A profile pipe bending machine is a very popular type of metalworking equipment. This is explained by the fact that pipe products of this type are today actively used in many areas, including for solving domestic needs. If cutting a profile pipe is easy to do even with hand tools, then to bend such a product it is necessary to use a special pipe bending machine.

Bending a profile pipe on a homemade machine

There may be only two options for obtaining such a machine at your disposal: purchasing serial equipment, for which it will be necessary to allocate significant financial resources, or making a device for bending profile pipes with your own hands. Today there are many design schemes according to which homemade machines for bending profile pipes can be made. It is worth dwelling in more detail on the simplest of them and, accordingly, the most popular among home craftsmen.

What is a pipe bender? types of pipe benders and the advantages of their use.

A pipe bender is specialized equipment used to bend a pipe blank to a certain radius.

A distinctive feature of this equipment is that the bending process is performed without deformation of the walls, the appearance of folds or changes in the internal section. In some cases, pipe bending machines are used for rolling rolled metal: profiles, rods, angles, etc. The scope of application of pipe benders is wide: production of metal structures, laying of gas, oil, water communications, heating mains, in construction, food production, etc.

The use of pipe benders allows you to:

- Rational use of the space allocated for the highway

- Reduce labor costs for pipeline repair or replacement

- Minimize the number of outlets, which in turn will make the system more airtight

- Reduce production costs for additional welding work and purchase of materials

- Reduce time for repair and installation work

- Install a pipeline from pipes made of various materials.

Types of pipe benders:

- Hand tool

- Electric pipe bender

- Hydraulic driven machine

- Pneumatic pipe bending machines.

Operational areas and service features

Pipe bending machines are most widespread in two industries:

- construction;

- housing and communal services.

In addition, it is worth noting that bending machines are used less intensively in other areas:

- automotive industry;

- petrochemical industry.

And also such machines are indispensable when making pneumatic and hydraulic pipeline structures. The operational scope of this equipment is very wide, so it is very popular and in demand everywhere. Let's look at what else pipes bent on pipe bending equipment are used for:

- Sports Equipment;

- various design solutions inside residential premises;

- when installing fences, railings, stairs, etc.;

- in the production of chairs and other furniture elements.

The need to bend pipes may arise in the manufacture of structures of various types and purposes.

Important! Before you start bending pipes on a pipe bending machine, you need to read the instructions for its use, and also study all the necessary contraindications, safety rules, etc.

The operator of a pipe bending machine must be trained in all the nuances of bending and, in addition, carry out preventive cleaning of the device (once a month), inspection of the main working parts of the device and preventive maintenance. Prevention of a pipe bending machine includes:

- lubrication of working elements

- adjustment of working elements;

When performing maintenance on a hydraulic model, do not forget to change the oil in the pump. The pump oil must be of high quality. If any functional element of the bending equipment fails, it must be replaced. It is recommended to purchase new spare parts only from trusted suppliers.

Types of pipe benders according to the mechanics of work

Pipe benders can be divided according to the type of drive used. In this case, the following devices are distinguished:

- Manual pipe bender. The simplest type of machine, the effectiveness of which depends on the strength of the operator’s muscles. Such pipe benders are often assembled by hand, but there are also commercial options.

- Pipe bender based on a hydraulic jack. Here the main structural element is the hydraulic cylinder.

- Electric pipe bender with gearbox. Such devices have a motor with a mechanical gearbox. Depending on the type of machine, either chain or gear reduction can be used.

- Electric pipe bender with hydraulics. As a rule, such devices are used in heavy industry, where process automation and work with large volumes of products are needed.

The presence of electromechanics in pipe bending equipment does not have the best effect on the mobility of the structure.

The use of a powerful gearbox not only increases the cost of the tool, but also affects its weight.

Therefore, in plumbing, the construction of greenhouses, gazebos, in auto repair shops and medium-sized businesses, either manual pipe benders or devices with primitive hydraulics are most often used.

According to the bending method, pipe bending equipment is divided into 2 groups:

The operating principle of a roller pipe bender is to bend the workpiece using several pressure points simultaneously.

The angle pipe bending machine allows you to create products of any shape, but is more suitable for soft metals. This is the most popular type of device because its design is very simple.

The principle of its operation is to bend that section of the workpiece that is placed between special supports. The angle tool has limited potential use.

It cannot be used for bending channels, angles and pipes with complex cross-sectional geometry.

Features of Pipe Bending Machine

A pipe bending machine differs in its design, and in general, based on the type and purpose of the device, each of them contains the following elements:

- Hydraulic cylinder.

- Rigid base and frame.

- Metal strips.

- Roller mechanisms.

If you want to make a pipe bending machine yourself, then for assembly, you will have to purchase all these parts. Below we will consider options for pipe bending machines for bending rolled pipes at home.

