Regardless of complexity, tasks and frequency of use, all tools require periodic maintenance or repair. Chainsaws are no exception, despite their thoughtful design and performance characteristics. But, like all equipment with moving parts, chainsaws are subject to wear and tear and require periodic inspection. And first of all, such parts include the saw chain, to extend the service life of which, timely replacement of the sprocket is important. This is exactly what we will talk about in this article.

Replacing a sprocket on a chainsaw: how to remove and change it yourself

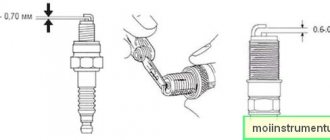

Any manufacturer indicates the tooth pitch in the operating instructions.

Considering that a driven sprocket is also installed on the saw bar (designed to create the necessary tension), the pitch here and there should be the same. Chainsaw drive sprockets can be solid or prefabricated. In the first case, the sprocket includes a hub onto which a ring gear is pressed. This is exactly how the parts in Champion chainsaws are arranged. When replacing, the product should be removed completely, since at home it is almost impossible to maintain the tension value specified at the manufacturer. And purchasing a crown separately is also a problem.

In chainsaws from Stihl or Husqvarna, the replaceable crown is located directly on the drum shaft, and therefore replacing it does not present any difficulties.

Tooth wear is determined by the following criteria:

- There are clearly visible radii at the transition points from the tooth to the cavity.

- The width of the tooth is uneven in height.

- There are metal chips at the top of the tooth.

- There are numerous burrs and marks on the inner surface of the hole in the hub (a consequence of poor lubrication).

- There is a noticeable groove on the sprocket from the saw bar (the chain also needs to be changed).

- The chain jams at the initial moment of start-up.

If at least one of the above factors is present, the drive sprocket must be replaced.

Before starting work (especially if the chainsaw has been running for relatively little time), it is worth checking the fastening of the saw bar. The tensioner screw has come loose or the fastening nuts have come loose - the guide is no longer aligned with the longitudinal line of the saw blade. It begins to contact not with the center, but with the periphery of the teeth of the drive sprocket, provoking their intense wear. After tightening the specified elements, check the operation of the chainsaw: if the play is not eliminated, then the sprocket will have to be changed.

As already noted, the sprocket can have a separate and pressed crown. Therefore, the sequence of actions will be different.

For a stationary located crown, the following is sequentially produced:

- Removing the casing;

- Removing the saw bar along with the chain;

- Disconnecting the clutch from the engine (the piston must first be locked);

- Removing the clutch together with the drum;

- Removing the crown from the drum using a regular open-end wrench (some manufacturers also include a puller with the spare parts kit).

The unit is assembled in the reverse order. For some models, before dismantling the crown, you will also have to remove the air filter.

When disassembling a chainsaw drive sprocket that has a replaceable ring, the procedure will be almost the same, but at the final stage only the ring needs to be replaced.

After completing the work, it is necessary to check the effectiveness of the replacement. To do this, check the chain tension: if, when the brake is released and an attempt is made to pull the chain in the direction of its movement, it is motionless, then the fastening is “overtightened” and the tensioner should be slightly released.

The success of the work is determined by the presence of a special repair kit purchased for a specific brand of chainsaw. Otherwise, you should know exactly the size of the saw and the pitch of the teeth.

The Husqvarna 137 chainsaw is designed in such a way that all resources maintain maximum performance for a long time:

- The Auto-Tuning option allows you to use automatic carburetor tuning.

- If air enters, secondary filtration occurs, which reduces the load on the filter.

- Vibration attenuation is due to the LowVib function.

- There is the possibility of easy starting, thanks to which the operation of the Husqvarna 137 chainsaw is not interrupted at any time of the year.

- The chain tensioner is located on the side of the housing.

- For various private adjustments and repairs, a universal key is used.

- The drive sprocket is equipped not only with an auxiliary hole for receiving lubricants.

The video will help you change the drive sprocket on a Husqvarna chainsaw. I will show you in detail and step by step how to do it.

An asterisk or centrifugal mechanism is a part shaped like a star. It takes on the engine torque and transmits it to the guide and saw chain. This guarantees the rotation of the cutting set and the sawing process itself. It operates automatically, which depends on the amount of engine speed.

The clutch drum can be located both outside the chainsaw and on its inside - under a separate cover. It performs a protective function not only in relation to the material from which the sprocket is made, but also for the operator, who may be injured by it during work. In addition to the function of chain rotation, the saw drive star prevents the occurrence of malfunctions of the motor system in cases where the chain jams or stops rotating.

