Size chart for furniture screws

| Screw size, mm | 5 | 6.3 | 7 |

| d1 (max), thread diameter, mm | 5.0 | 6.3 | 7.0 |

| dk, head diameter, mm | 7.5 | 10 | 10.0 |

| k, head height, mm | 6 | 7–9 | 10 |

| s, turnkey size | 3 | 4 | 4 |

| L, length, mm | 50 | 50 | 50; 70 |

Description

Furniture tie screws are used when assembling cabinet furniture.

The product is also called a confirmat, euroscrew, euroscrew or furniture tie. These screws feature a countersunk head with a hexagonal socket, a smooth threadless part under the head, a blunt end and protruding lower threads. They are designed for cutting threads in a pre-prepared hole, therefore they have a conical shape and are made with serrations.

After installation, Euroscrews are often hidden using decorative plugs, the size of the protrusion of which must match the size of the hexagonal recess in the screw heads.

Installation

Drilling

The drilling depth must be at least 50 mm. In this case, drills with a stepped cutter are best suited, allowing you to immediately chamfer the location of the screw head, or drills with a special working head, which prepares an expanded hole for the neck of the screw and countersinks the place for the head. The best option is to use drills for furniture ties.

The hole must be drilled strictly perpendicularly, and it is advisable to place a piece of chipboard under the part before doing this to avoid chipping at the exit of the hole. When drilling two parts at the same time, they need to be fixed, for which you can use clamps.

Marking

Before installing the tie screw, you need to mark the hole. On the element that will overlap the end of another element of the furniture structure, two types of markings are made:

- drilling depth (5–10 cm);

- the center of the future hole (if the thickness of the joining part is 16 mm, it should be at a distance of 8 mm from the edge of the slab).

The easiest way to mark the markings is to use a special template for drilling holes for confirmation.

Sequencing

The sequence of work operations when disassembling a unit or assembly using a hexagon is as follows:

- A hexagon is selected that completely matches the dimensions of the fasteners being removed.

- The key is inserted into the slot to its full depth.

- In this case, it is preferable to insert the L-shaped key with the short part in order to provide a longer lever.

- A torsional force is exerted on the tool, which should increase until the moment when the screw begins to turn.

Size table: furniture screw-screw

| L/d | 5 | 7 |

| 50 | X | X |

| 70 | X |

You can buy furniture tie-screws and any fasteners wholesale at low prices at the TsKI representative offices in Moscow, St. Petersburg, Samara, Saratov, Pskov, Vyborg, Ufa, Perm, Yekaterinburg and Chelyabinsk.

Modern industry offers a wide selection of the latest accessories for fastening, which significantly facilitate the assembly of furniture products and increase the period of its operation even in the most unfavorable conditions. Among the many types of connecting fittings for furniture, the furniture screw occupies a leading place.

What is it and its purpose

A furniture screw is a special fastener, the main purpose of which is to connect parts made of wood materials by screwing and creating threads inside the product. It is used in the assembly of furniture structures, carpentry and construction products, since such fastening has a positive effect on the quality of furniture, its service life, and aesthetics.

Used for such building materials that are used in the production of cabinet furniture, such as:

- solid wood sheets;

- chipboard;

- fibreboard;

- laminated chipboard;

- plywood;

- thin drywall.

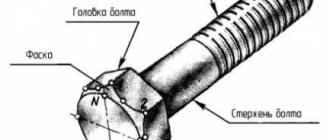

Externally, a furniture screw is a rod made of metal and designed:

- a head of a certain shape, which is part of the fastener and also serves to transmit torque;

- slot - a recess of a certain shape at the end of the hardware head;

- massive, widely protruding thread above the main rod, the lower turns of which are conical and jagged;

- sharp tip.

Thanks to the large thread and rod surface, the stress on the parts to be twisted is minimized. As a result, the assembled structure becomes resistant to any impact. Also, the screws are in close contact with the material being fastened due to the same diameter of the smooth and core parts of the hardware.

In the production of furniture screws, high-quality high-strength carbon steel is used, which, due to its chemical composition and heat treatment, has the necessary set of mechanical characteristics. This allows you to easily remove hardware from the material if it is installed incorrectly. To increase the anti-corrosion properties, the screws are treated with a special composition based on nickel, zinc, and brass.

