Purpose

Such devices greatly facilitate the work, because with their help you can drill precise holes. Furniture jigs and templates are necessary when assembling cabinets, tables, and other interior items for home, office, production, even elements of confectioners’ furniture for a bakery. During their assembly, craftsmen perform the same actions related to marking and drilling. Special equipment will help speed up these processes.

The furniture template is a strip with holes and sleeves. The distance between them is different, the diameter of the holes is different. By applying the jig to the part, holes of the required size are drilled with a certain pitch.

Advantages of using templates for making furniture:

- fast drilling;

- easy hole making process;

- drilling accuracy.

Some products facilitate the process of drilling and assembling parts, while others are necessary to simplify marking. Depending on this, the conductors are either marking or drilling. Most often, equipment is purchased in a store, but some make the devices themselves. It is easy to make a jig from a carpenter's square or a metal ruler.

Various products are used in furniture assembly: slats, sheets. Rack templates are used when marking elements longer than 1 m. Sheet templates are suitable for small parts. There are also combined devices that combine several types.

Furniture conductor

The simplest furniture template

Marking on the template

Drilling furniture templates and jigs for marking the body

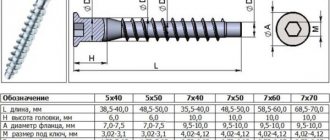

In its simplest design, a furniture jig for marking for confirmation and other connecting fasteners is a flip ruler with holes for drilling holes with a diameter of 5 mm in increments of 32 mm.

Moreover, in confirmed joints, a distance from the edge of 37mm is absolutely not critical. Many furniture makers also retreat 32mm to add holes for assembly. In kitchen furniture you can find a gap of 50mm. But all subsequent holes are made in 32mm increments.

For kitchen and other modular furniture with identical sidewalls of a “mirror” assembly, to speed up the assembly process, it is important to make additive cards in such a way that they are absolutely symmetrical in terms of fasteners. And the master did not have to “throw” the part. System 32 with the same distance from the edge for through holes on both sides contributes to this.

Device and characteristics

The conductor is made of wood, metal, plastic, MDF, chipboard and other materials. There are standards according to which holes are made at a distance of more than 8 mm, counting from the edge. The distance between them is no less than 32 mm. The centers are further expanded, the thread is installed, and the emphasis is placed on the rail.

An important element of the jigs are their supports, which are necessary for firmly fixing the device on the furniture piece. Supports can be spherical, notched, or flat. The following types of plates are used to install bushings:

- hanging;

- lifting;

- rotatable;

- permanent;

- removable.

For oblique holes

Under the hinges

With turret

For confirmations

Installing an eccentric coupler

When connecting parts with an eccentric coupler, it is important to strictly observe the installation dimensions. Correct installation of the tie will ensure an accurate connection of the parts. The installation dimensions for all types of eccentric couplers are the same, with the exception of the rod dimensions, which were mentioned earlier.

Fig.2.

Installation of an eccentric coupler. The installation diagram and installation dimensions are shown in the drawing. The necessary grooves are made in the parts to be connected, after which the rod and eccentric are installed and the parts are tightened.

When connecting parts with an eccentric coupler, it is important to monitor the position of the rod relative to the eccentric. If the rod is tightly twisted, then the eccentric cannot be rotated 180 degrees and the connection will not be secured; if the rod is not tightened, then it will not be possible to tightly connect the parts with an eccentric tie.

Varieties

A furniture template can be of different types. Products differ in design method and functional features. Depending on this, jigs and templates for marking and drilling may fall into one of the following categories:

- invoices;

- rotary;

- tiltable;

- universal.

Overhead products are considered the best option for drilling holes in flat parts. They are suitable for chipboard and MDF boards. During operation, they are applied to the surface of the element on which a hole needs to be made, and held with hands so that they do not move. In other cases, the furniture template is placed in a specific place or fixed.

The rotating mechanism has a working surface that moves horizontally or vertically. The template allows you to make holes on parts whose axis is located at an angle. A rotary jig is used when you need to make a hole on elements that have a complex geometric shape.

Tiltable devices are needed to work with parts located in different planes. Universal products allow them to be reconfigured for the production and assembly of furniture of various types. They are used mainly in small workshops that produce cabinets, tables, chests of drawers in small batches.

