In a home workshop or small business producing products from thin sheet metal, sheet metal shears, more simply - a guillotine - will never be superfluous. The driven version can be installed, for example, in a garage, and a manual guillotine will not take up much space at all. If you have a fairly large number of manufacturing options (in drawings, videos or descriptions), as well as some adapted components from some decommissioned equipment, making homemade metal shears is an accessible reality.

Homemade hand guillotine

How to make a guillotine for cutting metal with your own hands?

In a home workshop or in a small enterprise for the production of thin-sheet metal products, sheet metal shears, or more simply a guillotine, will never be superfluous. The driven version can be installed, for example, in a garage, and the manual guillotine does not take up much space at all. If there are quite a large number of manufacturing options (in drawings, videos or descriptions), as well as some adapted components from decommissioned equipment, it is quite possible to make homemade metal scissors with your own hands.

Other features of laser cutting

One of the so-called “disadvantages” of laser cutting is its low availability. Laser cutting of metal with your own hands, taking place in some small garage, is a very controversial opportunity for a simple buyer who does not have a large amount of money to purchase laser equipment.

Based on the high cost factor, only if such a step is sufficiently justified should laser metal cutting (equipment) be chosen. Its price, however, although high, there are many enterprises and individuals who have the financial means to purchase such equipment.

The work of the simplest metal scissors

The principle of cutting with guillotine (sheet) shears is that the knife beam of the device, to which the movable part of the tool is attached, along the working end must have an angle of 1.5-3°, as a result of which metal cutting occurs non-simultaneously across the entire width. This reduces the cutting force, but requires a technique that would compensate for the shear of sheet metal (tin, thick cardboard, etc.) during cutting. You will need a reliable clamp.

To drive a homemade guillotine, you can use a low-power electric motor, since the energy intensity of the process is low. Based on the results of calculating the maximum cutting force, a manual drive, for example, a lever type, is often sufficient (this is often what is offered in home-made devices). You will also need reliable guidance of the moving parts during the cutting process, as well as a rigid supporting surface of the frame. In this case, the parts of the homemade guillotine and the product itself will not be elastically deformed.

The drawings indicate the limits of the thickness and width of sheet metal or sheet metal for which the device is designed. If the entire process of obtaining sheet shears with your own hands is carried out independently, the design begins with clarifying the power characteristics of cutting and choosing a mechanism diagram.

The initial data for choosing a design are:

- the type of material with which operations will be carried out;

- maximum sheet dimensions in terms of thickness, length and width;

- separation accuracy;

- maximum overall dimensions of scissors;

- type of drive.

Mechanical guillotine shears

The manual device is the simplest in design. It includes:

- support table where the initial workpiece will be located;

- two or four stands, providing the scissors with strength and stability;

- a rotary axis with plain bearings (rolling bearings are unsuitable, because the clearances during operation of such a guillotine will change greatly, which will quickly lead to jamming);

- knife beam, where seats are provided for fastening replaceable knives;

- fixed knives, which are mounted on the front end surface of the work table;

- a rotary lever that produces forceful movement of the beam during cutting;

- clamps for fixing metal.

The manufacture of the machine should begin from the table. Its dimensions must be sufficient for convenient placement of the workpiece, taking into account places for fixing clamps: there must be at least two of them, on each side of the sheet. The thickness should prevent deflection under deformation forces. The easiest way is to use a steel plate, which you install yourself on the channels. The joints are bolted flush with the top surface, but welding can also be used. The front end must be ground to ensure evenness of the subsequent fit of the stationary knife to it.

The next stage is obtaining support posts. They must be made from a solid profile. Square pipes made of high-quality medium-carbon steel or a channel are suitable. The section size is easily calculated from the maximum load on the racks, which is the sum of the self-weight of the components of manual guillotine shears for metal, and the cutting force P, kN.

The latter is calculated according to the dependence:

k is a coefficient that takes into account the likely unevenness of the working gap, bluntness of cutting edges, quality of the material being cut, etc. Typically k = 1.05-1.3;

B – maximum width of the metal sheet, mm;

s – maximum metal thickness, mm;

σav – ultimate shear strength of the material, MPa.

For the most common materials in everyday life, this parameter is, MPa:

- for low-carbon steel – 280…290;

- for medium carbon steel – 300...400;

- for high carbon and stainless steel – 400…500;

- for sheet metal, aluminum – 65...80;

- for copper, brass – 180...200.

