20.03.2020

- Purpose and description

- Varieties

- How does a lathe work and what does it consist of?

- Diagram of a lathe with all the main devices

- What does a lathe do and how does it work?

- Operating a lathe: how to turn on the device and start working

- How to install and configure a lathe

- How to choose a metal lathe and make out the markings

Turning is one of the most popular and in demand metalworking methods. In this article we will tell you about the design of a universal metal lathe, what kind of equipment it is, what technical characteristics it has, how to choose and install a suitable one and carry out processing on it, as well as about its types.

Purpose and description

In fact, any enterprise that works with steel has a unit in its workshop that is capable of turning the necessary elements, for example, shafts, from a cylindrical workpiece.

The design itself is used not only for working with metal products, but also with other materials. The first progenitors of the installations were created back in the 7th century BC. They were used primarily for wood or bone and had a primitive processing mechanism: a wooden frame, not the most durable clamps and a manual drive. However, the essence of the operation remained the same.

And only at the beginning of the eighteenth century the first models appeared, which were intended for work in workshops with metal blanks.

Now modern devices have an electric drive, a strong base, and a durable tool made of tool steel. Some machines are equipped with numerical software, that is, they have a high degree of automation.

The essence of the metalworking operation is as follows. The raw material is clamped on both sides with special clamps. The spindles begin to rotate, and along with them, the workpiece itself begins to move. Then the tool begins to move. It has several axes - guides, depending on the modification of the equipment. Let's see what the lathe looks like in the image:

Various tools are then used. The cutter removes the top layer from the surface, performing the main operation - turning. Universal devices also additionally have the ability to make holes and apply threads.

Let's consider what purpose this unit has. It performs the following functions:

- ● production of screw-cutting taps and dies - you can make a full-fledged bolt or self-tapping screw from a rod;

- ● creating a cone - full or truncated, solid or hollow;

- ● reaming holes - blind or solid, their subsequent grinding, various processing;

- ● trimming edges, end parts;

- ● cutting one element into two or more.

Universal units have the maximum range of functions. However, the classic old model can only perform few tasks. The main thing is to remove the top layer of metal from a cylindrical workpiece.

Scope of equipment application

In single and small-scale production, it is advisable to use universal lathes. Special devices will help expand their scope of application. When the units are equipped with electrically or hydraulically driven copy supports, quick-release chucks and other devices, universal turning equipment can be used in mass production conditions.

Automatic and semi-automatic machines are more typical for large-scale and mass production.

Maintenance of such machines consists of a set of activities, during which the tool is adjusted, followed by machining and control of the resulting surfaces. The peculiarity of semi-automatic machines is that all movements related to installing the workpiece and removing the finished product are performed manually. It should be noted that automatic control of work processes is carried out by the camshaft and cams attached to it. Go to list of articles >>

Types of lathes

Products are classified on several grounds. The main features and characteristics can be understood from the markings. Let's consider what criteria are fundamental when choosing.

Lathe accuracy class

Everything here is extremely simple. The better the tools are sharpened and the drawing is verified, the more accurate the result will be. But there is a noticeable difference between a manual and an automated process. Equipment equipped with CNC has a great advantage over manual labor. This is especially true for small details.

The letter included in the marking characterizes the accuracy class. We present them in ascending order from normal to especially high in this table:

| Designation | Permissible error in percentage | Manufacturing complexity, % |

| N | 100 | 100 |

| P | 60 | 140 |

| IN | 40 | 200 |

| A | 25 | 280 |

| WITH | 16 | 450 |

Weight

Any metalworking equipment has a significant weight. In most cases, additional reinforcement of the floors is required, for example, pouring a concrete base. Typically, such heavy structures are placed on the ground floor.

What can be done on a lathe, that is, what to work with, depends on what class the unit belongs to. Small units will handle small parts well. But if the question is about processing for mechanical engineering purposes, then it is often not enough. Let's see in a small table what varieties are distinguished:

| Name | Maximum weight (tons) |

| Easy | up to 1 |

| Average | from 1 to 10 |

| Heavy | more than 10 |

| Unique | above 100 |

Degree of automation

The more automated the machine is, the less physical labor the employee must use. The turner experiences less impact on his health at work, since he does not have to constantly experience fatigue, as well as the influence of high noise levels.

The second advantage of automatic machines is the acceleration of all processes and increased productivity. This is especially true for mass production, when all production is put on an assembly line.

The third benefit is a reduction in errors and an increase in accuracy. Usually, any errors and defects are the result of erroneous actions of the turner. The absence of costs for defective workpieces will help to save significantly. Let's look at how to work on a metal lathe, depending on the degree of automation:

- ● Manually controlled. The drive of two main movements (rotation and feed) is mechanized. But moving the tool, installing the workpiece, fixing it, removing chips, supplying lubricant - all this must be done manually.

