Artistic metal cutting (another common name is figured) is the creation or application of original drawings, inscriptions or other visual elements onto sheets of material. It can be performed using special equipment, most often machines, that allow processing durable and hard materials such as steel and other metals and alloys. To work with such equipment, as a rule, professional skills are not required; it is enough to carefully study the instructions and processing techniques.

The process of figure cutting of metal using a plasma cutting machine MAXILITE 3000

Let's take a look at the MAXILITE 3000 plasma cutting machine in its basic configuration. MAXILITE 3000 is a machine that is used for cutting metal with a thickness of 0.3 to 20 mm with good speed and high quality. The thickness of the metal that our machine can cut depends on the power of the plasma source. The machine has a modular design, so transporting it to the desired location is not difficult. So, we list the main distinctive features of the machine:

- lightweight collapsible frame

- portal made from a rectangular profile, also lightweight

- CNC control rack has a very “grown-up” look

- integrated desktop

- for stable work with thin sheet metal there is a mechanical control of the burner height

- optimal cost with decent characteristics

We can select a device and a plasmatron for you to suit your tasks, for example, you can reduce the size of the desktop, if necessary, and, accordingly, this will affect the cost downwards.

Please note that to operate the machine separately you will need the following equipment:

- exhaust fan with an impeller of at least 200 mm;

- air compressor with a capacity of at least 400 l/min;

- refrigerated compressed air dryer;

- main filter for class 1 air purification from solid impurities, oil and water.

In order to start working, the machine must be correctly installed, connected to power and be sure to properly organize an exhaust hood to remove smoke from particles of burning metal

This is important because a lot of smoke is generated during work, and breathing these fumes is not very good for health. The software with which the machine is controlled is available in the basic version, this is Pure Motion from the Russian company Purelogic

In the following articles we will try to analyze this software in detail, since it is still not as simple as we would like.

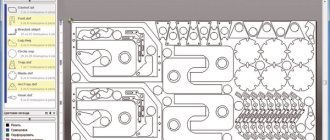

So, in order to cut out any detail, you will need to draw it first. You can use any software that allows you to export or save any drawing in DXF format. These can be programs such as AutoCAD, Compass, Corel Draw, etc. They, of course, are not included in the kit.

You will also install the SheetCAM program, with the help of which a special G-code will be generated, which will need to be transferred to the Pure Motion program.

It turns out that the procedure is such that first in a third-party program you draw the necessary artistic element, save it in .dxf format, import it into SheetCAM, save the generated G-code, and then import it into the Pure Motion program and it transfers it directly to cutting table with all necessary actions and coordinates.

You will also need to correctly configure the Pure Moiton program because when working with different thicknesses and metals, the speed settings, plunge height and working height of the torch will also be different. In one of the following articles we will also look at these settings in detail.

Artistic cutting of metal with plasma is performed with a plasma jet, which is used as a cutting tool. After you press the button to start the process of cutting the product, an electric arc is formed (between the metal and the electrode), the ignition of which occurs due to a pulse or short circuit; gas under pressure is supplied from the nozzle; under the influence of an electric arc, it turns into a plasma jet, the temperature of which reaches 30 thousand degrees and the speed of 1.5 thousand m/s. The cutting speed depends on the thickness of the metal, the power of the plasma source, and the complexity of the cut pattern. During the process, the drawing you drew in the program will be cut out of a sheet of metal.

It may seem that working on a CNC plasma cutting machine for figure cutting of metal is very difficult, but this is only at first, as in any other business, at first there will be mistakes, you can’t do without it, but then you will get the hang of it and get an inexhaustible source of realizing the most bold creative decisions.

Selection of gas medium

High-quality artistic laser cutting of metal requires careful selection of the optimal gas environment.

Experts advise carrying out the work process in an oxygen or nitrogen-filled environment. Oxygen is successfully used when processing low- and medium-alloy steel. The only exceptions are parts that require further staining along the sections. When oxygen hits the base of the workpiece being processed, it begins an oxidation reaction of the metal with the simultaneous release of a certain amount of heat. Due to this, the overall cutting temperature increases. This makes it possible not only to increase the processing speed of products, but also to increase the thickness of the workpieces themselves. Also, in a number of situations, this technology promotes partial evaporation of the metal (its sublimation). The presence of impurities in the composition significantly complicates cutting and slows down its speed. Therefore, whenever possible, it is worth using the purest possible oxygen.

