In this article you will find useful information regarding choosing the best lathes. Much depends on the purpose of the device - which parts need to be processed and in what ways.

The purpose of lathes is to process metal workpieces with a high level of accuracy. Devices can be large (industrial) or compact (home). It is impossible to say unequivocally which lathe is better, so we will consider in detail the features of different types and draw conclusions. In addition, do not forget to purchase high-quality coolant for the lathe - they are necessary so that the device does not overheat and lasts longer.

Industrial machines are equipped with many attachments that increase functionality, and they can also process large-sized parts. Mini-machines are often installed in a garage, workshop or home; they can be placed on a table and do small turning work.

The article will discuss the best metal lathes from different categories.

How to choose a metal lathe - characteristics

When choosing a device, pay attention to the material from which it is made and how the frame guides are attached: the fact is that the bed is a very important component; it not only acts as a box where other elements are attached, but working mechanisms move along its guides. The bed should be massive, preferably cast iron, and stable, then the machine will vibrate less and cut metal more accurately.

What else you should pay attention to:

- The guides are attached to the vertical posts using welding or bolts. The structure can be equally rigid in both cases, but the bolts will need to be checked and tightened occasionally.

- The bed must stand on the pedestals without distortion, otherwise the parts will be defective. The number of pedestals varies from 2 to 4 depending on the size and weight of the lathe.

- Before buying a tabletop machine, pay attention to the following aspects: absence of play in moving parts, connection method and required voltage in the network, dimensions of the workpiece that can be processed.

- It is not necessary to buy the most expensive model with many functions - in many cases it is more profitable to choose a simpler model and, over time, equip it with the necessary tools.

- Before purchasing, it is advisable to check that the device operates stably and without interruptions at all speeds declared by the manufacturer - this is the main criterion that guarantees comfortable interaction with the machine.

When considering which lathe to choose, you need to immediately take a good and accurate model, and not hope for the possibility of independent modification.

Useful tips when choosing a device

The main criterion for choosing a lathe is its declared technical characteristics. But no less important are some nuances that few know about:

- It is better to purchase a model from a well-known and large manufacturer. Powerful companies are responsible for the quality of their products and provide customers with a long warranty and excellent service.

- Among lathes, models with helical gears are considered the best - such modifications have a good and smooth running and a reduced noise level.

- In good machine models, roller bearings are arranged in one pair and can be located either at the back of the spindle or at the front. It is important that the bearings mitigate the effects of expansion as much as possible. And the spindle itself had 12 constant speed positions.

- It is desirable that the machine has up to 3000 revolutions.

- The presence of a headstock (cast iron body, which is fixed on the left side of the machine). This element ensures smooth rotation and movement of the machine.

Ensure that your lathe model is equipped with safety systems that will prevent accidental injuries during operation.

The most important criterion for choosing a lathe is its pricing policy and technical characteristics. Before visiting a specialized store, determine the area of future work of the metal machine and for what purposes it will be used.

Which lathe manufacturer would you choose?

DomesticForeign

Regardless of the chosen brand, brand and model features, a lathe is a profitable and effective tool that will benefit every craftsman. And it will help you open your own business in the field of processing and manufacturing of metal products.

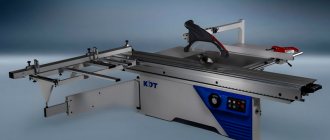

Best table saws

The rating will consider the following models:

| Name | Spindle speed | Engine power | Dimensions | Price |

| METALMASTER MML 1830V | From 150 to 2500 rpm | 0.6 kW | 83x39.5x35.5 cm | From 60 thousand rubles |

| Stalex SBL-280/700 | From 50 to 1800 rpm | 1.5 kW | 140x55x50 cm | From 190 thousand rubles |

| Jet BD-6 | 100 to 2500 rpm | 0.25 kW | 60x30x30 cm | From 50 thousand rubles |

METALMASTER MML 1830V is a joint production of Russia and Germany. Produced in China, Russia, Poland. This model has stepless control in two ranges. The following components are included in the package: return cams, thrust center, and replacement metal guitar gears.

Stalex SBL-280/700 is manufactured in China. The model is quite large, but the standard delivery includes a pair of steady rests.

Jet BD-6 is a miniature machine weighing only 33 kilograms. The engine is also low power, so its processing capabilities are limited, although for small home applications, choosing this option may be worthwhile.

Small Business Equipment

The selection of fuel assemblies for a production or repair business project is always carried out taking into account the inevitable modernization for similar tasks. There are no problems with processing precision for equipment in this category. Wear resistance is also at the level. But some manufacturers rely on the universal potential, others on the dimensions of the machine’s working area. Identify your main tasks and look for a machine to implement them. Then the purchase of a new fuel assembly will not affect the profitability of the business.

