Reamer refers to tools for finishing pre-drilled or countersunk holes. The operation allows obtaining geometric parameters, dimensional accuracy and high-class surface roughness.

Reamers are a more precise tool than twist drills or countersinks. Due to the precision of tool manufacturing and the small allowance removed during processing, inaccuracies and deviations after previous processing are eliminated.

Depending on the type of hole, processing conditions, and requirements for the quality of the finished surface, reamers of different types and designs are used.

Operating principle

The use of a reamer makes it possible to obtain internal surfaces with an accuracy grade of 6-9 and a roughness Ra of 0.32–1.25 microns. High-class characteristics are achieved due to the design of the tool with a large number of cutting edges, which can be from 4 to 14 pieces.

The quality of processing when performing a deployment operation is determined by a set of factors:

Surface roughness classes

- The size of the allowance removed during processing;

- Machine cutting conditions;

- Quality of workmanship and sharpening;

- Features of geometry and design;

- Type of material being processed.

The deployment process goes like this. A cutting tool of the required diameter is brought to the edge of the hole. Then it receives a cutting movement, which, with manual and mechanical feed, consists of rotation of the tool and feed along the axis of the hole.

The amount of allowance in tenths or hundredths of a millimeter is the difference between the diameter of the hole and the selected tool.

Cylindrical and conical holes are processed by reaming using hand and machine tools of the appropriate shape.

Reamer is a cutting tool that is needed for finishing holes

Machine reamers

The emergence of various machines can significantly increase labor productivity. A drilling machine with a low spindle speed allows you to produce high-quality holes in less time. GOST also defines the classification of tools according to a fairly large number of different characteristics. The cylindrical machine reamer is characterized by the following features:

- The tool has a large number of cutting edges. It is worth considering that as this indicator increases, the quality of the surface significantly improves.

- In the manufacture of the cutting part, carbide metals are used that can withstand high temperatures.

- The cutting part can be quite long.

Conical reamers

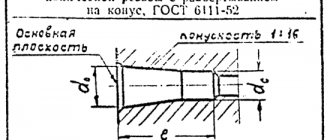

There is also a machine conical reamer, which is designed for use on machine tools. Machine deployment is performed when high performance is required. It is worth considering that due to the large number of cutting edges, it is important to accurately regulate the rotation speed.

In the manufacture of tools, special high-speed steel is used, which can withstand prolonged mechanical stress and temperature changes. Due to the special shank, the tool can be mounted in various equipment for machine tools.

Description of design

In most designs, the reamer looks like an oblong pin. Its working part is cylindrical or conical, with longitudinally running cutting edges for removing metal, and grooves that form the structure of the tooth. The opposite part is used to secure the tool and transmit the cutting motion. The end of the shank has a square or tapered shank. A transition neck connects the working part and the shank.

Floating chuck for fastening reamers

The tool is mounted with a shank in the conical chuck of a metal-cutting machine, and a wrench is put on the square for manual processing.

The cutting edges of the working part are divided into several zones. The first is the fence part, it is conical in shape and short in length. Behind it there is a guide and calibrating section, at the end there is a reverse cone to prevent jamming.

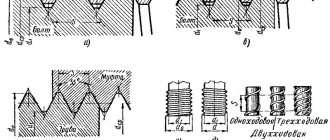

The teeth are straight, helical and spiral. Only in some cases the cutting edges follow the helix. Their use is justified when cutting intermittent holes.

The form-building structure of the tool is clearly visible in cross section.

In cross section, the structure of the working area consists of:

- Cutting edges;

- Ribbons;

- The front cutting surface along which chips flow;

- Posterior surface and back of the head.

The tooth shape is different in the sampling and calibrating parts. On the intake section it is sharpened, and on the calibrating section it has a ribbon for smoothing the walls.

A reamer, like a countersink, consists of a working part, a neck and a shank

Manual reamers

Manual reamers

It should be taken into account that manual cylindrical reaming differs significantly from machine reaming. By doing the work manually, high precision can be achieved. When choosing a product, pay attention to the following points:

- Type of cutting part.

- Caliber.

- Number of teeth and uniformity of distribution.

- Groove profile.

- Clamping configuration.

Manual conical reamers are widely used. Hand tools are characterized by their relatively low cost. At the same time, they can be called a universal version. There is a version available with a smooth guide diameter. In addition, the spiral reamer gradually removes the remaining allowance, thereby improving the quality of the surface.

The hand tool has a cylindrical shape. The features include the following points:

- The cutting teeth have sharp edges along their entire length. Due to this, work efficiency can be significantly increased.

- The diameter of the working part can vary from 3 to 58 mm. In this case, the step is about 1 mm. In addition, hand tools are produced in increments of 3.5; 4.5; or other fractional indicators.

- You can also purchase special sets that are presented with a combination of tools of various diameters. Due to this, there are no problems with processing holes of different diameters.

- A distinctive feature is that the shank must fit the collar. This part is designed to transmit rotation and force. For such fastening, the shank must have a square cross-section of the conical part.

- The front surface of the working part of the hand tool has a smaller diameter than the cross-sectional diameter of the main part. This ensures easier entry of the tool into a pre-prepared hole.

- You can increase the quality of the resulting surface by purchasing and using a tool with a large number of cutting edges.

In the manufacture of the main part of the tool, various metals can be used. As a rule, they are characterized by fairly high hardness and wear resistance, but are not designed to work at high cutting speeds.

Main types

Taking into account the thickness of the layer being removed, processing is carried out with one tool, or a set of rough and finishing reamer, and sometimes semi-finish. The tool for preliminary and finishing processing differs in the type of cutting blades and their number. There are teeth or projections along the tooth line of the rough and semi-finish reamers.