The drum, located at the base of the mechanism's clutch, is an integral part of the chain drive system. This part is shaped like a star, which is how it got its name. Depending on the type of chainsaw, the part can be professional or household. Since a professional saw is used more often than a household saw, the drive sprocket also requires regular replacement. If we talk about household tools, then everything depends on the amount of work performed and the load that is placed on the device circuit.

Most often, the sprocket, ring and saw bearing require replacement.

In any case, the main reason for replacing the sprocket is the wear of its teeth by the chain. In the case when a monolithic drum is installed in the device, the surface of the chain cuts through it almost completely, which requires a complete replacement of the entire part. If the chainsaw has a drum with a replaceable crown, then you can limit yourself to only replacing the crown.

Usually, in order to remove the sprocket from a chainsaw, many people turn to specialized service centers, but if there is a need to save the family budget, you can do this work yourself. This event does not look complicated, but it requires having all the necessary parts and tools. The sprocket replacement process is similar for any device model.

The Allen wrench is the main tool you will need when replacing the sprocket.

The most common reasons that force tool repairs associated with replacing the drive sprocket are:

- chain jamming due to defects occurring during operation of the unit;

- high sprocket wear as a result of long-term operation of the unit.

With regular use of the device, increased wear of the drive sprocket occurs as a result of increased loads placed on it during the process of sawing wood. There are two ways to operate the device:

- use of one saw chain;

- using several saw chains alternately.

When using the first method of operation, the chain is operated until it is completely worn out. This method has several disadvantages. The main one is the problem with monitoring wear during intensive operation of the unit.

When using two or more chains in the process, it is possible to achieve uniform wear of the chains and sprocket, which allows you to extend the period of operation of the device before repairs, which involve replacing the sprocket. In addition to sprocket wear, you should not forget about the bearing that is installed in the sprocket. This structural element operates at any engine speed. When replacing the sprocket, the bearing must also be replaced at the same time.

The coupling complete with sprocket must be replaced promptly. If repair work is not carried out in a timely manner during operation, the tool experiences increased vibration, which leads to increased wear of the bearings installed in the internal combustion engine on the crankshaft axle shafts.

The design of the chainsaw has not only a driving sprocket, but also a driven sprocket. The driving sprocket of the chainsaw is located in the design of the tool, and the driven sprocket is located at the end of the bar. The purpose of the driven device is to equalize the tension and direction of movement of the chain device.

Driven star on tool bar

Leading devices can be solid or prefabricated. Solid products consist of a hub with a pressed-on gear ring. When replacing, the entire mechanism assembly is dismantled, since the gear structure is one-piece. Chainsaws of many well-known brands are equipped with solid gears from the factory.

What does a solid gear look like on a chainsaw?

Collapsible products are more advanced, since the process of replacing them is simplified through the simplest mechanism design. Only one crown is replaced, the cost of which is 2 times less than the prefabricated mechanism. The appropriate wear of gear teeth can be determined by the following signs:

- The presence of large radii at tooth transition points

- Uneven tooth width

- Detection of chips and metal shavings on the top of the teeth

- Scores and marks on the inner surface of the holes in the hub

- When starting the tool, chain jamming is detected

Currently reading: Adjusting the ignition of a Ural 2 electron chainsaw.

Technical characteristics of the Ural 2T Electron chainsaw If the driving device wears out, it is necessary to replace it. You can do this yourself, for which you initially disassemble the tool and determine the version of the installed device. Even if a non-separable gear is installed on the tool, then instead of it you can install a prefabricated mechanism, which is more rational.

Collapsible gear type for chainsaw

There are two types of installation of leading stars on chainsaws. The first method involves placing the gear on the outside. Such designs are the most common on Stihl chainsaws. The design of such a device is shown in the photo below.

Non-separable type product on the tool

The second option is typical for instruments of Chinese origin. The gear teeth are located not on the outside, but on the inside, that is, the device is located in reverse.

Star design on a Chinese chainsaw

Depending on the design of the tool, the process of dismantling the products in question will differ.

A little about the rules for operating the node

All chainsaws, regardless of the manufacturer, are divided into:

- Household. Low power. Designed for small amounts of home repair work. Duration of continuous operation: half an hour - an hour. Recommended use is up to 50 hours per month.

- Semi-professional. Medium or high power Capable of working without interruption for several hours. Suitable for small construction or renovation. Monthly use is up to 100 hours.

- Professional. High power, additional functionality. Can be used continuously throughout the entire work shift. Designed for logging, medium and large construction, procurement workshops of enterprises.

