Angle grinder (grinder) MAKITA GA4530 without soft start. Photo 220Volt

When buying a cheap angle grinder, it will probably not have a soft start option . During startup, especially with a powerful angle grinder, you can feel all the “delights” of the jerk that the grinder produces when turned on. If you have a soft starter, the power tool will begin to do its job in a comfortable environment for the user . Undoubtedly, an angle grinder with this option costs more. However, it is possible to install a soft starter on the angle grinder yourself. This will solve the issues of saving money and will facilitate further operation - a device made by yourself is easier to repair if it fails.

Device

In grinders without a soft start, the windings of the commutator motor are immediately supplied with a 220 V mains voltage , and to bring it into working condition an increased starting current is required. The soft starter ensures a gradual increase in voltage and, accordingly, the current during startup also does not increase abruptly.

This starting mode can be achieved using a special electronic circuit . Its main component is a semiconductor chip , which controls another, more powerful semiconductor device, a triac, which supplies power to the electric drive of the angle grinder. The thyristors of the microcircuit operate with a delay in the supply voltage until the circuit capacitor is fully charged. The principle of operation of the microcircuit is successfully combined with ensuring a smooth start of angle grinders.

Microcircuits k1182, LM358

The most famous microcircuit for the K1182 soft starter. This microcircuit was created back in Soviet times and now it is not so easy to find. There are other more affordable chips, for example, LM358. Many modern angle grinders use the LM358 chip in the factory version of the device.

LM358 chip

Features and service life

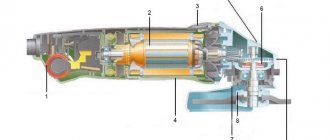

In hand-held power tools, such as an angle grinder, a circular saw, a screwdriver, a drill, commutator motors with sequential excitation are used.

They can operate on direct and alternating current.

To power them, in most cases, a conventional electrical network of 230 V 50 Hz is used. Previously, a 380 V network was used for professional tools. Now, with the increase in consumer power in single-phase networks (offices and residential sector), professional power tools for 220 V have also appeared.

Commutator motors have high torque and starting torque, are compact, and can be easily manufactured for higher voltages. Torque is key here. With the low weight of the machine, it is just suitable for hand-held power tools. But such electric motors have disadvantages and weak points. One of these weak points is the brush assembly.

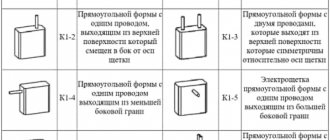

Brushes made of pressed graphite with fillers rub against the copper plates of the commutator and are subject to mechanical wear and electrical erosion. This leads to increased sparking and increases the fire and explosion hazard of the power tool. Ingress of mineral dust will accelerate wear. Although the fans provided in the design blow air outside, dust and cement can easily get inside. During downtime, if the tool is placed poorly, dust can easily get inside. In practice this is a constant occurrence.

Extruded graphite motor brushes

Another disadvantage of power tools is frequent gearbox breakdowns. This happens precisely because of the high starting torque. Advantage turns into disadvantage. If the gearbox breaks down, you have to change the tool; they usually cannot be repaired. Unfortunately, the industry, in an effort to reduce production costs, does so at the expense of quality. If you want to use a good power tool, pay a lot of money.

The last drawback can be effectively combated with a soft start. Many manufacturers do this, but do not always pay enough attention to it. Not all tools have good speed controllers.

Operating principle

The soft start device in a factory-made angle grinder is located inside the angle grinder body and is connected by contacts to the power button and the stator windings of the electric drive. It takes a certain time for the angle grinder to reach its nominal mode, and the electromagnetic field created by the uniformly increasing current and voltage through the stator windings causes the armature of the angle grinder drive to smoothly gain speed.

For grinders where the manufacturer does not provide such a device, usually in very rare cases it is possible to hide it under the body of the grinder. Most often it is performed in the form of a separate block, arranged in a break in the power cable circuit. However, this does not change the principle of operation.

DIY soft start device

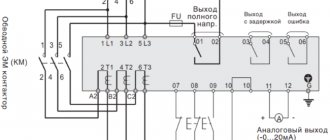

It is worth considering the type of soft start device for an asynchronous electric motor using the KR1182P microcircuit. It is required for a 380 volt three-phase electric motor.

It has some useful features that are worth describing:

- The windings in an electric motor are star connected.

- The output switches are powerful thyristors connected in a parallel-counter circuit.