When assembling the racks with your own hands, it is necessary to maintain the parallelism of the supporting surfaces and their perpendicularity to the axis of rotation of the knife beam. To do this, it is better to use a laser level. The floor where the scissors are installed should be made level and durable. Do-it-yourself installation of equipment on compacted soil, laminate or other polymer coating options is not allowed.

A particularly important moment is the creation of a knife beam: its profile must be made so that during the rotation process the movable knives come into contact with the metal being cut. To do this, you need to provide two options:

- profiling along the contour of the saber, with a gradual increase in the radius of curvature as it approaches the lever handle;

- a pyramidal profile with a bevel angle of no more than 5-60 (at a larger angle, the metal will begin to deform and bend in the direction of the rotation axis).

The saber-shaped profile is more difficult to make, but it provides a smoother integration into the metal being cut.

For better direction of the body, it is placed either in a special groove on the table, or - with increased deformation forces - special guides are designed that are attached to the racks.

It is better to make the turning axis from high-quality carbon steel, and then harden it to a hardness of at least 42-45 HRC. Bearing bushings are made of OF 10-1 bronze, which has good wear resistance.

For the manufacture of tools, tool steels U10 or U12 are used, hardened to a hardness of 48-54 HRC. Hardened knives are carefully polished with your own hands, after which they are sharpened at an angle of 85-90°. The gap between the knives is taken within 3-6% of the thickness.

My home guillotine

Hello! My name is Alexander, and I have a guillotine in my basement...

I made it myself. Her knife goes down at least once a week, and sometimes several times a day. There was a topic here the other day about executioner swords. I read it and thought - why don’t I tell you about my dungeon and “instruments of torture”?

To make everything clear, I’ll start from afar. I had to go underground on January 10 last year. This day at 6 am my beloved wife told me that she was a chipmunk. I mean, she has two stripes.

I would like to write that I work a lot with wood. But this is not true. I work with people, but I relax with wood. I mainly cut sculptures with a chainsaw, but I also do other little things. Men know how hard it is to carve out a corner in the house for their “dusty” hobby. I'm lucky. As soon as we moved into the apartment, I occupied the entire room. I made furniture, did repairs, slowly. He lived without bothering himself.

And here's the news! The action plan was clear, without preamble - to bring the apartment into a habitable state by September. So we had to move underground - to the basement. Everything could have been done quickly. But I did it my way. After all, this is not just a basement. This is literally an alchemical laboratory where I planned to turn a dead tree into living Pinocchio.

Just below is a table for small work. Solder something, burn it out, assemble something. Above the table is a cabinet for tools for this “small something.” On the right is a machine for sharpening chains (for a chainsaw). I used to sharpen one at a time, but now I save up and sharpen in bulk - 30 pieces each. It’s easier on the nerves.

The Holy of Holies is the workbench. EVERYTHING is done on it. ABOUT! I saw a walkie-talkie in the photo. With its help, radio communication with the “base” is carried out. Like: “Base to first!” Get out, dinner is ready!”

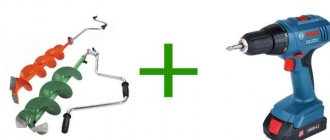

Trying to make a manual guillotine with your own hands

A manual guillotine for cutting metal with your own hands is not such an unattainable goal. You must be able to work with welding and some plumbing tools.

Metalworking machines are expensive and complex equipment that not every workshop, let alone an individual, is able to buy. But many of the machines can be made independently. For example, a manual guillotine for cutting metal with your own hands is not such an unattainable goal. All you need is the ability to work with welding and some plumbing tools.

Naturally, it is impossible to do without financial investments. For example, there is no way to make knives yourself. This is a complex factory-produced part that requires special steel and machines to process it. But you can easily buy guillotine knives on the market, on the Internet or in specialized stores.

If they offer guillotine knives that have worked for several years at a large factory, you can buy them, but be mindful of what kind of metal you are going to cut on your machine. If roofing steel or corrugated sheeting, then buy without fear. After sharpening, they will cope with such a task without difficulty. But for cutting reinforcement, corners or sheets thicker than 1.5 mm, new knives will be required, without “work experience”. They are relatively inexpensive, and you can choose them by length, sharpening angle and height.

A knife made from a spring will never have the capabilities of a factory one.

