc, many welders use the method of tapping the tip of the electrode on the metal, but we recommend not tapping, but striking (similar to matches).

First, “idle”, practice moving the end of the electrode smoothly along the surface of the metal. Once you can do this quickly, you can start lighting the arc.

After igniting the arc, it is necessary to ensure that it is of sufficient length. It is important to learn how to do this quickly, otherwise the electrodes will stick and ruin the whole job.

How to prevent electrode sticking

So, we should summarize and highlight the main points so as not to encounter such a problem as sticking of the electrode during welding.

What we finally have:

- Electrodes must be suitable for welding with an inverter, selected in accordance with the thickness of the metal being welded and absolutely dry;

- The welding current on the inverter must be set in accordance with the diameter of the electrodes used for welding;

- The surface of the metal being welded should not be dirty or rusty;

- The voltage in the electrical network (which was not mentioned above) should be normal. Often, a voltage deviation downwards leads to the fact that the inverter simply does not draw or produce the required current parameters;

- In the process of welding metals, it is extremely important to eliminate errors such as incorrect ignition or an arc that is too short.

All of the above tips should help novice electric welders in their difficult task.

Content

- Reasons for electrode sticking when welding with an inverter:

- 1. Damp electrodes

- 2. Wrong choice of electrode

- 3. Poor quality electrodes

- 4. Low welding current

- 5. Wrong way to ignite the arc

- 6. Short arc

- 7. Poorly cleaned metal surface

- Tips to prevent the welding electrode from sticking to the metal:

- 1. Choose appropriate settings

- 2. Keep the electrode and surface clean

- 3. Follow proper arc striking technique

- 4. Use the appropriate arc length

- 5. Store electrodes in a dry place

- Conclusion

Which electrodes to use to avoid sticking

If you want to avoid sticking of the electrode when welding with an inverter, consider the basic recommendations of experts. The main rule is that the electrodes must be designed to work with direct current.

If you don't want the electrode to stick, don't skimp on consumables. Choose trusted manufacturers whose products you have already tested. Electricals must comply with GOST or other international standards, demonstrating high quality and durability.

If you want to learn how to properly use an inverter welder, learn how to start and hold the arc. The theoretical basis will help you avoid common mistakes that lead to the creation of an unsightly seam of the wrong diameter.

Rating of electrodes for inverter

Electrode ratings are published constantly; they can differ significantly from each other in different sources.

Without pretending to be objective, the “arithmetic average” rating is as follows:

- rutile-cellulose consumables from the famous Swedish company ESAB ;

- American Omnia 46 from Lincoln Electric;

- Russian OZS-12 ;

- Russian electrodes Resanta MR-3;

- UONI–13/55;

- ANO : the most popular in Russia.

Causes of electrode sticking during welding - Welding Profi

Very often, from the practice of welding work, the question arises from beginners: why does the electrode stick when welding?

Experienced welders know that the causes of this disease can be different. Let's look at the main ones and possible ways to solve this phenomenon.

Poor quality materials

Electrodes are consumables for manual arc welding. Due to their prevalence, you can come across counterfeits of well-known brands and be disappointed when using them. Their quality may vary even in different batches of the same manufacturer.

Knocked down coating

If the core at the end of the electrode sticks out of the coating, it will cause sticking. Raw materials are often susceptible to coating shedding.

Before use, it is advisable to “burn” the bare end of such an electrode by striking it on an unnecessary sheet or corner of the metal, and when it burns, begin welding the part.

Dampness

The coating of the welding electrode is very sensitive to humid environments. Due to the unstable formation of the welding arc, the welder tries to “weld” with a short arc and “clings” to the base metal.

The use of raw electrodes also reduces the quality of the weld by saturating it with hydrogen, which leads to the formation of cracks. When stored for a long time, a characteristic white coating appears on them.

Possible methods for drying electrodes:

- Calcination at a temperature of 130-150 °C for 40-50 minutes. You can dry it in a home gas oven (not microwave!) at 250 °C for 30 minutes.

- Warming up with electric current. An old method from experienced craftsmen, used when there is no time for drying. They take a new electrode and with a sharp movement “stick” it to the table and count to 7. Then they quickly tear it off, twisting it to the side and up. However, modern inverters with an anti-stick function will not allow you to do this trick.

We recommend! Cutting and preparing metal before welding

Incorrect welding modes

The next group of reasons why the electrode sticks when welding with an inverter is incorrectly selected welding modes, as well as erroneous actions of the welder.

