DESCRIPTION Encore Corvette-320

The universal machine "Corvette 320" is used to work with workpieces made of wood and other derivative materials as:

planer , by planing, using a guide bar,

sawing machine, by longitudinal and transverse sawing, with an installed movable table and with a transport stop,

drilling machine for drilling operations,

milling machine for performing milling operations.

Drilling and milling operations are performed with end mills, while the workpiece is placed on the work table, and to perform work with it, it is moved along three axes and pressed with a clamp.

The machine is widely used in workshops with a small working area, as it allows you to perform all of the above operations with minimal time to switch to different operations.

The machine has a cast iron planing table, a powerful asynchronous motor with a belt drive, which protects the motor from overloads and makes it relatively quiet during operation. The machine has smooth adjustments: the height of the disc reach, the angle for sawing at an angle. The machine is also equipped with a protective strip for the planing shaft and a connection pipe for connecting a vacuum cleaner. The protective guard on the saw blade ensures safe operation.

The warranty period for CORVET machines is 36 months.

Drive and work area

The base surface is a planing work table made of high-strength cast iron - its dimensions reach 964 * 210 mm, which allows you to work with large workpieces. Its fastening allows you to tilt boards and bars at an angle of up to 45 degrees, due to which the Enkor Corvette-320 model can work in the manufacture of complex finished products. In addition, the manufacturer also provides for the use of a second work table on which drilling and milling is carried out - despite the fact that the price of the device is low, it has maximum convenience due to the ability to quickly move along the guides. The electric motor installed on the device is the only thing that somewhat limits productivity, but allows you to achieve maximum efficiency. Its power reaches 1.5 kW, which allows the Enkor Corvette-320 unit to achieve high efficiency in using any function - drilling, milling, sawing, planing. In addition, like other similar devices that the manufacturer’s catalog contains, the machine is equipped with all the necessary safety systems, including overload protection, an electromagnetic starter and a set of thermal relays.

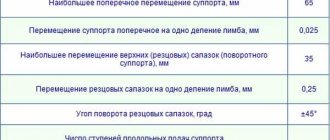

CHARACTERISTICS Encore Corvette-320

| Manufacturer | Corvette Encore |

| Input electrical characteristics | |

| Rated motor power input | 1500 W |

| Rated supply voltage | 220/50 V/Hz |

| Motor type | asynchronous |

| Technical data | |

| Planing | Yes |

| Working shaft diameter | 74 mm |

| Working shaft speed | 3500 rpm |

| Maximum width of workpiece processed | 200 mm |

| Maximum planing depth per pass | 3 mm |

| Number of knives on the working shaft | 3 pcs. |

| Working table size (planing table) | 964x210 mm |

| Guide bar inclination angle | ±45 deg |

| Sawing | Yes |

| Spindle diameter | 20 mm |

| Spindle speed at idle speed | 3500 rpm |

| Disc outer diameter | 254 mm |

| Disc mounting diameter | 30 mm |

| Maximum thickness of workpiece processed | 70 mm |

| Maximum width of the processed workpiece (sawing) | 300 mm |

| Miter sawing at an angle | ±45 deg |

| Drilling/milling | Yes |

| Drilling diameter | 1.5 - 13 mm |

| End mill diameter | 1.5 - 13 mm |

| Cross travel of the work table | 60 mm |

| Longitudinal travel of the work table | 70 mm |

| Vertical stroke of the moving table | 45 mm |

| Diameter of the dust collector pipe | 40 mm |

| Net/gross weight | 98/120 kg |

| Package size (LxWxH) | 1130Х595Х400 mm |

Operating characteristics

If we talk about planing, the device is sold using a knife shaft equipped with three blades, which can spin up to a rotation speed of 3500 rpm. Due to this, the universal woodworking machine Encor Corvette-320 receives good characteristics - it can remove 3 mm of wood in one pass, subject to the permissible width of 200 mm. The use of a saw blade with a diameter of 255 mm also makes it possible to cut workpieces up to 70 mm thick and 300 mm wide - including sheet finishing materials. The side work table is designed for drilling and milling with a tool diameter from 1.5 to 13 mm, regardless of his appointment. The vertical stroke of the surface is 40 mm, the longitudinal stroke is 70 mm, and the transverse stroke is 45 mm, which ensures maximum operating convenience. To secure the workpiece, a clamp with a large support base equipped with a plastic tip is used.