They all have a similar design of the main components and high build quality. The main difference lies in the design of the working chain and the materials used for the manufacture of parts and assemblies.

Chainsaw device

The suitability of a chainsaw for use depends on the style of use of the blade and sprocket. There are usually two of them:

- The chain is used until the teeth are completely worn out. The gear is also changed along with it.

- Several chains with different pitches are used, which have their own gears corresponding to them in terms of the number of teeth and pitch.

In the first case, they cut everything, including nails and staples. This causes increased wear on both the chain and gear. You have to frequently edit and sharpen the chain, spending a lot of time on it.

The chain and sprocket should only be replaced together. During operation, the blade rollers are worn into the gear, stretching somewhat as the teeth wear. If the old chain is paired with a new sprocket (or vice versa), there will be no such correspondence.

When starting, the teeth will hit the links, which will lead to increased vibration and wear of the entire chainsaw.

The condition of the gear-blade pair also affects the operation of the clutch and drive bearing. In the “Work” mode, the crankshaft rotates. In idle mode, with the clutch disengaged, the bearing begins to rotate. If it is insufficiently lubricated, it is subject to increased wear, which causes even greater tooth runout.

Both the blade and the sprocket are subject to periodic replacement. It's better to do it at the same time

Causes of malfunctions and how to determine the need for replacement

When idling, the spring compresses the cams and they do not touch the drum. As the speed increases, the centrifugal force exceeds the spring stiffness and the cams come into contact with the walls of the drum. The latter begins to rotate.

The teeth of the saw chain mesh with the teeth of the drive sprocket. One of the functions of an automatic centrifugal clutch is to protect the engine when the load on the chain increases beyond the permissible limit. This can occur when the chain gets stuck.

The outer part of the drum is covered by an emergency brake band. When the handle is folded back, the belt is pressed against the drum and slows down its rotation. The effect is the same as when the chain jams.

A feature of all chainsaws is that the drum and clutch cams are attached to the shaft using a nut with a left-hand thread so that the mechanism does not unwind during operation.

Wear on the drive sprocket teeth can occur for several reasons:

- natural wear and tear along the chain teeth;

- accelerated wear as a result of excessive chain tension or lack of lubrication;

- incorrectly selected chain;

- technological defect.

Metal wear can be determined visually by inspecting the sprocket without removing it from the saw. Dents and chips on the surface should not exceed 0.5 mm.

The need for replacement is determined by increased noise when the chain moves, but this is typical only in the presence of deep potholes. It is difficult to notice shallow wear during operation, but the chain will wear out greatly. When the teeth are broken, the chain may move jerkily, which is especially noticeable during operation.

The clutch operates automatically, depending on the number of engine revolutions.

The units are equipped with a centrifugal clutch, which operates automatically, depending on the number of engine revolutions.

When the engine of the unit operates at idle or low speed, the elements of the clutch basket, which have friction linings, have a certain level of freedom in the circular direction. The presence of freedom of movement leads to the fact that, under the action of springs, the elements are attracted to the center of the rotation shaft and do not transmit rotational motion to the sprocket drum.

As the engine speed of the device increases, the centrifugal force exceeds the force of the springs, which leads to displacement of parts with friction linings. Replacing the piston on a Chinese chainsaw. Replacing the piston group of a Chinese chainsaw 4500replacement piston group of chainsaw 4500 cylinder-piston group for a 45 mm chainsaw replacing the piston group on a chainsaw stihl ms180 chainsaw china replacement.

Replacing the sprocket on how to unscrew the clutch on a chainsaw. On a Chinese chainsaw. These elements are pressed against the inner walls of the drum under the influence of centrifugal force. Due to this contact, rotational motion is transmitted to the drum and sprocket, which drives the saw chain of the tool.

More common reasons that force tool repairs associated with replacing the drive sprocket are:

- chain jamming due to defects appearing during operation of the unit;

- the highest wear of the sprocket as a result of long-term operation of the unit.

- professional;

- household.

The main difference between them is the frequency of replacement and the rate of wear: in the models of the “Pro” series, wear occurs faster and repairs occur more often.

The latter consist of a hub with a stationary crown of a certain number of teeth. Their factory pressing does not allow the crown to be removed separately from the hub. This situation is typical for many Chinese chainsaws, for example, from the Champion brand.

The situation with prefabricated sprockets is simpler: the removable crown is quickly unscrewed from the drum axis, so repairs do not cause any particular difficulties. This option is an advantage of most saws of European origin, for example, Shtil or Husqvarna.

