The main reasons for chainsaw failure

Although the chain saw is a simple device, from time to time problems arise in its operation, which can only be eliminated by disassembling it. Examples include the following faults:

- the chainsaw does not gain speed;

- the chainsaw stops functioning when cutting;

- the chainsaw starts and stalls;

- the chainsaw loses its power;

- The chainsaw stalls when pressed.

Most often, malfunctions are associated with interruptions in the functioning of the motor, as well as with malfunctions of other systems and components. Proper handling of this equipment is of great importance. If all the rules of use are followed, problems with a high probability lie in the most obvious ones. When looking for the causes of problems, it is advisable to start by checking the simplest part of the chainsaw and finish with the most complex.

Why does it wear out?

This is one of the questions that chainsaw owners ask all the time. It's easy to answer. Friction occurs on the surface of the headset, which causes wear.

The contact of dust and dirt on the rubbing surfaces increases wear of parts.

There is another pressing question: why does a tire wear out prematurely? This can be answered by studying the design of the tire and the operating principle of the lubrication system, which is what we will try to do.

The lubrication system begins with the oil tank, where oil is filled and then, using an oil pump, it is transferred to the point where the bar shank comes into contact with the chainsaw body. To adjust the oil supply, the tool pump is equipped with a special screw. At the tire installation site there is a special slot that coincides with the hole for obtaining lubricant on the tire. The cause of premature wear may be insufficient lubrication of rubbing parts, which in turn occurs due to the following malfunctions.

- excessive contamination of the oil filter (the first thing you need to pay attention to);

- contamination of the oil supply channels on the headset or on the instrument itself;

- incorrect adjustment of oil supply by the pump;

- malfunction of the pump itself;

- the use of low-quality lubricants or oil that does not meet the requirements of the chainsaw manufacturer.

To increase service life, manufacturers recommend using special oils with high adhesion.

Choosing original chain oil is the choice of real men!

Thanks to this property, at high chain speeds, the lubricant is distributed and retained throughout the tire, and not just on its upper part, as is the case with conventional oils.

It is unacceptable to use waste oil from a car engine as a lubricant. The waste contains metal impurities from the car engine, which, falling between the rubbing parts, act as an abrasive tool and significantly increase wear.

Checking the main chainsaw systems

If the chainsaw refuses to work normally, you need to make sure that all the conditions required for its normal functioning are provided:

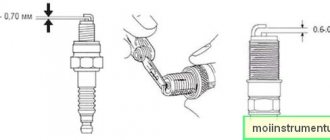

Then you need to sequentially check the functioning of all its elements. First you need to check the fuel tank. If the reason is not the volume or quality of the fuel, then the likely cause of the malfunction may be the spark plugs. The spark plug gap should not exceed 0.5 millimeters. If it is too small, this means that carbon deposits have deposited on the candles. In this case, you should remove the spark plugs, clean them, then put them back in place and try to start the chainsaw. In addition, it is advisable to completely replace the spark plugs with new ones from time to time, even if they are in good condition.

Then you need to check the condition of the fuel filter and carburetor. Cleaning the fuel filter yourself is not a difficult task, but carburetor repair is best left to specialists.

Installing the bar and chain

The tire is dismantled to clean the oil line, check its technical condition, or replace it. The operation sequence is described in the operating instructions. Upon completion of installation, ensure that there is no play and that the threaded fasteners are tight.

If you have certain skills, it only takes a few minutes to dismantle and install a new or sharpened chain. The technology requires the inclusion of an unauthorized start blocker and, in some cases, an emergency stop mechanism.

- Depending on the design of the tensioner, the chain is loosened to the desired extent by rotating the adjusting screw or setting disk until the shanks freely exit the groove of the guide bar.

- After checking the direction of rotation, the shanks of the new chain are inserted into the guide groove and onto the crown of the drive sprocket. Tensioning is done in the reverse order.

- To check the degree of tension, simply pull the chain in the middle of the bar. The extension of the link shank in this place should not exceed 2/3 of its height. A properly tensioned chain should move along the bar with little effort.

After installing and adjusting the saw set, it is advisable to start the engine and keep the saw at medium speed for several minutes. During this time, you can check the operation of the lubrication system.

After turning off the power unit, it is necessary to turn on the start lock and check the headset for local overheating of the tire and changes in the degree of chain tension.

