Unscrewing a rusty, oxidized bolt or nut is always a problem for us. It seems nothing complicated, but such an activity can take quite a lot of time and effort.

Also, a broken bolt is often the result of a large number of troubles, regardless of the model and brand of the vehicle. Under the influence of an unfavorable environment, the bolts rust. The fragility of the metal manifests itself and the bolt breaks inside the thread when unscrewed due to heavy load.

After reading the article, you will find the most suitable option for yourself, which will help you easily and quickly deal with the frozen “culprit”.

How to unscrew a rusty nut at home

If a rusty nut cannot be unscrewed, do not get excited and try to rip it off - there are many effective ways to unscrew it without wasting effort.

The main reason for jamming of rusted joints is metal corrosion. During the process of metal rusting, the products of its oxidative reaction, or, more simply put, rust, increase many times in volume, tightly gripping together the parts connected by the threaded connection. The situation is further aggravated by the ingress of small particles of dust and dirt onto the threaded surfaces. Tool selection The success of unscrewing difficult-to-work threaded connections largely depends on the tool used. Do not try to unscrew a rusty nut using an open-end wrench. The weakness of the design of such a tool will lead to the fact that the jaws of the wrench will simply move apart and jump over the edge of the nut, and the short length of the tool will not allow the necessary force to be applied. In such a situation, it is better to opt for ring wrenches or use a set of sockets with a knob - both the edges of the nut and your hands will be intact. As for the integrity of the hands. To avoid injury, when unscrewing threaded connections in hard-to-reach places, applying force to the tool with your hand, you should avoid foreign objects in the direction of movement of the hand with the key or wrench. Dissolving rust If, despite the titanic efforts made, the nut still does not unscrew, you should not force the tool and exhaust yourself with excessive physical exertion. It is enough to moisten the rusted thread with a liquid that can partially dissolve the rust and thereby reduce the friction forces. The arsenal of such liquids is quite wide: from special rust converters and the well-known WD-40 to gasoline, diesel fuel, kerosene, turpentine and brake fluid. By the way, ordinary table vinegar and an alcohol solution of iodine from a car first aid kit have an effective effect on rust. In extreme cases, even Coca-Cola containing phosphoric acid will do. Having generously moistened the rusty connection and waited from 10 minutes to half an hour, you can pick up the tool and try to unscrew the stubborn nut. If even after this the thread does not give in, and time allows, it is advisable to wrap the threaded connection with a napkin soaked in one of the listed liquids and leave it for an hour or two. Most of the nuts unscrew slowly after this procedure, especially if you work on them by working the tool back and forth, that is, rocking. Instead of unscrewing, twisting is an original and very useful method that allows you to destroy a layer of rust, using a slight tightening of the nut instead of unscrewing. After the nut moves at least a little in the direction of tightening, it, although tightly, will begin to turn out. Tapping the edges For this procedure you will need a small 100 gram hammer. Applying light blows with a hammer to the faces of the nut, you should alternately move from one face to another in a circle. Microcracks that appear during the tapping process will slowly but inevitably lead to deformation and destruction of rust. The main thing is to avoid strong blows with a hammer, which can damage the edges of the nut, bend the bolt, or even destroy the part held together by them. Heating Using a heat source (gas torch, blowtorch, lighter, match, candle, soldering iron, hair dryer or ordinary boiling water), you need to heat the nut, being careful not to heat up the bolt or stud on which it sits. When heated, the nut will expand and increase in volume, becoming several microns wider than the bolt, which will greatly facilitate the process of unscrewing it. In addition, due to uneven heating, the layer of rust on the threaded connection will collapse and lose its former strength. Be extremely careful when working with open flames and heating devices! Destruction This method is undesirable, but in some cases it is sometimes the only one that can solve the problem of rusted threaded connections. Armed with a hammer and a sharp chisel, you need to punch grooves on the edges of the stubborn nut. Uniform insertion of the chisel from all sides will lead to its deformation and increase in internal diameter, which will allow you to unscrew it from the thread without much effort. In the end, the threaded connection can be destroyed by sawing the bolt with a grinder or a hacksaw, the nut can be knocked off by cutting the bolt with a sharp chisel, it can be sawed in half along the axis of the bolt, and you can also try to drill it out using an electric drill. In all these cases, the nut and bolt will be hopelessly damaged upon completion of the work.

Bolt with torn edges

Now we will figure out how to unscrew a bolt with torn edges. As a rule, the reasons for this problem lie in the following:

- The parts held by the bolt were misaligned in an unnatural way. This leads to pinching and damage.

- The bolt itself was very tight when tightening.

