Drilling machines. Boring machines

- 2A106P

drilling table Ø 6, Molodechno - 2A112

table drill Ø 12 - 2A125

vertical drilling Ø 25, Sterlitamak - 2A135

vertical drilling Ø 35, Sterlitamak - 2A150

vertical drilling Ø 50, Sterlitamak - 2B118

vertical drilling Ø 18, Vitebsk - 2B125

vertical drilling Ø 25, Krasnorechensk - 2G103P

table drill Ø 3, Kalyazin - 2G106P

table drill Ø 6, Yerevan - 2G125

vertical drilling Ø 25, Krasnorechensk - 2G175

vertical drilling Ø 75, Sterlitamak - 2L125

vertical drilling Ø 32, Lipetsk - 2M103P

drilling table Ø 3, Kirovakan - 2M112

drilling table Ø 12, Kirov, (Selmash) - 2M118

drilling table Ø 18, Orenburg - 2N106P

drilling table Ø 6, Molodechno - 2N112

drilling table Ø 12, Perm - 2N115pm

drilling table Ø 15, Perm - 2N118

vertical drilling Ø 18, Molodechno - 2N118-1

vertical drilling Ø 18, Molodechno - 2N125

vertical drilling Ø 25, Sterlitamak - 2N125L

vertical drilling Ø 25, Molodechno - 2N135

vertical drilling Ø 35, Sterlitamak - 2N150

vertical drilling Ø 50, Sterlitamak - 2Р135Ф2

vertical drilling machine with CNC Ø 35, Sterlitamak - 2С50

vertical drilling Ø 50, Sterlitamak - 2S108P

drilling table Ø 8, Molodechno - 2С118

drilling table Ø 18, Chelyabinsk - 2S125MP

vertical drilling Ø 25, Orenburg - 2S125, 2S125-1 (2S125-01), 2S125-04

vertical drilling Ø 25, Sterlitamak - 2С132, 2С132К

vertical drilling Ø 32, Sterlitamak - 2СС1м (2СС1)