Proma SKF-800 – from RUB 272,365.

The combination of milling and screw-cutting devices within one lathe turned out to be one of the best solutions of the Czech Proma SKF-800.

The rotary drilling unit and the impressive diameter of the hole in the spindle allow you to work with fairly large parts. 2 identical three-phase motors guarantee sufficient torque for each device. A worthy option for those who plan to engage in professional activities in a small workshop. The only design flaw is the lack of tight contact of the protective panels with the frame. Because of this, chips and lubricants can cause rapid wear of the drive mechanisms. The manufacturer recommends that exposed parts be thoroughly cleaned and lubricated twice a day. I recommend checking the belt tension during each maintenance break. Characteristics of Proma SKF-800

| Characteristic | Meaning |

| Permissible diameter of the workpiece above the bed, mm | 420 |

| Distance between centers, mm | 750 |

| Spindle through hole diameter, mm | 28 |

| Speed, rpm | 160 -1360 (7 steps) |

| Weight, kg | 230 |

| Features of the basic configuration |

|

| Homeland of the brand and country of origin | Czech |

Video from the manufacturer Proma, the video shows the performance characteristics and reveals the functionality of the machine:

MetalMaster X32100 – from RUB 284,970.

Thread indicator, digital display device, longitudinal and transverse automatic feed system; supply of lubricant and cooling fluid - a machine from MetalMaster simplifies the process of metal processing without loss of quality. Professionals often compare the functionality of this machine with Soviet equipment of a similar profile. I consider such analogies to be incorrect - apart from a certain set of functions, nothing connects them.

- X32100 removes 3 mm chips in one pass

- Discretion of carriage stroke in any direction – 0.001 mm

- MetalMaster provides the opportunity to reduce equipment costs by 12% by eliminating the digital display device (12% of the cost).

With such a ratio of potential, compact dimensions, ergonomic controls and 1 year of official warranty, this machine has no competitors in the price segment up to 300,000.

Characteristics of MetalMaster X32100

| Characteristic | Meaning |

| Permissible diameter of the workpiece above the bed, mm | 330 |

| Distance between centers, mm | 1000 |

| Spindle through hole diameter, mm | 38 |

| Speed, rpm | 65 - 1810 (18 speeds) |

| Weight, kg | 520 |

| Features of the basic configuration |

|

| Development/production | Russia/countries of Southeast Asia (SEA) |

The video shows the machine in operation - the thread cutting process on this unit is demonstrated. In principle, everything is done easily, and special training is not needed at all to work on this machine:

Jet GHB-1330A – from RUB 350,000.

The scope of use of this fuel assembly is small-scale production and piece products.

Weight, length of the frame and a small basic set of accessories indicate the professional orientation of the equipment. That is, when the necessary equipment is purchased as needed to perform specific tasks. Having experience working on this machine, I can say that in addition to convenient control and actual power, the length of the bed or the width of the through hole of the spindle is definitely not enough. Changes had to be made to the order for meter-long spatial structure elements made from a 50-millimeter pipe at the discussion stage. If the specifics of the work are not related to the maintenance of construction sites, then this machine will be a justified investment in the development of your business. Characteristics of JET GHB-1330A

| Characteristic | Meaning |

| Permissible diameter of the workpiece above the bed, mm | 330 |

| Distance between centers, mm | 760 |

| spindle through hole diameter, mm | 38 |

| Speed, rpm | 70 - 2000 (8 speeds) |

| Weight, kg | 600 |

| Features of the basic configuration |

|

| Development/production | Switzerland/SEA, Europe |

Detailed video review of the model. The author provides the performance characteristics of the machine, its functionality, and demonstrates it in operation:

The best machines for home (home)

In home workshops, semi-professional machines or miniature models are usually installed. The former are more expensive and larger, but more functional and powerful. Conventionally, home devices are divided into:

- Lathe-screw, screw-cutting. With their help, you can both grind parts and create threads or recesses. The price of such devices is higher than conventional ones, but the minimum spindle runout allows you to process different types of metals.

- Tabletop. Inexpensive and compact, they are used to create various cuts or bevels, trimming, drilling holes, forming grooves and much more.

- Universal, used for a variety of tasks.

If, in addition to metal, you need to process wood and other materials, then you should consider milling machines.

The list of home lathes includes a variety of brands, but the most successful of them are Stalex and JET, the representatives of which are discussed in the previous section. Examples of great models for home:

- Stalex SBD-920W

- JET BD-X7

- Stalex SBD-X7

- Jet BD-7

- JET BD-6

Their prices are relatively affordable for a private individual, but the functionality and characteristics at the same time give quite a lot of freedom of action in matters of metal processing.