The chainsaw starts and stalls - the reason

If the chainsaw starts and stalls during the first attempts to do the job, then the reason may be problems with the chain brake or its jamming due to lack of lubrication. In this case, measure the oil level. If the amount of lubricant is sufficient, then the reason may lie in the tube that leads it to the lubrication mechanism.

Another reason could be a carburetor failure. If it only needs adjustment, you can do it yourself according to the instructions. If the carburetor needs cleaning or repair, then you cannot do without the help of professionals.

Another possible cause of this malfunction is a low fuel level in the tank. In this case, the chain saw stalls when tilted, since the remainder of the fuel mixture ends up in the part of the tank opposite to the place where the suction tube is located.

Why does a chainsaw stall when heating up?

It often happens that the chainsaw starts when cold, but stalls when it warms up. This behavior of the tool can be caused by the following reasons:

- The carburetor is not adjusted correctly. This problem can be identified by how the device starts up when cold. If it is carried out without closing the air damper, and the engine starts without a preliminary flash, this means that after the engine warms up, fuel floods the spark plug. The solution to this problem is to adjust the carburetor. Details about carburetor adjustment

- Malfunction of the coil (ignition module). This problem can be identified by sequentially checking the spark, first on a cold and then on a hot engine. If there is no spark on a hot engine, then you need to replace the ignition coil.

- Spark plug faulty. In this situation, as in the case of a faulty ignition module, the spark disappears when the engine heats up. You need to replace the spark plug with a new one, and if this does not solve the problem, you should check the ignition module and the distance between it and the flywheel.

Incorrect carburetor setting

This is perhaps the main reason why a chainsaw stalls when hot. Diagnosis is quite simple: when starting on a cold chainsaw, it starts with the throttle open without the first short-term flash. Let me remind you that when starting correctly when cold, you need to close and pull the starter until the engine tries to start and stalls immediately after that. Only after this the valve needs to be opened and the chainsaw will start up in operating mode.

So, if the chainsaw still starts right away without first pulling the starter with the damper closed until the first preliminary flash, then this means that initially enough fuel mixture is supplied so that the chainsaw is immediately ready for work without preheating, and then during warming up it occurs expansion of the fuel supply channels, due to which the gasoline mixture begins to flow in too large quantities and simply floods the spark plug, since the fuel does not have time to completely burn.

Therefore, carburetor adjustment is required, in which it is necessary to slightly reduce the supply of gasoline mixture. This is done by rotating the corresponding screws, marked with the letters H and L, which are accessible from the surface of the saw body. On household models there is sometimes only one screw.

You can make the adjustment by eye yourself, but it is better to contact a service center, since precise adjustment requires special equipment, which the average user, as a rule, does not have.

What to do if the chainsaw stalls when you press the gas

In addition, this malfunction may be associated with a defect in the fuel tank breather. Due to the formation of a vacuum in the fuel tank during the operation of the chain saw, the required volume of the fuel mixture does not enter the engine, as a result of which it cannot gain speed or stalls. If you stop the chainsaw, open and close the fuel tank and turn it on again, it will work normally for about five minutes, and then again stop picking up speed or stall.

Another possible reason that the chain saw is not able to gain speed may be excess carbon deposits in the muffler, which makes it difficult for exhaust gases to escape, which reduces engine power and speed.

Add a comment Cancel reply

You must be logged in to post a comment.

Owners of chainsaws sometimes have to deal with the fact that the saw, for no apparent reason, stops working normally. In our article we will try to figure out why the chainsaw stalls in various operating modes, as well as describe how the malfunction can be diagnosed.

What causes electric saws to fail most often?

Any breakdown does not occur out of nowhere. Its roots often lie in poor assembly and quality, or in improper operation. If you buy a quality tool from a reliable one, it is not so easy. But still, most often malfunctions arise due to:

Power surges in the network. If the instrument has built-in fuses - protection against voltage surges, then it will withstand deviations from 220 V by 10% in one direction or the other. Not more. If there is no protection, the motor burns out.

Non-compliance with recommendations. Often the instructions indicate: half an hour of work, 15 minutes of break. Once it is written, it must be observed. Avoiding the mode means overheating the engine.

Untimely lubrication. The vast majority of electric saws have automatic lubrication. Make sure you don't run out of oil. Remember that running “dry” is death for the motor. If oil does not automatically flow to the sprocket, then lubricate it yourself every 3-5 hours of operation.

