Sometimes in a store that sells construction tools, you can see confused people standing in front of a display case with staples for staplers. The thing is that the tool comes with a certain amount of fasteners. When it ends, people go for a new portion, and then they fall into a stupor: it turns out that there are staples of different types and sizes. Moreover, they are made of different metals. Moreover, the staple guns themselves do not work with any type, but only with some of them. In order not to find ourselves in such a situation, we will sort it out.

When going for staples for a stapler, you need to know what type your item handles. This information is on the packaging, duplicated in the instructions (mechanical models do not have instructions) and on the case. Most often, it’s the sticker on the case that saves the day: it’s stuck on properly, and if the inscription isn’t worn out, all the necessary information is there. If you haven’t found anything that your tool can work with, take it with you or remember/write down the name of the model. For experienced sellers this is enough. Another way out is to find information on the Internet. In stores, the technical specifications or description of the model indicate the type of fastener for which the stapler is designed.

The type of fastener with which it works is written on the handle of the tool.

What types of staples are there?

Most use U-shaped brackets. But they are not the only ones. There are also T-shaped and arched ones - in the form of an inverted letter U.

Arc-shaped ones usually work with a special tool, which is designed for fastening wires and thin cables. There are only two types of such staples:

- Type S. Also designated as type 28. Semicircular staples for cables with a diameter of 4.5 mm. Leg height from 9 to 11 mm, thickness from 1.25 mm.

- Type L. Also designated as type 36. The shape is similar, the larger diameter is a bracket for 6 mm cables. The thickness is the same 1.25 mm, and the height of the leg is from 9 to 10 mm.

T-shaped clamps and the tool that works with them are not common: they do not create such a reliable connection, and their scope of use is very limited. The range of U-shaped ones is much larger. They are available in different back lengths/thicknesses and leg heights.

The two most common types

With the length of the leg it is clear: the thicker the material you need to connect, the higher the bracket should be. But in this case, the tool must have high power, otherwise the fasteners will not be completely clogged.

The length of the bracket or back is also more or less clear; if it is desirable for the fastener to be invisible, take narrow products. But not all models work with them either. You need to select a stapler and, most likely, from a professional series.

The width of the bracket is also not difficult: if you are working with durable material, fasteners of a small thickness are sufficient. This is considered 0.75-0.8 mm. For thin and non-woven materials (polyethylene film or vapor barrier), fasteners with a greater thickness are used, most often 1.25 mm, but there are also up to 1.65 mm.

These are the three key types of staples for staplers: 53 or Type A, 53F - Type D, and E or J pin.

Instructions for use

To understand why a furniture stapler bends staples, you need to check whether they are inserted correctly, and also compare the material of the base and the staple. The required fastener characteristics are indicated on the tool label. You need to study it carefully and choose exactly the brackets that are indicated.

If you have taken the necessary staples, but the furniture stapler does not hammer in the staples, there may be several reasons:

- tool malfunction;

- discrepancy between the selected metal and the hardness of the base;

- blunt ends of the staple if there is an obstacle to its entry into the material;

- incorrectly threaded stapler;

- unadjusted instrument.

Before work, you need to make sure that this type of paper clip is suitable in shape and size for the stapler. If these parameters do not match, the tool will not work. The exact description of the required consumables is indicated on the box for the stapler or on a sticker located on the body of the tool.

How to insert staples into each specific stapler is indicated in its instructions. Usually they are located with sharp edges down on a special holder with a spring. It is filled all the way so that the stapler lasts a long time. The exact number of paper clips is indicated in the instructions. It is in the box with the stapler.

If the tool is mechanical, then it needs to adjust the screw regulator (if equipped). The greater the depth of the staple, the tighter the handle should be tightened. Sizes from 10 mm are taken into account.

The adjustment is checked on an inconspicuous place or unnecessary material, identical in properties to the base. The adjustment is carried out gradually, from the minimum position to the maximum. Adjustment is carried out until the bracket enters the base with one blow. Once the tool is set up, it can be used directly on the part.