Laser cutting of metal using nitrogen is just as popular in Moscow. It is indispensable when working with stainless steel alloys and high-alloy steel. After all, these cutting materials require exclusively inert gases. And nitrogen is best suited for this.

Also, the choice in favor of such a gas is relevant for further staining of the formed sections. This can be not only powder painting, but also finishing with other paints and varnishes. If increased demands are placed on the accuracy of the profile being formed, then the use of nitrogen is useful when working with workpieces thicker than 2.5 cm. But it is worth remembering the need to increase the nitrogen pressure in the system as the thickness of the workpiece increases.

Sketches for plasma cutting

Both in the city and in the countryside, the tradition of decorating your own space with original things, made to order or with your own hands, is returning. Expressing your aesthetic needs in decorating your home or garden has become easier with the advent of plasma metal cutting.

Unlike hot forging, which has been used for centuries to create fences, porch canopies, weather vanes, fireplace and stove doors, the plasma cutting process requires less physical effort. Artistic cutting of metal with plasma is a faster manufacturing process, forging, and the design is more delicate and delicate.

Heating the metal to very high temperatures does not in any way affect its technical characteristics due to the short-term contact of the processed material with the flame. Due to this, no sagging is formed on the cuts, which means that the finished product will not require sanding.

The most painstaking work in the artistic cutting of metal with plasma is creating sketches for cutting. Not being an artist, you will have to use the method of enlarging the drawing you like to the required size, projecting it onto a sheet of metal using a light bulb placed in a box located behind the image on paper. This homemade enlarger is used if there is no slide projector in the house from ancient times. The size of the image is varied by moving the pattern towards the beam of light or removing it to the required distance.

Artistic metal cutting can vary in cutting technique. To create a garden sculpture, you need a clear outline of the object. It is better if the cutting takes place in long, clear lines. Also, this method of guiding a cutting arc along the contour of an element is necessary for cutting out large elements in a fence, on gates and other decorative details. Small cuts are created by short "strokes" of flame across a sheet of metal.

Shaped metal cutting

Shaped metal cutting - applying inscriptions, drawings or other graphic elements to metal.

Such cutting is most often performed using plasma or laser machines. Plasma cutting machines are more affordable, but the quality of the cut on a plasma machine is slightly lower than on a laser cutting machine. Due to greater availability, we will look at the budget plasma cutting machine MaxiLite 3000. First, we will look at the areas of activity in which shaped metal cutting is used and we will figure out whether this service is in demand.

Where is metal cutting used?

As noted above, a plasma cutting machine cannot boast of the highest quality of metal cutting, however, there are many areas of shaped metal cutting where such equipment is applicable. Over the past few years, our machines, including the budget plasma cutting machine MaxiLite 3000, have found application in the following areas:

- in the manufacture of weather vanes;

- decorative elements for the fence;

- decorative elements of stairs;

- for the manufacture of barbecues, outdoor fireplaces;

- as well as other artistic elements made of metal, which are subsequently planned to be painted.

Let's look at what finished products look like when cut on a MaxiLite 3000 plasma cutting machine.

Shaped metal cutting - weather vanes

Shaped metal cutting - decorative fence elements

Shaped metal cutting - staircase elements

Shaped metal cutting - street fireplaces

Shape cutting of metal - other products with shape cutting

How to make a plasma cutter from an inverter - instructions

If desired, any owner can make such equipment with his own hands. However, in order for a homemade plasma cutter to do its job effectively, all the rules must be followed. In such a case, an inverter will be practically irreplaceable, since with the help of this device a reliable supply of current will be ensured. Due to this, there will be no interruptions in the operation of the plasma cutter, and it will also be possible to reduce energy consumption. However, it also has disadvantages: it is designed for cutting material of a smaller thickness than when using a transformer.

Selecting elements

If you decide to make a plasma cutter yourself, then you should prepare the necessary materials and equipment:

An inverter or transformer with the required power. In order not to make a mistake when purchasing this device, you need to tell the seller in the store about the thickness of the material you plan to use it for cutting. Based on this, the selection of a suitable mechanism will be made. Considering that cutting will be done manually, it is advisable to purchase an inverter, which is associated not only with its lightness, but also with its ability to reduce energy costs.