Drive gears, according to their design, are divided into:

- Whole. The part includes a hub into which the crown is pressed. You can only remove the part for replacement in its entirety. In the industrial conditions of the manufacturing plant, it is possible to ensure the design values of the interference. Special equipment is used for this. This operation cannot be carried out in a home workshop. Difficulties also arise when trying to buy a crown separately - the manufacturer does not consider it an independent part and does not supply it to stores and service centers.

- Prefabricated. The crown is made as a separate part; it can be removed using a special puller or special tricks with a universal tool.

Solid sprocket

Experts identify the following signs of wear on the drive gear teeth:

- semicircular depressions are visible at the base of the tooth;

- the thickness of the tooth varies with height;

- chipped zones at the top;

- scratches appeared inside the hub hole;

- the chain has worn out the groove on the sprocket;

- When starting, the chainsaw jams.

A chainsaw sprocket with such signs should not be used; it must be removed and replaced.

According to the manufacturer's recommendations, the tool should be inspected before starting work. In this case, be sure to check the condition of the saw bar and whether it is securely fastened. If the screw that regulates the position of the chain roller and its tension is loosened, or the nuts securing the bar to the body are loosened, it deviates from the plane of the chain.

Sprockets with replaceable and stationary crown

After tightening the fasteners and making adjustments, do a test run. If free play remains, the sprocket will have to be removed and replaced.

The Husqvarna 137 chainsaw is an amateur, semi-professional class tool. The model achieved high popularity among consumers due to its good performance, light weight and versatility. These days, the Husqvarna 137 chainsaw is actively used not only by gardeners, but also by utility workers.

There are already several 10-cylinder chainsaws in operation from different manufacturers, capacities, and most importantly for special purposes. Saws are divided into:

- prof (for felling and construction);

- household (garden).

Currently reading: Chainsaw MAKITA EA3202S40B, owner reviews

Accordingly, their drive gear will be different, as well as the sequence of actions. Discover 253 best selection of husqvarna chainsaw sprockets 142 chainsaw chainsaw replacement. Assembling a husqvarna 142 chainsaw. Husqvarna 140 chainsaw. Replacing a chainsaw sprocket. Husqvarna 340 chainsaw repair, chainsaw replacement sprocket.

In this regard, you need to know how to remove the sprocket from the chainsaw correctly so as not to damage the tool. This part is also called a centrifugal mechanism or clutch disc.

To better understand the entire process, it is necessary to understand what an asterisk is and how it is used.

You may also be interested in the article,

DIY chainsaw chain sharpening

.

The main malfunctions of chainsaws and steps to eliminate them are described here.

And in this article, you can learn how to repair a Parterre 350 chainsaw.

If the part is not replaced in a timely manner, the stability of the tool will be impaired. A worn part provokes excessive vibrations, which, in turn, have a negative effect on the crankshaft bearings.

Tooth wear of up to 0.5 mm is considered normal. However, users often bring the part to a deeper groove of about 1 mm, not realizing that operation causes damage to other parts of the chainsaw. Naturally, subsequently there is a breakdown of the bearings, which need to be replaced.

When the engine of the unit is running at idle or low speed, the elements of the clutch basket, which have friction linings, have a certain level of freedom in the radial direction. The presence of freedom of movement leads to the fact that, under the action of springs, the elements are attracted to the center of the rotation shaft and do not transmit rotational motion to the sprocket drum.

When the engine speed of the device increases, the centrifugal force exceeds the force of the springs, which leads to displacement of elements with friction linings. These elements are pressed against the inner walls of the drum under the action of centrifugal force. Due to this contact, rotational motion is transmitted to the drum and sprocket, which drives the saw chain of the tool.

The main advantage of this type of clutch is that when the saw chain jams, elements with friction linings slip, which protects the internal combustion engine from serious damage.

The main malfunctions of chainsaws and steps to eliminate them are described here.

Features of the Husqvarna 137 chainsaw, which is suitable for all types of work in gardens and households, plantations, small factories and more, is designed with a 2.2 horsepower engine. The fuel tank is designed for 0.4 liters. Recommended tire for Husqvarna 137 chainsaw.

H30, and the length can vary from thirty-four to thirty-eight centimeters. It should be borne in mind that in order to avoid early wear and unforeseen failures, you can not only meet the manufacturer's performance requirements, but also use original spare parts for the Husqvarna 137 chainsaw, which are in an affordable price range.