- The tool used to tighten it was the wrong size and improvised means were used (screwdrivers or chisels are often placed in larger keys when there are no suitable small ones).

Before unscrewing a broken bolt or nut, you need to do some preparation. This will allow you to spend less time and effort, and sometimes save expensive equipment.

Sequencing

- Coat the joint with liquid to aid unscrewing. Such a liquid can be the famous WD-40, brake fluid or kerosene. Take your time and let the liquid do its job. As practice shows, you can safely leave the part alone for thirty minutes, or even an hour.

- Take any available tool and lightly, not forcefully, tap the hardware from all accessible sides. Your goal, in this case, is not to launch the bolt like a golf ball, but just to slightly loosen it at the place where it is attached. While performing this activity, there is a danger of damaging the thread, so balance the strength and swing.

- If you have the opportunity and space, try heating the bolt. A gas burner is suitable for this. Make sure there are no flammable liquids or objects near the workplace. Also, before you start warming up, make sure that in case of an emergency you have somewhere to retreat. Do not heat the part with an open flame in enclosed spaces. It is better to open the gate or move the bolt to the air. Rust and grease scorched in this way will turn into ash and will no longer prevent the bolt from being unscrewed.

However, it often happens that it is the screw that jams that cannot be reached with a torch or tapping tool. In this difficult case, you should use a grinder or any available tool such as a chisel to make a deep cut on the preserved cap. This will become the hook that will allow you to pull out the entire bolt.

Now you can, clinging to this protrusion, try to unscrew the stubborn screw. Press the screwdriver into the recess, and while lightly hitting the handle of the hammer in the direction of unscrewing (not clockwise), slowly turn the bolt.

Effective ways to unscrew a rusty bolt or nut?

If we consider more effective ways to combat rust, it is worth highlighting the following methods.

Heat.

From the physics course we know that metal tends to expand as temperature increases. This feature can be used to solve the problem.

To unscrew a rusty nut, warm it up thoroughly, and then immediately try to unscrew it.

It is important to act quickly here so that the metal product does not have time to cool down. The essence of the manipulation is that due to uneven heating, the rust is deformed and has less restraining force. Heating can be carried out in any available way

This could be a gas burner, a candle, a lighter or even a soldering iron.

Heating can be carried out in any available way. This could be a gas burner, a candle, a lighter, or even a soldering iron.

You can also use a blowtorch or other device.

When using this technique, be careful and remember the contraindications. In particular, heating is not recommended if wood or paintwork products are located in the joint area.

In this case, the part will be damaged and you will have to spend money on replacing it.

Tapping.

You can unscrew a rusty nut or bolt using the traditional method - by tapping around the perimeter of the part.

Mechanical impact on each side allows for greater deformation, which contributes to the scattering of rust.

While tapping, be careful not to damage the edges of the nut. Otherwise, the task of twisting will become more difficult. Spin

Twist.

You can also go the other way. First, tighten the nut (bolt) with maximum force, and then try to rock the connection and dislodge the rust layer in this way.

If the manipulation is successful, unscrewing the nut or bolt will not be difficult.

Wax cup (difficult, not practical, but possible).

This technique cannot be called popular, but in terms of effectiveness it is in no way behind its “competitors”.

The algorithm of actions is simple. Make a cup-shaped shape from plasticine or wax so that its sides are above the level of the nut (about 2-3 mm).

Then dilute the sulfuric acid, pour the liquid into the prepared cup and add a little zinc. This chemical combination provides a galvanic effect and the ability to unscrew the part.

Destruction.

If none of the above methods produces results, and the upper part is broken or severely deformed, there is another solution - breaking the bolt and drilling it out of the vehicle part.

Here, to complete the work you will need a hand or electric tool, as well as a set of drills of a suitable diameter.

Before drilling, place the drill bit in the center of the bolt and hit it with a hammer. This is necessary to deepen the product in the central part to a certain depth.

First, work in small increments and make sure that the drill enters exactly in the central part (tilts to the left and right are prohibited).

Start with a small diameter drill and then move on to a larger piece.

When choosing a drill, pay attention to two criteria - price and country of origin. Please note that high quality products cannot be cheap, because they are made from hardened steel and sharpened in a certain way. Please note that high quality products cannot be cheap, because they are made from hardened steel and sharpened in a certain way.

Please note that high quality products cannot be cheap, because they are made from hardened steel and sharpened in a certain way.

At the same time, special drills do an excellent job with aluminum, cast iron and other materials (including brittle ones).

To ensure correct drilling, use special lubricants, which can solve several problems at once - protect the drill from strong heat, cool the metal and lubricate the drilling elements. As a result, the whole process becomes easier.

What is strictly forbidden to do (use of force)?