drilling table Ø 6, Saratov - 2T118

vertical drilling Ø 18, Gomel, GSZU - 2T125

vertical drilling Ø 25, Gomel, GSZU - 2T140

vertical drilling Ø 40, Gomel, GSZU - 2T150

vertical drilling Ø 50, Gomel, GSZU - 2118

vertical drilling Ø 18, Novocherkassk - 2135

vertical drill Ø 35, Sterlitamak - AS2116m

drilling table Ø 16, Astrakhar - VSN

drilling table Ø 16, Kasimov - VSN-12

desktop thread-cutting machine M3..M8, Vitebsk - GS-520

drilling table Ø 16, Gomel, (GZSU) - GS2112

drilling table Ø 12, Gomel, (GZSU) - GS2116k

drilling table Ø 18, Gomel, (GZSU) - EM-102

drilling table Ø 12, Saratov - ZIM-426

drilling table Ø 6, Novosibirsk - ZIM-427

drilling table Ø 6, Novosibirsk - Corvette-42

drilling table Ø 16, Voronezh - Corvette-44

drilling table Ø 16, Voronezh - Corvette-45

drilling table Ø 13, Voronezh - Corvette-46

drilling table Ø 16, Voronezh - Corvette-47

drilling table Ø 16, Voronezh - Corvette-48

drilling table Ø 16, Voronezh - KS-02

drilling coordinate Ø 12, Kaunas - MS-36

drilling magneticØ 40, Grodno - MS-51

drilling magneticØ 51, Grodno - NS-12

drilling table Ø 12 - NS-12A

drilling table Ø 12, Vilnius - NS-12B

drilling table Ø 12 - NS-16

drilling table Ø 16, Rostov-on-Don - NS-23

drilling table Ø 23, Chelyabinsk - NS-Sh

drilling table Ø 12, Novocherkassk - NSP-2

drilling table Ø 6, Riga - NSF-1

desktop drilling and milling Ø 12, Chelyabinsk - NSF-23

desktop drilling and milling Ø 23, Chelyabinsk - R-175, R-175m

drilling table Ø 16, Chistopol - S-25

table drill Ø 5, Kalyazin - S-106

drilling table Ø 3, Kalyazin - S-155

drilling table Ø 3, Kirovakan - SV-20

tabletop drilling five-spindle Ø 14, Yoshkar-Ola - SNVSH

tabletop drilling Ø 16, Rostov-on-Don - SNVSH-2

drilling table Ø 16, Rostov-on-Don - SNS-12

drilling table Ø 12, Alapaevsk - SUS-1

drilling table Ø 12, Vilnius - SF-1

drilling and milling tabletop Ø 23, Orsha - SF-16, SF-16-02, SF-16-05

drilling and milling tabletop Ø 16, Sterlitamak - TMNS-12

drilling table Ø 12, Tchaikovsky - 2A430

jig boring machine 280 x 560, Kaunas - 2A450

coordinate boring machine 630 x 1100, Moscow (MZKRS), Kuibyshev - 2A470

coordinate boring two-column 1400 x 2240, Leningrad, (Sverdlov) - 2B440A

jig boring machine 400 x 800, Kuibyshev, Samara - 2B460

coordinate boring two-column 1000 x 1600, Leningrad, (Sverdlov) - 2D450

coordinate boring machine 630 x 1120, Moscow (MZKRS) - 2E440A

jig boring machine 400 x 710, Kuibyshev, Samara - 2E450

coordinate boring machine 630 x 1120, Moscow (MZKRS) - 2E450AF1

coordinate boring machine 630 x 1120, Moscow (MZKRS) - 2E450AF30

CNC coordinate boring machine 630 x 1120, Moscow (MZKRS) - 2E460

coordinate boring two-column 1000 x 1600, Leningrad, (Sverdlov) - 2E470

coordinate boring two-column 1400 x 2240, Leningrad, (Sverdlov) - 24K40SF4

jig boring machine 400 x 800, Kuibyshev, Samara - 2421

jig boring machine 250 x 450, Kaunas - 2431

coordinate boring 320 x 560, Kaunas - 2431sf10

jig boring machine 320 x 560, Kaunas - 2450

coordinate boring 630 x 1100, Moscow (MZKRS) - 2455

jig boring machine 630 x 900, Kuibyshev - KR-450

coordinate boring two-column 380 x 520 - 2A53

radial drilling Ø 35, Odessa - 2A55

radial drilling Ø 50, Odessa - 2A554

radial drilling Ø 50, Odessa - 2A576, 2A587

radial drilling Ø 80, Odessa - 2A592

radial drilling Ø 25 x 130, Vitebsk - 2B56

radial drilling Ø 50, Kharkov - 2E52

radial drilling portable Ø 25, Gomel, (GZSU), Oktemberyan (Gyumri) - 2K52, 2K52-1