Video: Assembling the Husqvarna 137 Chainsaw

The weight of the chainsaw without the headset is 4.6 kg at full speed. 5.5 kg. The rugged body houses the 2.18-liter X-Torq two-stroke carbureted internal combustion engine. With. To start the Husqvarna chainsaw, an inertia starter with a spring is provided to facilitate the starting procedure. Built-in forced air supply system. Duplicating air purification increases the service life of the air filter and, accordingly, the chainsaw itself. The ignition system is contactless. Thanks to the built-in Auto Tun system, the carburetor is installed automatically. To increase safety when working with the tool, an inertial chain brake is provided, which is activated in case of play, hand protection, “Low Wib” anti-vibration protection, and a muffler.

READ Gasoline saw partner

The chain tensioning mechanism is located on the side of the Husqvarna 137 chainsaw. A special universal wrench is used to secure the bar and adjust the chain tension. For this modification of the chainsaw, H30 tires measuring 33 cm (33 cm) are used; options with tires from other manufacturers no longer than 38 cm are possible. Lubricant is supplied to the chain mechanism automatically with a moving chain.

Characteristics

| engine | 137 | ||

| Cylinder capacity, cm | 36 | ||

| Piston stroke, mm | 32 | ||

| Idle speed, rpm | 3000 | ||

| Recommended max. Speed without load, rpm | 13 000 | ||

| power, kWt | 1,6 | ||

| Ignition system | |||

| Director | RE Felon | ||

| Ignition system type | CD | ||

| Spark plug | Champion | ||

| Interelectrode gap, mm | 0,5 | ||

| Fuel and oil system | |||

| Director | Valbro | ||

| Carburetor type | Wt-660 | ||

| Fuel tank capacity, l | 0,37 | ||

| Oil pump performance at 8500 rpm, ml/min | 6. 8 | ||

| Tank capacity with oil chain, l | 0,19 | ||

| Oil pump type | Car. | ||

| Weight | |||

| Without tires and chains, kg | 4,6 | ||

| Noise level | |||

| Equivalent acoustic pressure level at the operator's ear, measured in accordance with international standards, dB (A) | 98 | ||

| Equivalent acoustic power level measured according to international standards, dB(A) | 108 | ||

| Vibration level | |||

| Front handle m/s2 | 4,9 | ||

| Rear handle, m/s2 | 7,7 | ||

| tirechain | |||

| Standard tire length, inch/cm | 13/33 | ||

| Recommended tire length, inch/cm | 13/33 | ||

| Useful cutting length, inches/cm | 12,5 / 32 | ||

| Pitch inch | 0.325th most common | ||

| Lead link thickness, mm | 1,3 | ||

| Number of teeth on drive sprocket | 7 | ||

| tire | chain | ||

| Length inches | Pitch inch | Maximum. Tire end radius | |

| 13 | 0.325th most common | 10T | Husqvarna H30 |

| 15 | 0? 325 | 10T | Husqvarna H30 |

Characteristics

- A light weight

- ICE X-Torq carburetor.

- The power of the gasoline engine is 2.18 liters. With.

- Carburetor Walbro WT-660.

- Simple starting system.

- Air injection. Additional air supply.

- Double purification of the air entering the carburetor.

- CD ignition system.

- Carburetor auto tuning.

- Anti-vibration system Low Vib.

- Chain lube. Automatic.

- Compact size.

- Mobility, no connection to a power source.

User guide

Every Husqvarna chainsaw comes with an instruction manual.

The instruction introduces the owner of the equipment to the tool, teaches methods and techniques of work, and also draws attention to the correct maintenance of the gasoline unit. The operating instructions consist of the following sections:

- The structure of the Husqvarna 137 chainsaw, step-by-step assembly of the unit, according to detailed descriptions from the instructions.

- Safety measures during operation and maintenance.

- Characteristics

- Sawing techniques and methods.

- Preparing the Husqvarna 137 chainsaw for use.

- Starting the chainsaw.

- Service.

- Troubleshooting the Husqvarna 137 chainsaw.

- Equipment.

Basic Safety Precautions

- Wear protective clothing and protect your hands.

- Protect your workplace.

- Transport the chainsaw with the high-voltage cord disconnected and the fuel and oil tanks tightly closed.

- Keep your chainsaw away from your work area.

- Learn sawing techniques and techniques.

- Warn about the presence of strangers in the area where sawing will be carried out.

Replacing a sprocket on a chainsaw: how to remove and change it yourself

The video will help you change the driven sprocket on a Partner chainsaw, we will show you how to simply and quickly remove the clutch.

The video will help you change the driven sprocket on a Husqvarna chainsaw. I will carefully and step by step show you how to do it.

A significant part of them are associated with the chainsaw drive sprocket or clutch disc - one of the important elements of all chainsaws without exception.

