Use abrasive powder

As with steel wool, the more grip between the screw head and the screwdriver, the better. You can sprinkle the surface of the screw with a small amount of abrasive scouring powder or fine sand, then apply a screwdriver to the screw and try to remove it. In many cases, powder or sand is enough to keep the bit from slipping off the screw.

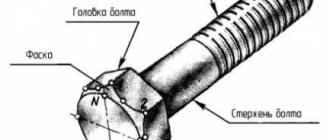

Why is a rusty bolt or nut difficult to unscrew?

Any metal fastener inevitably undergoes corrosion and rust over time. The process is accelerated if the bolts and nuts are often exposed to aggressive environments:

- contact with water;

- interaction with chemicals, including detergents;

- street dirt, dust, caustic salts - they accelerate the corrosion process.

Despite special protective coatings against rust, if the surface of the fastener has been even slightly damaged, then over time the process of destruction is inevitable.

After some time, the rusted bolt must be removed and replaced, but a problem often arises - it will not unscrew. Due to the oxidative processes of the metal, rust grows on fasteners and parts and the surfaces “grab” together. If this process develops at the location of the bolt thread, then the situation becomes even more difficult.

Drill the screw

Select a drill bit that is slightly smaller in diameter than the screw head. Place it in the center of the screw head and drill slowly to create a hole 1 to 3mm deep. Remove the drill from the screwdriver and install the cue ball. Often the hole will help the screwdriver go deep enough into the screw, which will improve the grip between the cue ball and the screw.

Recommendations for working with screw heads and self-tapping screws

While performing the above work, in order to get the expected result and avoid injury, you must adhere to the following rules:

- Before attempting to unscrew the screw, you need to inspect the back side of the workpiece. If its end peeks out of it, then you can try to unscrew it from this side, and when the head is free, grab it with pliers;

- you need to decide whether the thread on the fastener is right-handed or left-handed in order to unscrew the screw or self-tapping screw in the correct direction;

- after the screw has been unscrewed, you can ensure reliable fastening in this place using a larger self-tapping screw or you can use a bolt with a nut;

- When using the described methods, nicks and chips are formed, so in order to avoid injury, you must work with protective glasses and gloves.

There are no lose-lose situations. If there is a problem with unscrewing a screw, screw or self-tapping screw, you need to assess the situation, choose one of the described methods, and then use it to remove the fastener.

Use elastic bands to grip

Wide rubber bands work well to ensure that the screwdriver has enough grip on the stripped screw. Cut the rubber band with scissors and place it on the head of the screw. Place the screwdriver on the rubber band and press firmly while turning the screw counterclockwise.

Follow us on Pinterest for more interesting articles.

Useful short videos from Make-Self.net

Video - The best ways to remove a broken screw

Sources

- https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/kak-otkrutit-bolt-s-sorvannymi-granyami.html

- https://vseprokrepeg.ru/stroitelstvo/otkrutit-shurup

- https://krepmetiz.ru/stati-po-krepeju/kak-vykrutit-sorvannyj-vint

- https://ingener-pto.ru/2019/12/12/kak-vyvernut-vint-s-sorvannoj-golovkoj/

- https://mehmanxona.ru/tehnologii/kak-otkrutit-slizannyj-vint.html

- https://tehznatok.com/kak-polzovatsya/kak-otkrutit-shurup-s-sorvannoy-krestovinoy.html

- https://banya18.ru/banshhikam/kak-otkrutit-shurup-s-sorvannoj-krestovinoj-prostye-sposoby

- https://mo-dmitr.ru/pro-tehnologii/kak-otkrutit-slizannyj-vint.html

- https://sdelai-lestnicu.ru/strojmaterialy/kak-vykrutit-vint-s-sorvannoj-krestovinoj-i-so-slizannymi-granami-pod-krestovuu-otvertku-kak-otvernut-treugolnyj-vint-i-prikipevsij

- https://KrepezhInfo.ru/7-effektivnyh-metodov-vykruchivaniya-slizannogo-bolta/

- https://SumkiVTrende.ru/tehnologii/kak-otkrutit-shurup-s-sorvannoj-krestovinoj.html

- https://traiv-komplekt.ru/articles/kak-otkrutit-sorvannyy-shurup/

- https://mebel-exp.info/kak-otkrutit-shurup-bez-otvertki/

Tool change

If the screwdriver constantly jumps off the slot, the reason may be that the tip is worn out. In this case, the tool is replaced. A new screwdriver is inserted into the screw head, making sure that the tip is pressed tightly against the slot, firmly inserted into the grooves, and try to unscrew the fastener.

Useful advice from Novate.ru: If the fastener cannot be unscrewed, the first thing to do is stop. Attempts to continue unscrewing can aggravate the situation, and a screwdriver that constantly jumps off can damage the material. Assess the condition of the screw and try other removal methods.

see also

Comments 58

This is all bullshit, there is a special Extractor tool on sale, but I learned about them after I learned how to remove screws with a drill that drills to the left. It happened by accident - I wanted to drill it out, but I turned it out. Currently I am making extractors from an old cross bit - 20 seconds near the sanding machine - the extractor is ready, and by the way, this is my personal invention, although there is no patent)))

Now I don’t have that tool with me, the meaning is simple: 1) grind the end of the bit so that it becomes flatter (that is, grind off 2 protruding parts on one side and the other) 2) sharpen it like a drill that drills to the left.

Cool! I'll have to stir it up.