Why does the chain fly off a chainsaw or electric saw?

Owners of chain saws from time to time face a common problem - the chain begins to fly off the chainsaw or electric saw.

We will discuss why this happens later in this review. There are only three main reasons why the chain falls off:

- stretching;

- tire problems;

- problems with the sprocket.

Let's look at why this or that problem occurs:

If the chain stretches, it begins to sag and slip off the tire

The reason, most likely, is the wear of the component itself. The chain has a finite service life and is the most quickly worn out working element of a chainsaw or electric saw. The metal is deformed due to loads, so it not only becomes dull, but also becomes approximately 1 cm longer than on a new tool. The easiest way is to change the component, that is, buy and install a new chain.

Read on in the review to learn how tightening is done and whether it is even possible to tighten the chain at home.

If there are problems with the tire, then they lie in the place where it is attached.

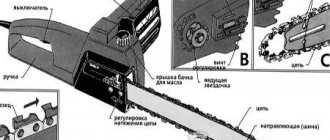

This reason is quite common: in the groove located between the outer plate mounted on the chain set and the inner plate located on the body of the gas or electric saw. Typically the casing is secured with a bolt. This attachment is called the motor assembly. The tire mount, like the drive sprocket, is covered with protective covers. When the mounting bolts become loose, the degree of vibration of the tire increases and it begins to move.

If everything is in order with the tire, the tension is normal, as is the operation of the tool itself. If the chain stretch is due to a loose bar, secure the bar and check how the chainsaw works.

Video - how to measure the length of a chainsaw bar:

Problem with the asterisk.

If the drive sprocket is poorly secured, the chainsaw chain will also need tensioning, since sagging cannot be avoided. Secure the tire sprocket by removing the engine protective cover, spark plugs and pulling out the air filter. A stopper is installed in place of the spark plug, the main task of which is to secure the piston. Next, you can use a special key or a universal key for an angle grinder to turn the clutch disc in the direction of clockwise rotation.

Get the piston to its extreme position - if you look into the hole for screwing in the spark plug, the piston should be at the bottom.

After fixing the piston, you can begin clamping the drive sprocket. Next, all the elements are assembled in reverse order.

Expert advice

In the first hours of operation, new chains stretch more than the old ones. Therefore, the tension should be checked after the first 12-20 minutes. work.

Over-tightening is fraught with excess load on the engine with loss of power and accelerated wear of the cutting set and parts of the chainsaw, primarily the drive sprocket and clutch.

After 3-4 chains are worn out, the tire should be replaced with a new one.

After 6-8 chains and 2 tires have worn out, you need to evaluate the condition of the drive sprocket. On different models they wear out after different service periods. The worn sprocket teeth are of non-standard size. Even if the chain does not slip along them, its service life is reduced.

After each tension adjustment, it is recommended to lubricate the driven sprocket at the end of the bar. For this purpose there are special holes near it. The oil from the pump gets there according to a residual principle, and sometimes it doesn’t get there at all. Therefore, along with a wrench and a screwdriver for tensioning, you need to have an oil can on hand. 3-4 drops are enough for lubrication.

Insufficient lubrication accelerates wear of the cutting set and stretching of the chain. The planned oil consumption differs for different chainsaws. For some models, 1 tank of oil is consumed almost simultaneously with 1 tank of gasoline. For others, 1 tank of oil is enough for 2 fillings of gasoline. A sign of good lubrication is the oily sheen of the chain and its smooth movement along the groove.

Do not use low-quality chains. They quickly stretch, damage the nodes in contact with them and require more frequent tightening.

Necessary equipment and tools for tensioning the chain on a chainsaw

In order to properly perform tensioning, you will need knowledge of some simple mechanisms and simple tools. In Stihl chain saws, tensioning is simple - using the built-in chain tensioner. This method is as simple as possible and this stretching is done very quickly. To tighten or adjust the degree of chain slack, the manufacturer recommends doing the following:

- Unscrew the sprocket cover using a wing nut;

- by rotating the adjusting wheel, determine the required length of the chain, tensioning it to the required degree;

- The sprocket cover is closed again and the chain is securely fixed to the bar.

If it is impossible to tension the chainsaw chain using the built-in mechanism, I use the following tools (using the Sparky electric saw as an example):

- grinder with a metal disc;

- hex key, diameter 5 mm;

- a piece of wire;

- wooden stick or strong sliver;

- flat screwdriver.

After de-energizing the electric saw, unscrew the screws with a hexagon, remove the housing cover, unscrew the tension screw with a screwdriver and remove the rod nut. The side of the screw adjacent to the saw body is ground using a disc. Then the saw is assembled in the reverse order. A sliver is required to clean the housing from sawdust.

How to properly tension a chain on a chainsaw:

Features of manual and mechanized sharpening

Dullness of the cutting edges of the saw chain is manifested by:

- noticeable decrease in performance;

- ejection of small chips;

- the appearance of a characteristic smell of burnt wood.

