The 163 screw-cutting lathe was developed in 1956 at the Ryazan Machine Tool Plant and was produced in various modifications for sixteen years. Currently, this company produces its modernized version under the symbol 1M63N. From the early sixties to the end of the eighties, lathe 163 under the symbol 1D63 was also produced by the Tbilisi Machine Tool Plant named after. Kirov.

Ryazan and Tbilisi lathes have the same technological characteristics, but they differ in some design features, which depend, among other things, on the year of manufacture.

Specifications

Like most turning equipment, the 160th screw-cutting lathes were produced in two modifications, in which the maximum length of longitudinal processing differed by a factor of two. In the standard version, the center-to-center distance is 2800 mm, and the turning length is 2520 mm. In the shortened version - 1400 and 1260 mm, respectively.

The maximum turning diameters (according to the passport) for this machine are:

- above the guides - 630 mm;

- above the carriage - 350 mm.

The through hole in the spindle in early models was Ø70 mm, later it was increased to 80 and 90 mm. The diameter of the three-jaw chuck is 320 mm. The rated power of the spindle drive motor is 14 kW.

Universal screw-cutting lathe. Specifications

Technical characteristics of the machine 163 are the main indicator of the suitability of the machine for performing certain jobs on the machines. For screw-cutting lathes, the main characteristics are:

- largest diameter D of the workpiece (part) being processed

- greatest distance between RMC centers

- maximum length of the workpiece

- spindle revolutions per minute

Below is a table with the technical characteristics of the universal screw-cutting lathe 163. More detailed technical characteristics of the machine can be found in the passport of the machine 163

| Quantities | ||

| Maximum product diameter installed above the bed | mm | 630 |

| Maximum turning diameter above the bottom of the slide | mm | 350 |

| The largest diameter of the bar passing through the hole in the spindle | mm | 65 |

| Distance between RMC centers | mm | 2800 |

| Maximum turning length | mm | 2520 |

| Height of centers | mm | 315 |

| Number of spindle speeds | 24 | |

| Spindle speed limits | rpm | 10…1250 |

| Main engine power | kW | 13 |

| Machine dimensions (LxWxH) | mm | 4950x1740x1350 |

| Machine weight | kg | 5000 |

Attention! The technical specifications given in the above table are for reference only. Machines produced by different manufacturers and in different years may have characteristics that differ from those given in the table.

Operating rules

When installing and operating the 163 screw-cutting lathe, the user of this equipment must follow the instructions set forth in Chapters 1 and 2 of its Operating Manual. They include the following sections:

- safety precautions;

- installation, installation and first start-up procedure;

- setup and operating modes;

- adjustment;

- Lubrication system;

- specification of wearing parts.

The procedure for commissioning and operating machine 163 does not differ from similar turning equipment. The only thing that attracts attention is the very detailed instructions on setup and operating modes.

Machine passport 163. Universal screw-cutting lathe.

This operating manual “ Passport for screw-cutting lathe 163 ” contains information necessary both for the maintenance personnel of this machine and for the employee directly involved in working on this machine. This manual is an electronic version in PDF format of the original paper version. This documentation contains the Certificate and Manual (instructions) for operating the screw-cutting lathe model 163.

CONTENT

General description of the machine

- Purpose and brief technical characteristics

- Controls

- Specification of the main components of the machine

- Table of main parameters of gears, worms, screws and nuts

- Kinematic diagram of the machine

- Specification of rolling bearings

- Machine lubricant

- Lubrication map

- Description of the operation of the electrical circuit of the machine

- Electrical Specification

Drawings of machine components

- Bed and switching

- Gearbox

- Tailstock

- Caliper

- Apron

- Gearbox

- Replaceable gears

- Fixed lunette

- Lunette movable

- Cooling

download the passport of the universal screw-cutting lathe model 163 in good quality from the link below.

Workspace dimensions

Geometric limitations on the possibility of processing a part are determined by the technical characteristics of turning equipment, the main of which are the center-to-center distance, as well as the height of the central axis above the guides and support carriage. For lathe 163 these values are 1400, 630 and 350 mm, respectively.

