Using any screw-cutting lathe, which can be used to process both metallic and non-metallic parts, turning operations are carried out.

External thread cutting

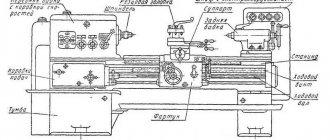

Structural elements of lathe-screw-cutting machines

Any screw-cutting lathe, belonging to the category of universal equipment, allows you to perform the following types of processing of parts made of various materials:

- opening holes;

- turning and boring surfaces of various configurations: shaped, conical, cylindrical;

- performing countersinking and drilling;

- end processing and trimming;

- cutting threads of various types.

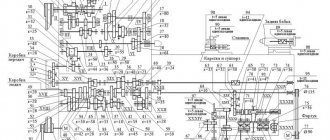

A universal screw-cutting lathe of any model consists of standard components and mechanisms, which include:

- machine support;

- front and rear stock;

- box providing speed control;

- supporting frame;

- spindle;

- electrical equipment;

- equipment cabinets;

- guitar gears;

- running roller;

- equipment apron;

- box providing selection and change of feeds;

- The main element of a screw-cutting lathe, which distinguishes it from a conventional turning model, is the lead screw.

What is typical is that the structural elements of screw-cutting lathes of different models not only have the same name, but also the same location. For example, machines of this category, produced by different manufacturers (including those with numerical control), are almost identical in design.

Main components of a screw-cutting lathe

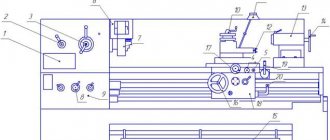

To ensure control of all working systems, screw-cutting lathes are equipped with various handles and levers. These include, in particular:

- a handle used to change the spindle rotation speed;

- control body responsible for selecting the parameters of the thread being cut (pitch and feed);

- a handle responsible for selecting the pitch category of the thread being cut - increased or normal;

- a control element that determines the direction of movement of the slide (longitudinal or transverse);

- handle for controlling the upper slide;

- a control element for enabling and disabling the rotation of the lead screw;

- a control element for selecting the direction of the thread to be cut;

- turning on and off the main engine;

- an element responsible for fixing the quill and automatically starting the longitudinal feed;

- the so-called steering wheel, which is responsible for the movement of the quill;

- feed parameters control body;

- control of caliper movement parameters;

- element responsible for fixing the tailstock;

- control element for the direction of movement of the spindle, as well as its stop.

Screw-cutting lathe 1K62

Typical control unit

When considering a modern universal screw-cutting lathe, you should pay attention to the control unit. To indicate the main processing parameters, levers and handles, buttons and other control units are installed. The main features include the following points:

- As a rule, a handle is installed to indicate the number of revolutions. A universal modern screw-cutting lathe can change this indicator, which is selected depending on the required cutting conditions.

- A screw-cutting lathe has a device that allows the formation of a threaded surface. Its parameters are set using a special control unit. Do not forget that some parameters can be set solely by installing the required replacement wheels.

- There are also handles that allow you to control the caliper. Screw-cutting lathes have main components that allow mechanical feed for quick positioning and processing with a constant movement speed.

Controls of screw-cutting lathes using the example of model 16K20

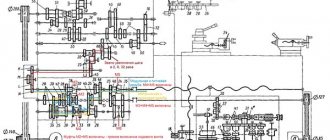

The CNC screw-cutting lathe has a more complex layout. This is due to the fact that such equipment can operate without operator intervention at intermediate stages.

Classification of universal lathes

Types of screw-cutting lathes are distinguished depending on several parameters, which include:

- weight of equipment;

- the maximum length of the part allowed for processing on a screw-cutting lathe;

- the maximum diameter of such a part.

The length of a part processed on a screw-cutting lathe of one model or another depends on the distance maintained between its centers. If we consider the diameter of the workpiece, which can be processed by a specific universal screw-cutting lathe, then this parameter is in the range from 100 to 4000 mm. It should be borne in mind that machine models that can process parts of the same diameters may differ in the length of the workpieces processed.

Heavy screw-cutting lathe 1A670

Universal lathes can have different weights. So, according to this parameter, equipment is classified into one of the following categories:

- heavy machines, the weight of which can reach up to 400 tons (screw-cutting lathes of this category can process parts with a diameter of 1600–4000 mm);

- machines weighing up to 15 tons (such equipment can process parts with a diameter of 600–1250 mm);

- equipment weighing up to 4 tons (with a permissible diameter of processed parts of 250–500 mm);

- lightweight machines whose weight does not exceed 0.5 tons (such equipment can process parts with a diameter of 100–200 mm).

A lightweight universal lathe is a benchtop model that is typically used in home workshops or small businesses.

Screw cutting lathe CU500

The most common types of enterprises with such screw-cutting lathes are:

- experimental sites of enterprises in various industries;

- enterprises engaged in the production of watch movements;

- factories producing instruments and control equipment.