The frame of the device can be made open or closed. And the main parts that take on the bulk of the load are the cylinders.

Also, a pressure mechanism should be located on the homemade device. It is placed in the extreme part.

To avoid making mistakes when bending round pipe-rolling materials, it is recommended to take measures to ensure that the workpiece is securely fastened.

To attach the upper and lower metal strips, it is recommended to use welding. This is also important for the persistent part. Without it, the structure will not be able to withstand heavy loads.

Watch the video

All features of the pipe bender should be contained in a drawing, which is recommended to be done at the very beginning of work.

Such a detailed plan must contain data on the exact quantity of all parts with their exact dimensions indicated.

IMPORTANT! Before you begin assembling the mechanism, you need to develop a drawing of a machine for bending a round pipe, prepare all the necessary materials and tools.

Making a lever pipe bender

A selection of photographs and drawings for making a lever-type pipe bender yourself, as well as a video with comments and explanations from the author.

This lever pipe bender is not too difficult to manufacture and allows you to work with fairly thick pipes

A video from the author will allow you to understand the key points and small nuances of manufacturing this pipe bender.

Common models of pipe benders

The range of pipe benders on the market is extremely diverse. On sale there are both expensive models of domestic and foreign production, as well as budget Chinese units of dubious quality. Let's consider proven and reliable equipment of various types.

When choosing a hydraulic pipe bending machine, it makes sense to pay attention to devices of the SWG (made in China) and TPG (Russia) series.

SWG benders have established themselves as high-quality equipment in the entry-level price category; the range includes models such as SWG 2A, SWG 3A and SWG 4A, the numerical nomenclature in the name of which indicates the maximum diameter of the processed pipes in inches.

data-ad-client=»ca-pub-8514915293567855″ data-ad-slot=»5929285318″>

A series of hydraulic pipe benders from TPG, represented by 7 models:

- TPG 1B (manual drive) – processes pipes with a diameter of 3/8-1″;

- TPG 1.24B (manual drive) - for diameters 3/8-1.25″;

- TPG 2B (manual drive) - for diameters 3/8 -2″;

- TPG 3B (manual drive) - for diameters 3/8-3″;

- TPG 2EP (electric drive) - diameters 3/8-2″;

- TPG 3EP (electric drive) - diameters 3/8-3″.

TPG pipe bender

- The cost of equipment varies from 23 (model 1B) to 90 (3EP) thousand rubles.

- Among stationary industrial units, a popular model is the SGT 60 pipe bending machine. This device has the following technical characteristics:

- working diameters - 22, 26, 33, 42, 48 and 60 mm;

- drive type - electric, power - 3000 W;

- bend radii - 3-4 d;

- machine weight - 410 kg.

The SGT 60 pipe bending machine will cost you 167 thousand. The optimal CNC unit in terms of price/functionality ratio is the UGS-1A unit, the cost of which is 240 thousand. Let's look at the technical characteristics of UGS-1A:

- working diameters - from 22 to 60 mm;

- engine power - 3 kW;

- maximum bend angle - 2100;

- bending time for 1800 - 20 sec;

- device weight - 330 kg.

UGS-1A

UGS-1A is capable of processing pipes made of steel, stainless steel and copper with a wall thickness of 2-4.5 mm. This is an automatic unit equipped with a CNC system; during operation, the operator only needs to install the pipe in the mounting socket and set the processing mode (radius and bending angle) in the CNC program; the mechanism will do the rest independently.

The products of Amob (Germany), which is the world's leading manufacturer of pipe bending equipment, deserve special mention. The company's product range includes the following lines of machines:

- Amob MA - for processing profile pipes (mandrelless, with manual adjustment);

- Amob MDH - electric mandrel bender, diameters up to 90 mm (automatic with CNC control);

- Amob CH - hydraulic mandrel bender, diameters up to 104 mm (CNC control);

- Amob CMSM are simple mandrelless units for diameters up to 127 mm (manual control).

Additionally, Amob provides services for setting up, commissioning and maintaining equipment, and also provides operator training.

“Do-it-yourself winding machine for coils” and “What is a winding machine for transformers?”

Crossbow type pipe bender

This tool is universal due to replaceable attachments for a specific diameter of pipe or metal profile. It is a T-shaped design. A pipe holder with rollers is installed at one end.

Perpendicular to it is a lever for transmitting force.

According to the drive design, the crossbow pipe bending machine most often uses muscular traction, but there are modifications with a different method of transmitting force to the bending shoe:

- Worm-gear.

- Mechanical hydraulics on the cylinder.

- Gearbox and electric motor.

- Hydraulics on an automatic pump.

This pipe bending machine provides bending at an angle of up to 90 degrees. For each type of pipe, the crossbow pipe bender has its own set of attachments. This design is called a “shoe” and is designed for quick replacement during operation.

