In a nutshell, plasma cutting of metal is a type of metal processing in which a plasma jet is used as a cutting tool. Gas is supplied to the nozzle of the plasma cutter, and an electric arc is ignited between its electrode and the metal being cut. It turns the gas into a plasma jet with a temperature T = 5000...30000 °C and a speed of 500...1500 m/s, which can cut metal with a thickness of ≤ 200 mm (however, in practice, it is more economical to cut extreme thicknesses with oxygen).

All details can be found in the article “Plasma cutting. Principle of operation" and other articles on the site (we recommend looking at the links).

Modern equipment allows us to perform artistic plasma cutting work efficiently and quickly in accordance with the customer’s sketches and drawings.

Where is artistic metal cutting with plasma used?

Now it has become fashionable to decorate rooms, facades and adjacent areas in country houses with artistic metal products made by plasma cutting. Most often decorated:

- balconies;

- fences;

- railings;

- doors.

Garden sculpture made of metal and various decorative little things that decorate the house, facade and site are very popular. Metal products made by a good craftsman have a number of advantages over other decorative elements:

- it is original, elegant and beautiful;

- they are strong, durable, wear-resistant;

- compatible with most other materials.

These products are versatile and unique. If you decorate the balcony of a country house with metal elements, this will undoubtedly decorate the facade. And if the grille, designed to prevent unauthorized intrusion, is made using artistic cutting, then, in addition to its main function, it will serve as a magnificent decoration.

A door is a kind of business card of a home, and decorating it with metal elements will give it a certain charm and style. The decoration of the canopies on the facades looks very impressive, gives the facade a feeling of some magical antiquity and looks simply magnificent. You can cut anything:

- Mailbox;

- vane;

- gates, gazebo, tables and benches.

Interesting: Table for plasma cutting of metal: design and choice

Special mention should be made about garden sculptures. With their help, you can create a real fairy tale in your local area. The effect will be stronger if a multi-colored anti-corrosion coating is applied to them.

Today, a wide variety of elements of the interior of a house can be made of metal. This will add additional harmony, coziness and comfort to your home. The situation changes dramatically if you install metal decorative products in the house - the usual interior details will look completely different.

But radical decisions should be avoided, as they can visually narrow the room and make it cold. Even if the interior is interesting, it is unlikely to satisfy you. There should be moderation in everything.

Operating procedure

Initially, you need to prepare the plasma cutter for work - depending on the type, it operates on a 220 or 360 V network. The preparation sequence is as follows:

- The device is installed in a place where there is good air access, and it should not be exposed to splashes of molten metal during operation.

- The equipment must be operated in a ventilated area equipped in accordance with fire safety regulations. The device must be protected from accidental ingress of moisture - for this purpose it is often even equipped with a moisture-oil separator to prevent them from entering the plasma torch structure, which leads to a decrease in the service life of consumables.

- It is advisable to also prepare the rolled metal to be cut - paint coating and corrosion lead to increased smoke emission, but do not affect the quality of the cut.

- Periodically it is necessary to check the integrity and cleanliness of the electrode and nozzle. The frequency depends on the intensity of use - for example, with constant operation, they may require replacement after an 8-hour work shift.

A high-quality cut without sagging and scale is possible only if the current strength is chosen correctly. It is selected taking into account the type of metal being cut and thickness. Dependence of current strength for cutting workpieces 1 mm thick from the following materials:

- Structural steel and cast iron - 4 A.

- Non-ferrous metals and their alloys – 6 A.

The cutting speed also affects the quality of the cut. It can reach 0.2-2 m/minute and depends on the thickness, type of material, and set current strength. In automated equipment, the speed is set by the program, but in a manual process, the cutter is responsible for this.

Before starting work, you need to blow out the plasmatron to remove foreign particles and condensate - to do this, press the ignition button and wait about half a minute. Then you can ignite the pilot arc; it burns for up to 2 seconds, after which the working plasma arc ignites.

An important point when plasma cutting is to maintain a constant distance between the nozzle and the metal being processed (usually 1.6-3 mm) - this affects the stability of the working arc and the quality of the cut. However, there are special guides for hand-held cutters on sale, which greatly facilitate the work process and increase productivity.