In addition, the workpiece turning area above the guides is limited by the dimensions and maximum strokes of the support, as well as the processing capabilities without a back stop. Another parameter that directly limits the size of processing is the maximum permissible weight of the workpiece (for this machine it is equal to two tons).

Design features of the machine

The peculiarity of screw-cutting lathes of the 163rd series is that they were produced at different machine-tool enterprises. For this reason, they have some discrepancies in the design of individual components and assemblies.

Among the basic differences between the Ryazan and Tbilisi machines, it should be noted that the former had both prismatic guides, while the latter had one prismatic and the other flat. The operating instructions and passports of 163 machines have many variations, which sometimes creates big problems when repairing this equipment.

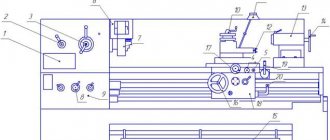

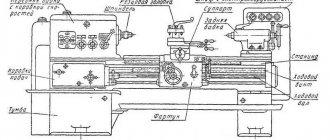

Location of main components

The 163 lathe has a standard layout for this type of equipment. Its structural basis is a cast iron frame, on the upper plane of which there are two prismatic guides (for Tbilisi machines - one prismatic, one flat). On its left side there is a headstock with a spindle assembly, and on the right side there is a tailstock with a retractable quill.

The main working body of the machine is a cross-shaped support with a tool holder, which moves along the guides using the lower slide. The main engine of the Ryazan machine is located outside, and the Tbilisi machine is located inside the headstock housing. The movement to the caliper is transmitted using a lead screw and a lead shaft from the feed box, which is installed inside the headstock. The tailstock moves along the guides manually and is fixed to them with four bolts.

Design features

The 163 machines were prepared from the very beginning to perform a variety of turning operations. It is this versatility that largely explains its layout and choice of basic elements.

The design of the unit is classic - the controls and its appearance completely correspond to the time of production.

A pair of supporting pedestals together with a three-dimensional frame form a single element. The cabinet on the left contains the electric motor. It is connected to the gearbox pulleys and drive shafts by a standard belt drive.

In addition to the main one, the screw-cutting turning unit has several additional motors. Several of them are necessary to ensure the operation of the cooling and lubrication systems, others speed up the movement of the caliper.

The tailstock moves along the upper guides, and the caliper slides along the side guides. Rotation is transmitted from the engine to the spindle through a gearbox, and then to the drive shaft through a feedbox.

The screw-cutting lathe has the following performance characteristics

- For turning cone-shaped products, the support is equipped with a mechanism that provides mechanical displacement.

- The choice of operations that can be performed on it is very wide. The machine has basic and additional functionality.

- If necessary, the unit is switched to operating mode when the spindle rotates at high speed.

- Work can be carried out with both special and standard cutters.

To select the desired pitch when applying threads, pairs of gear wheels in the guitar and the gearbox of the screw-cutting lathe are adjusted.

Kinematic diagram

The kinematic diagram of the 163 lathe consists of several interconnected components, the main ones of which are the following kinematic chains:

- control of operating modes and spindle rotation speed;

- thread cutting;

- longitudinal and transverse feeds;

- high-speed movements of the caliper.

The beginning of the kinematic diagram is the drive pulley of the gearbox friction shaft.

Review of lathe 163: design, characteristics, operating rules

The 163 series lathe was designed by the Ryazan Machine Tool Plant back in 1953. The production of this model continued for a long time, as it has unique technical and operational qualities. And the machine is still used to perform work in specialized workshops.

Design features of the machine

The 163 Series was originally designed to perform a wide range of turning operations and is therefore considered a universal machine. This was reflected in its layout and structural elements.

The arrangement of components in the equipment is classic. There are polished guides on the surface of the bed. They are equipped with a carriage with a tool holder, which has a cutting tool feed mechanism. The main drive is carried out by the operation of an electric motor, which is connected to the gearbox using a belt drive. To regulate the spindle rotation speeds in the gearbox, you can change the clutch of the transmission gears.

