For modern craftsmen, the need to create holes is a task whose implementation is not difficult. Moreover, the diameter of the hole does not matter. Nowadays, there are drilling tools that can handle even such durable materials as steel and reinforced concrete. All you need is to choose quality equipment and the right tool for the job.

To effectively drill metal sheets, metal crowns are used. Especially if they are made of carbide material. Due to the fact that metal crowns have a special shape and structure, they can be used to quickly and efficiently make the required number of holes.

Operating principles of metal crowns

People who have never used metal drills often make mistakes that quickly cause the equipment to fail. To prevent this and increase the durability of the crown, you need to consider some recommendations:

Drilling metal workpieces:

You need to leave free space under the metal workpiece so that the nozzle can pass through. It is important to keep the work area free of metal shavings. To do this, the nozzle is quickly raised and cleaned with a quick rotation.

Using metal crowns, you can drill through holes of different diameters in metal workpieces. This equipment is suitable for working with different types of metals. In order for the attachments to last longer, you need to take into account the recommendations of specialists when working with them.

Source

Plastic dental crowns

Sometimes in our country, where there are no standards of treatment, they are used as permanent crowns. Although all over the world, according to all standards, they can only be used as temporary (the wearing period, depending on the manufacturing technology, is from several days to several months). Why? Plastic is a fairly soft material and wears out quickly. The surface is unstable to mechanical and chemical influences - it quickly loses its appearance, is stained with food dyes, becomes unsmooth, promoting increased accumulation of soft plaque, causing bad breath. Both bridges and single crowns can easily break due to the fragility of the plastic. The marginal fit of such crowns to the tooth is quickly disrupted - accordingly, caries easily develops already under the crown. In general, wherever you spit, there are continuous disadvantages. The advantages are simplicity and low cost of production, acceptable appearance (although mostly only at the very beginning of wearing them). These advantages determine their widespread use as temporary restorations.

Plastic dental crowns - white, fast, cheap... but not for long

Metal crowns

I want to buy a set of metal crowns, but not fake ones. Who can advise? Only Bosh saw it live. The task is to drill steel sheets of different thicknesses, say up to 10-15 mm.

I would also like to know the diameter of the holes.

*Boston* wrote: I would also like to know the diameter of the holes.

And the laser is absolutely beautiful

, however, about two hundred rubles per hole Here is a similar topic: ">

No, a blaster is not the issue. Often you need to make holes on the finished product; you can’t slip it in and bring it under the laser.

It’s just that the author’s tasks are somewhat vague

*Boston* wrote: I would also like to know the diameter of the holes.

It is difficult to drill 15 mm steel with bi-metal bits. There are many chances that they will simply burn out and lose their working condition, so to speak.

taels wrote: It’s just that the author’s tasks are somewhat vague

sizes from minimum to 60mm, but I haven’t heard anything about what you can take

.

akm2000 wrote: but I haven’t heard anything about what you can take

Didn't you hear, or didn't want to hear?

taels wrote: Didn't you hear, or didn't want to hear?

I heard only this was said like take what you want from these. I would like detailed reviews from users about what they drilled, how it drills, how long it lasts.

akm2000 wrote: I would like detailed reviews from users about what they drilled, how it drills, how long it lasts

I can say about Bosch and Bacho - they are good, durable. They work for me on installing locks on steel doors. Over 3 mm. we try not to drill with them, we take care of them. We drill slowly, and with cooling. I can’t say exactly how much is enough, but we rarely change them. I don’t take others yet, following the well-known proverb: good is not sought from good. But I don’t think that Irwin or Ruko were worse, they all had 8% cobalt additives. As for your desire to drill 10-15 mm in steel, I would not recommend all of the above, here you need to look towards carbide alloys, but this is not cheap.

Source

Metal dental crowns

Here it must be said that metal dental crowns can be made using two completely different methods.

A) Stamped dental crowns

They are made from standard materials (stainless steel, in rarer cases gold). In our country they are still used, unfortunately, and are also very fashionable to this day in the countries of Asia closest to us.

If you do not plan to settle in an African-American ghetto or in the Asian countries of the former USSR, then such a smile is unlikely to evoke admiring glances from others...