- Damping circuits are included in the circuit in parallel with the thyristors. Here they are used purposefully. Their main task is to prevent false switching on of thyristors.

- Varistors are necessary to absorb switching noise occurring in the circuit.

a power supply in the circuit , which consists of a rectifier, capacitor and transformer. Such a block is necessary to provide power to the switching relays. After the rectifier bridge, an integral stabilizer at the output . It provides a stable output voltage of 12 volts. Additionally, it is able to provide protection against short circuits and various overloads.

Disadvantages of angle grinders without soft start

Cordless angle grinder Metabo W 18 LTX 125 602174850 with soft start. Photo VseInstruments.ru

In addition to providing comfortable working conditions for the user, the angle grinder with soft start has a number of other advantages.

- The absence of a large starting current during the soft start of the angle grinder , which is several times higher than the nominal value of this parameter during operation, increases the reliability of the electrical part of the power tool. In this case, the winding wires do not experience overloads and do not crack, the commutator lamellas and brushes are not subject to wear from increased sparking, and processes that worsen the connection do not occur at the contact points.

- During a uniform increase in the speed to the nominal value, the angle grinder with a soft start does not experience increased dynamic loads that arise in its absence. An instantaneous acceleration of 6000 rpm or more does not leave its mark on the gear transmission and bearing units . They fail faster, so angle grinders without such a device are more often repaired.

Start via autotransformer

This method is used by using an autotransformer in the electrical circuit, which is connected in series to the machine. It serves to ensure that startup occurs at a voltage reduced by 50 - 80% of the rated voltage. As a result, the starting current and starting torque will decrease. The time interval for switching from low to full voltage is adjusted.

However, there is a drawback here. During operation, the machine switches to mains voltage, which leads to a sharp jump in current.

How to make a starter unit for a power tool

There are quite a lot of options for independently equipping an angle grinder with a soft start device. Some of them are presented in the author's videos.

Starter unit based on LM358 chip

In the following video, the author shares his experience of independently manufacturing a soft-starter board according to a diagram taken from the Internet, based on the LM358 chip . The author made the housing for the board from a shampoo box, which speaks of the rich imagination of amateur craftsmen. The author did not just blindly copy the circuit from the Internet, but modified it by replacing the characteristics of some of its elements : transistors, diodes, resistors. The radiator for cooling semiconductor devices is taken from a tape recorder. In order to be able to place the soft start unit inside the body of the angle grinder, and not as in the case of the proposed option, a smaller board was developed.

Technology of work on the manufacture of the starting unit

The author of the following video describes in detail the work methods, components used and auxiliary technological materials for the manufacture of a soft starter. the k1182 microcircuit is taken as the basic element . The technology is not designed for use as the basis of a printed circuit board; the author calls such an assembly “surround mounting” technology. In this type of work, in addition to soldering, individual elements are fastened using fasteners, for example, this is how a triac is attached to a heat sink. The ready-made launcher is not universal for all angle grinders. On two angle grinders taken separately by the author, they reached the operating mode in significantly different periods of time.

One of the layout options for a homemade launch unit

As the initial option, the author of the following video chose a well-known assembly with the LM358 chip . Since the assembled starting unit did not fit inside the body of the angle grinder, the author “packed” only a triac with a radiator inside, due to good cooling conditions from the angle grinder’s fan wheel. The rest of the block, together with the microcircuit, was secured to the body of the angle grinder.

Using an iron as an additional load to reduce the speed of an angle grinder

This method does not specifically relate to the topic of soft start of an angle grinder. However, to understand the principle of operation of an electronic device, a dimmer , which is used to adjust the power (or number of revolutions) of an angle grinder, is quite acceptable. In the next video, the iron takes a certain power from the angle grinder, thereby reducing its speed.

The typical starter circuit diagram should be modified for each individual power tool

The author of the following video tells how he equipped his household grinder with a soft start device to increase its service life.

Important: the circuit may work perfectly for adjusting the brightness of the lamp, but for the necessary functioning of the angle grinder, upon startup, be unable to perform the task. To operate effectively, it must be “customized ,” namely, select the required resistor values, capacitor values, and possibly change the characteristics of semiconductor devices.

How to install a standard dimmer in an angle grinder to adjust speed

In the next video, the author modified the power button (made it spring-loaded) in order to use the capabilities of a purchased dimmer to adjust the speed of the angle grinder. After turning on the angle grinder, moving the button sets the required speed mode. The dimmer fixes this mode and when turned on again, it is set.