Welding current

An underestimated value of the welding current for the selected electrode diameter will inevitably lead to sticking. The insufficient amount of energy required to form a weld pool and a stable arc forces one to maintain a small gap between the electrode and the base metal. The likelihood of adhesion to metal increases significantly.

Power supply problems

Low voltage in the welding machine socket is also a common cause of sticking. It is possible to use wires of insufficient cross-section, which reduces the characteristics of the welder and does not produce a normal, stable arc.

The problem can be solved by connecting to a network with nominal characteristics, or by using voltage stabilizers of the required power. If you connect the welding inverter through an extension cord, make sure that the required cross-section is at least 2.5 mm2.

You can try using thinner electrodes and cooking at a lower current.

As you can see, the reasons for electrode sticking can be different. The methods described above will help you identify difficulties and solutions.

Why does the electrode stick when welding?

This question is often asked not only by novice welders, but also by those who already have some welding experience. Many welders blame the manufacturer for the electrodes sticking to the metal being welded, but they and all other welders should remember that the most common problem is the high moisture content in the coating of the welding electrode.

You can’t immediately blame the manufacturer for everything, so you need to remember that you need to first look for problems at home, and only then move on to the manufacturer.

The main problem when starting an arc is poorly cleaned metal, but if your welding electrode sticks to the metal being welded, then you need to get rid of the excess moisture content in the coating of the welding electrode.

get rid of moisture in the coating of the welding electrode by calcination.

By calcining the welding electrodes at the required temperature, which can be found on the packaging, you will make the percentage of moisture what it should actually be.

To prevent it from increasing, you need to store welding electrodes correctly. You need to store them in a dry room, where the moisture content in the air is the least.

Therefore, in order to prevent the moisture content from increasing, you need to store the electrodes in a special oven for calcining the electrodes. Purchasing such a furnace will not be difficult, and the benefits from it are enormous, so using it as a place for storing and calcining electrodes, welding will be comfortable and of high quality, which will result in a durable product.

Recommended:

- Drying cabinet for electrodes

- Thermal pencil case for drying electrodes

There are also cases where electrodes are sold in sealed packaging, which means that they cannot be exposed to moisture, however, you need to remember some features of electrodes packaged in such packaging. The peculiarity of such electrodes is that you must use them within eight hours after the packaging is depressurized.

After opening the package, you do not need to calcinate the welding electrodes, but if more than eight hours have passed after opening, you should preferably calcine them at the temperature indicated on the package. If the packaging does not indicate the calcination temperature, then you can find it on the Internet. There is a lot of information on this matter.

Also an important reason for poor ignition or sticking of the welding electrode during welding is the incorrect choice of welding electrodes or the purchase of low-quality welding products. You can purchase such electrodes from friends or simply at the market. Yes, such electrodes will most likely cost less, but their quality will remain in question .

Therefore, it will be best for you to buy electrodes in specialized stores that provide only high-quality products. One of these stores are manufacturing plants, which are listed on the “Contacts” page. By going to the website of one of them, you can purchase the appropriate welding electrodes.

Plasmatec electrodes

Electrodes Garant

Selecting an inverter device

To understand why the electrode sticks when welding with an inverter, you must first make the right choice of welding machine in relation to the conditions of specific work. The unit must meet certain requirements that will ensure optimal operation of the device in real circumstances. An example of such a device created for Russian conditions is the inverters of the “Neon” line produced in Nizhny Novgorod. Based on these devices, we will talk about the basic requirements for welding machines, which will reduce the likelihood of electrodes sticking during welding. These properties are as follows:

- the mains supply voltage ranges from 160 V to 250 V, which makes it possible to work in conditions of unstable power supply;

- the presence of an automatic protection switch, including overheating;

- PV at maximum welding current 60%;

- open circuit voltage 70 V, which allows you to confidently hold the arc even at extreme input voltages;

- there is a hot start function for reliable ignition of a short circuit arc, as well as arc afterburner;

- To prevent the electrode from sticking, there is an anti-stick function;

- guaranteed stable operation at ambient temperatures from -40 °C to +40 °C.

It should be noted that these characteristics serve as a basis for selection, and not as a dogma, but stable operation at extreme temperatures and network voltages is very important for Russian conditions. For comfortable work, it is useful to use the hot start function, which helps to confidently start the process and optimally use welding electrodes for inverters.

Particular attention should be paid to such functions as anti-stick or anti-stick. Its essence is that at the moment of sticking, the welding current is reset to zero and this allows both the electrode itself and the inverter to be kept intact. Afterburner also helps eliminate sticking, allowing you to increase the welding current at the risk of arc breakage and prevents interruption of the weld, which has a beneficial effect on the quality of work.