The main mistake of many beginners is a thoughtless approach to twisting and the use of “force” methods.

Remember, in order to unscrew a stuck element, it is important to be patient and not rush. Solving the problem requires a consistent and measured approach.

Haste in resolving an issue can cause many problems.

Thus, car owners often rush to unscrew a rusty bolt and tear off its upper part.

The result is drilling out the broken product, which will take a lot more time.

In addition, the result of haste may be damage to nearby nodes with the key, which will lead to the need for additional investments.

Before starting work, draw up an action plan, and then begin to implement it.

If you work in a hurry, the total cost of time and money may be higher. Moreover, there are enough methods to quickly unscrew a rusted nut or bolt. We will talk about them below.

Unscrew the broken bolt

In order to remove the broken bolt with an extractor, you will need to use a drill. You also need to take drills, dies for taps, and a strong core. In the broken “culprit” it is necessary to make a hole, the diameter of which should not exceed the diameter of the thread of the broken bolt.

The extractor has a reverse thread.

An extractor is screwed into the hole. When you screw the extractor, or rather its reverse thread, into the broken bolt, you remove it along with the latter.

If the bolt breaks off and it is possible to reach it, then you need to restore the geometry of what is left of it. Use a file or coarse sandpaper. Then you need to carefully paint the surface. Otherwise, the drill will always walk along the rest of the bolt and it will not be possible to make a hole strictly in the center. It is also necessary to maintain alignment. The hole should be drilled as close to the center of the bolt as possible.

It is necessary to start drilling with a small diameter drill and clearly position the hole in the center. The centered hole can be expanded very easily. The diameter of the extractor must be taken 1 mm larger than the diameter of the hole

It is important not to drill through the hole so that the extractor has something to grab onto.

The extractor must be screwed into the recess of the bolt surface. Then the extractor must be installed in the recess and struck with a hammer, trying to hammer into the hole like a nail. After this, it should remain in the recess.

It is necessary to clamp its head with a die and rotate it in the direction of unscrewing the bolt itself. You need to rotate the die slowly and as carefully as possible. By crashing into the bolt, the extractor tightens it as much as possible and transfers its torque to the broken “culprit”. In turn, the torque will unscrew the broken bolt.

Hex bolt

The edges of the axis are convenient for both tightening and unscrewing. Clear and even, they provide a reliable support for the key. If the bolt is suitable for your hand and of the appropriate size, at first you can comfortably twist it by hand, later tightening it with the help of a tool. However, there are often cases when, due to excessive use of the screw itself, or heavy loads on the connection, the edges are torn off and the fastener remains sticking out in the joint. It is uncomfortable to handle; it slips out of your hands and tools. Let's look at several options for solving this problem, with corresponding solutions.

Make a notch on the head of the bolt using any available method. However, there is one important point when making this notch. The walls of this notch must be vertical, without slope. Otherwise, the tool that you then press into the recess will simply slide along the head. And in this case, there is a great danger of damaging not only the tools, but also the master’s hands. Use special so-called extractors for screws with torn edges. Extractors have threads cut in the direction that is directly opposite to the threads of the bolt itself. Thus, when a hole is drilled in a bolt and an extractor is inserted, it is fixed in the bolt tightly and does not turn when the bolt is unscrewed with pliers. Use a reverse left rotation drill and a reverse drill. The idea is to make a hole in the fastener with a regular drill, insert the left drill into it and, using the reverse of the drill, unscrew the stuck bolt. Find a suitable TORX sprocket. An ideal sprocket should not fit into the hole of the hexagon with splines, but at the same time not be too large for it. The TORX sprocket will cut through the head of the bolt with its slots, locking tightly onto the head. Now you can unscrew the screw with a strong movement

Proceed with caution, as in this case there is a great danger of tearing off the splines on the TORX sprocket.

A screw with a hexagon hole can be unscrewed in the following way:

- You need to take a file and make it the size for a hex key. By making such a cut, you will save significantly, since you will be able to use this fastener more than once in the future.

- Make a notch on the cap with a grinder or any other convenient method, for example, with a hacksaw. And use a flat-head screwdriver, resting on its handle as if it were a rotation arm.

- You can also use one of the appropriately sized TORX sprockets to unscrew the screw.

For connecting rod bolts made of steel, there are only two methods:

- Use an extractor. A properly selected extractor and your careful actions will help not only unscrew the screw, but also do it without significant damage to the tool.

- Call in electric welding for help. Using electric welding, you can attach any hexagonal element that you no longer need to the torn fastener. Welded in this way, it will become the new head for the screw. It will be convenient to rest against it and unscrew it. But unfortunately, this method can only be used for parts made of steel. Unfortunately, this convenient method cannot be used with bolts made of other materials.