Throughout the civilized world, our person can easily be identified using such “fixes”. In fact, the place of this technology has long been in the museums of medical universities and students should study it not in the cycle of orthopedic dentistry (as is still the case), but exclusively within the framework of such a useful subject as the “history of medicine”. I will therefore not dwell on these dental crowns in detail. The technology is the simplest (a technician cuts a metal cylinder blank to the required length and, tapping it with a hammer, brings the shape closer to the semblance of a tooth), the cost is a pittance. For the same amount of money you get the same kind of treatment.

Minuses:

- complete absence of any aesthetics (although some residents of the above-mentioned countries could argue with me in this place);

— the edge of the crown hangs between the tooth and the gum, being an excellent tool for accumulating food reserves for a rainy day, causing chronic inflammation of the gums, circular caries, giving the breath a corresponding aroma;

— inability to create a normal anatomical shape; most often, such crowns have an absolutely flat chewing surface, worsening the chewing process and causing problems in the temporomandibular joints;

- the thin walls of such crowns often wear out and rub through, leading to the destruction of the tooth underneath by caries...

I think this is quite enough.

This photo shows stamped dental crowns coated with “gold” titanium nitride. Spraying itself is a carcinogen and is prohibited for use in civilized countries. Here you can clearly see the condition of the crowns themselves and the surrounding tissues after several years of wear. Oddly enough, a crown that has not fallen out for many years does not mean quality treatment. Here you can see what is happening around the crown...

... and here's what's happening underneath. The teeth are completely rotten and cannot be replaced with prosthetics.

An example of a single stamped dental crown without coating...

... and a whole bridge. Such flat chewing surfaces without a pronounced anatomical relief lead to numerous problems that are not always easy to treat. This is especially true for diseases of the temporomandibular joint.

Pros:

— it would be unfair not to mention at least some advantages. If you show the miracles of tolerance, then I can hardly squeeze out two - low cost, minimal processing of tooth tissue. That's it, let's forget about them.

B) Cast metal dental crowns

This is a more modern option, which is widely used in modern dentistry and has a right to life. The technology for making a cast dental crown involves the entire standard sequence (this is discussed in the first part of how dental crowns are installed): processing a tooth with a ledge, taking an impression, casting a model, modeling the crown from wax and melting the wax blank into metal. If all stages are properly completed by the dentist and technician, the result is a crown that fits exactly to the tooth and well reproduces its anatomical shape. It can be made from a conventional alloy (most often KHS - cobalt-chromium alloy) or from a precious alloy, which is certainly better.

Cast metal crowns function at the proper level, are durable and reliable. Therefore, if you are not embarrassed by the prospect of sending sunbeams into the eyes of your interlocutor with your teeth when smiling in clear weather, then you can completely opt for them...

Minuses:

- extremely low aesthetics, although the lateral teeth, which are not so noticeable when smiling and communicating (especially the upper ones), can well be restored with just such crowns

— allergic reactions to metal (especially ordinary alloy) are possible

Pros:

- high wear resistance

- relatively low price

Ring crown for metal: technical features and method of application

Metal is a material that has recently significantly expanded its scope of application. More recently, it was associated with frames, floors, and rigid dimensional structures. Today, metal shelves, tables, and decorative elements decorate the interiors of many homes.

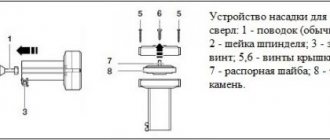

Core drills used for machining metal products are also known as annular cutters.

It is easy to cut a pipe, angle, or sheet using a metal saw blade. To connect workpieces into a structure, most often it is necessary to make a hole, which is made in the metal with an annular cutter - a crown. The crown design consists of the following elements:

About the selection rules

Crowns, which are made of fast-cutting steel, are characterized by increased elasticity. Therefore, they are used for processing steel alloys that are not very strong. Of course, if the hole diameter does not exceed 35 millimeters. At the same time, the special design of the crowns allows you to avoid frequent breakages.

In other words, if you need to process a durable steel part in the form of a hole that is larger than 35 millimeters, then you will need crowns equipped with carbide tips. Such attachments have a significantly increased working life. Especially when compared with conventional metal cutting tools.

Another important criterion that must be taken into account during the selection process is the geometry of the processed products. The characteristics of the material from which these products were made are also important. You need to understand that products of different thicknesses and different metals require different nozzles.