When choosing an inverter device, it is important to pay more attention to Russian models, since they are repairable and better adapted to work in the conditions of our country.

Recommendations

One of the easiest ways to overcome this problem is the additional “anti-stick electrode” function, which is available on modern welding machines. Naturally, it will not help in the most difficult cases, but it will make their use much simpler and easier.

You also need to pay attention to the correct selection of the electrodes themselves and the modes of their use. This is the main way to avoid sticking. After all, sometimes it is enough just to raise the current to the required level and the arc will stabilize.

Before using consumables, they should be dried and calcined to remove moisture. Even if these are new consumables, these procedures should be carried out, since during transportation and storage they could absorb liquid from the air.

It is necessary to check the end of the electrode, both during the first ignition and during subsequent ignitions. Since at the very beginning the coating may crumble. And then slag may stick to the end, which will interfere with welding.

Recommendations for DIY repairs

When repairing inverter-type welding machines, you should adhere to a certain algorithm:

- If a malfunction occurs, you must immediately disconnect the electrical device from the network, allow it to cool, and only then open the metal casing.

- Diagnostics must begin with a visual inspection of the electrical components of the inverter. There are often cases when repairing an inverter welding machine involves simply replacing damaged parts or soldering conductive contacts. Visually enlarged capacitors or cracked transistors should be replaced first.

- If a visual inspection fails to determine the cause of the malfunction of the welding machine, you must proceed to checking the parameters of the parts using a multimeter, voltmeter and oscilloscope. The most common failures of power units are associated with malfunction of transistors.

- After replacing the electrical elements, it is worth moving on to checking the printed conductors located on the inverter board. If you find torn or damaged tracks on the printed circuit board of a welding tool, you must immediately eliminate the defect by soldering jumpers or restoring the tracks using copper wire of the required cross-section.

- After completing work with the tracks, it makes sense to move on to servicing the connectors. If the inverter device stopped working gradually, then there may be poor contact in the connecting connectors. In this case, it is enough to measure all contacts with a multimeter and clean the connectors with an ordinary household eraser.

- Despite the fact that malfunctions of a welding inverter are rarely associated with diode bridges, it would be a good idea to check their performance. It is better to diagnose this electrical element in a soldered state. If all the legs of the bridge are short-circuited, then you should search for the faulty diode and replace it.

- The last step in inverter repair is checking the board and control panels. Diagnostics of all components of the board should be carried out using a high-resolution oscilloscope.

If the diagnostics have been carried out, but it was not possible to find out what is broken in the welding machine, you should stop doing independent repairs and contact specialized workshops.

When performing independent repair work, you should not forget about the safety rules:

- Do not use electrical appliances without a protective top casing;

- all diagnostic and repair work should be carried out on completely de-energized equipment;

- It is safest to remove accumulated dust and dirt using an air flow generated by a compressor or a compressed gas cylinder;

- Cleaning of printed circuit boards must be done using neutral solvents applied to a special brush;

- Long-term storage of electrical appliances should be done in dry rooms and completely switched off.

Most inverter electrical appliances are supplied complete with accompanying documentation. In these papers you can find a description of the most common faults and repair methods. Therefore, if malfunctions occur, you should carefully study the documentation and only then begin repair work.

Electrode sticking and overview of welding machine faults

If the electrode sticks when welding with an inverter, it is important to understand why this happens and how to troubleshoot. If the welding machine is under warranty, it would be better to contact the service center. Non-experts do not recommend repairing the device yourself, since understanding the cause of the problem requires many years of experience in welding.

If the breakdowns are not critical, you can try to fix them yourself. For example, DIY manufacturers may equip the welding machine with weak wires, which will cause the welding machine to malfunction and prevent you from connecting metal parts.

To determine which part of the welding unit has failed, visually identify elements that are burnt out, cracked, or darkened. To replace a specific part, obtain the necessary information from the labeling. If you use the GOST table or international documents, you will be able to select the correct part.

If a visual assessment is not enough, use a multimeter. This is a device for diagnosing welding equipment. Test the board and transistors for serviceability. You may find burnt areas on the board. If such can be traced, they need to be replaced. If the jumpers are burned out, you can solder them again. If there is burnt on the board, use an eraser to remove it.

Sometimes the diode bridges located on the radiator break in the welding machine. Despite their strength and reliable fastening, breakdowns occur. To test the diode bridge, you will have to unsolder the wires and remove it from the board while using a multimeter. This is how you will detect a faulty diode. If the above steps do not give the desired result, it is better to contact a specialist.