Machine 163 has the following design features and performance qualities:

- variety of operations performed. Using this equipment, you can turn, boring, and form metric threads on the surface of cylindrical workpieces. As an additional function, the manufacturer has provided the ability to perform drilling;

- the ability to activate the processing mode at high spindle speeds. In this case, not only cutters with standard characteristics are installed, but also special models;

- the caliper has a device for mechanical displacement. Thanks to this, the machine can turn conical parts.

To implement rapid displacements of the caliper in the longitudinal and transverse directions, the design has two electric motors. This reduces processing inertia and improves the quality of turning work. However, prior setup is required before activating these modes.

The pitch adjustment during thread formation is carried out by changing the pairs of gear wheels in the gearbox. Additionally, it is necessary to adjust a similar parameter for the guitar of the machine.

Description of technical characteristics

The Model 163 lathe is easy to use. Achieving optimal results in processing workpieces is possible only after studying its technical characteristics and operating rules for this equipment.

Like all equipment of this class produced in the middle of the 20th century, the lathe has quite large dimensions, which are 353 * 152 * 129 cm. This is explained by its versatility and the ability to perform a wide range of operations. The weight of the installation is 4050 kg.

To accurately analyze the capabilities of the 163 screw-cutting lathe, you should study its main technical characteristics. They are as follows:

- The maximum permissible dimensions of processed parts depend on the method of their installation. Above the bed this parameter cannot exceed 63 cm, above the support – 35 cm;

- the length of the workpiece cannot be greater than 140 cm;

- the spindle head has a hole with a diameter of 70 mm;

- the spindle can rotate at a frequency from 10 to 1250 rpm;

- the number of spindle head speeds depends on the direction of rotation. For forward movement, this parameter is 22, for reverse movement – 11;

- the number of feeds of the cutting slide, longitudinal and transverse carriage is 32;

- rapid displacements are carried out at a speed of 3.6 m/min (longitudinal) and 1.3 m/min (transverse).

The electric motor power for the main drive is 13 kW. But in addition, when calculating the maximum load on the electrical network, the characteristics of auxiliary power units should be taken into account. Their total power is 2.2 kW. They also include electric pumps that ensure the functioning of the lubrication system and coolant supply.

The functionality of the 163 machine includes operations for forming threads of various types: metric, pitch and inch. Before performing this work, install the appropriate pair of gears in the gearbox.

Equipment operating rules

Reading the instructions is a prerequisite for efficient and safe operation of the 163 machine. However, it should be taken into account that the model has not been produced for a long time and therefore the actual characteristics may differ from the passport ones.

At the first stage of work, it is necessary to check the components and assemblies of the equipment. This includes analyzing the condition of the gearbox, electric motors and checking the linear dimensions of the headstock, tailstock, tool slide and caliper. Then the components are lubricated according to the attached instructions.

To ensure safe operation of the machine, the following conditions are observed:

- availability of good lighting;

- briefing workers before work;

- correct installation of the machine on special supports or a prepared platform;

- use of personal protective equipment: work clothes, safety glasses.

Only after this can you begin turning operations.

The video shows an example of how a 163 screw-cutting lathe processes a steel workpiece:

stanokgid.ru

Gear shift mechanism

On the 163 lathe, the spindle rotation speed is set by two handles: rotating and rotary. With the help of the first, the movable gear blocks are controlled, while the set spindle rotation speed is indicated on the dial of this handle. The rotary handle is designed to lock the selected gear transmission.

Electrical diagram

In the electrical circuit diagram of the 163 lathe, the manufacturer of this equipment identifies the following individual circuits:

- main switch and door lock;

- power supply for control elements;

- main spindle;

- coolant system drive;

- feeds and movements of the carriage and support.

AC control circuits are powered by a voltage of 110 V, and DC control circuits are powered by a voltage of 24 V. Asynchronous motors are powered by an alternating three-phase voltage of 380 V, and electromagnetic clutches are powered by a constant 24 V.

Diagram of machine 163. Screw-cutting lathe. Electrical principle

Below is a sketch of the electrical circuit diagram of the lathe 163

You can download a free electrical diagram of the 163 screw-cutting lathe in good quality from the link above. Option 1: It is contained in the Electrical Manual

You can download a free electrical diagram of the 163 screw-cutting lathe in good quality from the link below. Option 2.