Method No. 1: dissolving rust

How to unscrew a rusty nut? We will not suffer with the tool, wasting our strength in vain. Let's go in search of a substance that will help dissolve rust and reduce friction. Of the most famous ones that have proven themselves well:

- Special product WD-40.

- Kerosene.

- Brake fluid.

- Petrol.

- Carburetor cleaner.

- Alcohol.

- Table vinegar.

- Iodine.

- “Coca-Cola” and other drinks containing inorganic phosphoric acid.

We are sure that at least one of the above is at your fingertips. Next, the algorithm of your actions is simple:

Wet the nut well with

Wait about half an hour. After this, try to carefully unscrew the part with a tool. If it doesn’t work out, apply the substance again and wait. The product will work better if you soak a rag or napkin in it and wrap it around the nut. You can then speed up the unscrewing by lightly tapping the part with a hammer. Another effective way is to try to twist the nut with a strong and sharp jerk after exposure to the solution. For a small nut, the “rocking” method will help - back and forth.

Alcohol solution of iodine

We are talking about the idea of an ordinary pharmaceutical alcohol solution of iodine. In this tandem, alcohol, also known as ethylene, and iodine, as an element of the periodic table, equally distribute among themselves the functions of freeing fasteners that have become soured in rust. Alcohol has a high penetrating ability, and iodine interacts with iron oxides and other iron compounds formed upon contact with the external environment. Thus, these two substances weaken the rust, making it easier to free the rusted bolt or nut. To avoid getting your hands dirty and for convenience, it is better to apply iodine to the connection using a syringe.

Ways to Prevent Corrosion on Threads

When you repair the threaded connection, take care to ensure that the problem does not reoccur. Threads can be protected from corrosion using lubricants with neutral acidity or slightly alkaline. This class of fuels and lubricants is called conservation, typical examples are graphite lubricant USsA and “Solidol”.

Protecting the threaded connection from the environment will also help. Most paints and enamels based on alkyd or polyurethane are suitable for this. You should not use silicone, because its high acidity only promotes the formation of rust.

Finally, don't forget that some threaded connections require maintenance and retightening. If the connection must remain detachable, it must be loosened periodically (every 2-3 years) and lubricated with at least ordinary machine oil.

rmnt.ru

Unscrewing methods

To unscrew stuck bolts, you can use several techniques and methods. You can perform these manipulations yourself at home. Before using this or that method, it is necessary to thoroughly clean the connection site from all contaminants and, during a visual inspection of the mounting site, try to determine the type of damage to the bolt. Depending on the type of damage, you can resort to mechanical, chemical or physical methods of unscrewing it.

Mechanical

Mechanical methods include all methods that involve the use of great physical effort when trying to break a damaged connection. The mechanical method can only be used if the bolt is not cracked, chipped or bent.

The mechanical method involves several nuances.

Using box wrenches instead of regular wrenches. Since a regular open-end wrench is capable of influencing only 3 edges of the head when unscrewing, as a result of strong impact these edges can be erased and the key will slide off. The spanner grips all 6 corners of the bolt, which will help you apply more force to unscrew it.

Using the extended handle of the key as a lever. Lengthening the handle of the wrench will help put more pressure on the bolt, and prevent rust from getting in the way.

Application of short-term force effects on different points of the rusted connection part. You will need a hammer and a chisel, with the help of which you first need to knock out a notch on the bolt head, and then hit it with force in the direction of unscrewing. This effect is more powerful than when unscrewing it with a wrench, and it will be possible to unscrew a stuck bolt much faster.

The impact of a force of alternating direction on a bolt. To unscrew a bolt using this method, you must first tighten it and then try to unscrew it. This manipulation can be repeated several times, since alternating movement in different directions will help free the threads from rust.

Destruction of the rust layer using impacts. It is necessary to strike those areas of the bolt that are most affected by corrosion. The applied force will help remove the rust, but damaged connection parts after such exposure will have to be replaced with new ones.

Physical

These methods for unscrewing rusted bolts are based on the physical properties of the materials used in the manufacture of connecting parts. There are the most common and frequently used methods.

Heating of connecting pair parts. To heat the parts, use any source of heat or fire: gas burner, blowtorch, soldering iron, hair dryer.

If you heat up the entire connecting structure, then under the influence of high temperatures the rust will begin to break down and fall off the connecting elements.

Applying liquid to threads. When penetrating into the micro-holes between the nut and bolt, liquids such as gasoline, kerosene, white spirit, and turpentine can reduce the friction between the stuck surfaces, which will ensure easier unscrewing. The same property is possessed by products called “liquid key”, which can be purchased at any auto store.