Depending on the type of fixation of the device on the surface of the parts, the furniture template is divided into sliding and fixed. Sliding ones lie freely on the surface of the parts, allowing you to make each hole separately. Such devices are considered less convenient. Dockable templates are more convenient to use, although they limit the actions of the wizard.

Almost all types of devices have a fairly simple design, so they can be made independently at home. This will save money.

Overhead

Sliding

Angular

Universal

The nuances of making a high-quality furniture conductor, we do it ourselves

A furniture jig is a simple mechanical device that serves to speed up and simplify the actions when drilling holes. The use of this device allows you to create technological holes without pre-applied markings and do this with perfect accuracy, as well as a adjusted slope. The device is indispensable during the assembly of furniture structures and carpentry work. For use in everyday life and in small-scale production, it is very easy to make a furniture jig with your own hands.

Nuances of choice

A furniture template can be made not only from a square and a metal ruler; other available materials are also suitable. A device made independently can be highly specialized. As an example, products for drilling holes for handles, hinges, and other elements. Such devices are more suitable if the production of furniture is carried out in small volumes.

For a more extensive process of manufacturing interior items by conductor production, it is recommended to purchase professional equipment. Please note that some models can be quite expensive. Using a professional template, the furniture will have high-quality fasteners and will last a long time.

When choosing, it is recommended to pay attention to multifunctional devices that allow you not only to make the correct markings, but also to fill holes. The equipment set includes clamps, replaceable bushings, and rulers, which greatly facilitate the assembly processes and production of interior items. With their help, holes are drilled at the required distance and a certain diameter.

Furniture jigs will allow you to make the correct markings for future holes and drill them at the right angle. Their various types allow you to accurately, quickly and efficiently connect furniture elements to each other. The end result is a product that will last a long time.

Advantages

A furniture hole jig not only improves the quality of assembly, but also minimizes the possibility of an error that could lead to a complete replacement of an expensive damaged part. Working with the template can be entrusted to low-skilled personnel, since this operation is simpler than manual reconciliation. Workers do not need to measure angles, mark and check measurements. The drilling angle is controlled by a jig, which eliminates the possibility of deviations. This significantly improves drilling accuracy, which is especially critical for deep holes.

In order for work with a conductor to be effective, the tool must meet the following requirements:

- be washable and intuitive to use;

- it should speed up the assembly process;

- allow you to make several holes at once without additional manual basting;

- improve the quality of work with a drill.

The material from which the conductor is made is of no small importance. For templates, plastic or plexiglass is most often used; drilling devices are made of steel. When choosing a conductor, pay attention to the following characteristics:

- passport value of deformations under increased loads;

- aligned axis of the hole for the drill;

- no overheating during operation.

Factory conductors have all the above advantages; they are manufactured on the basis of long-term scientific research and have undergone strict quality control.

Materials and tools

To manufacture a device, you must first decide on the tasks that it will perform. Accordingly, the necessary material is selected from which the furniture template will be made with your own hands. The most durable, reliable and “long-lasting” is considered to be a metal conductor. To create a furniture jig for drilling with your own hands, it is permissible to use wood, plywood, textolite, and plexiglass. This is due to lower labor costs and cheaper materials. All this is important, especially if you are going to make several different templates yourself.

To make a conductor, a piece of reinforcement, a block or a plate is suitable - something that can probably be found in any garage or home workshop. To make a simple marking device, you can take a regular school ruler - wooden, plastic or metal.

Of decisive importance in the manufacture of the jig is the accurate calculation of the location of the holes on the workpiece. You can take a ready-made diagram or make it yourself. The latter option is preferable, since the dimensions in the drawings must correspond to the tasks being solved.

Tools you will need:

- drill;

- grinder or jigsaw;

- a set of locksmith tools;

- clamps;

- vice.

Conductor for assembling furniture with your own hands: buy or make it yourself

Hello dear friends, lovers of assembling and making furniture with your own hands! Today we have a quite interesting and useful topic for many. After all, we will be talking about a conductor for assembling furniture.

Such a device can be bought without any problems on Aliexpress, purchased at Leroy Merlin or any specialized store. But reading reviews and talking on furniture forums, I noticed that many, instead of buying a jig, make it with their own hands.

There are various drawings available online; you can easily find a universal template and use it to create your own device with your own hands. We will definitely talk about this today. But first, I propose to delve into the essence of the device, understand the varieties and answer a few basic questions.