THE BASIC PACKAGE OF THE Encore Corvette-320 INCLUDES:

- Support (saw);

- Guide bar;

- Work table (tenon-cutting) Bevel guide;

- Drill chuck, key (drill chuck);

- Protective strip;

- Protective casing (saw blade);

- Clamping device for drilling unit;

- Caliper (drilling);

- Saw blade;

- Rack;

- Drill;

- Ripper;

- Bracket (protective strip);

- Open-end wrench;

- Hex key;

- Fixation screw;

- (Comes without stand)

Key Features

All adjustments of the main characteristics are carried out smoothly, which allows you to achieve the required combination of efficiency, accuracy and productivity.

Before placing an order in the Encor24 online store, you can be sure that you will be offered a favorable price for the “universal woodworking machine Encor Corvette-320 (93200)” in the amount of 59,500.00 rubles, but also the opportunity to receive an additional discount after registering on the site or by promo code. When making a choice, be sure to read reviews about the “universal woodworking machine Encore Corvette-320 (93200)”, consult with an online consultant or ask your questions by calling in Voronezh +7 (473) 203-203-0 and toll-free in Russia.

You can buy a “universal woodworking machine Encore Corvette-320 (93200)” on our website in just a few clicks. After that, our managers will call you and let you know when you can receive your order, or specify the cost and delivery time.

Lathe components for the machine

There are six modifications of the Corvette 322 universal woodworking lathe. The average cost of the mechanism is 55,000 rubles. The most popular version, which is capable of working with products with a diameter of 20 cm and a length of 30 cm. The mechanism is connected in a 220 V phase.

The main component of the unit: spindle with tailstock MT 1. The unit is equipped with a collector shaft drive with a power of 250 W. Spindle speed output is 750-3200 rpm.

Real professionals choose a Corvette 322 or 320 woodworking lathe for their work. This universal aggregate mechanism is capable of turning, grinding and high-precision polishing of parts. The unit is stationary. Average weight is at least 90 kg. Installed using four legs to provide support.

Main characteristics

- It has an asynchronized motor with a power of 750 W.

- The maximum frequency of movement of the rotating spindle is 200-500 revolutions per minute.

- The maximum length of the workpiece is about 108 cm, with a diametrical cross-section of 35 cm.

- The main type of cone error is M 2.

The presence and convenient location of the variator makes this unit a real advantage of such a branded model. It is possible to adjust the spindle smoothly, as well as install a socket for installing the copy mechanism. This makes it possible to process workpieces with a diameter above average.

The Corvette 320 woodworking machine is capable of high-quality planing, thicknessing, sawing, drilling and milling devices. This mechanism can:

- Plan along the guide line.

- Plan according to the thickness of the product.

- Sawing and drilling along the guide.

- Volume mill the shape and size of the product.

The machine is the easiest to use. The spindle rotates at a frequency of 3500 rpm. The width of the planing surface is 200 mm, the penetration depth of the band saw is 3 mm. Due to the use of the latest transmission system, the unit becomes the least noisy and vibrating during operation. This model is capable of replacing several highly specialized units.

Video: capabilities of Corvette machines.

Universal woodworking machine Enkor Corvette-320

— This product has a CASHBACK (RETURN) promotion of 17% of the price on the card or in cash. — Check the terms of the promotion by phone. — PRICE AFTER CASHBACK (WITH DISCOUNT) -17% of the cost.

The CASHBACK promotion does not apply to discounted items.

************************************************************************************************************************************

Such a device has universal application - it combines three devices, each of which has maximum performance. The high power of the engine makes the universal woodworking machine Encor Corvette-320 one of the most functional in the budget class, however, it is worth remembering that the functions can only be used alternately - the motor is the only one and it is necessary to switch the drive, changing its configuration. Relatively small dimensions and moderate weight allow you to quickly move the model over long distances, as well as install it on a regular table without the use of a special stand. It is necessary to note the maximum ease of use, which is achieved through the use of large work tables and smooth adjustments of characteristics.