Many craftsmen use various metal machine parts for knives, for example springs made of steel of sufficient hardness. But such scissors will be useful only for rough cutting of thin-sheet steel - achieving ideal straightness of the blade without lateral deviations at home is difficult, almost impossible. It is better to stop at buying factory-made knives. The peculiarities of the interaction between the knife and the steel sheet require special strength of the cutting edge.

Homemade paper cutter

In this article we will consider only straight cuts of one sheet of paper.

Everyone who works with paper and cardboard has faced the need to cut this very paper or cardboard. Let's look at the main methods.

Advantages: low cost of tools, ease of use

Disadvantages: difficulty in obtaining a high-quality cutting line of great length.

General recommendations for this method:

— Cutting must be done on a substrate. This could be a self-healing mat, cardboard, old magazines or a sheet of glass. For thin paper or tracing paper, glass, in my opinion, allows for the best cutting quality. For thick binding cardboard, it is better to use cardboard or paper as a backing.

Advantages: low cost of instruments, relative ease of use, ability to obtain high-quality cuts of long length.

Disadvantages: difficulty in fixing a long ruler, increased risk of injury.

There are a great variety of such cutters. They differ in type (roller, saber, guillotine), in the size of paper sheets - from A4 to A1, in price, etc.

Relatively inexpensive small cutters allow you to successfully solve the problems that a hand maker faces when working with sheets of paper of small size and density. But as the paper size increases, the price of the cutter will increase rapidly. Ultimately, a high-quality paper cutter measuring 70x100 cm (the standard size of a sheet of designer cardboard or paper) will only pay for itself on an “industrial” scale of production.

Advantages: ease of use, high productivity and cut quality (with appropriate quality of the cutter itself)

Disadvantages: high price (especially for cutters with long cutting lengths).

Unfortunately, this method, along with its advantages, also inherits the disadvantages of “combined” methods.

The most common reason for creating and using homemade cutters is the inappropriateness (impossibility) of purchasing a “branded” cutter. This reason prompted me to create my own homemade paper cutter.

When making photo albums, I use binding cardboard, designer cardboard, designer paper, and tracing paper. The dimensions of sheets of all these materials, in most cases, are 70x100 cm. To cut sheets of paper of this size (after analyzing the advantages and disadvantages of the above cutting methods), method No. 5 was chosen.

Now it was necessary to choose the design of a homemade cutter. The cutter had to meet the following requirements:

— the ability to cut paper of various densities measuring 70x100 cm.

— simplicity of design and absence of expensive components.

— acceptable cut quality.

Having surfed the Internet, I found an interesting version of a cutter made from two metal rulers by Evgeniy Kuznetsov.

I was inspired to create a more complex cutter by another tool. Unfortunately, I didn’t remember the author of this device, and now I can’t find it on the Internet.

As a basis, I took an old drawing board that had spent many years in oblivion in the open air. The edges that had become unusable had to be sawed off.

A steel ruler 100 cm long was taken as a guide for the knife. It was shortened to 80 cm. To add rigidity, a duralumin rule for construction work was purchased. I also shortened it to the required size.

To secure the steel ruler to the duralumin rule, the choice of fastening method arose. Due to varying degrees of expansion with temperature changes, as well as constant mechanical stress, the adhesive connection method was rejected. The most reliable method under these conditions is mechanical.

Since the steel ruler is quite thin, it would be quite difficult to “sink” the heads of the screws or bolts that secure the ruler to the rule flush (as well as to grind them down later). A work colleague gave me a dozen duralumin rivets that he had left over from the Soviet Union. With their help, it was possible to securely fasten the ruler to the rule.

To make it easier to fix the ruler, guides were made from bolts. It is better to drill the holes for the bolts with a slightly smaller diameter than the bolts themselves, so that they are screwed into the board and do not fit freely. The bolts are additionally secured with nuts with special bushings that prevent spontaneous unscrewing.

The ruler is secured at the top with wing nuts, which are easy to tighten by hand. Springs are bolted under the ruler. When we unscrew the thumbs, the ruler rises on springs and our hands are freed up to work with paper.

I will make a reservation that with a given length of the cutting line, even a rule with a thickness of 2 cm. After clamping the wing screws, it bends a little and to fix the sheet of paper it is necessary to press the ruler with your hand in the central part.