Photo 9. Guide device for maintaining a constant gap between the nozzle and the workpiece.

During operation, the cutter nozzle should be located perpendicular to the metal being cut or at a slight angle (deviation up to 10-50°) when cutting materials with a thickness of up to 25% of the maximum allowable for specific equipment. This technique will minimize the risk of deformation of thin-sheet workpieces.

Examples of work: sketches

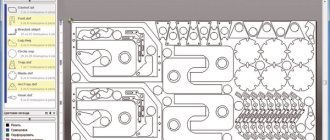

Below are sketches of models for plasma cutting in format (*.DWG and *.DXF).

Braziers

Download sketch

Download sketch

Fire pit

Download sketch

Address plate

Download sketch

Download sketch

Download sketch

Download sketch

Download sketch

Download sketch

Download sketch

How to choose a plasma cutter?

The choice of a plasmatron for cutting metal is made according to performance characteristics, taking into account the work performed (dimensions, thickness and type of rolled metal).

Thickness of the metal being cut and current strength

The expected thickness of the metal being processed affects the rated current of the equipment - for example, to cut ferrous metal and stainless steel, 4 A of power is needed for every 1 mm of thickness. Therefore, to cut 10 mm sheet structural steel, you need to set the operating current to 40 A. At the same time, it is better to buy a plasma cutter with a small power reserve.

Duration of activation

PV or on-duration determines the time of continuous operation of the device. If the technical characteristics of a plasma cutter indicate a duty cycle of 60%, this means that out of a working cycle of 10 minutes it can operate continuously for 6 minutes. If this threshold is exceeded, overheating and failure are likely.

Recommended PV values depending on the scope of application:

- Domestic needs - 40% PV is sufficient.

- Workshops, small metalworking companies - PV 60%.

- Large factories, enterprises for the production of metal structures - PV 80-100%.

Required compressor power

The stability of the plasma cutting process directly depends on the compressor power. Therefore, the device should have 20-25% greater productivity than indicated in the plasma cutter passport. It is also desirable that it be equipped with an oil and moisture separator to eliminate the influence of condensate and impurities on the quality of the plasma.

Hosepack length

The length of the hose package can range from 1.5 to 8 or more meters, so when choosing, you need to be guided by the overall dimensions of the rolled metal with which you are supposed to work.

Video on how to choose a plasma cutter

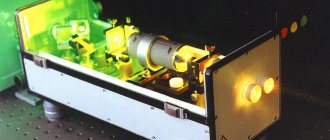

Cutting Equipment

Our website reviews many machines that can successfully cope with this task. Refer to the articles "Plasma cutting machine "Kometa", "Plasma cutting machine "AGAT" and be sure to use the links in these articles.

There are many advantages to equipping equipment with computer numerical control (CNC) modules:

Possibility of performing geometrically complex cuts

high speed, despite the variety of shapes and ornate lines

Only the part of the product on which cutting is performed is heated by the plasma. This significantly increases process safety

artistic plasma cutting of metal produces a clean cut, the additional mechanical processing of which is not required

the place of heat treatment is not deformed and no sagging is formed on it

good pattern repeatability, etc.

The operation of plasma artistic cutting on CNC equipment is simply an irreplaceable operation in the conditions of small-scale and piece production. Using such equipment, you can even create paintings that will serve as a magnificent decoration for your office and will fit perfectly into the interior of any building.

Interesting: Table for plasma cutting of metal: design and choice

Features of plasma cutting

This technology allows you to process workpieces using a high-temperature plasma jet. Gas is supplied from the plasma cutter nozzle, which, under the influence of an electric arc, turns into plasma, the temperature of which can reach 30,000 degrees Celsius, and the speed – up to 1,500 m/s.

The characteristics of plasma enable it to cut workpieces up to 200 mm thick with high efficiency. The technology is accurate, easy to use and allows you to perform work with minimal time.

Using a plasma cutter, you can perform artistic cutting according to a wide variety of sketches, including the most complex ones.