Chemical

The action of chemical methods is based on dissolving a layer of old rust using acids. Acids have properties that help destroy the corrosion layer:

- salt;

- sulfuric;

- lemon;

- orthophosphoric.

To dissolve the layer of rust on the connecting pair, the joint must be treated with a few drops of the reagent so that they can penetrate the micro-holes on the bolt thread. If a large area is affected by corrosion, then, if possible, the bolt can be soaked in acid.

The time required for exposure to the acid must be at least 24 hours. After it has expired, first tap the connection with a hammer so that large pieces of rust fall off, and then try to unscrew the nut with a wrench.

Following the recommendations given, it will be much easier to unscrew a stuck connection. If none of the above methods failed to remove the stuck bolt, you can resort to cutting it off with a grinder or drilling it. But before applying these measures, it is necessary to weigh all their positive and negative sides.

Removing the screw

Screws with torn edges cause a lot of trouble. Unscrewing such screws is not easy, but there are several ways to solve this problem. To make it easier to unscrew them, you need to do the same preparatory measures as for the bolts.

In the simplest case, when the screw protrudes above the surface, you can try to grab it with pliers, wire cutters or another similar tool and unscrew it in this way. But most often there is nothing to grab onto. Then you can try the following methods:

- Sometimes it helps to use thin rubber, for example, from a balloon. A piece of such rubber is placed on top of the screw and unscrewed, pressing the screwdriver through it. This increases friction and prevents the screwdriver from slipping.

- A screw with a curly head can be converted into a flat-head screwdriver by sawing through the groove with a hacksaw.

- In order to solve the problem of a screwdriver slipping, you can use cyanoacrylic-based glue; this glue dries quickly and holds metal surfaces together efficiently. The procedure is simple: the screw and screwdriver are degreased, glue is applied to the head of the screw and the screwdriver is pressed against it, maintaining alignment. To speed up the setting of the glue, you can sprinkle it with soda. Wait until the glue has completely hardened and try to unscrew the screw.

In order to avoid such problems in the future, renew all threaded connections with taps or taps before assembly. Replace any damaged fasteners. Be sure to lubricate the threads and fasteners in general. It is best to use graphite lubricant for these purposes.

The hex key can be replaced:

| Types of bolts | Popular Alternative Methods |

| Bolts with external edges | Use a metal brush to scrub the jammed surface, apply a drop of kerosene to it and wait 20 minutes. Then you can use a spanner wrench. |

| A gas wrench is an ideal option when the edges of a bolt or nut are torn off. | |

| Carefully make new edges using a grinder. Their number can be reduced, as well as their size. It will be easier to unscrew such a bolt, since it will be possible to select a wrench of the appropriate size. | |

| Chisel and hammer. Deliver precise tangential strikes. The method helps to move jammed fasteners. | |

| Drill a small hole in the head, insert a faceted pin in the shape of the letter “L” and pull out the bolt, turning it. | |

| Using welding, weld a rod to the head of the bolt and use it to unscrew the jammed part. | |

| Bolts with internal edges | Use a regular screwdriver that fits the groove. You just need to insert it into the groove, resting against it and turning the bolt. |

| A bolt and a set of nuts that correspond to the standard size of the hexagon. They need to be screwed onto the thread and placed inside the hexagon. Then unscrew and tighten using a wrench. | |

| A triangular file is what you can use to replace a hexagon. It needs to be inserted inside the bolt and scrolled. | |

| Make a hole for a flathead screwdriver and use it instead of a hexagon. |

A hex wrench is a common tool, especially in furniture production. It is used to loosen or tighten bolts that have a hexagonal groove in the head.

Sometimes this tool is not at hand and you need to look for a way to replace the hexagon at home.

To fix bolts with outer edges, wrenches are used, which cannot always be used because the edges of the part are damaged in some way.

Recommendations

In order to no longer be tormented by the question of how to unscrew rusted nuts, when installing them, it is important to treat the threads with a special lubricant. You can use graphite, silicone or Teflon

Many craftsmen do not recommend using lithol or grease. Such products are more suitable for dynamic rather than static nuts and bolts. Choosing them will lead to the fact that such a lubricant will soon ossify and will interfere with the rapid unscrewing of parts.

Experts recommend working by heating the part. A change in temperature leads to expansion of the metal and, as a result, to the destruction of the corrosion layer and loss of strength of the thread connection. For heating, it is better to take a blowtorch. A hair dryer or lighter will also work.