Power overload. If it happens, it’s also your fault, not the manufacturer’s. If it is stated that you can cut logs up to 5 cm in diameter, then cutting a ten-centimeter trunk is clearly overkill.

Design flaws. This is already an oversight by the manufacturer. The most common disadvantage is the rigid coupling of the gearbox with the anchor. When transferring a strong load (dull tape or hard wood), it jams and heats up. Gears wear out quickly. The way out of the situation is to sharpen it in time and avoid overload.

Why does a chainsaw stall when heating up?

The situation in which a chainsaw starts up when cold, but may stall while warming up, is familiar to many who deal with them. The main reasons for this behavior of the saw are as follows.

- The ignition module (coil) is faulty. You can determine the malfunction by checking the spark first on a cold engine, and then on a hot one. If there is no spark on a hot engine, then you should try to fix the problem by replacing the ignition coil.

- The chainsaw carburetor is not set correctly (fills the spark plug hot). You can determine the problem by how the saw starts when cold. If for a cold start it is not necessary to close the air damper, and the engine starts without a preliminary flash, then the fuel mixture is not formed correctly and after the engine warms up, the fuel floods the spark plug and makes starting impossible. The problem is eliminated by adjusting the carburetor.

- The spark plug is faulty. In such a situation, similar to a faulty ignition coil, the spark disappears when the engine heats up. It is worth trying to replace the spark plug with a new one, and if this does not help, then you need to check the ignition coil and the gap between it and the flywheel.

You can check the ignition coil using a multimeter or by replacing it with a known good one. Checking the primary and secondary windings with a multimeter is carried out in resistance measurement mode. The resistance of the primary winding, the working coil, is 1 kOhm - the secondary is 4 kOhm.

Why is it heating up?

In some cases, during operation, you may notice that the tire heats up excessively; there are two reasons for this phenomenon. The first is a manufacturing defect. Such parts are equipped with low-quality bearings, which heat it up during operation. A defective part will heat up and nothing can be done about it, only replace it with a new one.

The second reason is, again, not enough lubrication, or its complete absence. If signs of overheating appear, such as melting of the paint on the tip of the tire and strong smoking, you should stop using the tool and contact a service center.

This is what an overheated chain looks like

The choice of chainsaw tire largely depends on the characteristics of the chainsaw itself. You should only choose components recommended by the manufacturer, taking into account the pitch of the drive sprocket, the width of the chain groove and the shape and size of the shank. The key to long-term service of a chainsaw saw set is the uninterrupted supply of a sufficient amount of lubricant of the appropriate brand. Excessive wear of the bar and chain, as well as their heating, is a sign of improper operation of the saw chain lubrication system. We have highlighted the main points of choice, remember them and take them into account when purchasing, and then you will definitely buy what you really need.

Why does a chainsaw stall under load?

In some cases, the chainsaw is unable to work normally when under load and simply stalls. A common reason for this behavior is improper carburetor adjustment, or air leakage through the crankshaft seals or carburetor gasket. This behavior can also occur due to a leak in the carburetor.

It is best to diagnose the cause and eliminate the fact that the chainsaw starts and stalls under load at a service center, since a special tool is needed to check the tightness of the carburetor and engine crankcase.

A saw that is unable to operate under load will also be unable to maintain idle speed. They will "float". Diagnostics begins with checking the crankcase and carburetor for leaks. If air leaks are detected through the crankshaft seals, they must be replaced. If air leaks are detected in the carburetor, the cause can be eliminated by installing a repair kit of gaskets.

Choice

Manufacturers of chainsaws recommend using a saw bar of a certain size and technical parameters for each specific model. To make the right choice, you should take these parameters into account and then there will be no problems.

Main settings

When choosing, consider the main five parameters:

- Length.

- Width of the guide groove.

- Tire sprocket pitch.

- The number of chain links intended for it.

- The type of shank and model of chainsaws on which it can be installed.

Depending on the power of the chainsaw, it is possible to install headsets of different lengths on it, which allows you to adjust the performance and load on the saw. Manufacturers can indicate the length in both centimeters and inches and, as a rule, this is not the entire length of the tire, but only a characteristic of the length of its working part. Choosing the right tire for a chainsaw should begin with studying the instructions for the chainsaw and finding out the permissible length for a particular model. For example, for the Shtil MS 180 chainsaw, the recommended lengths are 14 or 15 inches.