Despite the relative simplicity of its design and the instructions in the operating instructions, every year thousands of inexperienced craftsmen reach a dead end in this matter and waste money on service centers or produce it incorrectly, which further aggravates the problem.

That is why we will dwell on this topic and understand the structure, functional features and repair of this working unit of chainsaws.

A fairly common problem in Husqvarna 137 and 142 chainsaws is oil pump failure. This video shows a quick one.

The video will help you change the drive sprocket on a Husqvarna chainsaw. I will carefully and step by step show you how to do it.

Operating instructions for Husqvarna chainsaws

In order to extend the life of the chainsaw and reduce wear of its main parts, you must carefully study and adhere to all the tips specified by the manufacturer in the instructions for use. Below we list a number of the most common questions related to the operation of Chinese and Swedish chainsaws manufactured by Husqvarna, and give detailed answers to them.

What kind of gasoline should I put in my Husqvarna chainsaw?

To prepare the filling mixture for Husqvarna chainsaws, you should use AI-92 fuel. It is extremely rare that the operating instructions for newer models of this brand indicate that 95 gasoline can be used to prepare the mixture.

Sequencing

Chainsaw sprocket, ring and bearing

The vast majority of household saws are sold under the Partner brand. It is enough to simply change the sprocket in them, even at home, by purchasing a repair kit.

Since most often the sprocket in household saws is a assembled mechanism, it rotates due to the bearing. That is, when changing the sprocket, you inevitably change the bearing and the shaft.

In professional models (such as Shtil and Husqvarna), as well as in household ones, if it is not possible to have a specialized wrench on hand for removing the star, they use a soft cord with a diameter of 5-6 mm.

In all cases, the sequence of actions is as follows:

- The side cover must be opened to gain access to the tire and sprocket.

- Next, you need to remove the tire by loosening the chain.

This is what a chainsaw tire looks like

- Once the sprocket is free, you need to unscrew the spark plug to gain access to the engine piston.

Is it possible to shorten

The chain on the saw breaks, this is a common occurrence and there is no need to be upset. Manufacturers have made sure that chains can be repaired and shortened. On sale are spare links for chains of different types and sizes, rivets for chains, riveting and riveting machines.

Using machines, you can rivet a chainsaw chain at home even for those who have never done anything like this.

Chains are available for sale in coils of 50-100 meters, which you can buy and rivet yourself.

Coils are beneficial for professionals who use chainsaws every day, for example, forest fellers or sawmill workers.

How to remove and change the sprocket on a chainsaw

On the left is a new part, and on the right the unit shows obvious signs of wear. If, after removing the tool guard, a chipped gear tooth is discovered, the part must be replaced. To do this, you need to buy an asterisk in a tool store or in an online store, where there is a much larger selection, which will allow you to choose the best option.

To change the gear, you need to decide what type of device is on the tool and what will be installed. For each type of mechanism, the sequence of actions will be different. Replacing the sprocket on a chainsaw of the first version of the non-separable type is as follows:

- Removing the casing, as well as the bar and chain

How to remove the protective cover on a power tool

- Removing the retaining ring and the washer behind it

Removing the corkscrew ring

- The gear is dismantled together with the drum mechanism. The condition of the product is assessed. The presence of defects indicates the need to replace it

- The roller-type bearing is removed, which is also better to replace if there are signs of wear. If the condition of the bearing is satisfactory, then it can be lubricated and installed in place. When installing a new bearing, it must also be thoroughly lubricated with Litol-24 type lubricant.

- Instead of a non-separable device, you can install a prefabricated mechanism. This will simplify the process of replacing the drive gear later.

The process of assembling the mechanism is carried out in reverse order. If you need to replace a collapsible type product, then the process will be almost the same, only in the end one crown without a drum is replaced.

Design differences between solid and collapsible type gears

Currently reading: Chainsaw ECHO CS-353ES-14: review and reviews

If the replacement process is completed, you need to check. The tension force of the chain is checked by turning on the handbrake and pulling the chain in the direction of its movement. The immobility of the product indicates that the fastening is overtightened. To loosen it, you will need to release the tensioner.

Features of saw designs

Professional chainsaw of the STIHL brand

There are already several dozen chainsaws in operation from different manufacturers, capacities, and most importantly for special purposes. Saws are divided into:

- professional (for felling and construction);

- household (garden).

Accordingly, their drive gear will be different, as will the sequence of actions. This is a feature of saw gear devices. For most professional tools, the tire can change its position on the saw in two planes.

The main malfunctions of chainsaws and steps to eliminate them are described here.

Repair of Partner P350 XT chainsaw. replacing the drive sprocket

Repair of Partner P350 XT chainsaw. replacing the drive sprocket.