For convenience when positioning a sheet of paper perpendicular to the ruler, I attached an aluminum corner purchased at a building materials store.

For the same convenience, on the part of the corner fixed on the side of the working part of the ruler, I decided to place an aluminum square with stops for a sheet of paper. By securing this “stop” to the corner with a clamp, you can position the sheet of paper with greater speed before fixing it with a ruler.

Having tried different options for substrate for cutting paper, I settled on the old proven method of cutting on glass. Glass from a furniture wall was used as a glass substrate (it is better to order glass of the required dimensions with a processed edge from a glass workshop). To maintain the quality of the cut line, it is necessary to monitor the condition of the cutting edge of the knife and regularly sharpen it or break off segments of the knife blade with a dull edge.

Possibilities of a homemade guillotine

A homemade guillotine can work like a factory machine. This has been proven by the designs of homemade craftsmen who are able to cut metal no worse than industrial machines. The most common types of guillotines are those with a straight movement of the upper knife and those with an angular rotation. The first type of machine more accurately corresponds to the name - the guillotine, and allows you to cut metal very accurately. But the features of the second type make it possible to cut not only sheets, but also fittings and corners of quite large sizes.

Size restrictions are set on do-it-yourself metal cutting installations for purely natural reasons. Unlike industrial ones, which have a hydraulic, electric or pneumatic drive, homemade ones are equipped only with a mechanical lever or pedal, and the thickness of the metal being cut depends on the physical strength of the operator.

An electromechanical drive can be installed in a DIY workshop, but hydraulics and pneumatics are very difficult to install. This is available only to highly qualified masters.

A do-it-yourself guillotine can cut:

- sheet black and galvanized steel up to 1.5 mm thick;

- aluminum;

- stainless steel up to 0.6 mm;

- plastic;

- cardboard.

The design of a homemade machine must take into account the features of already working structures. A description of one of the guillotine options is given below.

Hydraulic units – guillotines of professionals!

The most powerful are hydraulic guillotines; they also have the highest characteristics in terms of cutting length and material thickness, which reach up to 8 or more meters and up to 60 mm, respectively. Such units are divided into two types, depending on the method of blade feeding:

- direct vertical type, in which the frame with the working blade moves up and down along guides, carrying out cutting;

- blade feed with a rotating beam - in this design, the working blade, mounted on the frame, rotates around two attachment points located on the side walls. The movements of the blade resemble those of a bulldozer bucket.

The advantage of the second type is the much smaller dimensions of the entire structure, ease of maintenance and low cost. The main advantage of direct blade feeding is the ability to adjust the angle of the blade, since for optimal cutting of different sheets it is necessary to set an angle from 0.5° to 4°, thanks to which such units cope with their task perfectly, whereas when feeding a blade with a rotary beam When cutting metal of great strength or thickness, the quality of the cut will be noticeably lower.

For hydraulic guillotines, it is important to have a durable, heavy body, the rigidity of which ensures high cutting accuracy. Knives for units usually consist of meter-long modules, which are made of high-strength steel. There are knives for cutting ordinary metals and especially durable ones. As a rule, one knife can have 2-4 working edges. By periodically changing sides, we significantly extend the service life of the entire unit.

Main parts of guillotine shears

- beds;

- desktop;

- vertical guides;

- gear racks;

- gearbox;

- lever (pedal);

- rulers.

Desktop

The base is a metal table made of a plate with a thickness of at least 10 mm. It is not advisable to use a wooden shield, even of great thickness. Wood is springy and can warp due to changes in humidity, and for cutting metal it is important that the machine is in a strictly defined position.

Two guide tubes of round or rectangular cross-section, or rods, along which the upper beam with the knife will move, are welded to the plate. If a tube is used, it must be thick-walled.

To prevent the tube from being deformed during welding, a smaller diameter bolt or steel rod should be installed inside.

The guides must be strictly parallel to each other and perpendicular to the plane of the table.

The horizontal beam to which the upper knife will be attached must move along the guides without resistance, but also without play. This will be ensured by bushings welded to the ends or mounted into the beam, into which the guides are inserted with minimal clearance. The inside of the bushing and the surfaces of the guides are ground and lubricated.

Drive unit

To ensure that both drive gears rotate evenly, they are connected by a shaft that runs under the table. A pedal can be used instead of a driving lever. To prevent the beam from lowering on its own, upper position clamps or return springs are installed.