Enterprises in the energy and mechanical engineering industries are equipped with heavy-duty screw-cutting lathes. Devices of this type are also used for processing elements of special mechanisms and assemblies - parts:

- turbine mechanisms;

- for equipping railway transport (wheel sets, etc.);

- for completing heavy rolling equipment.

However, screw-cutting lathes belonging to the middle category are most widespread. It is through the use of such machines that it is possible to perform semi-finishing and finishing metalworking operations, as well as cut threads of various categories.

A universal lathe, which belongs to the middle category, has a number of significant advantages: a wide range of working tool feeds and spindle speeds, high structural rigidity and engine power, which allows you to perform a wide range of work with workpieces made of metal and other materials.

Medium-category screw-cutting lathes, in addition, are equipped with various mechanisms and devices that significantly expand their functionality, allow processing with greater precision, and make the work of operating personnel more comfortable and safe. Such elements of additional equipment, which is convenient, allow you to automate many processes of processing workpieces on screw-cutting lathes.

Separately, it should be said about screw-cutting lathes with numerical control (CNC), which in Soviet times were produced simultaneously by several enterprises. As a rule, enterprises that produced a large range of small-scale products were equipped with such machines. The design of a screw-cutting lathe of this type and the possibility of its quick changeover make it simply irreplaceable in situations where it is necessary to quickly switch to the production of parts of a different modification.

Screw-cutting lathe 1M63

Classification of equipment by type of accuracy

Based on the accuracy that a mounted turning unit provides, it is assigned a grade:

- C. Characterize the equipment with particular accuracy;

- B. Assigned to units that provide high accuracy during operation;

- N. They give machines with normal accuracy;

- A. Assigned to devices that are particularly accurate;

- P. All have machines that provide increased processing accuracy during operation.

Basic technologies for processing parts on screw-cutting lathes

Lathe equipment is typically used to machine external cylindrical surfaces. In such situations, a through cutter is used as a tool. The allowance along the length of the workpiece is usually from 7 to 12 mm. This size reserve is necessary so that the workpiece can be cut to the required length and its ends processed.

To trim the end of the workpiece, several types of cutters can be used - thrust, straight through and scoring. To perform trimming and grind small ledges on a part, thrust-type cutters are used.

A universal lathe also allows you to cut grooves of varying depths on parts. For these purposes, a special groove tool is used, and the procedure itself is carried out at low spindle speeds.

Cutting the finished product is carried out according to a similar principle. The cutting process is completed at the moment when the diameter of the jumper at the cutting site reaches a value of the order of 2–2.5 mm. At this point, the cutting process stops, and the finished part is simply broken off from the workpiece.

What operations can be performed?

A large-scale or benchtop screw-cutting lathe is installed to form shaft or flange type parts. The cutting tool is a through cutter, which is selected according to the cutting conditions.

Shafts Flange

In addition, there are scoring cutters that can be used for processing end surfaces. The formation of grooves is carried out when installing thrust-type cutters. Different types of cutters are used to perform certain operations. In this case, attention is paid to the shape, as well as the type of material used in manufacturing. A precision screw-cutting lathe also allows you to carry out basic types of work.

Some types of this equipment can also be used to perform drilling operations. But it is worth considering that in this case the drill is located along the axis of the workpiece. The principle of operation of this drilling scheme is as follows: the tool is mounted in a special equipment on the tailstock, is in a stationary state, and the workpiece itself receives rotation. The tailstock can be moved longitudinally to perform feed.

DRO Features

When considering a precision screw-cutting lathe, one should note its applicability in a wide variety of fields.

Versions with DRO have become quite widespread. These types of turning equipment have high operating accuracy due to the display of the axes of the main organs on the display display. There are quite a large number of models with DRO, each with its own characteristics. The precision screw-cutting lathe is equipped with components that are also characteristic of other models belonging to this group. A screw-cutting lathe with a DRO is cheaper than a CNC screw-cutting lathe, which determines the cost-effectiveness of their installation in certain cases.

What is the block in question intended for? This digital block allows you to control the position of various structural elements, as well as calculate the required information, for example, the distance by which a caliper or other element should move. The production of such units began relatively recently; the purpose of some models is expanded due to their equipment with this control unit.

Specifications

When choosing the most suitable model, technical characteristics are always considered. They determine the features of the work and the possibility of application in a given situation.

The main technical characteristics are included in the description. These include:

- Number of revolutions: minimum and maximum. The main technical characteristics determine the possibility of processing according to the specified parameters. When creating a drawing, the technologist indicates at what rotation speed the cutting should take place.

- Accuracy class. The drawing contains data on the accuracy with which the processing should be carried out. GOST establishes standards for determining the accuracy class by which equipment is marked.

- In order to be able to adjust the spindle speed, a gearbox is installed. Established GOST standards require the number of gears to be indicated in the passport.

- The part can have a variety of sizes, which determines the possibility of installation.

- Weight and overall dimensions.

- The amount of feed and maximum movement along the axis.

All technical characteristics can be found in their passport data and other documentation.

General view of a screw-cutting lathe