When you start immersing yourself in making furniture with your own hands, there is a need to simplify your work with the same type of operations associated with the preliminary marking of parts for fasteners. Furniture drilling jigs are an excellent tool for the home craftsman. Many people prefer to make templates from blanks themselves. However, there are quite a few budget devices on sale on Aliexpress that are easier to buy than to reproduce. And they will last much longer, maintaining the original accurate calibration.

You can read about how to properly prepare sawn parts for further assembly in the article about adding and drilling chipboard with your own hands.

Furniture templates for installing handles

Any furniture handle has an installation base - the distance between the screws is subject to system 32. That is, it is a multiple of pitch 32, corresponds to the values 32, 64, 96, 128 mm, etc. When installing handles, it is important to maintain the same distance from the edges of the facade. Templates for drilling holes for handles can make marking easier. They can have different looks and shapes. The package may include drills.

Branded conductors

Well-known brands Hafele, Hettich, Blum, Salice, Accura offer universal templates of various designs, having holes with a pitch of 32 mm, which corresponds to the European system of furniture fastenings.

With their help, you can easily and quickly install guides for sliding structures of all types, shelf holders, any types of hinges, confirmations, dowels, eccentrics, handles, furniture lifting mechanisms and drill rows of holes.

Branded templates are made of high-quality metal, are comfortable, aesthetically pleasing, but are quite expensive. Their kit may also include drills and cores.

In some types of such devices, alternating guide grooves with a pitch of 16mm, 18mm or more allows them to be used for working with chipboard, MDF, wood panels and other furniture materials.

They can also be used for marking and drilling planes and ends of parts.

Many furniture manufacturers order the production of these devices on individual projects. In this case, they are designed for specific operations and differ structurally.

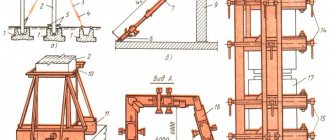

Homemade templates

But not all furniture manufacturers need universal templates when developing strictly defined types of furniture products.

In some cases, it is much easier and cheaper for them to make a jig for marking and drilling similar parts, using available materials such as wood, plywood, plexiglass, and when these temporary devices wear out, they are simply replaced with similar ones.

More durable ones are made of metal, solid oak, by placing an aluminum plate with holes on them or by inserting aluminum bushings into the holes of the template.

This often turns out to be more justified than spending money on expensive branded products or making it out of metal, especially since metal jigs accelerate the wear of drills.

Much here is determined by the experience of the master and production needs.

The same holes for dowels, for drilling of which a number of designs of metal jigs are offered, in practice it is better to make them using a router, since the drilled holes do not provide adequate strength to the body assembled on the dowels.

This tool (in carpentry) can be rigidly mounted on workbenches, while many homemade templates are designed in such a way as to fix the part in a certain position and feed it onto a permanently installed drill, and not vice versa.

Portable templates are used mainly for assembling furniture and are necessary for all specialists involved in assembly, both in the workshops of enterprises and at customer sites.

Furniture jigs for marking fasteners for guides for drawers

The fastening of any guides and pull-out systems also obeys the furniture “law”: the distance from the edge for fastening the first screw is 37 mm, and then the installation holes are located in increments of 32 mm at distances of 64, 128, etc.

Most manufacturers of components for drawers offer their own furniture jigs to facilitate marking for fasteners. However, you can also choose universal templates. Most often they consist of a set - left and right conductors.

Nuances of choice

A furniture template can be made not only from a square and a metal ruler; other available materials are also suitable. A device made independently can be highly specialized. As an example, products for drilling holes for handles, hinges, and other elements. Such devices are more suitable if the production of furniture is carried out in small volumes.

For a more extensive process of manufacturing interior items by conductor production, it is recommended to purchase professional equipment. Please note that some models can be quite expensive. Using a professional template, the furniture will have high-quality fasteners and will last a long time.