Plasma cutter or plasma torch point. When choosing it, you must rely on the same criteria as in the case of an inverter. The important point here is that direct impact equipment is designed to work with conductive materials, while an indirect impact plasma cutter is more suitable for working with products that are not capable of conducting electricity.

Compressor for air circulation

Here you should pay attention to its power, according to which it should be correlated with other selected components.

Cable-hose package. His task will be to combine all the above-described elements.

Assembly

Even before you start assembling a homemade plasma cutter, it doesn’t hurt to find out whether the components you purchased are compatible with each other. If you have never made a plasma cutting machine with your own hands before, it is advisable to seek help from more experienced craftsmen. After analyzing the power of each element needed, they will give you their recommendation. You should definitely make sure you have a protective set of clothing. You will have to use it when the time comes to test the performance of a homemade plasma cutter. If we talk about the procedure for assembling plasma cutting equipment, it includes the following steps:

At the first stage, it is necessary to prepare all the necessary elements for assembly and protective clothing.

Next, you should resolve the issue with an uninterruptible power supply.

Then you need to take an inverter or transformer, as well as a cable of suitable thickness and electrodes

Pay special attention to the last element, which should be made of beryllium, zirconium, thorium or hafnium. Such materials are considered the best choice for air plasma cutting

Hafnium may also be considered as an alternative because it will provide greater safety to the welder or craftsman who will be doing the work of separating the sheets. The listed elements must be connected to each other in order, the result should be an electric arc.

Next, a hose is connected to the compressor. It is through this that air will flow into the plasma cutting machine. The second edge must be connected to the plasma torch.

Take a small piece of aluminum and test the operation of the device you have made. Pay special attention to the security of connections.

Regardless of whether you plan to make a plasma cutter with your own hands or buy it in a store, you should first study all the models, get acquainted with the principles of their operation and design options. An important point is the type of material that is planned to be cut using this equipment in the future. You can simplify your selection task if you first watch a video that shows the operating principle of a manual plasma cutting machine and the technology for working with it.

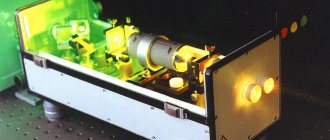

Types of laser cutting

Laser equipment used in modern metalworking has different classifications. Depending on the type of working fluid used in the machine, units are divided into solid-state, gas and gas-dynamic. Their power is 6, 6-20 and 20-100 kW, respectively.

Important! In installations of the first type, ruby plays the role of a solid body.

As an alternative, it is possible to use special glass with additives.

Such lasers are capable of creating a powerful pulse literally in a matter of moments, and their operation is possible not only in a pulsed mode, but also in a continuous format. The operation of devices of the second type is carried out through the use of a gas mixture, which is preheated to the required level through the action of electric current. Due to the energy obtained in this case, the directed flow of gases acquires its directionality and becomes monochrome. The mixture itself includes nitrogen with helium and carbon dioxide.

If we talk about the third type of equipment, then such units are also gas lasers operating under carbon dioxide conditions. Once heated, it passes through a narrow passage with rapid cooling and expansion at the same time. It is at this moment that a powerful energy flow is released, which ensures cutting of even the thickest workpiece. This laser cutting of metal to order allows you to obtain the highest cutting precision. The equipment is characterized by high power, but at the same time it is quite economical.

Quality of parts

Comparing the quality of the resulting parts and based on the cost of consumables, we can come to the conclusion that laser cutting is more effective than plasma cutting for thinner sheet materials, and plasma cutting for thicker ones. It should be taken into account that operating costs for both types of cutting vary widely and are largely determined by the geometric parameters of the workpiece, the number of holes in it, and the type and thickness of the material being cut.