The disadvantage of small cheap angle grinders is the lack of soft start and speed control. Anyone who has plugged in a powerful electrical appliance has noticed how the brightness of the network lighting drops at that moment. This is due to the fact that powerful electrical appliances consume enormous current at the moment of startup, and accordingly, the voltage in the network sags. The tool itself may fail, especially a Chinese one with unreliable windings.

The soft start system will protect both the network and the tool. There will also be no strong kickback (shock) at the moment of switching on. And the speed regulator will allow you to work for a long time without overloading the tool.

The presented circuit is copied from an industrial design, installed on expensive devices. It can be used not only for an angle grinder, but also for a drill, milling machine, etc., where there is a commutator motor. The circuit is not suitable for asynchronous motors; a frequency converter is required.

First, I drew a printed circuit board for the soft start system, without components for adjusting the speed. This was done on purpose, because... In any case, the regulator must be wired out. Having a diagram, everyone can figure out what to connect where.

In the circuit, the regulating element is a dual operational amplifier LM358, which controls the power triac BTA20-600 through transistor VD1. I didn't get it from the store and installed BTA28 (more powerful). For a tool up to 1 kW, any triac with a voltage of more than 600V and a current of 10-12A is suitable. Because Since the circuit has a soft start, the starting currents will not burn such a triac. During operation, the triac heats up and should be installed on a radiator.

The phenomenon of self-induction is known, which is observed when a circuit with an inductive load is opened. In our circuit, circuit R1-C1 dampens self-induction when the grinder is turned off and protects the triac from breakdown. R1 from 47 to 68 Ohm, power 1-2W. Film capacitor 400V.

Resistor R2 provides current limitation for the low voltage part of the control circuit. This part itself is both a load and, to some extent, a stabilizing link. Thanks to this, after the resistor it is possible not to stabilize the power supply. Although there is a variant of the same circuit with an additional zener diode. I didn't install it because... The supply voltage of the microcircuit is within normal limits.

Possible replacements for low-power transistors are indicated below the diagram.

The regulator is adjusted using multi-turn resistor R14, and the main adjustment is done using resistor R5. The circuit does not allow power adjustment from 0, but only from 30 to 100%. If you need a simpler, powerful regulator from 0, then you can assemble a version that has been proven over the years. True, for an angle grinder, obtaining the minimum power is pointless.

We check the functionality of the circuit by connecting a 220V light bulb with a power of 40-60W. If the brightness is adjustable, then after disconnecting from the network, we check the triac by touch for heat generation. It must remain cold. Next, we connect the board to the grinder and check the smooth start and speed control without load. If everything is in order, we move on to testing under load.

So a cheap grinder turned into a mid-level tool.

Components for assembly

- LM358 can be purchased here

- S9014 can be purchased here

- S9015 can be purchased here

- A set of resistors can be purchased here

- BTA20-600 can be purchased here

How to connect, installation

For users of grinders who do not have electrical installation skills, you can purchase a separately sold soft start unit. You just need to install it correctly. There are two options for placing the starting device - inside the body of the angle grinder and, if not possible, outside.

In the next video, the author placed one of the purchased blocks inside it with the help of a slight modification of the angle grinder body. The two wires of the starting unit are connected according to the following diagram: one wire to the switch contact, the other to the stator winding of the electric drive.

In another video, the author also managed to place the purchased block inside the grinder. However, he chose a different connection scheme - to break the network. In this case, it is not important to consider where to connect the “zero” and where the “phase”.

Application in an angle grinder

When starting an angle grinder (angle grinder), high dynamic loads appear on the tool parts.

Expensive models are equipped with soft starters, but not ordinary varieties, for example, angle grinders. An inertial jerk can tear an angle grinder out of your hands, and this poses a threat to life and health. In addition, when starting the electric motor of the tool, an overload of current occurs and, as a result, wear of the brushes and significant heating of the stator windings, wear out of the gearbox and possible destruction of the cutting disk, which can crack at any time and cause harm to health, and maybe even life. The tool needs to be secured and for this you should make an angle grinder with speed control and soft start with your own hands.

How to check

At home, before assembling an angle grinder with a soft starter, it’s a good idea to check it for an open circuit. The following video tests a three-pin device. Usually there is a connection diagram . There are two network wires here, one goes to the electric drive. If you assemble a circuit with an indicator light and include a starter in it, then you can determine the break in it by the indicator light coming on/not coming on .