- ● Semi-automatic. All of the above procedures are computer controlled. The exception is mounting and removing a part.

- ● Automatic The most advanced models, they are mostly equipped with a CNC control panel. The operator has sole control over the independent operation of the machine.

A wide selection of automatic installations is presented in the Sarmat online store. Their use will be economically beneficial not only in large factories, but also in small small-scale production.

System flexibility

There are classic machines, and there is a GPU, that is, a flexible production module. The second is different in that you can quickly and easily reconfigure the purpose of the work. That is, moving from one cycle to another. This is beneficial when there is a whole series of products with different standard sizes in production.

Special purpose in metal processing

There are a number of machines that have unique capabilities. They are used exclusively for one operation, but perform it with the highest quality and precision.

Versatility

What can be done on different types of lathes depends on multitasking. Universal devices have many tools and also have the ability to move the caliper in many directions. Classic units have only two axes of movement, while there are up to 6 directions.

Almost all CNC products make it possible to perform many tasks, including screw cutting, all of which are presented above.

Older models are usually not equipped with a control panel and have a narrow focus. Modernization in production often involves replacing outdated designs with more versatile ones. This allows not only to speed up the production process, but also to reduce labor costs, in some cases, jobs, since now with new devices many actions can be performed by one operator in the same time.

Tips for choosing equipment

Metalworking machines

The choice of a metal cutting machine is always based on the characteristics of its future application. This is what its performance characteristics depend on (power, electrical parameters, list of available functions, accuracy, overall dimensions).

Particular attention should be paid to the following factors:

- Functional. It is worth considering in advance the list of technological operations that will be required to complete production tasks.

- Level of automation. The higher it is, the more expensive the equipment will be. But with an increase in the level of automation, the accuracy of the operations performed, their complexity and speed also increases.

- Tooling of the machine. It is important to take into account the minimum and maximum dimensions of the workpieces being processed, the amount of movement along the axes, the maximum diameter above the support and frame, and the spindle rotation speed.

- Software. When purchasing a CNC metalworking machine, the ability of the equipment to work in conjunction with other devices and its compatibility with CAD/CAM technologies becomes fundamentally important.

- Manufacturing company. When choosing any equipment, it is important that the manufacturer provides full warranty and service maintenance; during operation, there are no problems with the supply of components or consumables.

How does a lathe work and what does it consist of?

The design of all installations includes the following components:

- ● Bed. This is a metal base that supports the entire weight of the remaining elements, as well as the workpiece. All other parts are also attached to it.

- ● Apron. Responsible for converting energy into movement.

- ● Grandmas. There are two of them - one is simply responsible for fixing, the other includes a motor and a spindle that holds and simultaneously rotates the workpiece.

- ● Support. He is responsible for the tool - its movement and fixation.

- ● Feed box and other elements that allow you to change the speed and direction of movement of moving units.

- ● Numerical control panel, which, in turn, includes a display, a cabinet with buttons and the program itself.

These are the main parts, but there are also additional systems, for example, the supply of lubricating and cooling fluid or the removal of chips.

Basic parameters of screw-cutting lathes

The main parameter of a screw-cutting lathe is the largest diameter D (Fig. I, 5) of the workpiece being processed above the bed. The gap between the horizontal plane of the guides and the diameter of the workpiece D is no more than 0.04D. Diameter D is approximately equal to twice the height of the machine centers.

GOST 440-57 provides for a range of sizes of screw-cutting lathes with D values from 100 to 6300 mm, built according to the law of geometric progression with the denominator φ = 1.26 (with slight roundings).

Another main parameter of the machine is the greatest distance between its centers, which determines the greatest length of the workpiece. It is determined when the tailstock is shifted (without hanging from the guides) to the right extreme position. Machine tools with the same largest diameter of the workpiece being processed can have different center-to-center distances within the limits provided for by GOST 440-57. For example, machines with a largest workpiece diameter of 400 mm are made with the largest distance between centers of 700, 1000 and 1400 mm. For most heavy-duty lathes, the greatest distance between centers is not regulated.

An important size of the machine is also the largest diameter of the workpiece being processed above the support D1 (Fig. I, 5). It must be no less than that provided for in GOST 440-57.

In addition to these basic parameters of screw-cutting lathes, GOST 440-57 establishes the maximum number of spindle revolutions, the maximum diameter of the rod passing through the spindle hole, the size of the spindle center (Morse or metric taper number), the maximum height of the cutter and the maximum permissible weight of the machine (without electrical equipment ).