A furniture screw has advantages and disadvantages. Positive characteristics include:

- reliable and stable fixation;

- the easiest possible installation;

- ability to withstand high fracture loads;

- the ability to connect structural elements one after another;

- tightly tightening furniture parts;

- does not require special skills or complex auxiliary devices.

In addition to the advantages, it is necessary to identify the disadvantages of furniture screws:

- the need to disguise products using a plastic plug in the color of the material;

- Elements connected using hardware cannot be disassembled, since the structure will not withstand repeated assembly.

A furniture screw is responsible for fastening furniture body parts together, fastening shelves, and connecting sections. It determines the reliability of the connection, safety, and the ability to easily disassemble and reassemble furniture without damaging it when moving is necessary.

Coatings used

Furniture fastening fittings are used in the vast majority of cases indoors, which protects them from the harmful influences of the environment. However, all metal elements made of steel subject to corrosion are subject to special treatment:

- Galvanizing gives metal fasteners higher functional and decorative qualities. In most cases it is a white, matte finish, less often – with a golden tint;

- Galvanic brass plating. Unlike galvanizing, this coating provides a more attractive appearance, which is achieved by adding copper to the coating alloy.

The above technologies for applying zinc and copper alloys to fasteners are designed to provide higher performance and decorative qualities. Screw elements made of aluminum are almost never coated with protective compounds, due to the properties of the material from which they are made.

Galvanized

Brass

Varieties

The more popular and popular samples used in the production, assembly, and installation of furniture include:

Also in the furniture industry, a number of characteristic screws are used that have blunt ends, large threads adapted for chipboard, and specific heads. One such product is a galvanized steel screw that allows you to attach chipboard sheets at a 90-degree angle.

Universal screw

The product is presented in the form of a cylinder-shaped rod with various types of heads and external threads. Its main task is to fasten individual assembly elements inside furniture structures. The upper part of this screw can have different shapes:

- the countersunk head of the product, which, after screwing, is completely recessed and does not protrude above the materials being fastened, its scope of application is the installation of shelves, handles, hinges, guide runners for drawers;

- the semi-countersunk head, due to the smooth transition from the rod to the thread, at the moment of twisting, goes into the material, as well as the mating part;

- semicircular head, the horizontal plane and the inner base of the surface of the semicircular head of which, during installation, additionally creates pressure on the material being fastened, increasing the strength of the structural unit, thereby eliminating its deformation.

The presence of a special thread makes it possible to easily attach the screw even to the hardest types of wood. Hardware splines can be simple or cross-shaped. Products with a cross-shaped slot have a number of irrefutable advantages:

- a screwdriver or drill is instantly fixed in the head;

- You only need one screwdriver;

- The installation process in hard-to-reach places is carried out without much effort.

When using universal screws, you must equip yourself with a screwdriver and screwdrivers with replaceable bits. To ensure a high-quality connection of materials, you should drill holes during the process of screwing in the screws, the diameter of which will be 70% of the thickness of the hardware, and also choose the right drill.

Confirmat

These products have another name - Euro-screws, which in modern furniture production are considered a more popular type of fastening and fixing devices, as they are among the most reliable, inexpensive furniture connections. Such products are resistant to mechanical stress and fracture.

Confirmat is used for joining structures made of materials such as wood, chipboard, multi-layer plywood, chipboard. In many cases, screws with dimensions of 5x50 mm and 7x50 mm are used. In addition to fastening parts, euroscrews replace a regular angle, performing a body-forming function, while withstanding all bending loads. To make cabinet furniture look aesthetically pleasing, confirmations are complemented with plugs made of plastic. They disguise a noticeable part of the hat to match the color of the furniture product.

Distinctive features of these fasteners are large threads, a blunt tip, a cylindrical head, and a hexagonal slot. When assembling structures, furniture hexagon screws do not require special skills or specialized equipment.

The screw tie is performed using a hex bit, a screwdriver, a special wrench, or a drill. Products designed to accommodate a Phillips screwdriver should not be used. This technology will not allow the connecting elements to be tightly tightened. As a result, the structure will become loose.

Disassembly using a hexagon

It will not be at all difficult to dismantle the part using a hexagon. It is only important not to violate the safety rules and not to strike the instrument in an attempt to increase its torque.