You can unscrew the rusty part using a wax cup. To do this, you need to take a little wax or children's plasticine and mold the product in the form of a mini cup. The height of the sides of such a product must exceed the height of the nut. Sulfuric acid is poured into an improvised cup and some zinc is added. Due to the interaction of the components, a galvanic effect will occur, and the rust will begin to break down. After carrying out such an operation, unscrewing the nut will become much easier.

Using one of the listed options, you can easily unscrew a stuck nut. More attention should still be paid to prevention and the use of special means to prevent metal corrosion.

How to unscrew the nuts, see below.

Prevention

Judging by the information given above, unscrewing a rusted bolt or nut is not difficult, but it takes a lot of time and effort.

It’s easier to prevent problems and take into account a number of recommendations. Below are just a few of them:

- Coat the nuts that hold the muffler with an anti-corrosion compound before tightening. After this, treat the product with grease (for greater effectiveness, add a little graphite to the composition). This prevents sticking.

- Wash the engine and the car as a whole from time to time. Dust and dirt that accumulate on the surface accelerate the process of corrosion.

- Buy only high-quality fasteners made of durable metal. When choosing, pay attention to such a criterion as strength class. Try not to skimp on nuts and bolts, because using cheap products leads to a number of problems in the future. At the same time, the question of how to unscrew a rusty fastener can become very relevant. Remember that we are talking about reliability and durability, savings on which are inappropriate.

- Do not abandon your car in a nearby or open parking lot. Storing a vehicle in a closed garage is an opportunity to reduce the risk of corrosion on connections. The negative impact of rain or cold negatively affects the condition of the body, as well as the vehicle’s fastenings.

- When performing work, use only high-quality tools - gas or ring wrenches, as well as special heads. Of course, this will require more money to purchase, but it is more convenient to use such a tool, and the mounts themselves last longer. A good tool allows you to solve two problems - maintain the integrity of the nut and protect it from damage, and also stretch the fastener with the required torque.

How to unscrew a licked bolt

When turning the bolt, pry it up with a nail puller and pull it out to the maximum possible height, leave it in tension and gradually unscrew it with a wrench. When you don't have a nail puller, you can use a screwdriver. A small bolt is removed using pliers by the head. If it does not give in immediately, then rotate it, clamping it with pliers counterclockwise with upward force.

Use a tap and insert it all the way

If you don’t have it at hand, then a screwdriver with a cone-shaped edge will do, which you carefully hammer in until it stops and try to unscrew

To prevent such situations from reoccurring, they must be treated with graphite lubricant before tightening the bolts. But solid oil or lithol are not used for this purpose, because they are used for rubbing parts, and after lubrication, bolted joints become jammed with them.

Before defeating “stubborn” fasteners, it is worthwhile to carefully understand what a bolted connection is, in principle?

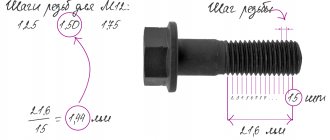

A bolt is a fastening element in the form of a threaded rod and a hexagonal head. It serves to transmit torque from the tool to the threaded rod when unscrewing/tightening the bolt. In turn, the threaded part (bolt shaft) is inserted into the hole of the parts being fastened. And it can either go out - then to fasten and tighten the parts, a nut is put on the end of the rod (with or without a washer, a spring washer or a pack of washers, or a locknut can also be used). Or the bolt can be screwed into a through or blind hole with internal threads. Then a nut is not required, although a washer can again be placed under the hex head of the bolt - to prevent the fastener from loosening during operation and/or to protect the surface of the part from damage during the initial tightening of the fastener.

Of course, in practice there are a variety of bolted connections. However, the tightening of the bolt is always ensured by tightly pressing the protrusions of its thread (external - on the rod) to the protrusions of the mating internal thread of the nut or hole in the body of the part.

Unscrewing methods

There are three main methods for unscrewing a stuck nut:

- dissolving rust and dirt;

- heating the nut;

- mechanical damage to the nut.

Let's deal with each of them in turn.

How to dissolve rust

The essence of the technique is a chemical effect on rusty threads and, as a result, reducing the friction force when unscrewing. Vinegar, alcohol, iodine, kerosene or gasoline may be suitable for these purposes. But it is best to use a composition called WD-40, which is designed specifically for such purposes.

I will describe the methodology in detail:

- The nut is thoroughly moistened with the substance described above and allowed to stand for 15-20 minutes. Then they try to unscrew it. If this does not work, wrap it with a rag soaked in the composition used, or with a napkin. Again they wait for a while.

- Most likely, everything will work out, and success can be secured by hitting the nut with a hammer. Just don’t hit the bolt threads, otherwise you’ll make your task much more difficult. I recommend lengthening the wrench with a piece of pipe of a suitable diameter - the lever will be much stronger. It will be easier to move the nut out of place if you securely place the wrench on it and make a sharp jerk. Just don't pull clockwise!