When choosing, it is recommended to pay attention to multifunctional devices that allow you not only to make the correct markings, but also to fill holes. The equipment set includes clamps, replaceable bushings, and rulers, which greatly facilitate the assembly processes and production of interior items. With their help, holes are drilled at the required distance and a certain diameter.

Furniture jigs will allow you to make the correct markings for future holes and drill them at the right angle. Their various types allow you to accurately, quickly and efficiently connect furniture elements to each other. The end result is a product that will last a long time.

Template for marking and drilling for confirmation

It will be useful for those who assemble furniture from laminated chipboard of any type and do pre-addition manually. The furniture jig is a ruler with holes for a 5-8mm drill for marking the front part of the parts (sidewalls) for confirmation with a countersink. The pitch can be set to even values from the edge (50, 70, 100mm) or in compliance with system 32.

Areas of use

Furniture jigs and templates are devices that are practically indispensable when assembling furniture structures. The use of jigs allows you to avoid the main problem that arises when drilling holes - the drill entering the workpiece at the wrong angle. Correcting this error takes a lot of time and effort, and it is not always possible to fix it at all. The jig used for drilling holes not only allows the drill to be correctly oriented at the processing site, but also prevents the tool from straying from the specified trajectory.

Devices such as furniture jigs and templates are used both in the production and assembly of furniture, when holes must be made in the elements being connected to accommodate fasteners. In such cases, a jig for dowels or a jig for drilling for confirmation is often used, without which it is not possible to make high-quality holes for fasteners. Such a device is indispensable in cases where it is necessary to make holes, including at an angle, in thin slabs (in particular, when making holes in chipboard or MDF).

A jig for oblique holes is indispensable when making hidden connections between panels and boards

When using a jig to drill holes, the process of assembling furniture is simple and fast. Using such a device, holes can be drilled at any distance from the edge of the part, regardless of its width.

Modern furniture actively uses dowels, which at the same time are a rather outdated fastening element. That is why the doweling jig is used in the production of furniture structures. The main difficulty when using such fasteners is that the axes of the holes made in the parts being connected have a right angle to each other. Accordingly, such holes should be located strictly perpendicular to each other. Without the use of such a device as a dowel jig, it is difficult to perform them.

A jig for making holes in tubes will be a very useful device for a home workshop

Furniture production is not the only area in which jigs designed for drilling holes are used. Templates are no less often used to drill a hole in a pipe and other cylindrical parts. Conductors allow you to make high-quality holes even in small-diameter pipes.

The size and operating principle of modern conductors may vary. Some of the models of such devices are much easier to buy, and some are easy to make with your own hands. The fact that serial devices, especially those for universal use, are not cheap, also speaks in favor of making a furniture jig for drilling holes with your own hands.

Universal furniture jig for drilling

In terms of functionality, it combines the two previous devices, since it can adapt to marking with drills of different diameters, and the ruler allows you to set any desired distance from the edge and pitch. It is used both for drilling the front surface of parts and the end.

Well-known manufacturers of furniture jigs include Cheron, Kreg and Wolfcraft. Before choosing any model, we recommend comparing prices, quality and functionality with smaller manufacturers and suppliers of furniture components Blum, Hettich and others. Often the optimal price-quality ratio, and even with a guarantee, can be found where it seems that “everything is expensive.” Do not exclude this possibility for yourself and consider all possible options. After all, a furniture jig can serve faithfully for many years, helping to speed up production processes without losing the quality and accuracy of making furniture with your own hands.

Template characteristics

Installing furniture hinges is an important step in assembling cabinets. A special insert template is used for this process. This element is made from different materials. You can purchase a ready-made part in a store or try to do everything yourself.

Work on installing facades is simplified by templates for furniture hinges. The finished element has many advantages. These include convenience, since there is a sketch for marking. Among the advantages of using a template are the strength of the structure, ease of use, and compactness of the product.

Features of drawing up a drawing

You can make a template yourself if you have a drawing of the future design. To develop a sketch, you need to know what elements the template consists of.

