The most inexpensive way to sharpen a saw is to purchase file for sharpening chainsaw chain and do it yourself without outside help. However, this scenario implies a lot of nuances. You need to know how to choose a file, what characteristics you should pay attention to, study the sawing technique, and, in the end, be patient, sharp eyesight and steady hands. The last three factors are mandatory, because without them it is impossible to carry out proper sharpening with a file.

Files for sharpening chainsaw chains

Files and accessories

The main one used to sharpen the working saw tooth is round. Flat is used to adjust the height of the tooth - limiting the depth of cut.

Round file

Round ones vary in diameter. The main diameters are:

- 4.0 mm

- 4.8 mm

- 5.2 mm

- 5.5 mm

Depending on the size of the tooth, it is necessary to choose the optimal diameter. To facilitate the process, special file holders or support rollers with an indication of the tooth sharpening angle can be used.

Flat file

The flat one should have a width of no more than 1 cm. It is convenient to sharpen the stop tooth using a special bar (filing gauge), which is installed on the chain and shows to what maximum depth the tooth needs to be ground in order to achieve optimal performance of the chainsaw.

File holder

A round file is installed in a holder and fixed with special clamps. On the plane of the holder there are several markings indicating a specific sharpening angle. When straightening a chain with a file with a holder, the markings on the device are placed parallel to the chainsaw bar, which allows you to accurately maintain the required angle.

Using the holder all the time is quite inconvenient. You can use this device from time to time to check the correct angle of the tooth.

Filing gauges

These devices are used to control the sharpening angle of the teeth, as well as the distance to the depth stop in conjunction with a flat file.

Sharpening device

Manufacturers of equipment for chainsaws make special guide machines for installing a file in them and sharpening them. The machines are mounted on the chainsaw bar and are adjustable in height and angle of location to the chain. The use of such equipment is relevant for those who are just trying to learn how to sharpen a Stihl chainsaw chain with their own hands.

Clamp

This device allows you to hold the chainsaw bar while sharpening. To use it correctly, the process must take place directly at the cutting site. The clamp is hammered into a tree or board, then the tire is clamped into it and securely fixed from displacement. The device can be used for all types of tires, regardless of size.

In some cases, for example, in garage conditions, instead of a clamp, you can use a regular vice; the tire is clamped in them in such a way that the jaws of the vice do not interfere with the free movement of the chain. Next, sharpening is carried out according to the usual scenario.

Files for sharpening chainsaw chains Stihl Stihl

There are various files on the market for sharpening Stihl chainsaw chains. Despite the external differences, they are all branded. Some of them are accessories for sharpening machines and are sold in packs of several pieces. They do not have handles, so they are difficult to use without a base. Files sold individually can be included in a set or sold independently. There are 2 options – with and without a sharpening template. In addition to files, Shtil also produces a number of auxiliary devices: • filing gauges; • mandrels for sharpening; • templates (holders) of different types; • clamps. Filing gauges are designed to check sharpening depth, clean grooves and check corners manually. The mandrel is a plate with guides printed on it, indicating the sharpening angle of the link. By moving in accordance with the guides it is easier to maintain the correct degree of angle. It is attached using magnets to a metal busbar. The clamp works on the principle of a holder and allows you to sharpen the cutting and limiting teeth of the link in one step.

Files for sharpening chainsaw chains Stihl

Description of the sharpening process

Let's take a closer look at how to sharpen a chainsaw chain. The first thing you need to do is prepare a place for installing a clamp, or if the process takes place without it, then it is convenient to use an ordinary log as a stop for fixing the tire in a horizontal plane. The chainsaw is placed on a flat surface, a log is placed under the tire, and the brake is applied.

To avoid injury when sharpening your chainsaw, be sure to apply the saw chain brake.

The next stage is the actual sharpening of the tooth. To do this, use a round file to make movements from the inside of the tooth to the outside.

It is very important at this moment to maintain the correct sharpening angle. The standard angle is thirty degrees from the perpendicular location of the file to the plane of the bar. How to position it correctly is shown in the photo below.