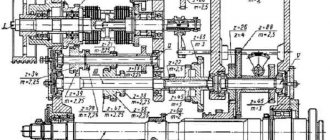

Diagram of a lathe with all the main devices

After the verbal description, let's look at the actual drawing of the product:

In the image we see a universal device, which is equipped with the ability not only to perform turning, but also to cut threads.

Here is another schematic photograph of a real unit:

On it we see, in addition to the main and secondary components:

- ● Front and rear cabinets. This is the element of the frame that bears the main load. When designing, the surface area is also taken into account. Their second task is to provide sufficient height for comfortable work of the turner.

- ● On the apron there is a wheel and a handle for moving the longitudinal and transverse slides.

- ● There are also screws for fixing on the tailstock.

- ● In the middle we see a movable block, which is equipped with a handle for attaching the tool holder and a tightening head - this is where the tool is installed.

Design features of lathe group machines

All machines designed for turning workpieces made of metal and other materials have standard structural elements in their design:

- bed - the supporting element of the turning unit on which all the elements of its structure are installed;

- apron (in this element of the lathe, the movement of the roller or lead screw is converted into the movement of its support);

- spindle headstock, on which the spindle of the device is located, and in its inner part there is a gearbox;

- caliper (in this element of the machine the cutting tool is fixed, the caliper is also needed in order to ensure longitudinal and transverse feed of the tool, carried out with the specified parameters; the design of the caliper must include a lower carriage, and some models have several of them, on the top of which a holder is attached for turning tools);

- feed box (using this structural element, movement is transmitted from the lead screw or roller to the machine support);

- the electrical part of the machine structure, which includes a drive electric motor, the power of which can vary significantly between different machine models, as well as elements that control the electrical equipment of the device (naturally, this part of the turning unit must meet safety requirements).

Main components of a lathe

All structural elements of the machine rest on two pedestals, which perform a load-bearing function and also ensure that the workpiece is placed at a height convenient for the operator. Such cabinets, distinguished by their massive design, can be seen in the photo of a lathe of any model.

The main part of the structural elements of turning equipment is unified, which makes it possible to quickly and cost-effectively carry out their maintenance and repair.

Lathe support design

Machine drive shafts

Example of lathe control layout (click to enlarge)

What does a lathe do and how does it work?

The operating principle of the equipment is quite simple. The electric motor generates a supply of energy, which in the gearbox is converted into a force of movement - rotation is transmitted to the spindle or faceplate. These elements cause the workpiece to rotate.

At the same time, the caliper begins to move. Regardless of the level of automation, there are horizontal and vertical devices. This affects which axis of tool movement is the main one.

Thus, there are only two movements - rotation and serve. The operator directs the support to the desired location. The cutting part removes the top layer from the metal surface and chips are formed.

Woodworking machines

Modern manufacturers offer a wide selection of woodworking machines. General-purpose installations, special models for the production of similar parts, or specialized devices for certain types of wood processing are produced.

To ensure that the equipment fully meets your expectations after purchase, we suggest using the following tips.

- Optimal power depends on the characteristics of the work and the list of operations that will be performed on the selected machine. Household models are considered to be models with a power of up to 3 kW/h, connected to a 220 V network; industrial models are units with higher productivity, which are also distinguished by a greater depth of cut, planing width, and a wider range of functions.

- The bed should be heavy and rigid (cast iron would be the ideal material for its manufacture).

- It is desirable to have a chuck on the headstock or the ability to install it. In the future, this will make it possible to process workpieces that are secured at only one end.

- The ability to install a drill chuck on the tailstock, which will greatly facilitate the task of sharpening blind holes.

- The presence of a spindle speed controller is a convenient feature that will help improve the quality of many technological operations.

- Universal models are equipped with a saw blade, drill, milling cutter, planing shaft with 3 or 4 knives.

Regardless of the type of lathe chosen, its parameters and technical characteristics, special attention should be paid to the quality of its assembly and the manufacturer’s use of materials that can withstand the planned loads. Universal multifunctional modifications always become the optimal solution: with the help of such a machine it becomes possible to solve almost any problem in metal or wood processing.

Show prices for lathes

Operating a lathe: how to turn on the device and start working

First you need to install the workpiece in two spindles and check the reliability of the fastening. If one of the holders flies out of its place at high speed, serious consequences are possible, both for the equipment and for the engineer. The second stage is the selection and installation of the tool. For classic tasks, cutters are used; sometimes drills or taps may be needed (when drilling holes and applying internal threads). In CNC-equipped equipment, both of these operations are often performed automatically. On semi-automatic machines this is done by the operator.

Further actions may vary depending on the type of machine.

On automatic:

- ● Develop a project, enter data into the control system.