When choosing a headset, do not neglect the instructions and use longer components, because... This can put excessive stress on the engine and cause premature wear.

The width of the guide groove, as well as the pitch of the sprocket on the bar, must correspond to the same parameters of the saw chain, otherwise installation of the chain on the bar will not be possible. The groove width for household models of chainsaws is 1.1 and 1.3 mm for professional models 1.5. The most common sprocket pitch sizes are 0.325 and 3/8 inches.

When choosing, remember that the pitch of the chain sprocket must be the same as the pitch of the chainsaw drive sprocket; accordingly, when replacing the tire and drive sprocket in the kit, you can select these parameters as you wish.

Depending on the type of shank, the bar can only be installed on certain chainsaws. This is because the chain lubrication hole on bars designed for certain brands of chainsaws may be located in different places. For example, a tire from a Stihl chainsaw cannot be installed on Husqvarna and vice versa, be sure to take this into account when choosing.

A high-quality video description of the selection process can be viewed below. In this video, a specialist from the gas-powered tools sales department talks about the main characteristics of the saw set, its types and sizes.

Why does the chainsaw not pick up speed and stalls?

If the chainsaw is unable to gain speed a minute after starting or stalls when the gas trigger is pressed, most likely the carburetor or engine crankcase is leaking. As in the previous case, the problem can be solved by checking for leaks and adjusting the carburetor.

If your chainsaw does not pick up speed and stalls after it has been running normally for about 5 minutes, the cause may be a defective fuel tank breather. The vacuum created in the fuel tank during operation of the tool does not allow the engine to receive the necessary amount of fuel for its normal operation, and for this reason it will be unable to gain speed or stall. In this case, if you stop the tool, open and close the fuel tank cap and start the chainsaw again, the tool will again work normally for about five minutes, after which it will stop picking up speed or stall.

The reason that the chainsaw does not pick up speed may also be excessive carbon deposits in the muffler, which makes it difficult to release exhaust gases, thereby reducing engine power and speed.

If you want to check the tightness of the crankcase, but do not have a special tool, you can use the following testing method.

Algorithm for checking the crankcase for leaks

- Remove the side cover and bar from the chainsaw.

- Unscrew the spark plug and insert a string with knots into the cylinder through the spark plug hole, thereby stopping the movement of the piston and crankshaft.

- You can use an old cord from a starter as a cord with knots, tying knots on it every 3-5 cm.

- Unscrew the chainsaw drive sprocket.

- Remove the oil pump cover and the pump itself.

- Remove the starter from the chainsaw.

- Unscrew and remove the flywheel.

- Remove the carburetor.

- Using a syringe, pour gasoline into the crankcase through the hole under the carburetor in the cylinder, while observing the crankshaft seals. If gasoline flows through them, it means the seals have become unusable and need to be replaced with new ones.

- It is better to entrust the installation of oil seals to professionals.

An indirect sign of crankcase leakage is oil leaks in the area of the seals.

Chainsaw chain problems

In addition to problems with the engine, the chainsaw may experience operational problems due to a malfunction of the cutting (sawing) unit, consisting of an oil pump, bar and saw chain.

There is no oil getting to the tire

Usually, if oil does not flow to the chainsaw chain, you need to check the channels through which oil is supplied to the tire and clean them of dirt. If the previous steps did not reveal the cause of the problem, then you will have to check the oil pump. To do this you need:

- remove part of the chainsaw casing;

- remove the coupling;

- unscrew the 3 screws and remove the cover hiding the pump;

- get to the worm gear gear that rotates the pump shaft.

If the thread on it is worn out, the shaft does not rotate, the pump does not work, and the chain is not lubricated. A worn gear needs to be replaced. You can also remove the oil pump itself and manually try to pump oil through it. If it does not pump, the pump should be replaced.

Chainsaw oil filter

Be sure to remove the oil filter from the reservoir and clean it if necessary.

Also, a lack of lubricant may be due to its leakage. You should check how tightly the pipes coming from the oil pump are connected. If the tightness is broken, the tubes are replaced with new ones.

The chain breaks

If the chain breaks while the chainsaw is running, this could happen when it hits a hard object, such as a nail. If the chain constantly breaks, then the reasons may be the following.

- Low quality of the metal from which the saw chain is made. It is necessary to buy gas cutter saws from reputable brands.