Shape and dimensions

A furniture screw is the most popular fastening method in the production and assembly of furniture. There are many sizes and shapes of hardware designed to carry out any technological operations associated with the manufacture of furniture products.

The length and diameter of such hardware are determined in millimeters or by number. The ratio of diameter to length varies for each standard, but these differences do not have much practical significance. The number is determined by a number from 1 to 20; the higher the number, the thicker the product. Diameters with numbers 2,3,4,6 are widely used.

GOST regulates the parameters of the product, but products may also have atypical sizes and be produced, for example, to special order. Table of nomenclature of universal screws in millimeters.

| Diameter | 2,5 | 3,0 | 3,5 | 4,0 | 5,0 |

| Length | from 10 to 25 | from 10 to 30 | from 10 to 40 | from 13 to 50 | from 16 to 70 |

The most popular size for furniture is 3 x 16 mm; 3.5 x16 mm; 4.0 x16 mm. The parameters of universal screws are regulated by the following types of GOST.

| GOST 1144-80 | A screw having a semicircular head and characterized by a straight slot |

| GOST 1145-80 | Fasteners that combine a countersunk head and a straight and cross-shaped slot |

| GOST 1146-80 | Product with a semi-countersunk head |

Confirmats for furniture have three main diameters, of which diameter 7.0 is the most commonly used. Nomenclature table for Euro screws in millimeters.

| Diameter | 5,0 | 6,5 | 7,0 |

| Length | 40-50 | 50 | from 40 to 70 |

Table of standard confirmat sizes in millimeters.

| Diameter | 7 |

| Thread diameter | 6,7-7,1 |

| Thread pitch | 3 |

| Body diameter | 4,7 |

| Tip diameter | 4,4-4,5 |

| Diameter of non-threaded part | 3-6 |

| Cap height | 10-12 |

| Cap diameter | 9,5-10,3 |

| Spline depth | 2,7-3,2 |

The screw parameters are individual for each type. The main determining indicators are their length and thickness. Length is the distance between the end and the plane under the cap. This figure is in the range of 6 - 150 mm. The thickness is equal to the diameter of the thread on the outer part of the hardware, and its size ranges from 3.5 to 6 mm. The weight of an individual hardware depends on its parameters and can be in the range of 0.3 - 16.6 g, and the weight of a package containing a thousand pieces will be from 0.26 to 20 kg.

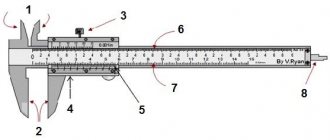

Drill bit for furniture euroscrew

In order to reduce the number of operations and speed up assembly, a special drill for confirmat has been developed. The instrument consists of three parts. The first is intended for drilling part of the hole for threading. The second is for the smooth part of the Euroscrew . The third is for countersinking a cone-shaped recess under the head.

The diameter of the drill for confirmation is determined by the most popular sizes of Euroscrews .

Basic markings

Drills of the following markings are common:

HSS stands for High Speed Tool Steels. It is these steels (domestic grades P18 and P9M5 or a foreign analogue - HSS4341) that are used for the production of drills.

Let's take, for example, the most commonly used Euroscrew 7×50. The diameter of the thread hole for it is 4.7 mm, for the cylindrical part - 6.7 mm. The corresponding drill diameters are 4.5 and 6.5 mm or 5 and 7 mm. For precision hole centering, the tip of the tool is made in the form of a feather. The drill can be either non-separable or composite, which allows for precise adjustment of dimensions.

Device Manufacturers

Tools of this type are produced both by domestic enterprises and by a number of foreign companies. Which manufacturer is better? The cheapest are drills made in China. But Chinese manufacturers often do not respect technological culture. In particular, they use other grades of tool steels rather than high-speed ones.

It must be taken into account that the preparation of holes for Euroscrews is carried out with high-speed tools and in large volumes. This leads to quite strong heating of the instrument. Steel not intended for this purpose is tempered, its hardness decreases. As a result, you have to put in a lot of effort when drilling, which can lead to defects when preparing holes.

Much better tools are produced by the American company DeWalt or the Swiss company Archimedes. However, their cost is 2-3 times more than domestic ones, with quite comparable quality. Therefore, in most cases it is quite enough to purchase a domestic product, for example, produced by the Tula Tool Plant.

