The functional purpose of the Corvette 401 machine is to process metal workpieces by turning them during rotation. However, this equipment allows you to turn products from plastic or wood.

The machine in question belongs to the class of screw-cutting lathes (universal). And in terms of its scale, it is considered a desktop one.

With its help you can perform the following types of work:

- produce conical, cylindrical or shaped turning of workpieces;

- trimming blanks;

- cut metric threads;

- perform drilling and boring;

- chamfer;

- choose fillets.

In order to be able to insert large-diameter workpieces into the chuck, reverse cams are installed in it (the chuck is centered on its own). And in order to be able to process long workpieces, a steady rest (both movable and fixed) is installed. The machine provides a wide range of options for choosing the method of processing the workpiece:

- offset from the center of rotation of the workpiece (for this you need to install a faceplate);

- turning at different speeds;

- change in the speed of longitudinal movement of the caliper;

- wide range of processing tools.

It seems interesting to examine the technical properties of the equipment in question in more detail.

Brief information about the manufacturer Enkor

"Corvette" is a brand of equipment owned by. The company was founded back in 1992, and currently it is the largest domestic company in the field of production and trade in equipment and processing tools for it. The work is carried out in two formats:

Through the company’s own representative offices in different regions of Russia (thanks to the franchising scheme of work). Through a dealer network of companies that operate both in the Russian Federation and in the countries of the former USSR (near abroad).

Enkor cooperates with reputable equipment manufacturers: in particular, orders for the production of Corvette 401 are placed in , Ltd, Shanghai. Enkor specializes in industrial equipment, in particular, the emphasis is on:

- industrial lathes;

- portable machines for processing workpieces made of wood, metal and plastic;

- production of cutting tools for woodworking operations;

- hand tool;

- equipment for machine tools and hand tools.

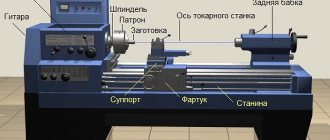

General structure of a metal machine

Any lathe designed for processing metal workpieces has the following functional parts:

- The bed, which is the basis for the entire machine structure. All vibrations are “grounded” on it, so the greater the hardness of the materials being processed, the more massive the bed should be (usually it is cast from cast iron).

- An apron is a carriage moving along the workpiece, on which a support with a cutting tool is attached. Movement can be carried out in both manual and automatic modes.

- A support is an element of a lathe where a cutting tool is secured in a tool holder. The caliper is mounted on the apron.

- The headstock is the part of the machine where the spindle itself is attached and its drive (gearbox, etc.) is located.

- The tailstock is located on the same axis with the rotating spindle. Designed for fastening the workpiece from the end through the stop.

- The electrical part of the machine is the traction motor, as well as all electrical equipment, which is located directly next to the front headstock of the machine.

The layout of the Corvette 401 machine is quite standard, but together with the kinematic diagram it makes it possible to ensure precision in the processing of parts corresponding to class “H” throughout the entire operational period.

What kind of work is it used for?

It seems reasonable to cover in more detail the functionality of the Corvette 401 machine. So:

Turning

The most common type of work performed on a lathe is turning rotating metal workpieces in order to give them the correct shape and exact dimensions. Depending on the complexity of the movement of the support, the following types of turning are distinguished:

Cylindrical

With this type of turning, it is necessary to obtain a cylindrical part. This is one of the simplest types of turning, when the support makes exclusively parallel movement along the axis of the fixed workpiece, and the cutting tool fixed in the tool holder removes everything unnecessary from the workpiece.

Shaped

If you fix a sample of the finished part in the tailstock of the machine, and a workpiece in the spindle, then, having fixed the same tool in the tool holder of the support, it will be possible to carry out copying - shaped turning.

The cutter on the tailstock side will “take dimensions” from the finished part, and on the spindle side it will “communicate” them to the workpiece (since the tool holder is a rigid element of the machine). This is the essence of shaped turning.

Conical

With this turning format, it is necessary to obtain a conical-shaped part. This requires the support to move in two directions at once: along the axis of the workpiece and across it.

High-quality conical parts can be obtained only if there is mechanization of both longitudinal and transverse movement of the caliper. (If feeding can only be done manually, then pattern turning is an alternative).

The tailstock of the Corvette 401 machine has the ability to move horizontally relative to the axis. This makes it possible to produce conical turning of the workpiece using a simple longitudinal movement of the caliper.

Trimming

Facing is the processing of the end part of the workpiece. It also includes cutting the workpiece to length.

Metric thread cutting

The Corvette 401 machine is equipped with an automatic longitudinal drive of the support, which means that the feed rate remains unchanged. With a constant ratio of the workpiece rotation speed and feed speed, it is possible to use special cutting equipment to cut metric threads into cylindrical workpieces.

Drilling

In this case, a drill is attached to the tailstock, which makes a hole in the rotating workpiece.