Drive and work area

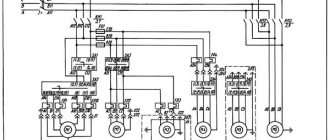

The base surface is a planing work table made of high-strength cast iron - its dimensions reach 964 * 210 mm, which allows you to work with large workpieces. Its fastening allows you to tilt boards and bars at an angle of up to 45 degrees, due to which the Enkor Corvette-320 model can work in the manufacture of complex finished products. In addition, the manufacturer also provides for the use of a second work table on which drilling and milling is carried out - despite the fact that the price of the device is low, it has maximum convenience due to the ability to quickly move along the guides. The electric motor installed on the device is the only thing that somewhat limits productivity, but allows you to achieve maximum efficiency. Its power reaches 1.5 kW, which allows the Enkor Corvette-320 unit to achieve high efficiency in using any function - drilling, milling, sawing, planing. In addition, like other similar devices that the manufacturer’s catalog contains, the machine is equipped with all the necessary safety systems, including overload protection, an electromagnetic starter and a set of thermal relays.

Operating characteristics

If we talk about planing, the device is sold using a knife shaft equipped with three blades, which can spin up to a rotation speed of 3500 rpm. Due to this, the universal woodworking machine Encor Corvette-320 receives good characteristics - it can remove 3 mm of wood in one pass, subject to the permissible width of 200 mm. The use of a saw blade with a diameter of 255 mm also makes it possible to cut workpieces up to 70 mm thick and 300 mm wide - including sheet finishing materials. The side work table is designed for drilling and milling with a tool diameter from 1.5 to 13 mm, regardless of his appointment. The vertical stroke of the surface is 40 mm, the longitudinal stroke is 70 mm, and the transverse stroke is 45 mm, which ensures maximum operating convenience. To secure the workpiece, a clamp with a large support base equipped with a plastic tip is used.

Key Features

All adjustments of the main characteristics are carried out smoothly, which allows you to achieve the required combination of efficiency, accuracy and productivity.

Reviews on the operation of the machine

“I own a woodworking workshop. I specialize in making Swedish decorative furniture. In February 2016, I purchased a Corvette 320 machine and to this day I am in a state of shock at its functionality. Incomes have increased manifold, because productivity is at the cutting edge. I am sure that this unit is worthy of untold praise. I wish success and prosperity to all those who intend to purchase such a highly effective device at a reasonable price” - Dmitry.

“At work I only use the Corvette 322 machine. I have had very positive impressions from the very moment I purchased it on credit, since its price turned out to be somewhat high. The device is ergonomic and easy to use. Power is great. I recommend this model to everyone. You won’t regret it” – Alexander.

“An excellent unit, it meets all the stated characteristics: it has been in service for more than three years and has never failed during its entire operation. The Corvette 321 is a dream machine that pays for itself in a matter of months. I advise everyone to buy this particular model” - Nikolay.

Republished by Blog Post Promoter

Flat layer cultivation equipment from Corvette

The presence of the model range is impressive - there are models such as the Corvette 320, Corvette 322 and 323. All of them are equipped with three high-quality cutters, which makes it possible to increase the efficiency of work many times over. Any machine from Corvette is capable of operating at a voltage of 220 V or more - an excellent purchase for home use and work in home-made workshops.

The range of grinding machines is truly impressive: there are 5 models of units from Encore Corvette, for example, 323, the average cost is up to 77,000 rubles. The cheapest options are the desktop version. Their purpose: work with sanding belts using discs of at least 15 cm in diametrical proportion.

The 322 Corvette has twice the horsepower and more table roll to work with. The rotation speed of the disk space is 4000 rpm. Belt speed – no more than 280 meters per minute. Considering the compact size of the machine, it becomes an indispensable assistant for woodworking at home.

The best professional model of the unit is the Corvette-321 machine. The model is very large-sized and weighs no less than 148 kg; it carries out an increased level of part processing. The delivery set includes a special cabinet. The tape block can occupy different positions: vertical and horizontal. The maximum permissible motor power is 2200 W, the belt rotation speed is about 1000 meters per minute.