The standard provides for the classification of scan types according to the following criteria:

- Type of hole being machined – cylindrical and conical;

- Type of processing (roughing, finishing);

- Tool fixation method;

- Cutting edge design;

- Teeth arrangement;

- Adjustable for processing size;

- Material for production.

GOST 1672-80 sets out the standards for the manufacture of conical reamers that form precise conical holes. Existing models allow processing cones for the following purposes:

Development GOST 1672-80

- For subsequent cutting of tapered threads;

- For installation of conical pins;

- For installation of metric cone;

- Mating hole “Morse taper”;

- For a standard range of tapers 1:20, 1:30 and others.

The regulatory document regulates the geometry of conical reamers, roughness, permissible dimensional deviations and accuracy class of holes obtained after machining.

Metal-cutting tools for deployment are divided into 2 large groups: manual and machine. Machine reamers are used in drilling, turning and boring machines.

There are visible differences between the groups. Hand tools - with longer working edges and square. Machine ones - with a shortened working part and a long belt. They are mounted in holders that are mounted in the spindle.

Manual

Reamers are produced in accordance with GOST 7722-77 with a size range of 3-58 mm with a design step of 1 mm and 0.5 mm up to a diameter of 15.5 mm. A set with a wide range of diameters allows you to machine a wide variety of holes in parts.

Reaming with a hand tool is accomplished by using a crank to secure and impart the cutting motion. The connection to the knob is made through a square section on the edge of the shank and a groove of the appropriate size.

Manual sweep begins with the work area and approach. The entry part is made at an angle to the axis and has a smaller initial diameter at the edge. The shallow chamfer section makes it easier to position and cut into the stock.

Machine

For unfolding by machine tools, metal-cutting machines with a conical chuck in which the tail part is fixed are used. Taper shanks are normalized and the number of taper used is related to the diameter of the reamer. Such a cutting tool is made in one piece from high-speed steel.

Several reaming options are available. The design and geometry are determined by GOST 1672-80.

Machine scans are:

- With cylindrical and conical shank shape;

- Mounted type;

- With replaceable or adjustable knives;

- With soldered plates.

Machine scan

Adjustable

Adjustable reamers allow you to change the outer size of the cutting head to suit a specific hole diameter. This is especially necessary if the processing diameter is not a whole number, but a fractional one, for example, Ø15.3 mm or Ø 10.75 mm.

Adjustable rack reamer 10.0-10.5 mm

The small diameter tool allows you to adjust the processing size within 1 mm. For larger diameters, a wider setting of 1-3 mm is possible.

In such reamers, replaceable high-speed steel knives are installed, which are fixed by wedge inserts with linings. The dial head is secured with two nuts. After loosening the locknut, the knives are set to the processing diameter, measured using a caliper and micrometer, and secured again.

When the adjusting nut is tightened, the knives move upward, thereby increasing the diameter of the tool. By loosening the nut it is possible to reduce the size. For convenience, when setting up, the processing tool is held by the square.

Expanding reamers

Expanding reamers - description

Due to their design features, reamers are called expansion reamers. The principle of adjusting the expansion reamer is based on the movement of the ball and screw. When the screw rotates from the bottom side, the ball moves and pushes the edges apart. They diverge from the center and the outer size increases.

The control limit for such a tool is smaller. It is 0.15-0.5 mm and depends on the size of the scan. It is recommended to control the adjustment force to avoid damage to the housing.

In the production of reamers, tool and high-speed steel are used - 9ХС, Р6М5, Р18, Р6М5. In tool catalogs of foreign companies, the material is designated HSS.

Practical guidelines for drilling holes

It is better to divide the boring operation into several stages: roughing and finishing. The allowance is divided accordingly and tools of two categories are used:

Reaming holes - process

- The allowance for a rough pass is 0.1-0.15 mm, for a finishing pass – 0.1-0.05 mm.

- To increase processing efficiency, the adjacent end surface is ground. The procedure allows you to use each tooth of the reamer during processing.

- For cast iron parts, the end of the hole must be machined so that the tool does not become dull.

- A clean deployment operation requires smooth execution. The smaller the feed, the better the quality of the surface. The speed is set to low.

- The metal-cutting tool is removed from the hole smoothly, avoiding rotation in the opposite direction, which can disturb the surface.

- The use of coolant will help improve the durability of the working element and the quality of processing. When deploying steel parts, coolant with the addition of oil is supplied to the cutting zone.

- Cast iron is processed using kerosene or compressed air.

To control the accuracy of finished holes, smooth plug gauges and bore gauges are used.

Reamers fall into the category of precision and expensive instruments. Requires compliance with operating and storage conditions in special wooden cells.

Application of sweeps

It is almost impossible to achieve high precision and surface quality when using a conventional drill. This is due to the peculiarities of the working part, which has a relatively small number of cutting edges. The use of the products in question can significantly improve the quality of the hole and bring all indicators to the required levels. The scope of application of the tool is extensive:

- Mechanical engineering industry.

- Production of precision products.

- Manufacturing of household appliances and various electronics.

- Machine tool industry.

Note that the wrench used is suitable for various hand tools. In addition, the machine-type product is suitable for almost all cartridges and can be used when performing intermediate operations.

In conclusion, we note that preference should be given exclusively to products from well-known manufacturers. This can be attributed to the fact that they guarantee high quality production and a long service life of the product. However, due to quality control at each stage of production and the use of high-quality materials, the cost of the product increases significantly.