| Options | Laser cutting | Plasma cutting |

| Cutting width | The cutting width is constant (0.2 - 0.375 mm) | The cutting width is not constant due to the instability of the plasma arc (0.8 - 1.5 mm) |

| Cutting accuracy | Typically ±0.05 mm (0.2 - 0.375 mm) | Depends on the degree of wear of consumables ±0.1 - ±0.5 mm |

| Taper | Less than 1° | 3° — 10° |

| Minimum openings | In continuous mode, the diameter is approximately equal to the thickness of the material. For pulse mode, the minimum hole diameter can be one third of the material thickness. | The minimum diameter of the holes is 1.5 times the thickness of the material, but not less than 4 mm. Pronounced tendency towards ellipticity (increases with increasing material thickness). |

| Internal corners | High quality corners | Some corner rounding occurs and more material is removed from the bottom of the cut than from the top. |

| Scale | Usually absent | Usually present (small) |

| Burns | Invisible | Present on sharp outer edges of parts |

| Thermal impact | Very little | More than laser cutting |

| Metal cutting performance | Very high speed. For small thicknesses, usually with a noticeable decrease as the thickness increases, prolonged burning of large thicknesses. | Fast burn; very high speed at small and medium thicknesses, usually with a sharp decrease as thickness increases. |

Cost of laser treatment

But how much does artistic laser cutting of metal cost and what does the final price tag take into account? The issue of cost is extremely important today. After all, processing must not only be of high quality and efficient, but also affordable from a financial point of view.

If we talk about pricing policy, the cost is calculated individually when processing each batch of products. This takes into account the number of products being manufactured, the selected material, its properties and characteristics, as well as the complexity of the processing itself.

But with the correct selection of equipment and a professional attitude towards the matter, unnecessary and unnecessary costs can be completely avoided.

Types of artistic metal cutting

Shaped metal cutting is performed in one of four main ways, which are based on the following technologies:

- laser;

- plasma;

- waterjet;

- guillotine

Each technology has advantages and disadvantages. The first two are considered the most modern and therefore progressive and widely used.

Laser cutting

Metal laser cutting uses a powerful laser to process and cut the material. More often, this technology is used on an industrial scale, where the laser beam is controlled by a special computer program. As a result of a narrowly targeted effect, the material in the area being cut rapidly heats up, melts, and then evaporates or blows out. At the same time, the technology makes it possible to obtain a narrow cut with an extremely small area of influence on the surface being processed.

Laser cutting has a number of advantages:

- relatively low level of costs (compared to most alternative technologies, with the exception of plasma cutting) when processing hard alloys;

- the ability to work with brittle alloys that are easily deformed;

- safety of technological processes (when using serviceable equipment);

- absence or extremely small deformation of the material, which is achieved through highly targeted processing;

- the ability to create a wide variety of complex contours;

- no need for subsequent finishing or surface treatment.

Thanks to the peculiarities of the technology, using laser cutting it is possible to create designs of any complexity without requiring additional processing, since the edges and edges are immediately smooth and even.

The disadvantages of laser cutting include the inability to work with aluminum and its alloys with stainless steel. This is caused by the reflective properties of the material. It can only be processed using particularly powerful laser equipment.

Artistic laser cutting of metal is a high-quality way to create a pattern with the least amount of material and time.

Plasma cutting

- an electric arc is formed (between the nozzle and the electrode or between the metal and the electrode), the ignition of which occurs due to a pulse or short circuit;

- gas under pressure is supplied from the nozzle;

- under the influence of an electric arc, it turns into a plasma jet, the temperature of which reaches 30 thousand degrees and the speed of 1.5 thousand m/s.

Plasma cutting of metal has the following advantages:

- the ability to create drawings and figures of any complexity;

- high-quality, clean and smooth cut;

- ability to process all types of metals;

- speed and performance of the equipment used;

- no deformation of the material;

- safety of technological processes (if the equipment used is in good working order).

Artistic plasma cutting can be applied to materials with rust or contamination, which does not lead to deterioration in the quality of processing. Compared to cutting using laser equipment, plasma has greater productivity and a range of materials that can be processed.

The disadvantages of this cutting method include:

- a cone formed on the edge caused by a technology feature;

- slightly larger cutting width compared to laser cutting.

Equipment for artistic cutting

For each technology used in processing, a significant amount of different equipment has been developed.

Laser cutting

Machines for laser metal processing are quite expensive. They are produced by many foreign companies, the most famous of which are: Trumpf (Germany), ESAB (Sweden), MultiCam (USA), Mazak (Japan), Bystronic (Switzerland), etc. Despite the fact that the technology has been in use for two decades, only relatively large industrial production companies can afford to purchase new equipment from the listed companies.