In the process of sharpening a chainsaw for a non-standard cut, for example, longitudinal. The sharpened angle changes to a less acute one. As a rule, it is no more than 10°. It is in such cases that a holder, hand-held machines or filing gauges are used to control the sharpening angle.

Some manufacturers of chainsaw chains, to facilitate sharpening, as well as to indicate the maximum possible sharpening, make a special mark on the upper surface of the tooth.

By holding the file parallel to the mark, you can be sure that the correct angle is maintained.

The number of working movements with a file should be the same for each tooth. This will allow all teeth to be ground evenly.

In the process of straightening the chain, it is customary to sharpen the teeth on one side first, and then on the other; this is convenient because there is no need to constantly change its location in relation to the chainsaw.

After the working teeth have been sharpened, it is necessary to adjust the height of the limiting tooth with a flat file. To do this, the filing gauge is placed on the chain so that the limiting tooth coincides with its slot, after which the protruding part is ground off with a file. This procedure is performed on all restrictive teeth.

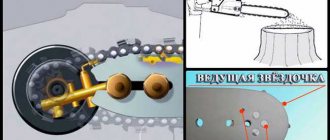

Application of roller device

The sharpening device, with which you can quickly and efficiently correct teeth, consists of a small guide template on which two rollers are mounted.

By installing the device on the tire, you can sharpen the teeth of a chainsaw, even without experience in such operations.

Proper sharpening of a chainsaw chain with a file

It is easiest to start sharpening directly on the bar, but some manufacturers oppose this, citing various arguments, and recommend removing the chain from the device and securing it in a vice. But this is extremely inconvenient, because... After sharpening each link, the chain must be dismantled and reinstalled.

If, however, the chain is sharpened directly on the saw, the bar can move while suspended under the pressure of a hand with a file, so it is necessary to install a stop for the bar on the opposite edge, for example, a block of wood. It is important to clean the chain from any remaining sawdust, grease and debris before sharpening. This will make the job easier.

Proper sharpening of a saw chain with a file

Begin sharpening from the most ground tooth. It is by this that all others will be aligned. If a tooth is broken, it must be replaced by riveting the chain with a special machine and installing a new element of the appropriate size and type. After the element is selected, sharpening begins. The file is moved straight away from you along the semicircular edge of the sawing tooth, resting the template against the edge of the adjacent chain link. In this case, it is necessary to maintain parallelism between the file and the plane of the surface on which the saw or vice is installed, as well as the angle of the guide indicated on the plate template. Thus, all links of the chain are processed one by one, i.e. only those that are on one side of it. Upon completion, they move to the other half of the links and perform the same operation, but at the opposite angle, also indicated on the guide in the template. After completion, the file for sharpening the chainsaw chain is set aside, and the chain is brushed with a brush, removing metal shavings.

Announcement:

Adviсe

For those who are just learning how to sharpen a chainsaw chain themselves, it will be useful to take into account a few basic tips for carrying out this process correctly.

- Whenever manipulating the chain, the engine must be turned off; under no circumstances should you sharpen the chainsaw chain while the saw is running.

- Before sharpening, the chain must be tightened to normal working condition.

- The saw chain brake must be set to the working position when straightening it.

- When sharpening the chain, gloves must be used to protect against cuts from the sharp edges of the teeth.

- Maintaining the same number of file movements is guaranteed to ensure uniform grinding of all teeth.

Below you can see how to sharpen a chainsaw chain with a file in the video; it describes in detail what files you need to use. How to best position the chainsaw. And of course, how should the sharpening tool be positioned in relation to the saw bar.

Finally, I would like to note the main advantages of sharpening with a file, compared to straightening the chain in a machine.

How to choose a file for sharpening a chainsaw chain

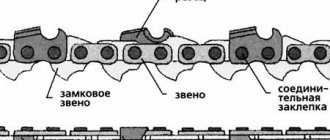

Most users are wondering how to choose a file for sharpening a chainsaw chain. The answer to this is complicated, because... implies a lot of options. But the most correct way is to pay attention to the chain pitch. The size (diameter) of the cylindrical file depends on it. But in addition to it, a second one is also required - flat. Two files are used to sharpen different parts of one link. If we look at the process in more detail, a cylindrical file is used to sharpen the saw tooth of the link, namely the end and top blades. Use a flat file to file down the sawing depth limiter. It is important that both files can be purchased as a set with a set of templates and a hook for cleaning the saw and bar from the saw set. Some manufacturers of chainsaws and their electric chain analogues even produce similar kits themselves.