- ● Turn on the lathe.

- ● Monitor the correct execution of the procedure.

For manual production:

- ● Turn on the engine.

- ● Using the gearbox, select the optimal number of rotations per second.

- ● Use the handles and wheel to control the movement of the caliper, cutting off the desired size of the top layer.

Also, control measurements should be carried out at different stages. Then you can sand it.

Turning and milling

A unique device for processing metal (ferrous and non-ferrous), wood and plastic , combining two machines - a lathe and a milling machine, so with its help it is possible to perform through turning of a workpiece, cut threads, apply chamfers, select fillets, and cut straight lines and curved grooves or drill holes on external surfaces. And all this is thanks to the presence of a vertical milling part with a second spindle in addition to the main elements. The equipment can be used in tool, watch and instrument production, used in private workshops, and also installed in schools for labor training of students.

Advantages:

- Availability . The cost of one combined machine will be lower than the cost of two.

- Compact sizes . One device will take up significantly less space than two, which is important if the workshop is small.

Cutting tools for a turning and milling machine include many more varieties, including cutters, drills, dies, taps, reamers, cutters for metal, and chisels for woodworking, depending on the planned work.

When choosing this equipment, in addition to the distance between centers and the maximum possible diameter of the workpiece, it is also important to take into account the maximum diameter of the end and end mills . This parameter determines which cutting tool you can use when milling a part. Our range includes devices that can use 13 and 30 mm accessories.

How to install and configure a lathe

First you need to choose a suitable location. This should be the first floor (or reinforced ceilings should be used in advance). The floor can be earthen or concrete. The room itself must have:

- ● good ventilation;

- ● bright lighting;

- ● fire safety measures.

When working with large-sized elements, the workplace should be equipped with a lifting mechanism, as well as a driveway - rails are often installed. For small parts, it is necessary to equip a separate cabinet to accommodate them. You will also need an area for tools.

The thickness and type of foundation depends on the weight of the equipment. The base can be local (pouring a small layer of concrete directly under the frame) or general, when ties and bolts are required.

Setting up the unit must be carried out by specialists. Without confidence in the performance and safety of the product, switching on is not recommended. not only deals with the sale of professional equipment for metalworking, but also configures all important systems.

This image shows the installation of the unit on a concrete floor:

Advantages of mini lathes

Units of this type have a number of advantages over large-sized, professional devices. For example, to operate such equipment, a standard household electrical network with a voltage of 220 V is sufficient. If desired, the mini-machine can be adapted to connect to a network with a voltage of 380 V (three-phase).

Another important advantage of a home turning unit is that it consumes a small amount of electricity during operation. The shelf life of micromachines of this type can reach several decades. How long it will serve you directly depends on two factors: proper use and timely maintenance.

To extend the service life of the metalworking unit, technical inspections and maintenance should be carried out regularly.

Due to its compactness, such a micro-machine can be placed in any suitable room (room in an apartment, garage, etc.). Units of this type allow novice turners to quickly learn how to process metal parts. It’s also worth saying that the cost of lathes for home use is more than affordable for most people.

And finally, an important advantage of such devices is that they can be equipped with additional devices. This allows them to be used for milling metal parts, which significantly expands their operational range.

How to choose a metal lathe and make out the markings

When purchasing, you need to consider:

- ● Production needs. For small-scale and exclusive work, universal devices that can be reprogrammed are needed.

- ● Plant type. Depending on the size of the parts being processed (mechanical engineering or the creation of small elements), different types of machines will be required in terms of weight.

- ● Workshop premises. Sometimes it is more convenient to install vertical units instead of horizontal ones - they take up less space, but are not suitable for all workpieces.

- ● Cost. The higher the accuracy class and the more functions, the more expensive the device is. We do not recommend taking used devices, as they can simply be damaged by improper handling. And repairs will cost more than buying a new one.

Pay attention to the labeling. It provides all the necessary information and special technical characteristics.

A wide range of products is presented in the catalog of the Sarmat online store. The company sells metalworking equipment with a numerical control panel. Here you can buy equipment of different price segments with high accuracy.

In the article, we tried to explain everything about universal lathes and how to cut threads on them, process metal, and make holes. Follow safety precautions when working.

Types of equipment

Lathes are classified according to a number of parameters, primarily by purpose, versatility or specialization of the equipment, and by its design features. They are also divided according to:

- accuracy class when processing a part;

- automation;

- weight;

- engine power and other parameters.

According to the current classification in the Russian Federation, there are the following types of lathes:

- single- and multi-spindle automatic and semi-automatic machines;

- cutting;

- screw-cutting;

- revolver;

- carousel;

- frontal;

- specialized;

- special.