- With a small thread diameter, it is very convenient to unscrew the nut by swinging, that is, working the wrench back and forth.

Heating process

Under the influence of high temperatures, metal tends to expand. As a result of such deformation, rust simply “looses its grip”, and the unscrewing process is greatly simplified. A hair dryer, a gas burner, a blowtorch - anything that produces a high heating temperature - can be used as a heating element. Don't be afraid - you are unlikely to be able to melt the metal from which the fasteners are made.

How exactly to proceed:

- Warm up the connection thoroughly, and then try to get the process off the ground using a spanner wrench.

- Sometimes it happens that the edges of the nut are licked off, then the wrench is useless. In such cases, a socket head is welded to it, the entire structure is heated, and then it is unscrewed using a wrench.

Mechanical impact

This method is resorted to if the previous two did not help or when there is no task to keep the connection intact. To work, you can use a hammer and chisel, a grinder or a hacksaw.

The essence of the technique is as follows:

- You can use a hacksaw or grinder to saw the nut along the axis of the bolt, and then removing it will not be difficult.

- There is another radical method - using a hammer and chisel. By driving it deeper, you can knock down the threads and increase the internal diameter of the nut. But this is completely, as they say, out of despair.

But the best way to combat souring of joints is to prevent it through timely application of lubricant. In this case, the service life of the fasteners will at least double.

Subscribe to our Social networks

How can you remove the slot of a self-tapping screw?

The grooves on the screw head can be damaged for various reasons, however, most often they are:

- ? A bad screwdriver attachment, with licked edges, is also the cause of destruction of the self-tapping slots. Therefore, you should not use a worn PH2 attachment on a screwdriver, since in the end you may not be able to unscrew the screw back.

- ? Low-quality self-tapping screws manufactured in violation of standards and requirements. The metal of bad self-tapping screws is too soft and the slot can be easily damaged, even without strong force, with a screwdriver or electric drill.

- ? Excessive application of force to the screwdriver while tightening screws also often leads to grinding of the slot. This is especially true for those moments when the nozzle fidgets on the head of the screw; in simple words, it is pressed against it perpendicularly, and with some bevel to the side.

Be that as it may, the licked screws can be unscrewed.

For these purposes, you will need a piece of rubber or a tool such as a bolt extractor. With the help of an extractor, you can unscrew even the worst version of the self-tapping screw, when its head does not have a slot at all.

How to unscrew a bolt with special equipment

Bolts can be unscrewed using a variety of tools, and this will allow you to drill out the bolt without damaging the thread, for example:

- keys;

- screwdriver;

- pneumatic impact wrench;

- ratchet.

But often it is not possible to solve the problem using the methods listed above, and then other tools for unscrewing broken bolts will come to the rescue:

- Thin open-end wrenches, but they are absolutely not suitable in case of rusty or stuck bolts, as this breaks off the edges.

- Impact wrench.

- Socket wrenches, which are more applicable, since they cover the head of the product more tightly.

- Welding equipment.

- Hexagonal socket wrench, which is less likely to cause edge breakage.

- Air impact wrench.

- A multiplier that allows you to apply more force to a stuck bolt.

- Screwdriver with large handle.

- Clamping tool.

- Set of extractors.

- A hairpin driver that is perfect for products that have a high head.

Working with a set of extractors

Initially, you will need to mark the center, which requires a center punch and a hammer. A pilot hole is then drilled to be used by the extractor.

Attention! In this case, it is important that the axis is not displaced, and the depth of this hole should be no more than three diameters of the drill used

The extractor will need to be inserted into the hole and slightly tapped to make the fixation more reliable. Only then can you use a tap to screw in the extractor. Working with it is quite simple, since after the extractor enters the product all the way, the product will begin to turn out.

Working with welding equipment

If a bolt breaks off, how can you unscrew it without damaging the equipment itself?

The fastest way is to use welding. To do this, take a nut of a suitable size and weld it to the broken part, but only from the inside. After this, the product can simply be unscrewed from the fastening element using a wrench.

Welding equipment makes it possible to unscrew a screw or bolt that has a broken head or torn edges.

In a situation where the head is torn off, it is necessary to melt a small amount of metal onto the remaining part, then put a regular nut on it and weld it.

Unscrewing with a wrench

Unfortunately, this tool cannot be used if the head of the fastener has been torn off. How to unscrew a licked bolt is described in another paragraph. To unscrew it with a wrench, you need to put a suitable attachment on it. The unscrewing process itself occurs due to the impact mechanism of the wrench.

The impact wrench itself is a device that facilitates the process of assembling and disassembling bolt-nut connections. It is very convenient if it is impossible to use a wrench.