Different types of files for sharpening saw chains

Sequence of operations when sharpening

High-quality sharpening of teeth requires strict adherence to the following rules:

- A file for sharpening a chainsaw should be placed strictly perpendicular to the direction of movement of the saw teeth in the vertical direction, and at an angle of 15...20 0 in the horizontal direction. The latter is controlled using a holder.

- The round file in the tooth mouth must be located slightly above its edge (for file No. 5 this is approximately 1...1.5 mm).

- A holder is installed on the tooth, the lines of which will show the exact direction of movement of the file in the horizontal plane.

- After several movements of the file, the sharpening surface is covered with magnetized shavings, which should be immediately removed with a hook.

- Sharpening begins in the direction away from you, without using excessive force: the notches should gently enter the metal of the tooth. It is recommended to make several movements and then turn the file by 20...30 0 so that the wear of the notches occurs more evenly.

- It is recommended to sharpen “through the tooth”: first sharpen the teeth in one direction, and then in the other.

- The pressure on the file during sharpening should be constant, as should the number of reciprocating movements on the tooth being sharpened.

When sharpening the depth limiter, proceed as follows. A template is applied to the limiter. When the stopper slot fits into the template groove, set the height of the worn area, which is removed using a flat file. The template is installed on one of two sides - Hard or Soft, which corresponds to hard or soft wood.

Sharpening will be easier if the chainsaw bar is clamped in a bench vise. The intervals between sharpenings can be increased if you promptly monitor the correct chain tension, monitor the condition of the limiter, regularly lubricate all moving elements, and periodically replace the drive sprocket.

The most inexpensive way to sharpen a saw is to purchase a file for sharpening a chainsaw chain and do it yourself without outside help. However, this scenario implies a lot of nuances. You need to know how to choose a file, what characteristics you should pay attention to, study the sawing technique, and, in the end, be patient, sharp eyesight and steady hands. The last three factors are mandatory, because without them it is impossible to carry out proper sharpening with a file.

Files for sharpening chainsaw chains

External signs of a dull chainsaw tooth

Among the most popular chainsaws are rightfully the tools of the Austrian company Stihl, in particular, Stihl-180 (to be precise, Stihl MS-180-14''). With such a chainsaw you can trim branches and deal with medium-sized branches - a power of 1500 W allows this quite well. Despite the high-quality steel that this brand (we don’t consider Chinese counterfeits!) uses to make the teeth, self-sharpening will require skill and time.

You should pay attention to the following external signs of a dull cutting chain:

- A conical section appeared on the working angle of the tooth.

- When moving from the working corner to the top edge, the radius rounding is visually different.

- At the moment of the initial feed, even at a relatively low intensity, the penetration of the working edge of the tooth into the thickness of the wood is carried out with great resistance.

- At the stage of a steady cut, the chainsaw chain begins to vibrate, and the noise level of the chainsaw increases noticeably.

- When sawing in the longitudinal direction, the cutting surface has rough cuts and chips of wood. The chips themselves become significantly smaller in size.

The trial test is carried out on dead wood, and in no case on wood with high humidity. The frequency of sharpening depends on the main cutting direction. If it is performed predominantly in the axial direction, then sharpening will have to be performed much more often.

Chain file

You need to understand that you won’t be able to sharpen a chain with an ordinary round file, much less a flat or triangular file, since a file for a chain must have its own parameters. Although it’s worth making a note here - you can sharpen the depth limiter with a simple flat file.

File parameters for chain sharpening

The most important parameter of a file for sharpening a chain is its diameter. It is important because, depending on the pitch of the chain, a file of a certain diameter is used. Below is a table showing which file is suitable for a chain with a particular pitch.