However, it must be taken into account that there is a wide supply of equipment in this category on the market that has already been used, but is in working condition. Even in this form, it almost always surpasses numerous Chinese-made analogues, which even new ones do not differ in either the quality of processing or reliability of operation.

Plasma cutting

There are two types of equipment for plasma metal processing:

- inventory plasma cutter. Compact, characterized by economical energy consumption, but more demanding on voltage stability;

- transformer plasma cutter. More reliable, but requiring significant energy consumption, and is larger.

Table made using artistic plasma cutting of metal

When choosing equipment for plasma cutting of metal, the following criteria are taken into account:

- power;

- work productivity;

- the material from which the burner is made;

- appearance and design of the unit.

Equipment for plasma cutting is extremely widely represented on the modern market, so anyone can easily find a model that suits them.

Automatic cutting

We create our products from sheet metal. The task is to accurately and efficiently cut out the required design on the sheet. For processing, we use metalworking machines that allow us to quickly and accurately create almost any picture. The main working element of the machine is the cutter, which can automatically move over the sheet of metal being processed. The sheet itself is fixed on the coordinate table, and the cutter moves along the X, Y axes of the coordinate table with high accuracy and a given speed. Also, the cutter can rise above the sheet of metal and fall closer to it (along the Z axis). The software sets the cutting parameters and movement of the cutter; this software can be used to produce metal products with very complex geometric patterns. The size of the finished product is limited by the dimensions of the coordinate table. The positioning accuracy of the cutter and the cutting parameters determine the quality of the finished product. When cutting, you can use different (according to the physical principles of their influence on the material) cutters. Waterjet and laser technologies are widely used. Waterjet cutters

They act on the metal with a thin stream of water supplied under pressure containing particles of an abrasive substance.

With this effect, microparticles are torn out of the metal (or other material) and washed off with water. This creates a cut. The water supply speed, the abrasive material itself and the size of its particles determine the cutting parameters.

With laser cutting

The determining factors are the radiation power and the diameter of the laser beam. The laser beam can be several microns in diameter, and in this case the accuracy can be very high.

These technologies have a number of advantages that allow them to be used to solve complex production problems. Our company uses air plasma cutting

. Let's look at its features in a little more detail.

Features of cutting different metals

The processing process for different metals has certain differences.

Here it is important to take into account all the advice and recommendations of the equipment manufacturer to obtain a finished product of the highest quality with minimal time and labor costs. If we talk about copper, then this material is characterized by fairly high thermal conductivity, and cutting should be performed exclusively at low laser speed. But with the maximum permissible power of the radiation generated in this case. If these rules are not followed, the edge being formed may be seriously damaged.

Laser cutting of aluminum, which is so often used today, is characterized by the greatest complexity of the production process. It's all about the uniqueness of this alloy. Cutting requires quite serious energy costs and the mandatory addition of gas equipment to the laser installation. Only in this case can you count on a smooth and maximally clean edge without the least damage and defects.

Important! Processing stainless steel requires the mandatory use of nitrogen as a protective medium.

This is the only way to guarantee a perfectly clean cut without any traces of scale.

But it is worth remembering that the power of the generated energy beam depends on the thickness of the workpiece. The larger it is, the more powerful the radiation should be. Accordingly, the overall cost of laser cutting of stainless steel increases. The use of lasers when working with brass is becoming increasingly popular today. And not only at large production facilities, but also when producing small batches of products. It is not surprising that the demand is so high. After all, this material is characterized not only by increased resistance to corrosion processes, but also by a relatively low cost. Moreover, brass does not require the use of overly powerful equipment or specialized settings of the laser unit. A standard configuration and a correctly loaded drawing are sufficient to obtain the required result.

You also can’t ignore titanium. Its processing is carried out in a protective environment based on inert gas. Although the gas environment eliminates the slightest possibility of metal ignition. The specific technology does not in any way affect the cutting efficiency or the quality of the resulting profile.

Ferrous metal and galvanized steel are cut using an oxygen environment.