The crossbow pipe bender works with both soft and hard metals. It can be used to bend products based on the following materials:

- Metal-plastic.

- Copper.

- Brass.

- Thin wall steel pipe.

The peculiarity of a crossbow-type pipe bender is that the bending angle can be changed during the processing of the workpiece. To do this, it is enough to change the distance between the support rollers on the guide.

The crossbow pipe bender has a significant drawback: each type of pipe or metal profile requires its own “shoes”. If the nozzle is incorrectly selected, this may result in rupture of the workpiece or a change in its internal diameter.

Important: This tool allows you to bend the pipe at a wide angle. But in some cases, if the pipe wall is thin, before using a pipe bender, you will have to fill the workpiece with sand so that the pressure is distributed correctly.

In models where movement occurs due to manual effort, a ratchet mechanism is used. The principle of operation of the ratchet mechanism is simple: a toothed roller and a tooth are installed on the device. This mechanism prevents the stressed pipe from returning to its original position when you grab the lever.

How to make a profile bender of an even simpler design

You can make a roll forming machine with your own hands using an even simpler design. If you choose a device of this type, you should keep in mind that in order to bend a profile pipe with your own hands on such a device, you will need serious physical effort.

Drawing of a small manual profile bender mounted on a mechanic's workbench (click to enlarge)

If bending equipment equipped with working shafts is used for rolling a profile pipe, during which it is bent, then the profile benders of the simplest design in question work on a different principle. On devices of this type, a profile pipe is bent along a radius, which must first be formed from rigidly fixed elements. Strong metal pins fixed in a concrete base are most often used as such elements. An arc is formed from such pins, along which the corrugated pipe is bent.

To make a device on which it will be possible to effectively bend a pipe along a radius, it is best to pour a concrete pad yourself and fix the metal pins on it as securely as possible.

Bending steel pipes, for which such a simple device is used, is carried out in the following sequence.

- One end of the pipe is securely fixed.

- By physically influencing the second, loose end of the pipe, they begin to bend the product smoothly and accurately, bending its surface around the pins arranged in an arc.

- After the pipe has acquired the required configuration, its second end is also fixed and the product is left in this position for some time so that the metal gets used to the new state.

Since working with such a device requires significant physical effort, to make the task easier (especially when bending large-diameter pipes), the future bend site is preheated with a gas burner or over a fire. You can learn more about the rules of operation on such a device in the corresponding video.

Of course, such a device, which can be built in the yard of your home, has minimal efficiency and functionality. For example, it is quite difficult to bend stainless pipes or make complex bends with it. Nevertheless, it is quite possible to use it for simple bending work. Such work, for example, may be associated with laying a pipeline or making a frame for a home greenhouse.

Manual pipe bender is a manual pipe bending machine. operating principle of a manual pipe bender drive.

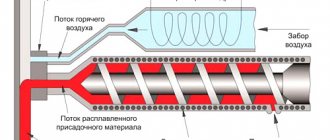

On manually driven mandrel pipe bending machines, bending is carried out using the winding or rolling method, when a person, with his muscular strength, drives the bending or rolling roller through a collar shaft and bends the pipe.

Manual mandrel pipe bender SM-30/2 PARTNER in 2-axis design

The diameter of the pipe to be bent on manual mandrel pipe benders operating by the method of winding, rolling and rolling usually does not exceed 30 mm. With the help of amplifiers (manual gearboxes, lever systems), you can increase the diameter of the pipe being bent, but then the reliability of the manual pipe bender decreases. The presence of a mandrel on a manual pipe bender that works using the winding method, such as on the SM-30 PARTNER manual pipe bender, ensures good bending quality even on thin-walled pipes. When bending pipes without mandrel, the quality of bending on a pipe bending machine depends on the thickness of the pipe wall and the bending radius of the pipe.

On manual mandrel pipe benders SM-30/3 PARTNER, a carriage can be installed to control the linear sections between bends and the angle of rotation of the pipe in space, with a system of linear stops. The presence of such a carriage allows the production of complex spatial parts from pipes. If there is no carriage on a manual pipe bender, then the pipe positioning parameters in space are controlled by eye, and the linear extensions of the pipe to the starting points of the bends are programmed using folding stops.

On manual roller pipe benders with one drive roller, the pipe is bent by rotating this roller, the pipe is pulled between 2 freely rotating rollers.

Manual pipe bender 3RM-30 START series

The power of a manually driven pipe bender is limited by human muscle strength and the frictional force between the drive roller and the pipe being bent. Therefore, the pipe is pressed to a minimum, and the number of runs increases.

A big plus of a manual pipe bending machine is mobility. A manual pipe bender is lightweight, easy to carry and transport even in a passenger car, and can be quickly installed on site. The manual pipe bender does not require any power source to operate.