Template structural details:

- Base. There are holes for drilling on it. This part of the furniture hinge installation template is key.

- Holder. The functions of an element include a limitation. The part is fixed to the door leaf, thereby eliminating shifts and deformations.

- Connecting parts. These elements help to adjust the template to specific door hinge sizes. The number of connecting elements depends on the complexity of the structure and the functions assigned to it. The primitive template has only 3 such details.

You can determine the amount of materials needed if you accurately determine the dimensions of the template. The design can be made more complex. You can add the installation of door locks to the functionality of the template.

Materials and tools

To manufacture a device, you must first decide on the tasks that it will perform. Accordingly, the necessary material is selected from which the furniture template will be made with your own hands. The most durable, reliable and “long-lasting” is considered to be a metal conductor. To create a furniture jig for drilling with your own hands, it is permissible to use wood, plywood, textolite, and plexiglass. This is due to lower labor costs and cheaper materials. All this is important, especially if you are going to make several different templates yourself.

To make a conductor, a piece of reinforcement, a block or a plate is suitable - something that can probably be found in any garage or home workshop. To make a simple marking device, you can take a regular school ruler - wooden, plastic or metal.

Of decisive importance in the manufacture of the jig is the accurate calculation of the location of the holes on the workpiece. You can take a ready-made diagram or make it yourself. The latter option is preferable, since the dimensions in the drawings must correspond to the tasks being solved.

Tools you will need:

- drill;

- grinder or jigsaw;

- a set of locksmith tools;

- clamps;

- vice.

When manufacturing a jig, you will need perfectly accurate drilling of guide holes and hardening of the finished device

Drawing of a homemade conductor for drilling holes for confirmations

Making your own template

Making a template for furniture hinges with your own hands follows a clear plan. It is important to follow the sequence of steps. If you follow all the rules, then no difficulties will arise in the process.

Stages of developing a template for loops:

- Selection and preparation of materials;

- Preparation of necessary tools;

- Development of template details;

- Final assembly of all elements.

Paper template for download

- To create a template yourself, you need to print a sample.

- According to its dimensions, make a blank from solid material, plastic or wood

- Attach the paper template to the workpiece

This is what you should get.

To create a workpiece you will need to take a drill, router, hammer, and jigsaw. You will also need tools for drawing markings. First you need to make a base. The optimal dimensions are 19x38 cm. A hole measuring 13.5x7 cm should be made in the center. The edges should be smooth. A router will help with this.

Bolts must be placed on the workpiece. It is important to maintain symmetry relative to the width of the base. The bolts must be buried in the structure so that they do not interfere with further manipulations. The hole is made wider than the connecting elements and additionally driven in using a hammer.

It is necessary to retreat 7 mm from the 13.5x7 cm holes and make small notches. Around an element with dimensions of 37.5x7 cm, notches are made on one side at a distance of 30 cm from each other.

A homemade template requires a holder measuring 2x5 cm and a length of 5.8 cm. You will need to install a limiter on one of the sides, which looks like a small block. This element will not allow the distance to shift when installing the facade.

Then all parts of the template are attached. Washers are installed under the bolts and nuts. This element increases the durability of the template. The manufacturing process does not require special skills or knowledge. It is enough to familiarize yourself in detail with the template development scheme.

Selection of materials for work

For the template, you can use plywood, chipboard or MDF. More durable structures are made of plexiglass and metal. You can take several materials for one template. So you can use chipboard for the base, and make the guides from a more durable material. It is easier to work with wood, as it is easier to process than glass and metal.

Required connecting elements:

- Bolts. You will need 6 pieces with a thickness of 6 mm and a length of 30 mm. To fix the connecting element, you need to have a 10 key.

- Nuts. Need 6 pieces. The main requirement for the element is convenient adjustment. Wing nuts are most often used.

- Washers. Their diameter should be 6 mm.

- Self-tapping screws. They are selected depending on the thickness of the remaining connecting parts.