The design of its crown determines such an important parameter as the choice of chain by pitch.

- Installing a new part on a worn sprocket reduces the smoothness of its operation, accelerates wear, and initiates the risk of its breakage and creating a traumatic situation.

- There is also an increase in operational loads on the engine and the elements of the kinematics of the tool.

- A similar process takes place when installing old stretched chains on a tire, the diameter of which is adjusted to the size of the tire by removing part of the links.

Experts also do not advise arbitrarily changing the size of the sprockets. The experiment may have a negative impact on the service life of the engine and the kinematics of the tool as a whole.

The safety of sawing operations of varying degrees of complexity is ensured by the effective operation of the emergency stop brake and devices that block the scattering of the ends of the chain in the event of an accidental break. In any case, the most reliable prevention of emergency situations is maintaining the chainsaw in good technical condition.

The drive sprocket for a chainsaw of any power category is made from special steel and processed using a special technology, so repairing the part by deposition arc welding and subsequent milling is not possible.

The price of the part itself is several times less than the cost of replacing it in service structures.

- The advantages of self-repairing the drive unit are less costly and time-consuming.

- If you have the appropriate tool, the job can be completed in a fairly short time interval.

If the gear has a replaceable ring, you should carefully check the condition of the base. If nicks, chips, deep scratches, changes in geometry or corrosion are detected, not only the crown, but the entire part should be replaced. The combined operation of worn and new parts in one assembly will lead to a reduction in the service life of the entire assembly. The risk of jamming or circuit breakage increases significantly.

In addition, the vibration load on the clutch, transmission and engine of the device will increase. The same factors arise during prolonged operation of one circuit.

You should also not change the diameter of the gears (and, accordingly, the number of teeth). When working with an enlarged or reduced sprocket, forces arise in the transmission and engine that the designers of the device did not expect. This will shorten the tool's service life and will not improve its performance.

Despite the presence in the design of the chainsaw of safety systems that instantly stop the movement of the blade when it breaks or the tire is destroyed and protects torn links from scattering, it is better not to lead to such situations. The need to replace the gear is only increased by safety requirements.

Are there ways to extend the life of an existing sprocket?

The main ways to extend the working life of a chainsaw drive sprocket:

- use several chains (preferably three). This method is the most gentle and convenient for the chainsaw owner in that there is no need to constantly tighten a chain worn out by intensive work. Operating three chains in turn will save the life of the sprocket and delay its replacement;

- high-quality maintenance of the drive sprocket bearing. This part plays an important role in the functioning of both the drive sprocket and the engine. For lubrication, it is recommended to use a special lubricant. The sprocket bearing is not constantly engaged, but only at idle speed, and therefore requires periodic lubrication. You can use a tire nose lubricant, such as standard lubricant from Repsol or Husqvarna.

Algorithm for self-replacement of the clutch drum with sprocket

Removing the chain

As with any other tool, chainsaws require careful maintenance. It is necessary to constantly check the oil supply to the chain, chain tension, operation of the brake, ignition system, etc. Fortunately, almost any problem can be solved at home on your own.

- dismantling the headset and air filter;

- installing a piston retainer in the spark plug hole;

- The clutch and the gear drive, integral with the drum, are removed using a puller; the sprocket can only be unscrewed clockwise.

If significant wear of the separator, breakage of the springs of the centrifugal mechanism and cams are detected, it is recommended to replace the entire set.

If the condition of the removed parts is beyond doubt, the entire mechanism is assembled in the reverse order. To securely fix the clutch on the crankshaft, it is enough to unscrew the piston stopper, pull out the standard starter cord and return it to its original position.

Amateur craftsmen should be warned against simplifying the requirements of repair technology and saving money by installing relatively cheap Chinese components.

The quality of the work done is guaranteed by attention, accuracy, and compliance with the sequence of all dismantling and assembly operations.

Removal and replacement process

In the first case, the removal process is somewhat simpler. To do this, you just need to pull off the retaining ring with a screwdriver, after which the sprocket can be easily removed.

In the second case, you will first have to remove the clutch. To do this, you need to lock the shaft on which it is located. This can be done in two ways:

- Or unscrew the spark plug and screw in a special piston stopper instead, which would prevent the latter from moving.

- Or, from the starter side, insert a suitable key or screwdriver into one of the existing holes to lock the impeller there. However, this method is dangerous because often the sprocket is tightened quite tightly, which is why it is more likely to break the impeller blades than to unscrew the star. Therefore, if you do not have a stopper from the previous method, then use the traditional method from the next point.