Knives, as already mentioned, are industrially manufactured. They are sharpened in the factory at a certain angle, which must be maintained when re-sharpening. They are secured to the frame and beam with bolts, holes for which are provided during manufacture.

The gap between the knives is adjustable within 0.1-0.7 mm, depending on the thickness of the sheet.

On factory guillotines, the inclination of the upper knife from the vertical is adjustable and amounts to 1-3 0. It is impossible to achieve such precision at home, so the knife is installed strictly vertically. With small thicknesses of the sheet being processed, a slight increase in the required force is almost imperceptible.

Structural elements

A manual guillotine for cutting metal has the following components:

- Bed;

- Desktop;

- Knife;

- Vertical guides;

- Toothed racks (drive);

- Gearbox;

- Lever arm;

- Ruler.

Desktop Features

The working surface is a metal plate no less than 1 cm thick. It is not recommended to use wood for this, even if it is a very thick panel, as it will spring back and become deformed. It is important for the equipment to remain in one unchanged position.

2 guides are installed on the plate (round or profile pipe). The upper beam with the knife will move along them. It is advisable to choose thick-walled material. In this case, the guides must be placed in such a way that they are exactly parallel to each other and in a perpendicular plane to the table.

The knife will subsequently be attached to the horizontal beam. The beam must be allowed to move freely along the guides. In this case, there should not be excess resistance, but there should also be no backlash. This can be achieved by welding bushings along the edges of the beam, which will be inserted into the guides with a small gap. The inner surfaces of the bushings should be lubricated.

Drive mechanism

The vertical movement of the beam can be ensured using gear racks by welding them at its ends. By placing the slats on both sides, you can achieve uniform movement. The forces on the rack will be transmitted from the gears connected to the lever mechanism. By considering different leverage ratios and gear diameters, it is possible to achieve the required force applied by the knife. In this case, the impact on the drive will be minimal.

In order to ensure uniform rotation of the gears, they must be connected by a common shaft, which can be placed under the working plane. An analogue of the design can be a pedal drive. To prevent spontaneous lowering of the beam, it is recommended to install an upper position lock or a return spring.

Reciprocating scissors

The second end of the knife is connected directly to the lever handle. The knife acts on the sheet of metal not simultaneously throughout the entire cut, but gradually, which allows you to cut metal of considerable thickness without too much effort. By adjusting the gap between the knives, you can achieve fairly decent results in terms of cutting accuracy and the absence of lateral deformations in the working area.

As a rule, the upper knife is placed on a bearing and frictional forces do not increase the operator effort required for cutting.

Advantages of gas cutters

Gas cutters or autogens are popular because of the simplicity and ease of working with them. With some handicraft manufacturing, a DIY gas cutter has quite acceptable performance and power. Self-manufacturing of the product allows you to save a significant amount of money, and it will completely pay off if you need to perform small amounts of work with metal.

As a result, it becomes clear why Russian inventors did not stand aside without coming up with some simple way to make a metal cutter.

Guillotine-scissors for cutting metal with your own hands: instructions and drawings

Guillotines for cutting are used for cutting sheet iron (even in a bundle, depending on the characteristics of the installation) in a “cold” way, that is, without thermal influence (for example, using a welder or grinder). In this case, the cut is smooth, therefore, after cutting the metal, additional processing of the edges is practically not required.

The convenience is obvious, but industrial machines have a significant disadvantage - a high price. Even the simplest manual (mechanical) models cannot be found cheaper than 48,500 rubles (Chinese crafts for 10,000 do not count).

The more functional (hydraulic) ones have considerable dimensions, so they are of little use for everyday use. And they cost at least half a million. Conclusion - it is advisable for a home craftsman to make a guillotine with his own hands. How to install it is the topic of this article.

Guillotine is the general name for all installations that allow cutting metal using the chopping method. The essence of the process is clear from the figure.

The author suggests taking a little break from the topic and thinking. There are several varieties of these units, the main difference between them is the principle of operation. Based on this feature, there are electric/mechanical, pneumatic, hydraulic and manual models (the simplest ones, which are often called guillotine shears).

A rhetorical question: are such complex and expensive units needed in everyday life, if the guillotine is a “narrow-profile” installation and is not used very often? It is easier for the owner of a workshop or a small metalworking shop to purchase it than to make homemade products. Moreover, it will pay for itself quite quickly. Therefore, below is the procedure for assembling guillotine (mechanical) shears.