Features of decorative metal cutting

The thinner the metal sheet and the lower its melting point, the greater the risk that by holding the cutting arc a fraction of a second longer in one place, the element may not turn out clear. To create paintings with small, closely spaced elements using plasma cutting, it is better to create on CNC plasma cutting machines.

Plasma cutting can be carried out on metals of different thicknesses. Some devices for plasma cutting provide a flame heating temperature of up to 30,000 °C, and their cutting depth reaches 20 cm. Figure cutting with such equipment parameters can be used not only to create stencil sculptures, but also for convex ones. It is more expedient and more economical to cut thick sheets of metal with oxygen rather than with a plasma torch, despite the rather high cutting speed.

Plasma arc cutting is characterized by high speed and controlled flame heating. Figure cutting is performed by a plasma jet, and not by a hard cutting object, which gives cuts without jagged edges. For some types of alloys, strong heating causes destruction of the metal structure. This is unacceptable for shape cutting. Due to the fact that when processing with a plasma cutter, a very thin section is heated and cooling occurs quickly, the structure of the metal does not change.

Advantages of plasma cutting on CNC machines

Complex geometric and floral patterns in metal art, the patterns of which must be repeated with millimeter precision, can come out with slight differences from a hand cutter. The reason for this may be a wavering hand of the master, or an accidental holding of the flame in one place. The technology for applying each artistic element is added to the CNC machine program. The flame either goes out or lights up again, but only at the moment when the cutter moves to a given point.

[Show slideshow]

The peculiarity of artistic cutting of a painting with small elements is that the cutter moves from one edge of the product to the opposite. At first glance, this is illogical, but not for working with heated metal. If you save time on moving the cutter, then you will have to lose it in the seconds required for the natural cooling of the metal. In this case, the process of figure cutting will be longer.

If everything is clear with the technology of figure cutting on a programmable machine, then for a master working with a manual plasmatron, the cutting technique will have to be worked out using the trial method.

Main technical parameters of plasma cutting, advantages

Plasma cutting is carried out using a plasma torch. All process characteristics depend on the parameters of the gas or liquid stream

Main technical parameters that are worth paying attention to:

- Speed. When cutting a metal sheet with a plasma jet, it is directed under high pressure onto the metal sheet. The principle of the whole process is to heat the metal to the point where it starts to melt, and then blow out the residue. The optimal speed for this is from 1.5 to 4 km per second.

- Temperature indicators. To form plasma, the air must be heated to 5-30 thousand degrees. This temperature is obtained due to the formation of an electric arc. After reaching the required temperature parameters, the air flow is ionized and ultimately changes its properties, acquiring electrical conductivity.

- There must be an electrical circuit. The work includes plasma torches with indirect and direct effects. When a direct impact device is used, it is necessary that the metal transmit electricity and be included in the general network, but for indirect impact devices, this parameter is not required.

Plasma cutting is popular because it has a number of obvious advantages:

- has much higher productivity compared to simple laser cutting;

- versatility – plasma cutting is suitable for a wide variety of metals;

- precision and high quality of cutting - “clean” edges without overheating and with a minimum cutting width;

- safety, since there are no explosive cylinders;

- low level of environmental pollution.

Price list for plasma cutting of metal

| S mm | BLACK STEEL (rubles per square meter) | STAINLESS STEEL (RUB per square meter) |

| Up to 1 mm | 20 rub. | 60 rub. |

| Up to 2 mm | 25 rub. | 70 rub. |

| Up to 3 mm | 30 rub. | 75 rub. |

| Up to 4 mm | 35 rub. | 80 rub. |

| Up to 5 mm | 40 rub. | 95 rub. |

| Up to 6 mm | 45 rub. | 100 rub. |

| Up to 8 mm | 50 rub. | 110 rub. |

| Up to 10 mm | 60 rub. | 130 rub. |

| Up to 12 mm | 70 rub. | 160 rub. |

| Up to 14 mm | 80 rub. | 230 rub. |

| Up to 16 mm | 90 rub. | 240 rub. |

| Up to 18 mm | 100 rub. | 250 rub. |

| Up to 20 mm | 110 rub. | 330 rub. |

| Up to 22 mm | 120 rub. | 420 rub. |

| Up to 25 mm | 200 rub. | 480 rub. |

| Up to 30 mm | 250 rub. | 570 rub. |

| Up to 32 mm | 300 rub. | 650 rub. |

| Up to 38 mm | 400 rub. | 780 rub. |

| Up to 40 mm | 450 rub. | 850 rub. |

| Up to 50 mm | 550 rub. | 1000 rub. |

| Up to 58 mm | 650 rub. | – |

| Up to 60 mm | 700 rub. | – |

- The cost is given in rubles including VAT per linear meter;