To restore the cutting properties of chains, several types of sharpening devices are used.

In the simplest version, it is a holder attached to a tire complete with a set of special files; in another, it is a power-driven sharpening machine. Both technologies have their own advantages and disadvantages.

Low-productivity and time-consuming manual chain sharpening helps preserve its resource. The mechanized method provides good performance, but the lack of an individual approach to each cutting link of the chain negatively affects its durability.

When to shorten or stretch a chain

What to do when the chain needs to be shortened or stretched, when links need to be added or removed?

First, let's figure out in what cases it is necessary to shorten the chain, that is, remove links from it.

The chain is shortened:

- if turning the adjusting screw is no longer enough to tighten it;

- if a tire of shorter length than the standard one was installed.

Accordingly, you can make the chain longer if:

- a longer bar will be installed on the saw;

- Some links are so worn that they need to be completely removed, which means the chain will become shorter and need to be lengthened to its original size.

As a rule, one or two links are removed. To reduce or increase the size of the chain, you will need the following tools:

- a machine for removing rivets - a punch (a mechanical device that works on the principle of a press, is equipped with tips for squeezing out rivets and replaceable grooves for different chain pitches);

- riveting and rolling machine (designed for chains with pitches from 1/4″ to 0.404″).

Principle of chain tensioning

The principle of chain tensioning is as follows:

- use the standard wrench included with the chainsaw to loosen the nuts on the cover;

- then the screwdriver is inserted into a special groove, rotational movements are made and the chain is tensioned;

- the key must turn slowly and carefully - after a couple of turns, the degree of tension is controlled manually, then, if necessary, several turns are made again;

- When the chain is sufficiently tightened, you need to put the cover back in place.

Advantages of producing a chain set

The chain and bar are included in the list of replaceable equipment, so the sawyer, depending on the specifics of the work, can use several sets of different lengths and performance. The average service life of wear-resistant branded tires allows you to work out the life of three saw chains.

The cutting edges of chain saw links require periodic sharpening. The undeniable advantages of using a set of several chains are uniform wear of the drive sprocket and good compatibility with the chains included in the additional set.

How to check chainsaw chain tension

To check whether the chain is properly tensioned and whether it needs tightening, pay attention to the following indicators:

- if it is tensioned correctly, the cutting quality is good, the bar quickly sinks into the material, cuts easily and without getting stuck in the wood;

- the tire does not heat up during operation;

- During sawing, both small and large chips are produced.

The chain needs to be tightened if:

- the tire gets very hot;

- the cutting quality decreases, the cut edge is uneven;

- fuel and oil consumption has increased;

- Only small chips are formed.

Chainsaw Stihl MS 271

An alternative stand for cutting logs.

The other day I needed to saw about 7 cubic meters of wood, i.e. cut into stumps. It is clear that the amount of work is impressive and it is impossible to do without a special stand. At first I wanted to make a universal goat, but then I changed my mind.

The main reason for my refusal from this idea was that I alone could not put a heavy log on the sawhorse. And I didn’t really want to do it. And then, to my luck, an ordinary small bench with overall dimensions of 550x340x240 mm turned up.

Before using the bench, I reinforced it with braces on both sides. Turn it over and that’s it, the stand is ready.

The procedure for cutting logs.

- From the general pile I select a log that is not jammed or crushed.

- I throw him to the ground.

- I bring one edge of the log onto the bench, and then the second.

Please note that the stand should be slightly offset from the center of the log towards the beginning of the cut.

- We retreat about 30 cm from the edge and saw off the stumps (blocks) alternately on both sides, gradually moving towards src=»https://dveridomaster.ru/wp-content/uploads/2015/08/DSCF8954.jpg» class=»aligncenter» width=”408″ height=”225″|fcw3qayjh5a| alt=”how to saw wood” src=”https://dveridomaster.ru/wp-content/uploads/2015/08/DSCF8959.jpg” class=”aligncenter” width=”408″ height=”250″|fcw3qayjh5a| alt=”how to saw wood” src=”https://dveridomaster.ru/wp-content/uploads/2015/08/DSCF8961.jpg” class=”aligncenter” width=”408″ height=”254″[/img ]

- The last cut will have to be done twice. The first, up to half, and the second, after the remaining fragment of the log has been turned over, is finally cut off. This is done to prevent the chain from jamming.

Reviews

Vladislav, Bucha:

“I would like to advise all novice chainsaw owners: no matter what kind of saw you have, you need to tension the chain on time! If it sag a lot or, on the contrary, it is very tense, both options are bad. In general, after about 3-5 cubic meters of firewood, I recommend tightening it up. And get saws that have a tensioner option. For example, almost all Husqvarnas are like this; the Patriots also have this function.

Also be careful with the chain so that it doesn’t fall off - it’s very dangerous if it falls off while you’re sawing! You can get seriously injured. Great job everyone!”