Boring

Boring means increasing the size of a hole already made in the workpiece. Boring can be done in several ways:

- a drill of a larger diameter is inserted into the tailstock of the machine;

- a cutter is inserted into the tailstock, which runs along the inner surface of the workpiece, boring it;

- Boring can be done by using the tool holder on the caliper. To do this, you need to position and secure the tool in such a way that the cutter can “reach” the inner surface of the hole in the workpiece. Here it is already possible to produce shaped boring.

Chamfering

Chamfering is carried out using specialized cutters that are accurately and properly secured in the tool holder. In this case, no lateral movements of the support are required during the turning process.

Selection of fillets

This is called turning with rounded cutters. This operation is required in order to make smoother transitions between cylinders with different diameters on the same workpiece.

Design features

The Corvette 401 machine has the following features that distinguish it from possible alternatives:

Brushed motor

It gives the machine additional power through more rational use of the electromagnetic field. (The circuits of the armature winding through which the current passes are not only attracted by the poles of the electric motor, but also repel as they pass).

Belting

Its use makes it possible to significantly reduce noise during operation of the machine and protect the traction motor from the risk of overload.

Magnetic switch

The power supplied to the winding of the traction motor may sometimes be turned off for a short time (for some reason - for example, in cases of a power outage). In this case, after switching back on for conventional machines, the machine starting system can be activated (with increased energy supply during the armature acceleration stage). With the Corvette 401 machine, this situation is eliminated due to the presence of a magnetic starter.

Spindle rotation reverse

Allows you to cut metric threads on the inner sides of the holes being made.

Reverse carriage feed

Allows you to significantly increase the productivity of the machine, thanks to the system for returning the support to its original position.

Replacement gear set

A set of replaceable gears makes it possible to cut metric threads with almost any pitch.

Table for setting thread cutting

To simplify the selection of the appropriate tool, the Corvette 401 has its own setting table for thread cutting.

Thread cutting indicator

It is necessary for the cutter to accurately hit the stream left during the previous passage of the cutting tool.

Dovetail

“Dovetail” is a technology for simultaneous transverse and longitudinal movement of the caliper carriage along the “dovetail” slide with the ability to adjust the smoothness of the carriage and prevent any backlash.

Rotary support for conical turning of parts

A rotary caliper is extremely popular when turning conical parts of short length.

Pallet included

Since the machine belongs to the class of desktop equipment, it is equipped with a pallet.

Protective cover

For safe operation there is a protective casing with a limit switch.

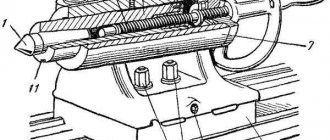

Location of components of the Corvette-401 screw-cutting lathe

Specification of components of the Corvette-401 screw-cutting lathe

- Headstock

- Spindle flange

- Three-jaw self-centering chuck

- Protective shield

- Chuck jaws

- Cutter mounting bolts

- Tool holder

- Toolholder fixing handle

- Tailstock center

- Tailstock quill

- Handle for fixing the position of the quill in the tailstock

- Tailstock

- Tailstock quill feed flywheel

- Tailstock fastening nut

- Bed slide

- bed

- Carriage Feed Screw Support

- Rotary caliper feed handle

- Carriage feed screw

- Rotary caliper

- Thread cutting indicator

- Automatic feed lever

- Cross slide feed handle

- Carriage

- Cross slide (cutting slide)

- Carriage manual feed handwheel

- Motor brush cover

- Chip tray

- Rubber foot

- Thread cutting indicator table

- Guitar guard

- Speed control knob

- Spindle rotation direction switch Forward, Off, Backward

- Emergency switch

- Speed shift lever in the range of High, Low speed

- Lever for setting the carriage feed direction with Forward, Neutral, Backward

Specifications

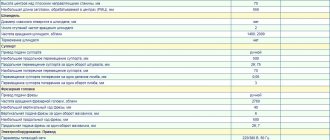

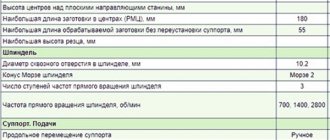

The technical characteristics of the Corvette 401 lathe are very interesting:

Main settings

The machine operates from a network of 220-230 volts, with an alternating current frequency of 50 Hz. The ambient temperature should be from +1 to +35°C, relative humidity – 80% (at a temperature level of +25°C). Further:

- The largest diameter of the workpiece being processed (above the bed) is 180 mm.

- The manufacturer sets the maximum turning depth for 1 pass - no more than 0.2 mm.

- The maximum size of the cutter holder is 10x10 mm.

Gearbox and spindle

- The diameter of the hole (through) in the spindle is 20 mm.

- The set of gears ensures spindle rotation at a frequency of up to 1100 rpm at 1st speed and up to 2500 rpm. - On the second.

- Reverse feed makes it possible to process workpieces at the same spindle speed.

- The diameter of the lathe chuck is 80 mm. (At the same time, its greatest radial runout does not exceed 0.01 mm).

The machine is not equipped with either a locking control knob or a spindle braking system.