Once the impact wrench is started, power is supplied to the motor, which transfers power to the gearbox, which causes the chuck to function. Almost all devices that are designed to unscrew nuts have a special spring that allows the chuck to rotate back. This fact makes it possible to use the impact wrench not only in mechanical engineering, but also in many other fields of activity.

A situation often arises when a bolt cannot be unscrewed. What should you do in this case if you don’t have any special skills? There are several simple tips that make it easier to unscrew the fastener:

- In order to carry out this procedure faster, the element should be preheated.

- How to unscrew a bolt with broken threads? In this case, you can use a hex key.

- While working, you can use acetone or oil for lubrication.

- Using a drill with a reverse thread can greatly facilitate the process.

- If you don’t have any special tools at hand, you can use a core and a hammer. To do this, the first one should be positioned at an angle of forty-five degrees and hit with a hammer, but only counterclockwise.

- If you cannot unscrew the element, you will need to drill a larger hole and re-tap the thread.

If the cylinder head bolt is broken

The method is suitable for cases where the bolt has burst and part of it in the form of a pin remains inside the cylinder block. We use welding, a tube, a nut.

Advantages of the method:

- there is no need to disassemble the engine;

- saves time.

Take a tube with the following diameters:

- The outer one is slightly smaller than the diameter of the cylinder head bolt.

- Internal – such that an electrode of 2–3 mm fits freely into the tube.

Weld a 17 - 19 nut onto one side of the tube.

- Insert the tube into the hole so that it touches the broken pin.

- Insert the electrode into the hole of the tube at a slight angle, so that its end is located where the edge of the tube touches the pin.

- Weld the tube to the stud.

- Use a wrench to unscrew the pin.

Another way if the cylinder head bolt breaks.

Suitable for cases where the broken pin is not deep, no more than 5 cm.

To unscrew the stud from the block, first use a drill and a long 10 mm drill bit. This will help you level and center its surface. Next, using a 4 mm drill, drill a hole in the stud with a depth of at least 1 cm.

Carefully drive a 25mm Torex key into the stud and use a lever tube to unscrew it. You need to unscrew without jerking, gradually increasing the force on the lever.

How to unscrew a broken screw

For this we will take several options.

1. The rudest, but in most cases helpful. Just press the screwdriver towards the screw and twist with sufficient force, so the friction will increase and therefore there is a good chance to slowly but surely unscrew the screw with the broken head

When performing repair work, sometimes the question arises: how to unscrew a bolt or screw with torn edges. This problem has several solutions, knowing which you can unwind almost any hardware. Even if you overdid it and tore off the head or broke the stud, there are ways and tools that allow you to unscrew the broken fasteners.

Hammer and chisel

You can use a hammer and chisel to loosen the bolt.

It is necessary to install the chisel on the edge of the bolt head at an angle. It is necessary to direct the tip of the chisel in the direction of unscrewing the bolt and give a strong blow to the chisel with a hammer.

In this way, you can unscrew almost any rusty bolt. Alternatively, hit the key, but without applying much force. If the “culprit” does not unscrew, there is a chance that you can “lick” the edges of the bolt with the key.

Recommendations for selecting nuts

If you need to find a nut separately due to loss or damage to the complete one, then you should remember a few simple rules:

| The best selection option is based on the sample | Of course, if you have an old element, then purchasing a new one instead is much easier. It is enough to compare two products and make sure that they have similar parameters and are interchangeable. But you don’t always have a sample at hand, so you can take with you the faucet part that requires a fastening element |

| Explore quality | If there is no sample, then it is necessary to take measurements very carefully and carefully, and when choosing, select the option that is made better: there are no burrs on the thread, it is rolled evenly and accurately, there are no stains or cavities on the surface. Every little thing matters, since it can be used to judge how well the element is made |

| Consider the type of tap cover | Putting a bronze nut on a chrome-plated structure, or vice versa, is not the best solution, as it does not look very attractive. Of course, this point does not apply to cases where the fastening is hidden and simply will not be visible; in such a situation, any color will do |

What is a nut and bolt?

Let's start with the theory and remember what a nut and bolt are, as well as what functions they perform:

- A bolt is a rod made of metal and having a square or hexagonal head, as well as a thread intended for screwing on a nut. Today there are many types of bolts, the design and shape of which depends on the purpose. Here it is worth highlighting anchor, hinged or eye bolts, bolts with a countersunk or semicircular head.

- A nut is a fastening element that has a hole with a thread cut inside. As a rule, nuts are hexagonal in shape and can be unscrewed with a wrench. But there are other versions of products - round with a notch, with a protrusion and others.