Financial Benefits and Empowerment: Metal Core Sets

If the question arises of choosing a crown for making holes in metal, it means that a lot of things in the house are done with your own hands. What should you decide on: buy an attachment for a specific single purpose or buy a set, looking into the future and anticipating the need? In case of an uncharacteristic isolated case, it is worth focusing on a separate product. Moreover, it would be useful to weigh and calculate what quality is worth paying attention to.

Even for a non-professional who wants to have a certain arsenal of household tools, it is better to prefer a set of metal bits for a drill. Advantages of purchasing this kit:

A set of crowns costs significantly less than attachments purchased separately

If you try to estimate the financial benefits of purchasing a set, the calculation will be approximately as follows: the price of a 40 mm metal crown “Anchor” is 270 rubles, a set of 5 similar cutters from this manufacturer costs 760 rubles. The price of one nozzle (on average) is almost two times less.

Sets of crowns for metal can consist of 5, 8, 10, 12, 13 units.

Helpful advice! When purchasing a set of metal crowns, you need to pay attention to the presence of a centering drill in the kit. Its absence will not allow the nozzle to be installed exactly in the center on the surface of the material.

About parameters and characteristics

The most important characteristic of crowns is their diameter. The size of the future hole, obtained using a drill or other drilling tool, depends on this. In addition, other equipment parameters depend on the diameter. For example, this directly affects the type of fixation and the length of the shank.

According to the standard, the diameter of the crowns can range from 1.4 to 18 millimeters. As for the drilling depth, it can reach 40 millimeters. This value is the maximum for all types of crowns. During the selection process, you should pay attention to whether the crown comes with a centering element, that is, a drill. With its help, you can make cuts with maximum precision without any deviations.

In most cases, crowns for metal are made from combined materials. In other words, carbide steel can be used to create the base of the supporting cylinder. But the main working surface is usually made of pobedite.

Universal mobile installation: magnetic drilling machine

A magnetic drilling machine is one of those devices that, despite their simple design, are highly efficient and cost-effective. Compared to a stationary drilling rig, it has a number of advantages:

Magnetic drilling machines are designed for drilling, milling and threading in metal workpieces

On a stationary machine, it is possible to make only small holes, since the distance between the crown and the working surface does not make it possible to place large workpieces. The magnetic device can be fixed to any metal plane using a special sole.

Such machines have different functional purposes. Using a 32 mm metal crown (and bits of smaller diameters) you can make a hole in thin material. Circular cutters from 50 to 150 mm with a reinforced design are used for thicker metal materials.

Related article:

Wood crown. Device and principle of operation. Types of hole saws. Features of operation of nozzles of various diameters. Bosh crowns, “Bison”, “Enkor”.

The magnetic part of the machines is quite powerful, it reaches 26 kN. This allows you to install the tool not only horizontally, but also at an angle, even vertically. If the surface is not level enough, the magnetic field does not reach the required value, additional clamps are used to secure the machine.

Magnetic drilling machines are more often used to make holes in large structures, so metal crowns of 50 mm or more are the most common attachments for such devices.

A proven, reliable tool: Bosch metal drill bits

One of the most popular are Bosch metal crowns. Most of the products produced by this company are bimetallic, that is, made of two types of metal: the body is made of high-speed steel, and the teeth are soldered and have a slightly different composition, which includes cobalt.

The diameter of the nozzles is very different, but the step is equal to one inch: the minimum size is 9/16, that is, 14 mm, the maximum is 6, which corresponds to 152 mm. Some sizes may not be found in the Bosch crown line.

Bosch models have a standard fit of 1/2 or 5/8 inch, so the bits are compatible with many types of power tools. The Power Change adapter is used as an adapter. Replacing the annular cutter is not difficult and does not take long; to do this, remove the outer race - the adapter will push the crown out.

It is very important to maintain the required number of revolutions. A 29 mm nozzle requires a frequency of 400 rpm, and a 40 mm metal bit requires 200 rpm. These requirements significantly extend the service life of the nozzles.

As for the price of Bosch annular cutters for metal, it should be classified as moderate. A crown of medium diameter (38 mm) will cost about 800 rubles. Although the cost of individual products may exceed this figure. This company also offers sets of hole saws. A set of 11 bimetallic products costs an average of 8,000 rubles.