How to choose the right one

To select the correct furniture screw, you should consider what material it will be installed in. The choice of head will depend on the force applied and the space available when screwing. It is also important to choose not only the type of head, but also the pattern for the tool used.

With proper selection of bits, a strong grip of the fastening element with the screwing tool is ensured. Only in this case, the screws smoothly and evenly enter wooden boards, drywall, laminated chipboard, MDF.

Some important nuances that will help buyers of fasteners much better navigate their diversity, as well as make the right choice:

- color - screws from the same batch must be in the same color scheme. This indicates that all products have undergone the same processing under similar conditions, and also have the appropriate strength and corrosion resistance;

- parameter - the sizes of one batch of products should not be visually different from each other, and also comply with standards;

- pitch - the load between the threads should be distributed evenly;

- hole - the slot must be clear, symmetrical, and be deep enough;

- marking - the standard designation of screws - is a number in which the first number is the size of the thread diameter, the second is the length of the product from its very head to the sharp tip.

If furniture screws meet the specified criteria, then you can be confident in the quality of the furniture fasteners, which will not break during installation.

In order to efficiently assemble and install furniture elements, you need to use such a convenient, accessible assistant in fastening work as a screw. This type of furniture screed will not only simplify the assembly and installation procedure, but will also be invisible after the installation process is completed, thanks to its unique structure. All structures and foundations fixed with such fasteners will retain their shape, appearance, and properties for a long time.

Set of hexagons of all sizes

Designers of machines and mechanisms use hexagonal splines if increased force must be applied to the fastening element. To quickly achieve the intended effect, installers usually keep many keys of this type ready at once.

Most often, such a tool set contains keys of all main sizes. Purchasing a variety of different tools, including a T-hex, will allow you to use the exact key and screwdriver that exactly match the configuration of the fastener if necessary.

Practical all-rounder

At the same time, you can find a universal hexagon on the market that allows you to install fasteners of many different sizes. This type of wrench is often used to solve locksmith problems, but due to its versatility, it is applicable in almost any industry.

- Repair;

- Assemblies;

- Packaging;

- Tuning.

Video

For the manufacture of furnishings, various elements for connecting parts are used. Self-tapping screws are a popular type of fastener that has its own undeniable advantages. They are especially often used for assembling cabinet furniture, ensuring a sound and durable connection of structural parts.

Self-tapping screws are a popular type of fastener that has its own undeniable advantages.

It is recommended to consult with the seller if you intend to create the furniture yourself.

Self-tapping screws have different types. It is important to select fasteners based on the material and its density, thickness, etc. The selection of self-tapping screws is also influenced by the type of design and the desired appearance of the product.

Self-tapping screws have different types.

Density of abutment and girth

To ensure that the fixation occurs clearly and the tool does not fall off the slot, you must select a wrench attachment that will fit very tightly into the mounting slot. The same principle applies to hexagonal socket heads.

A tight fit will ensure that neither the spline nor the head of the fastener is damaged in any way.

What is a self-tapping screw?

This type of fastener, known as a self-tapping screw, is a type of metal screw with a screw thread and a pointed or flat end. The head of the element has a notch (straight, cross or polygonal) for twisting it into the fabric. To more quickly connect parts of a cabinet or other object, for elements with a sharp end, use a screwdriver (in the absence of a screwdriver).

The selection of self-tapping screws is also influenced by the type of design and the desired appearance of the product.

To connect specific parts, elements with different coatings are used.

Self-tapping screws are used to fasten parts without prepared holes or with them. Due to the thread, the screw is easily screwed into a wooden panel or chipboard. For hidden fastening of furniture parts, an eccentric coupler is used, in which self-tapping screws play a major role. As a result of this type of assembly, tables or other objects are neat, without external traces of installation that spoil the appearance of the product.

This type of fastener, known as a self-tapping screw, is a type of metal screw with a screw thread and a pointed or flat end.

Important! The length of the screws can reach up to 50 mm and above. These fasteners are designed for thick solid wood panels.

The appearance of the product is affected by the possibility of installing a hidden connection.

Why are they needed?

Furniture is assembled in stages, combining different parts into a single piece of furniture. Conventional fasteners are not suitable for such purposes. Ties allow you to connect parts together at the desired angle, maintaining the strength of the connection and the entire structure.