In order not to make a mistake in the distance from one bracket to another, mark it with a pencil. Some staplers have a lock that allows you to set the desired length between the staples without basting. It is better to insert the staples not parallel to the edge of the sheet, but with an inclination of 45°

To ensure that the edges of the product look neat and do not have to redo the work, the material is held while driving the staples. It is necessary to check after each row that the required number of paper clips is present. When upholstering upholstered furniture, the distance between the fasteners should not be too small to prevent damage to the fabric. It is best to insert paper clips into the fold of the material, which will extend the life of the product.

Safety precautions when working with a stapler require you to put the tool on safety after finishing the work or session. This will prevent injury and damage to the instrument. If you follow these simple rules, working with a stapler will not cause any inconvenience, but will allow you to quickly and easily carry out the necessary repairs.

What metals are they made from?

Staples for staplers are made from different metals:

- Aluminum ones are the cheapest, but it is better not to use them with hard materials or in places of heavy loads: they bend when driven with great force, and can also burst under load. But they don’t rust, which can be important.

- Copper ones attach well to non-rigid materials and certainly don’t rust. But their price limits their distribution. These staples are good under wallpaper or plaster: no drips or rust stains.

- Steel staples for staplers can be hardened or not. Hardened ones are a little more expensive, but much stronger. The disadvantage of both is that they rust.

- Galvanized and stainless steel. This is the most durable and reliable type of fastener. Almost all branded staples from stapler manufacturers fall into this category.

If the legs are sharpened, it’s easier to work and you can set less power

Since the humidity in the bathhouse (steam room and washing room) is very high, you need to use stainless, aluminum or copper staples for the stapler. In those places where the load on the material will be small - when attaching a vapor barrier, for example - you can install aluminum ones, and if you decide to staple the lining with a stapler, then use stainless steel ones. Aluminum ones are not suitable because they have insufficient strength and can be torn out when the wood swells.

With all that, in each group there are options with sharpened legs, and others with unsharpened ones. Working with sharpened ones is faster and easier: they penetrate better and require less impact force. If you are working with a manual staple gun, then sharpened staples will make the job easier. In order for the unsharpened ones to penetrate completely into dense material, you have to apply good pressure on the stapler. If you need to hammer several thousand pieces, this is a significant load.

If you use steel staples, take hardened ones - they are much stronger

As the experts say, buying cheap staples means saving pennies and losing rubles. And all because during driving they bend and break. The result is that you waste time and, accordingly, money - both on finishing off or removing unsuccessfully installed fasteners, and on installing another bracket, which can also bend or break.

Materials for production

Staples for furniture staplers are made from various types of metals. This allows you to select a material with the most suitable properties. There are several main types of metal:

- aluminum is the cheapest material with low rigidity. On a solid frame and when there is a heavy load on the joint, fasteners made of this metal are not used, as they bend and break. But aluminum is resistant to corrosion, which is one of its advantages;

- copper is a soft but corrosion-resistant expensive metal;

- steel - two types of fasteners are produced: hardened and without hardening. The first is higher in strength, but more expensive. Both types are susceptible to corrosion;

- plain stainless steel or zinc-coated - such elements are highly durable and are considered the most popular type of staples.

The choice of metal for staples is carried out taking into account the place of their use and purpose. It is also worth paying attention to the budget allocated for repairs and the cost of materials.

Aluminum

Copper

Steel

Popular types of staples and their sizes

The most popular sizes for construction staplers are 53 and 140. Here are their parameters:

- Type 53: back thickness 0.7 mm, width - 11.3 mm, and depth (leg height) can be 4-14 mm.

- 140 type: it is more rigid, the thickness of the bracket is 1.25 mm, its width is 10.6 mm, the height of the leg is from 6 to 14 mm.

There are many more different sizes, and some stapler manufacturers have staples with the same parameters, but named differently. Some of these designations are shown in the tables below, as well as their sizes.