- The popular method is that, instead of a special stopper, you can push a piece of fabric into the combustion chamber through the hole where the candle is wrapped, leaving part of it outside so that you can later pull it out. The fabric will occupy all the space inside and will not allow the piston to move upward, which will cause the shaft to stall. Moreover, due to the fact that the fabric itself is soft, it will not cause any damage to the walls of the cylinder.

Once the shaft is locked, you can unscrew the clutch. You need to use either a special puller, or you can get by with a suitable open-end wrench by inserting it into the recesses on the clutch. Unscrewing is done clockwise, since the thread on the shaft is left-handed.

Having unscrewed the clutch, you can now easily remove the sprocket.

Installation of new spare parts must be done in reverse order.

As you can see, it’s nothing complicated—everyone can do it.

Tools required for work

When starting riveting, the first thing you need to do is remove the link from the chain; for this you will need to rivet the rivets. For riveting, you will need an anvil, a hammer, a thin bit, a vice, a grinder with a grinding wheel or emery cloth. These tools do not allow for quality work, but everyone has them. A more cultured and gentle way is to remove the rivets using a special punch.

There are several designs of punches; we’ll tell you about the most popular.

Rivet punch

A punch is a machine that is used to remove rivets.

It is mechanical and works on the principle of a press. The kit includes a special anvil, in which grooves are selected for installing the headset with different pitches. There are also replaceable tips with which the rivets are extruded.

We invite you to watch a video that shows how to rivet a saw chain using a mechanical punch.

After the chain is riveted, it is necessary to remove the old link, install a new one and rivet it. For this purpose, a riveting-rolling machine is used. It is electric, so it costs much more than a punching machine.

Riveting and rolling machine

The machine is equipped with a gear motor with high torque.

Used for riveting and rolling headsets in increments from 1/4″ to 0.404″. The cutting depth of chains that can be riveted using this machine is from 1.1 mm to 2 mm (0.043″ - 0.080″). Special rotating inserts and anvils for different types are supplied with the machine. Inserts and anvils are marked. Marking “A” means that the inserts are designed for a headset with a pitch of 3/8″ and 0.404″. “B” is for 1/4″ and 0.325″.

The machine works as follows. The saw chain with a new link and rivets is installed in the guide inserts. The repair link with the rivets installed in it is pressed by the working roller against the anvil, after which the engine is turned on and the roller begins to rotate, gradually crushing the rivet, at this moment the machine operator slightly increases the pressing force of the roller by tightening the adjusting screw. For clarity, we suggest watching a video about the operation of a riveting-rolling machine.

It is not profitable to use such a machine for riveting houses, because it is expensive. If you do not need to rivet regularly, you can do without it. Let's look at how to shorten a chainsaw chain with your own hands without using expensive machines. You need to start by riveting and removing the link.

The advantage of the machine is that the rivets riveted with its help are practically no different in quality from those riveted in the factory.

Design problems of different models

A design feature of a significant part of chainsaw imports is the placement of a sprocket on the clutch mechanism.

- If the teeth are significantly worn, the drum, which is integral with the drive, must be replaced.

- A more advanced design of the drive sprocket allows you to restore the performance of the part by replacing the ring.

In the list of factory kits supplied with saws, such a tool is extremely rare. The problem is solved by replacing the worn-out part in a service workshop or by making the necessary device at home.

Types of stars

Depending on the class of chainsaw, all sprockets are divided into two groups - professional and household. The first type of parts have increased wear resistance and are made of durable metal alloys that are not subject to corrosion and mechanical damage. Household ones more often require replacement and scheduled repairs; if the tool is actively used, diagnostics are recommended every six months. Based on their design features, the following types of sprockets can be distinguished:

- Prefabricated. The removable crown can be easily unscrewed from the drum axis, which simplifies checking and replacing this part. Almost all European chainsaw models are equipped with such stars.

- Solid. They consist of a hub and a stationary crown (the number of teeth may vary; you must carefully read the instructions for the chainsaw). Due to the factory press fit, the ring cannot be removed separately from the hub, so in the event of a breakdown it is necessary to disassemble the entire clutch drum. This mechanism is usually found on Chinese models.

Alternative solutions

The sequence of operating moments is identical for almost all known models on the domestic market of chainsaw equipment. Experts advise using a branded part for replacement.

If we are talking about modernizing this unit, the feasibility of such a change should be clarified by consulting an experienced specialist.

The best option is to purchase a repair kit, which also includes a replacement bearing. In addition to the key, you may need a clutch drum puller individual for each model, a metal or plastic stopper to fix the piston in a given position.