Special furniture fasteners have long replaced traditional self-tapping screws and screws with nuts. Among the advantages of using there are 3 reasons:

- Increased reliability. After disassembly, the interior item does not lose strength.

- Design features. A separate element is used for each detail or type of furniture. Often the use of conventional fasteners is not possible.

- Aesthetics. The screed makes the connection almost invisible. The design looks beautiful and complete.

If nails are used during assembly, the parts may crack or become detached. When installed with self-tapping screws, parts of the furniture delaminate or burst. When the load on the piece of furniture increased, the fasteners came out with “meat”.

Due to the design features, conventional fastenings are not suitable for connecting several cabinets or mezzanines together. The tie helps to twist parts at an angle of any complexity, without reducing the strength of the product. The interior item does not lose stability even with frequent disassembly and transportation.

Why are screeds needed? Source neureiter-shop.at

Types of self-tapping screws

Depending on the material and features of the design parts, there are two types of fastenings:

- with rare carvings and a sharp end;

- confirmations.

Due to the thread, the screw is easily screwed into a wooden panel or chipboard.

The first type is used for solid wood, chipboard, laminated chipboard and MDF. May vary in length and diameter.

Short screws are used to assemble narrow panels and plywood.

Confirmats often have a flat end and therefore require prepared holes.

For your information. Short screws are used to assemble narrow panels and plywood.

The second is used for making furniture mainly from wooden boards of sufficient width. It differs in that at the junction of the thread and the smooth upper part it begins to thicken. Confirmats often have a flat end and therefore require prepared holes.

Confirmats often have a flat end and therefore require prepared holes.

These fasteners are designed for thick solid wood panels.

Selection of hexagon sizes

Hex keys and screwdrivers are produced in one and a half dozen dimensional modifications, which are regulated by the nomenclatures of ISO and ANSI standards. Currently, you can find models of instruments on sale, the working diameter of which ranges from 0.7 to 46 mm.

To effectively use a hexagon, you should choose an option that, in terms of diameter and features of the hand grip, fully corresponds to the tasks of the upcoming assembly or disassembly.

Advantages and disadvantages

For furniture layout, fastenings are of utmost importance. And the appearance of the product is influenced by the possibility of installing a hidden connection.

For furniture layout, fastenings are of utmost importance.

The advantages of self-tapping screws as fasteners are:

- eccentric coupler;

- neat and reliable connection;

- precision in fitting parts.

When purchasing self-tapping screws, it is important to consider many points.

They are especially often used for assembling cabinet furniture, ensuring a sound and durable connection of structural parts.

If a set of self-tapping screws is used to assemble a furniture structure, then if you work with them carelessly, the following is possible:

- distortions of parts;

- loosening of the fastening when screwing in repeatedly.

The base of the screws is steel.

Imbus modification of the instrument

Various modifications of hexagons are used for screwing and disconnecting various fasteners used today.

The imbus hexagon is the most primitive type of this tool. It can be used without hesitation or hesitation to work with any fastener equipped with a six-sided internal spline.

How to choose?

When purchasing self-tapping screws, it is important to consider many points. The base of the screws is steel. To connect specific parts, elements with different coatings are used. When assembling furniture, you must consider:

- length of fastening elements;

- their diameter;

- cap thickness;

- carving;

- degree of corrosion (depending on the coating).

| Thread width and height | Application |

| Rare and high | MDF, wood, chipboard, fiberboard |

| Frequent and low | Hardwood |

| Combined (two-way) | Combined materials (with different densities) |

To connect specific parts, elements with different coatings are used.

The selection of self-tapping screws is also influenced by the type of design and the desired appearance of the product.

The color of the fasteners is also important when the connection is open. In this case, it is worth choosing elements to match the canvas.

To make a table or cabinet, you may need different screws, so it is recommended to consult with the seller if you are going to create the furniture yourself.

It is worth choosing elements to match the canvas.

Self-tapping screws have different types.

Confirmat is used for a more reliable screed. At the same time, a cap is often placed on the cap to make the fastener look more aesthetically pleasing.

To make a table or cabinet, you may need different screws.

Self-tapping screws are used to fasten parts without prepared holes or with them.