- In the absence of technical documentation for the order, the agreed price may increase by 10% or more depending on the complexity of the project;

- The work is carried out using CAD/CAM systems;

- These prices are not final; the exact price is calculated separately for each order depending on the complexity, volume, and nomenclature;

- Delivery of finished products by our vehicles is possible;

- By agreement, cutting from our materials is possible;

- Minimum order value – 3,000 rubles;

- Order fulfillment time is from 1 day.

One of the most modern and highly efficient methods of metal processing is plasma cutting, which is significantly superior to traditional metal processing methods. It is more accurate and efficient, making it possible to quickly and efficiently cut any type of metal, both regular and shaped.

Benefits of laser technology

Speaking about the advantages that artistic laser cutting of metal can offer the user, we cannot fail to note the following:

- The laser is equally effective when working with different metals and alloys based on them. Only the thickness of the blanks differs. The thickness of copper can reach 15 mm, aluminum - 20 mm, steel 20 mm, and stainless steel - 50 mm;

- During work, there is minimal contact of the working fluid with the product. Due to this, the processing of workpieces made of soft, brittle and deformable materials is significantly simplified;

- It is possible to create a profile with a configuration of any complexity. The computer programming used in this case makes it possible to reduce human participation in work to a minimum and minimize the likelihood of defects;

- Laser cutting of metal itself is carried out as quickly as possible and without the least complaints about the quality of the cut being formed;

- The introduction of a laser into the production process makes it possible to obtain economical products with low production costs when producing not only single products, but also large batches of goods;

- Regardless of the complexity of the processing, using a laser makes it possible to get by with a minimum amount of waste.

Finished products according to drawings for plasma cutting

A huge number of bright ideas remain at the idea stage, without being implemented, only because their author does not have any skills. For example, he cannot transfer an idea into a drawing format or does not know how to cut a product according to a drawing. Our company will help you get the job done.

We will provide you with:

- competent technical advice on technologies and materials;

- translation of drawings into electronic form;

- full production cycle from development to delivery of the finished product to the recipient.

We have all the necessary equipment for the production of metal products, so we take responsibility for solving the most complex and unusual tasks in the field of metalworking for you.

To work on an order we accept:

- sketches;

- blueprints;

- design project.

We have all the necessary equipment for fast and high-quality cutting, ensuring high cutting accuracy, even when it comes to shaped and complex products.

Our company promptly fulfills orders from individuals and companies. The cost of the service remains low, and cost savings can be achieved through minimal energy consumption by the machine.

Advantages and disadvantages of plasma cutting

As with other methods of cutting or cutting rolled metal, plasma cutting has both advantages and some disadvantages.

About the benefits

- Plasma cutting equipment is less expensive than laser equipment;

- The plasma torch easily copes with thick-walled rolled metal, which is inaccessible for laser cutting;

- Plasma can be used to cut any rolled metal, as well as conductive metals: steel, cast iron, copper, brass, titanium;

- The thickness of the cut made by plasma equipment depends on the type of device and tips. Devices that have a minimum cutting thickness significantly reduce the percentage of metal loss with an increase in concentrated plasma flow;

- the cut does not require additional processing;

- it is possible to perform complex shaped cutting;

- non-metallic materials can be cut with plasma;

- safety of plasma cutting equipment. This parameter is ensured by the absence of cylinders containing compressed gas. They are the cause of explosions or fires;

- with automatic cutting, especially with CNC machines, user intervention is minimal, which allows rational use of the labor of maintenance personnel.

With so many advantages, there are not so many disadvantages.

- Twenty centimeter thick metal is not available for plasma cutting.

- It is necessary to monitor the deflection angle, which should not exceed 50.

- One machine – one cutter. It is impossible to cut with two cutters at the same time.

How to choose a plasma torch?