Marking of annular drills

Each product has a marking that is indicated on the packaging or design of the device. From the manufacturer's markings you can find out the following information about the product:

- Manufacturer of the product. Branded companies are required to indicate their names based on the devices

- Device material. Based on the material, you can determine what the device is intended for: wood, concrete or metal

- Geometric parameters. The digital designation indicates which holes can be drilled with attachments

Karnash brand annular cutters are available in different series or lines. Each series is intended for certain types of metals:

- Gold Line. For manufacturing, high-speed steel with a wear-resistant coating is used. Suitable for metal materials with a thickness of no more than 2 cm

- Hard Line. The cutting teeth are made of carbide plates. Suitable for metal materials with a thickness of 2 cm or more

- Real Line. For manufacturing, carbide inserts with multi-stage tooth sharpening are used. With their help you can drill railway rails

- Blue Line. Allows you to drill hardened railway rails, cast iron products, as well as aluminum and stainless steels

Metal crown: tips for proper use

Almost all new instruments have an attractive appearance. On the pages of online stores you can find a meaningful description of the product, sometimes even supported by positive customer reviews. In order not to be disappointed with the purchase, you need to seriously study the capabilities of the tool. You can evaluate core drills for metal in the following order.

With the correct selection and use of crowns, a hole in metal can be made in a matter of seconds. The tool is applicable for various household and industrial purposes. Compliance with technical requirements can extend the service life for a long time. Conversely, one thoughtless use can cause defects that will make the crown unsuitable for use.

Source

Metal-plastic dental crowns

Another type of technology unclaimed by modern dentistry. As you might guess, it combines a metal frame and a plastic cladding (full or only on the outside). The metal frame can also be stamped or cast. This technology combines all the advantages and disadvantages of those already mentioned. The only special drawback is that the metal and plastic do not have any chemical bond, and therefore the adhesion strength is very low. From here, the plastic cladding often flies off, leaving bare metal underneath. It can only be properly used for making temporary crowns for long-term wear (several months).

Metal-plastic stamped dental crowns…

Metal-plastic cast crowns... The lack of a chemical bond between plastic and metal leads to frequent chipping of the veneer

Crowns for a hammer drill - how to choose and how to work so as not to “ruin” the crown.

Many people have encountered the problem of drilling large diameter holes in concrete or brick, usually over 30 mm. The drill bits suitable for a regular hammer drill are a maximum of 26 mm, so you can’t drill any more with them. What then should you do if you need a hole, for example, 50 mm?

Most often, the need for large holes arises when laying pipes through a wall or when you need to make a hole for an outlet.

In such work we will be helped by a drill bit, the main purpose of which is to make large diameter holes in brick and concrete.

The crown is made of metal, at the base of which we see carbide plates made of Pobedit (hard alloy VK8), with which, in fact, the hole is drilled. Crowns come in different sizes, but the range of work is very wide. The minimum diameter is 35 mm and goes up to very large diameters of 110 and 120 mm.

Most often, a home craftsman needs to drill a hole for sockets; when installing wiring into the wall, special boxes are placed for the wires. What size crown is needed for rosettes? It all depends on the size of the box; most often a 68 mm crown is used, a little less often 70 and 75 mm.

SDS+ or SDS MAX?

Since we are talking about bits for a regular home hammer drill, the shank has an SDS+ (plus) connector. Of course, when you need to drill a very large hole with a diameter of 120 mm, you need a more powerful hammer drill, preferably with an SDS Max connector. Both types of shanks are shown in the photo, the one that is thicker (upper) is the SDS Max:

In order to install a crown on such a hammer drill, it will be enough to buy a special shank with the same connector. Having purchased it, you remove the standard SDS+ shank from the crown and install another one. The thread on the crown is standard, so the shanks can be interchanged.

Correct drilling technique

First, a couple of important tips:

- Since the crown consists of carbide tipped teeth, the use of the impact function is IMPOSSIBLE! The soldering joints are very sensitive to shock. So, if you use a crown, turn off the impact!

- Next, the hard alloy is very sensitive to overheating, so let the crown cool down after 1-2 “holes”. This will extend the life of the tool.

Sometimes it becomes necessary to make a deep hole, for example, 30 centimeters long and also large in diameter, from 30-40 mm and above. It’s simple, also use a crown, although you’ll have to buy a special extended shank; they come in different lengths, starting from 300 mm and more.