Caliper

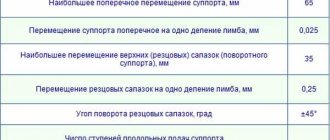

The longitudinal movement of the support allows you to process workpieces with a maximum length of up to 300 mm. The transverse movement of the support is 65 mm, the stroke of the rotary support (movement of the upper cutting slide) is 35 mm, the angle of rotation of the cutting slide is no more than 45°. All calipers have mechanical adjustment, but the carriage on which they are mounted has an automatic longitudinal feed mode.

Gearbox

The machine has a belt drive, which ensures low noise and smooth operation. The model has 2 speeds, with the idle speed at the first speed being 1100 rpm and the second speed being 2500 rpm. In addition, the gearbox ensures spindle rotation in both directions.

Tailstock

The maximum movement of the machine tailstock quill is 40 mm. (We are talking about the lateral deviation of the headstock from the main axis of the machine - thanks to this displacement, conical parts can be turned). Spindle cone – Morse No. 3; tailstock cone - Morse No. 2.

Electrical equipment and drives

The machine as the main power plant has a commutator electric motor with a power of 0.5 kW, designed for a voltage of 220-230 volts and an alternating current frequency of 50 Hz. The torque drive to the gearbox is a belt drive.

Dimensions and weight

Overall dimensions of the machine - 850x305x320 mm. The total weight of the machine including the pallet is only 38 kg.

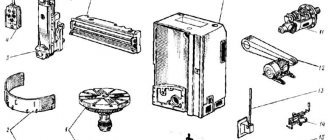

Assembly diagram of the Corvette-401 screw-cutting lathe

| No. Code - Name - Quantity | No. Code - Name - Quantity |

|

|

Safety precautions

When operating a tabletop lathe, it is strictly prohibited:

- wear loose clothing, especially on your arms. Hair must be tucked under a headdress;

- turn on the machine without conducting its preliminary technical inspection;

- perform actions on the machine that are not related to the technological process of processing the workpiece;

- operate a machine whose centers have noticeable mechanical wear;

- use a defective processing tool;

- to correct defects that arise in the electrical cabinet of the machine (in its guitar) to persons who do not have the appropriate qualifications for this;

- allow third parties to work who are not familiar with the features of the machine or who do not have the appropriate competence.

Reviews and Reviews

Watch the videos (above) and reviews (below), they are often better than text reviews. You can read more reviews or leave your own in the comments to this page. Thank you for your review or rating!

Normal machine. Just right for my tasks. If you add a little more to the normal assistant. Personally, I have no regrets; he earns his money back with interest.

Anton 01/11/2019

Rate this model:

Model rating: 4.1 / 5. Number of ratings: 11

Features of the 94010 specification

The distinctive characteristics of specification 94010, corresponding to the Corvette 401 model, from similar models Corvette 402 (special 94020) and Corvette 403 (special 94030) are the following:

- The maximum diameter of processed workpieces is 94010 smaller: 180 mm versus 220 on analogues.

- The longest workpiece length that can be processed on the machine in question is also the smallest of all three models (300 mm versus 500 mm on the Corvette 402 and 750 mm on the Corvette 403).

- The greatest turning depth in 1 pass for 94010 is only 0.2 mm, and for its analogues it is 0.3 mm, the maximum cross-section of the cutter holder for 94010 is 10x10 mm, and for analogues it is 13x13 mm.

- The Corvette 401 has a smooth change in spindle speed at idle, while its analogues have 6 steps.

- The maximum lateral movement of the caliper for the 94010 is 65 mm, while for the analogues under consideration it is 110 mm. (The movement of the upper cutter slide on the Corvette 401 is 35 mm, and on analogues it is 50 mm).

- The Corvette 402 and Corvette 403 models are equipped with synchronous (brushless) electric motors with a power of 0.75 kW.

- The overall dimensions of the Corvette machine are 401–850x305x320 mm, and for the Corvette 402–1030x480x475 (Corvette length 403–1250 mm).

Description of the operation of the electrical circuit of the Corvette-401 lathe

The machine is connected to a 220V outlet. 50Hz using a grounding plug. Before connecting, you must check the reliability of the connection between the machine and the grounding pin of the plug.

To turn on the machine you must:

- set the speed control to its original position by turning it counterclockwise until it clicks

- release the emergency shutdown button of the machine SB 1 by sliding the cover to the side

- select the direction of rotation of the jaw chuck using switch SA1

- turn on the rotation by turning the speed regulator P clockwise and set the required speed

The change in rotation speed is directly proportional to the voltage coming from the converter AR1.

There are three ways to turn off the machine:

- turning the P regulator counterclockwise until it clicks

- by pressing the emergency shutdown button

- removing the connecting plug from the socket

In any case, to resume operation, you can turn on rotation only as described above. Therefore, to temporarily turn off rotation, use the regulator, gradually reducing the rotation speed. Use the emergency shutdown button for its intended purpose.

The electrical equipment of the machine is protected from overloads and short circuits by fuse FU1. If it burns out, install a similar fuse or contact a service center.