To cut metal with a plasma cutter yourself, it is important to buy equipment. Before making a purchase, it is recommended to take into account the properties and parameters of the device

They will have a great influence on the functions of the plasma torch. The price will also vary

Before making a purchase, it is recommended to take into account the properties and parameters of the device. They will have a great influence on the functions of the plasma torch. The price will also vary.

Plasma cutting can be done by two types of plasma cutting machines:

- Inventory - has a compact size, its operation requires a small amount of energy, the device is lightweight with an attractive design. At the same time, it does not turn on for long; voltage drops will negatively affect the device;

- Transformer - long switching time, if the voltage jumps, the plasma cutter does not fail. The size and weight of the unit are quite large; such a plasma cutter also consumes a lot of energy.

IMPORTANT TO KNOW: Gas (oxygen) metal cutting

When choosing a plasma torch for cutting with your own hands, it is recommended to pay attention to the parameters. Such a plasma cutter will be able to maximally satisfy the needs of the master and get the job done

Such a plasma cutter will be able to maximally satisfy the needs of the master and get the job done.

Power

Depending on the characteristics of the product that needs to be cut, the power is selected. The size of the nozzle and the type of gas will also differ.

So, with a power of 60-90A, a plasma cutter can cope with metal 30 mm thick.

If you need to cut a large thickness, it is recommended to buy a plasma cutter with a power of 90-170A.

When choosing a unit, consider the current strength and voltage that it can withstand.

Time, material cutting speed

This indicator is measured in cm, which the machine can cut in 1 minute. Some plasma cutters can cut metal in 1 minute, while others can cut it in 5.

In this case, the thickness of the material will be the same.

If it is important to reduce cutting time, then it is worth considering the cutting speed. The devices differ in operating time - the duration of cutting metal without overheating

If it is indicated that the operating time is 70 percent, this means that the plasma cutter will operate for 7 minutes, after which it must cool down for 3 minutes.

If it is necessary to make long cuts, it is recommended to choose units with a long operating time.

Plasma cutter torch

It is worth assessing the material that will have to be cut. The plasma cutting torch must have the power to cut it efficiently.

It is worth considering that working conditions can be difficult and cutting can be intense.

Additional elements can be attached to the handles of such plasma cutters to support the nozzle tip at a certain distance. This makes the work much easier.

If a plasma cutter will be used to cut thin metal, then you can choose a unit whose burner receives air.

If you plan to plasma cut thick metal, you should prefer a plasma torch, the torch of which will be supplied with nitrogen.

External characteristics

When doing plasma cutting with your own hands, you most often choose portable plasma cutters, which are compact in size.

They are not difficult to operate without sufficient experience; shape cutting is available.

Video:

Stationary units are heavy and are designed for cutting thicker materials; their price will be correspondingly higher.

What metals can be cut?

Using plasma technology, almost any metal can be processed:

- Cutting and cutting of sheet metal from steel, titanium, non-ferrous metals (copper, aluminum, etc.) and their alloys (including bronze, brass, etc.).

- Cutting steel of different thicknesses and workpiece shapes. Processing of carbon and alloy steels of almost all grades is provided, incl. high alloy stainless steels. Plasmatrons can be used to cut strips (narrow long steel strips) and cut rolled steel.

- Cutting cast iron. Plasma ensures deep cutting, which makes the method more effective compared to other technologies.

- Cutting and processing of pipes of different diameters. Special pipe cutters with centralizers are used. In addition to cutting, you can process the surface of pipes, chamfer, clean welds, and process edges.

- Formation and processing of holes.

- Shaped cutting of metal blanks. Special equipment even allows for artistic carving and production of parts of complex shapes.

Types of cutting tinplate

Sheet metal cutting can be done in two main ways: manual and automatic. The manual method is aimed at cutting strips, blanks along the contour, grooves using scissors or hacksaws. This process is very labor-intensive and takes a lot of physical effort. When cutting, you should follow safety precautions to avoid getting splinters in your eyes.

Cutting on automatic lines is a priority and more in demand. The equipment consists of several devices:

- Serving;

- Unwinding;

- Cutting block;

- Control panel.

All operations are carried out automatically without the involvement of workers, which is very convenient. Only one operator controls. After cutting, finished blanks are stacked in packs of up to 2 tons and sent to wholesale and retail customers.