- Chain overheating due to poor lubrication. As a result, the saw overheats, the properties of the metal change, and it breaks under load. It is necessary to check the entire chainsaw lubrication system (discussed above).

You can also learn about the reasons for frequent circuit breaks from this video.

The chain doesn't turn

This nuisance often plagues inexperienced chainsaw owners. They forget to remove the brake after starting the engine. As a result, the chain does not spin, the brake system overheats, and the clutch mechanism fails. The problem is solved by removing the saw from the brake. If the clutch is not burnt out, you will notice the chain turning. Otherwise, the clutch mechanism will need to be replaced.

The chain gets dull quickly

Basically, the reason that the chain becomes dull quickly is the poor quality of the saw. Trying to save money on buying branded chains, chainsaw owners buy saws from unknown manufacturers, or, due to inexperience, purchase counterfeits of well-known brands. It is best to buy a cutting element for a gas cutter in company stores. Stihl saw chains are very popular among owners of this equipment.

The chain doesn't stop

If, when working with a chainsaw, you notice that the saw chain does not stop at the right moment, then this breakdown may have 2 options.

- The brake band is dirty. When operating the saw, dirt, sawdust, dust, etc. may get under the band. As a result, the brake mechanism becomes blocked and the chain does not stop when the gas is released. The problem is eliminated by cleaning this unit.

- The brake band is worn out. This element of the brake system needs to be replaced.

The chain is jammed

This happens when the drive or driven sprocket wears out. The chain usually starts to jam under load. But without load the saw can rotate. The photo below shows a worn chainsaw drive sprocket.

The next photo shows that the reason why the chain jams must be looked for at the location of the driven sprocket.

But what to do if the chainsaw is completely jammed, and all attempts to pull the starter are unsuccessful? This malfunction sometimes occurs on Chinese-made chainsaws. It is caused by the bolts that screw the engine to the plastic casing of the unit becoming loose due to vibration. These bolts are located directly under the flywheel (magneto). In the photo below, arrows show the location of the problem bolts.

As they unscrew, they begin to rub against the flywheel and can completely jam the chainsaw. The following photo shows the flywheel with some scuff marks from the bolts.

To fix the problem, you will need to remove the flywheel from the engine shaft and tighten the bolts.

The chainsaw cuts crookedly

This problem can occur if the chain is dull or improperly sharpened. This applies to a greater extent to new chainsaws. But if the tire is worn out, then even after replacing the chain you will notice that the saw is pulled to the side. Tire wear can be easily determined by placing it on a level table and applying a square to it, as shown in the following photo.

In this case, you can see that there is a gap of about 2 mm between the tire and the corner. It is because of this one-sided tire wear that the chainsaw cuts crookedly. The problem can only be solved by replacing the tire with a new one.

Important: to extend the life of the chainsaw bar, it must be removed and turned over from time to time. Thanks to this, the tire will wear more evenly and will not cause chain misalignment.

Malfunctions leading to improper operation of the chainsaw

There are a number of malfunctions that must be taken into account when diagnosing, since they can lead to interruptions in the operation of the saw.

- Wear of crankshaft bearings. If the crankshaft bearings are worn out, runout will inevitably appear on the main shaft where the flywheel is attached. In such a situation, it is impossible to adjust the gap between the flywheel and the ignition coil, which leads to interruptions in spark formation and unstable operation of the chainsaw.

- Impulse channel is dirty. The pulse channel serves to ensure the operation of the fuel pump; accordingly, its contamination will lead to improper operation of the pump, which will make it impossible for the saw to operate (it will start and immediately stall).

- CPG wear. As a rule, with increased wear of the CPG, a decrease in compression in the chainsaw engine is observed, which will certainly affect its ability to develop speed.

- Dirty fuel and air filters.

Which tire is better to install

Answering the question of which tire is best to install on a particular model of chainsaw is quite simple. It is worth installing the model recommended by the tool manufacturer. As a rule, leading companies producing chainsaws, in parallel with the production of the tool itself, also produce consumables that are specially designed for their tool.

Accordingly, it is better to choose a tire for a chainsaw in the direction of products designed specifically for your model and manufactured by the manufacturer who assembled the saw itself.

If this is not possible, a good option is chainsaw bars that are made by leading companies in the saw chain and chainsaw bar industry, such as Oregon.