Types of brackets, their designations from different manufacturers and sizes

Content:

- 1. Features of the tool

- 2. Basic parameters for choosing a stapler

- 3. About useful additions

- 4. Secrets of a successful purchase of a furniture stapler

The law of comfort in the home is simple - furniture should be comfortable and beautiful. Unfortunately, upholstered furniture quickly loses its original appearance compared to wooden furniture - the upholstery gets dirty, worn out, and torn. What to do if this happens to your favorite sofa or chair? It would be a shame to throw it away, because it is so comfortable to sit on. For many, a piece of furniture becomes a faithful friend for decades, so you can give it a chance for a second life - simply replace the upholstery. And you can do it yourself, spending a minimum of money. To do this, just think over a new design, choose the right fabric and arm yourself with a furniture stapler.

How they are sold and prices

Staples for construction staplers are sold in small boxes that can contain 500, 1000, 2000, 3000, 5000 pieces. They are fastened with adhesive film into small blocks. Depending on the magazine capacity, a whole block and/or part of it is inserted - break off a piece of the required length.

Prices vary greatly. From 30 rubles for 1000 pieces of 53 types of the Saturn campaign, up to 212 rubles for the same volume from Bosh. But, as mentioned above, the difference is in the metal from which the staples are made. It feels very good while working.

Staples for a construction stapler - main characteristics and designations from different manufacturers

Tool Features

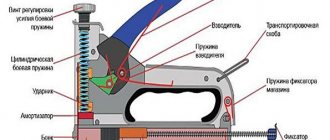

The most rational option would be to buy a mechanical stapler: it is lighter in weight than an electric one, which significantly simplifies the work. In addition, it is independent of the power source. The tool works very simply: a clip of fasteners is loaded into the magazine, the working part is brought to the installation site of the fastener, and when you press the handle, the bracket flies out and plunges into the material. This way you can attach soft upholstery to a wooden frame, or sew together sheets of chipboard or plywood. This is an indispensable tool for a furniture maker, but increasingly it is being used in everyday life. The simple design makes use understandable even for a beginner and eliminates all sorts of breakdowns that often happen with electric and pneumatic analogues due to improper operation. The service life of mechanical devices can reach 6 - 8 years, so the purchase costs will be justified, and the tool will help you out year after year.

Have you decided to buy a furniture stapler for work in your home workshop? Or are you planning to open your own furniture manufacturing and finishing business? In this case, it is necessary to take seriously the issue of choosing a tool that is optimally suited to the volume of work and the upcoming tasks.

A little history

A device for fastening sheet materials is called a stationery stapler . Stitching occurs using a thin wire that pierces several pieces at once. The owner of the first such device was the French king Louis 15 in the 18th century. It was rarely used as a tool; it was more used as a toy.

A century later, when the rapid development of science and industry began, and with it the office, through the efforts of John McGill, who improved this mechanism, the stapler came into use among all bureaucrats in the world.

Raw materials for paper clips

The different purposes of the staples also determine the different materials for the production of these consumables. They must meet various requirements: rigidity, corrosion resistance, etc. Therefore, all brackets are metal.

Aluminum fasteners

These are the cheapest, but at the same time acceptable quality, paper clips. That is why tools using such fasteners are the best-selling. In addition, they do not rust. But other qualities make their use limited in comparison with analogues from other materials.

Secrets of a successful purchase of a furniture stapler

Undoubtedly, all of the above features make the tool convenient to use. But this is far from the last thing you need to pay attention to. It is very important that the tool is durable and easy to store and transport.

If you are going to not only work with a furniture stapler at home, but also transport it, for example, to the country, or carry out field work on reupholstering furniture, a case for storing the tool will be useful. It’s better to buy a model that already comes in a branded case, for example, Pro FIT 32165 or STAYER PROFI 3150-H4_z01 (they also come with a set of fasteners). When you plan to use a tool frequently, preference is given to products with an all-metal body that is resistant to mechanical damage; it can withstand harsh operating conditions and is excellent for working with hard wood. If you need a furniture stapler for infrequent work, for example, decorating, upholstering chairs, banquettes and other furniture made of soft wood or chipboard, you can choose a tool with a plastic body. It is much lighter than metal, so your hand will not get tired from working.

Use the information presented in this article when purchasing a mechanical stapler, and you will make a profitable purchase. If you are already looking at specific instrument models, read reviews about them in the product cards on the website - this information will help you when choosing. You can buy the stapler you like by placing an order on our website or by phone.