Such a small-sized installation is quite suitable for use in an outbuilding, shed, or garage.

pros

- Small size and weight. Therefore, changing the location of the guillotine, even moving it to another site, will not be difficult. Full autonomy at work. You don’t have to think about how to connect the industrial/voltage to the installation.

Materials and tools Guillotine cutter

I now have the much desired guillotine cutter. I wanted one from Martha Stewart, but I couldn’t find it in stock anywhere. And if there is, it’s with an exorbitant price. This one is good too. Moreover, I am already familiar with this company. Quite compact and functional.

The paper size is 13 inches or 33 by 35 cm.

Markings in centimeters on one side.

On the other hand, in inches.

There are markings on the site for commonly used formats of postcards and works.

The clamping bar holds the paper very comfortably and firmly and serves as protection for the fingers.

The handle of a knife, the guillotine itself (a terrible name, for some reason France immediately comes to mind).

Ruler on the lower knife, which is not movable.

Pull-out bars with rulers, inches and cm, which increase the working area.

This is the bottom. It has non-slip feet, and a key for adjusting the stroke of the knife, attached to a special socket.

This is the articulation unit of the cutter itself, which is adjusted with a key. How convenient it is to cut. Smooth ride.

We measure on the ruler as much as we need.

Lower the cutter. Everything was cut effortlessly and evenly, evenly!

I cut a stack like this in about fifteen minutes. Takes 160 g/m paper, four sheets. Well, a simple notebook, in small piles. Well, just don’t overload it with thickness. Film and cardboard are also possible. It is written in the instructions that there is a lifetime guarantee, as I understand it, the knives themselves appear to be self-sharpening. This is nice, we'll test it with time. No, I wrote it wrong, the stack of sheets that is in the photo and another one that has already become notebooks.

I am pleased with the purchase, especially the desired one. She described the cutter in such detail, maybe it will be useful for someone, for example, it would be very useful for me. It’s convenient to use, doesn’t take up much space, and looks very nice. And you can use it from the age of 14, as it says on the packaging and in the instructions. Thanks for your attention and viewing! I am glad to everyone, I wish you health and peace!

Olenka, congratulations on your purchase, I will look forward to new works.

Elechka, thank you! I already have some work, I made four notebooks. On springs. I'm mastering binder.

What a necessary item.

Tanya, thank you for your feedback. The thing is necessary, I have wanted it for a long time, it is needed on an equal basis with a scoring board. It makes the job very easy, the edges are smooth and even.

LLC What a valuable acquisition. Great!

Yes, Lilechka! Really good purchase, so far I'm happy with it!

Wow, what a cool car! Olechka, congratulations on such a necessary and wonderful acquisition!

Thank you, Lyubushka! I’m thinking about asking Dedik Morozik to wear slippers for New Year’s Eve or Christmas. Well, probably something simpler, some consumables.

Olenka, congratulations - a wonderful purchase. I remember the Soviet photo cutters)))

Thank you, Elena Ivanovna! Yes, we had one, but it was put somewhere, or thrown away, or given away, I don’t even know. I searched and couldn't find it. It would have been useful, especially since it was big. Well, science will, don’t throw it away, think about it.

Olya, happy new thing for you!

Marina, thank you! I love tools, all kinds of gadgets!

Wow. I regret that I wasted my time and didn’t buy a good big cutter. Now I'm looking at this one too

Olya, thanks for the story! I also heard about guillotines that they don’t need to be sharpened.

Irina, this gnome is undoubtedly very useful and is constantly at work, I wonder how I managed before. He has his own whims, well, you can adapt to them, for example, he always wants to bend thin, limp paper in one place, so I lower the cutter in two movements, lift it a little and let the paper straighten, well, this is due to the paper, to its quality . It cuts our beautiful and thick scrap paper perfectly, it can cut several sheets at once. My conclusion, the board and cutter are very good purchases, needed. Let me boast, I started using a binder, time after time the spring turns out smoother. I made 16 notebooks, I spend more time decorating and thinking about the decor than making the notebook. Gnome helpers! You, Irina, need such an assistant, especially since you have students!

Hello. I’m faced with choosing a cutter, I saw your review of the tool. Please tell me what it is called (brand or maybe there is a link to where you bought it). And a few months later, how he showed himself at work. I need it to make notepads. I would be grateful for your answer.