Popular manufacturers

Anyone can read descriptions of different models of tabletop lathes and order such equipment online. At the same time, not all buyers know which company’s devices are better in terms of price, quality and set of characteristics. In order not to choose a model of a particular brand at random, you need to carefully study user reviews and recommendations from experts.

The best manufacturers according to buyers:

- CALIBR (Russia);

- Enkor (Russia);

- JET (Switzerland);

- Record Power (UK);

- PROMA (Czech Republic);

- Optimum (Germany);

- METAL MASTER (Russia/Germany).

The best lathes for the workshop

A small workshop requires a machine of compact size, but with a wide range of functions and good power - after all, orders can be very different.

Examples of suitable models:

- JET BD-920. 120 thousand rubles. Produced in Switzerland. Works well with small elements. There is no play in the caliper, the nut is fixed very tightly, which is convenient when processing soft metals. Motor power is 0.97 kW, consumes 550 W.

- FDB MASCHINEN TURNER 320 X 1000 S. 260 thousand rubles. Produced in Germany. It shows very high precision in processing parts, but the device itself is heavy and massive - it weighs 650 kg. This can also be called an advantage, since due to the large weight, vibrations are minimal, the machine sits on the floor like a glove.

- ZENITECH MD250-550 VARIO. 140 thousand rubles. Produced in Russia. It has a stylish design, which attracts many buyers. The quality of processing is also excellent. Power 1.1 kW. The spindle rotation speed is displayed on a special display, so it is convenient to monitor it.

- TV-9 "RUSTAN". 470 thousand rubles. Produced in Russia. A functional representative of the rating, distinguished by the high quality of assembly and operation of each unit. Equipped with a collet, chuck, centers, so it allows you to perform a wide range of work. For greater convenience, TV-9 can be equipped with an LED machine lamp.

Which lathes to choose for a garage

A garage machine is one of the most popular use cases. There are many options for its use both in working with a car and in the process of arranging a personal plot. Sometimes some small part cannot be found in any stores - but turning it yourself is easy and quick.

Key selection criteria:

- Budgeting. As a rule, they purchase a basic assembly, and, if necessary, subsequently purchase additional components.

- Small dimensions. There are already a lot of things stored in the garage and a car, so the machine should not take up a lot of space.

- Proven quality. The thing is expensive, so you need to approach the choice with all seriousness.

The main options for devices for garage use are desktop (often without a tailstock and with minimal functionality), universal (with a milling cutter included), school (smooth speed adjustments, reverse, light weight) and screw-cutting lathes (expensive models with minimal spindle runout) .

Examples of suitable companies:

- Encore - Corvette 407 and other modifications. Semi-automatic machines in which peeling must be done manually, and the remaining operations must be carried out with automatic feed of the caliper.

- Optimum. German brand, but made in China.

- Weiss. Tabletop machines with minimal vibration levels. Their feature is that after the spindle stops rotating in the roller bearings, it can be reversed to move the caliper.

How to do it yourself

You can save on buying a device and make the machine yourself, which will require finding many stainless steel components with a thickness of at least 3 cm (for supporting parts). The main thing is to pay attention to reliability

- Calipers (needed for fastening, moving and fixing);

- Statins (supporting element).

Not everyone can cope with such a task, so it is recommended not to experiment, but to trust trusted manufacturers.

Best CNC Lathe

There are several main criteria for selection. For example, budget: CNC (computer numerical control) machines are generally expensive, but the price range is quite wide. The minimum cost can be called 450 thousand rubles, these are amateur options. The cost of industrial models reaches 15 million.

Which device to choose depends on what parts are planned to be processed - this means dimensions, complexity of shape, material used, and quantitative volumes.

The main popular brands:

- Hyundai . For example, turning center KIT4500.

- Takisawa . For example, the NEX series, which is used in all areas of the mechanical engineering industry, aviation, and instrument making.

The best Soviet lathes (USSR machines)

In the Soviet Union they made things that lasted for centuries. The industry was structured in such a way that the emphasis was not on variety of models or beautiful design, but on durability. Therefore, Soviet lathes are successfully used to this day. For example:

- IT-1M. A screw-cutting lathe, most often used in small workshops or educational institutions. Has light weight. Allows for axial drilling, turning of conical workpieces, processing of rounded blanks, threading, etc.

- Universal 2 and Universal 3. Quite compact and functional models that allow for jointing, sharpening operations, processing with a circular saw or jigsaw, drilling, etc.

We hope that now it is easier for you to choose a lathe. And you can purchase coolant and related products for it from the Loc-Line company, located in St. Petersburg.