Guillotine device

The picture explains everything well:

Since metal is cut using a guillotine, the main requirement for the design is stability and strength.

bed

It is clear that it is unlikely to be possible to select cast iron racks. Unless to carry out partial dismantling of decommissioned industrial equipment/equipment. But does everyone have this opportunity? For arranging supports for a household guillotine, a channel, a large cross-section pipe, or a large angle are quite suitable. Here you need to know what samples you plan to work with - thickness, type of metal (aluminum, steel).

Tabletop

In addition to strength, it must have strict geometry. An integral part of the guillotine is a clamping bar that securely fixes the sheet (or bundle) on the tabletop before cutting. The slightest distortion can lead to uneven edges, the appearance of burrs, and the like. For the table surface you need to choose thick sheet iron (at least 8 mm).

All other options - chipboard, OSV, FC, getinax and so on - are not suitable. There are recommendations that indicate exactly these materials. But it does not specify how long such a table will last, especially if the guillotine is used frequently. In addition, a tabletop made of thick metal adds stability to the entire structure, which cannot be said about plywood or other light-weight samples.

Its dimensions are chosen arbitrarily, based on the dimensions of the sheets that are supposed to be cut. That is, everyone designs a guillotine to suit their needs.

Both the upper and lower ones should only be made of tool steel, and with proper sharpening. These are probably the only components that will have to be ordered, since you definitely won’t be able to make them yourself. For example, through friends at a factory, in a specialized workshop.

How to make a guillotine for cutting metal with your own hands?

[With a guillotine for cutting metal] you can produce high-quality, accurate and efficient cutting of sheet metal and profile aluminum.

The machine traditionally consists of a bed with a feed table (metalworking companies use a conveyor), equipped with a knife, scissors, a holding or guide beam and a material feed depth limiter.

In production, machines with a return tray are used, into which the cut metal is collected.

The cutting parts are usually made of titanium or high quality alloy.

Sheet metal cutting is determined by the parameters of the shears and cannot be adjusted, however, the sheets are not subjected to heat treatment, which is especially important when working with soft metals such as aluminum sheets.

Which paper cutter is best?

The choice in one direction or another depends on how the device will be used. For home use, it is enough to have a roller cutter; for the office you can purchase a reciprocating cutter, with which you can cut up to 20 sheets of A4 format. For printing houses or enterprises with a large document flow, it is better to choose a guillotine model. When figuring out how to choose a paper cutter, it is worth noting the following important points:

Paper cutter rating

Among the entire range offered on the market by manufacturers, the following models are distinguished:

Types of guillotines

To cut sheet metal on a guillotine, two types of scissors are used - vertical and horizontal (some mechanisms can be of a combined type). The cuts are made in the following order.

The vertical incision is made first, the horizontal incision second. For horizontal cuts, the sheets are additionally held by a side bar.

Depending on the type of drive that sets the scissors in motion, the following types are distinguished:

- mechanical;

- hydraulic;

- pneumatic;

- electromechanical guillotine.

The mechanical guillotine is a table with manual scissors. It works on the principle of air cutting, so there is no support beam.

Cutting sheet metal from the inside of the cut creates a seam that requires additional grinding.

The mechanical guillotine must be made of titanium steel so that there are no bends during metal cutting. Also, a mechanical guillotine can be used to make an even bend in sheet metal.

Since the mechanical guillotine is not driven by electricity, but by a lever-spring system with your own hands, a certain amount of physical strength is required.

Therefore, it is usually used for cutting aluminum sheets with your own hands, rather than high-strength metal. This machine also cuts plastic, cardboard, plexiglass and other sheet materials.

The hydraulic machine is started thanks to a hydraulic cylinder, which is compressed with a pressure from 4 to 120 atmospheres.

By opening, the hydraulic guillotine “forces” the scissors to cut metal sheets. Its main advantage is the accuracy of the cut and cutting of metal of various thicknesses. Typically, a hydraulic guillotine is used in industrial plants.

A pneumatic guillotine, like a hydraulic one, unlike a manual mechanical one, runs on electricity and can cut thicker metals.

Sheet metal cutting is carried out by supplying compressed air using a pneumatic mechanism.

The electromechanical guillotine can have different designs. The cutting is carried out thanks to an electric motor, the operation of which is regulated by the operator or even computer equipment.

The electromechanical guillotine is used for cutting thick metals and is one of the most productive types.

Features of work

Those devices that are designed for cutting metals, mainly sheet type due to a chopping motion, are called guillotines.

In most cases, metal cutting is carried out at industrial enterprises; special-purpose equipment is used for this.

The need for cutting sheet metal may also arise for home craftsmen who are accustomed to doing all the housework with their own hands.

In this case, special manual guillotine metal shears are used for cutting sheet metal, which can be seen in the photo below.

In addition, you can assemble a special unit for cutting metal. This simplified device consists of a sharpened blade, which is driven by a lever that is firmly attached to its base.

In order to cut metal using such a unit, it must be laid on the frame and the blade must be set in motion with a smooth movement. If you assemble it according to all the rules, you can cut metal with great precision.

Manual guillotines, together with metal shears, are used in their work by roofers, who use these tools to cut the necessary blanks from the roofing material.

The operation of hand-held devices for cutting metal is somewhat similar to devices that are used in the printing industry for cutting paper and cardboard.

Such units are compact in size and do not require electrical energy to operate.

It should be noted that repair of guillotine shears, if necessary, can be carried out on your own.

Automatic guillotines, which are mainly used in industrial enterprises, have a more complex design.

The scheme of their operation is vaguely reminiscent of the functioning of manual units, but the functionality is several times greater.

Making a manual guillotine in the video below.

Guillotines with hydraulic and electric drives, as well as crank devices, can be distinguished. All these units differ from each other in design, and also have both advantages and disadvantages.

DIY metal cutting machine

Metal cutting can be done not only in production.

If there is a need to cut sheets of metal, for example, sheets of profile aluminum, and obtain an even and smooth cut, then a manual guillotine cutter can be made independently.

The main element of such a machine is a screw press clamp, to which a cutting tool is connected.

The steel supporting base of the press must be at least 10 millimeters. In order to secure the lower knife and table to the base, grooves are made in it with a drill for shaped bolts.

Guide tubes are put on these bolts and welded to the base. The upper knife, or rather its blade, must be made of tool steel.

Attach it with your own hands to the heads of the shaped bolts and the reinforcing cradle. The lower knife is attached to the base using five bolts.

The material from which the table and press lid are made can be ten-millimeter plywood, textolite, fiberglass.

The protruding parts of the tie rods, which are secured with nuts in the stack, must be flush with the base.

The cutter must be stable, and to ensure cutting accuracy, a ruler is glued to the press table strictly perpendicular to the edge of the lower knife.

The machine, assembled with your own hands, works as follows.

A sheet of aluminum or other sheet metal should be placed on a pull-out table and pressed against a ruler. Fix it with your own hands, tightening the nuts on the tie rods of the press, and activate the upper knife using the nuts.

Cost of cutting services

When the need arises to use a guillotine, you can make it yourself or purchase a ready-made one.

Read also: IP44 protection level of the lamp

The simplest version of a ready-made cutter is a stationary manual guillotine, costing approximately ten thousand rubles.

However, its disadvantage is that a manual machine can cut sheet metal up to 7 mm in thickness. Therefore, it is more often used for cutting aluminum.

Profile aluminum sheets have been the most popular material in construction lately; its price is not high, it is easy to use, but often requires cutting.

Manufacturers whose hand guillotines are of high quality include Stalex and Say-Mak. The Far Eastern company Papsher produces scissors for private use; their range includes not only manual, but also electromechanical guillotine. The price of devices on the Russian market is affordable for the average buyer.

Unfortunately, the electromechanical guillotine, which is used not in production, but in home construction, although it has a maximum pressing force of 1400 Joules, the electromechanical guillotine will not be able to cut steel.

Cutting steel sheets with your own hands is only possible using the hydraulic type.

For metal cutting services, you can contact any metalworking enterprise. This is a relatively cheap cutting method, in which the cut areas must be polished with a special grinding disc.

If you still decide to buy a guillotine rather than seek services, we recommend purchasing an imported machine due to its higher quality.

For example, the Bosh company offers high-quality knives, the functionality of which is quite large, their price is also high, but at the same time their service life exceeds the service life of analogues by 4-7 times.

Another important property is that the manufacturer creates diamond-coated knives, which allows the cutter not to become dull for a long time (about ten cuts).