radial drilling portable Ø 25, Gomel, (GZSU) - 2K522

radial drilling portable Ø 32, Gomel, (GZSU) - 2K550V

radial drilling Ø 55, Gomel, (GZSU) - 2L53

radial drilling Ø 35, Oktemberyan (Gyumri) - 2L53U

radial drilling Ø 35, Oktemberyan (Gyumri) - 2M55

radial drilling Ø 50, Odessa - 2M57

radial drilling Ø 75, Odessa - 2M58

radial drilling Ø 100, Ivanovo - 2Н55

radial drilling Ø 50, Odessa - 2Р53

radial drilling Ø 35, Odessa - 2С550А

radial drilling Ø 36, Sterlitamak - 255

radial drilling Ø 50, Odessa - 257

radial drilling Ø 75, Odessa - 2532l

radial drilling Ø 32, Oktemberyan (Gyumri) - GS545

radial drilling portable Ø 45, Gomel, (GZSU) - 2А614

horizontal boring Ø 80 Charentsavan - 2A620

horizontal boring machine Ø 90, Leningrad, (Sverdlov) - 2А620Ф1

horizontal boring machine Ø 90, Leningrad, (Sverdlov) - 2А620Ф2

horizontal boring machine Ø 90, Leningrad, (Sverdlov) - 2A622

horizontal boring Ø 110, Leningrad, (Sverdlov) - 2А622Ф1

horizontal boring machine Ø 110, Leningrad, (Sverdlov) - 2A622F2

horizontal boring machine Ø 110, Leningrad, (Sverdlov) - 2А622Ф4

horizontal boring machine Ø 110, Leningrad, (Sverdlov) - 2A636

horizontal boring Ø 125, Ivanovo - 2А636Ф1

horizontal boring Ø 125, Ivanovo - 2A637

horizontal boring Ø 160, Ivanovo - 2А656Ф11

horizontal boring Ø 160, Leningrad, (Sverdlov) - 2V622F4

horizontal boring machine Ø 125, Leningrad, (Sverdlov) - 2E656

horizontal boring machine Ø 160, Leningrad, (Sverdlov) - 2L614

horizontal boring machine Ø 80, Charentsavan - 2M614

horizontal boring machine Ø 80, Charentsavan - 2N636GF1

horizontal boring Ø 125, Kolomna - 262g

horizontal boring machine Ø 85, Leningrad, (Sverdlov) - 2620, 2620A

horizontal boring Ø 90, Leningrad, (Sverdlov) - 2622, 2622A

horizontal boring Ø 110, Leningrad, (Sverdlov) - 2611F2

horizontal boring machine with CNC Ø 80, Ivanovo - 2620V

horizontal boring Ø 90, Ivanovo - 2622V

horizontal boring Ø 110, Ivanovo - 2636

horizontal boring Ø 125, Ivanovo - 2657

horizontal boring Ø 150, Leningrad, (Sverdlov) - 2A78

finishing and boring 500 x 1000, Maykop - 2А78Н

finishing and boring machine 500 x 1250, Maykop - 2E78P, 2E78PN

finishing and boring machine 500 x 1000, Maykop - 2G942

milling-central-turning Kostroma - 2054m

thread-cutting machine M8, Molodechno, Krasnorechensk - 2056

thread-cutting machine M18, Molodechno - A9518

thread rolling 63 kN, Ø 3..45, AZKPA - MR-71M

milling and centering Kostroma - UPW 12.5 x 70

thread rolling 125 kN, Ø 3..70, GDR - UPW 25 x 100

thread rolling 250 kN, Ø 10..100, GDR

2.1. Vertical and benchtop drilling machines

2.4. Jig boring machines

2.5. Radial drilling machines

2.6. Horizontal boring machines

2.7. Finishing boring machines and special

Economic aspect of choosing a lathe.

1.1. Cost of manufacturing a part.

It is necessary to take into account fixed and possible (variable) costs. Fixed: initial capital investment, machine depreciation, loan interest (if any). Variable: costs for materials, energy, labor, tools, maintenance and repair, spare parts, in case replacement is required. It should be taken into account that the cost of manufacturing a part using cheaper equipment will be lower, since machines of a smaller standard size, as a rule, cost less. Also, the cost of manufacturing a part is very closely related to processing productivity. The same parts can be produced using a variety of types of equipment, but depending on the technology and type of equipment, they can differ significantly in cost. It is necessary to take into account the serial production, the size of the average production batch of the smallest and largest parts. It is very important to calculate the load factor of equipment of each standard size. If we are talking about a group of lathes for the entire range of processed parts, then it is necessary to calculate which parts need to be processed on machines of a smaller standard size, and which ones on a larger standard size.

1.2. Footprint.

Another criterion in modern production is the space occupied by equipment.

It is no secret that machines built on the new principles of lean manufacturing with the same working area can have up to 1.5 times less occupied space, both by the machine itself and the area for servicing the machine. Scheme for determining the area occupied by the machine

A - work area for a simple operator B - area for extending the chip container C - area for connecting a bar feeder or automatic loader D - area for electrical cabinets and centralized stations

Grinding machines

- 3A10P

cylindrical grinder Ø 15, St. Petersburg, SPZPS - 3A110

cylindrical grinder Ø 140, Tbilisi - 3A130

cylindrical grinder Ø 280, Lubny - 3A151

cylindrical grinder Ø 200 Kharkov - 3A161

cylindrical grinder Ø 280 Kharkov - 3A164

cylindrical grinder Ø 400, Kharkov - 3A184

centerless cylindrical grinder Ø 80, Vitebsk - 3B12

cylindrical grinding machine Ø 200, Vilnius, Leninokan (Gyumri) - 3B151

cylindrical grinder Ø 200, Kharkov - 3B153

cylindrical grinder Ø 140, Vilnius - 3B161

cylindrical grinder Ø 280, Kharkov - 3E12

cylindrical grinder Ø 200, Vilnius - 3E180V

centerless cylindrical grinder Ø 1..10, Vitebsk - 3E184

centerless cylindrical grinder Ø 4..80, Vitebsk - 3K12

cylindrical grinder Ø 200, Leninokan (Gyumri) - 3M131

cylindrical grinder Ø 280, Lubny - 3M132v

cylindrical grinder Ø 280, Kharkov - 3M151

cylindrical grinder Ø 200, Kharkov - 3M152

cylindrical grinder Ø 200, Kharkov - 3M162

cylindrical grinder Ø 280, Kharkov - 3M151F2

CNC cylindrical grinder Ø 200, Kharkov - 3M153

cylindrical grinder Ø 140, Vilnius - 3M174

cylindrical grinder Ø 400, Lubny - 3M175

cylindrical grinder Ø 400, Lubny - 3M182

centerless cylindrical grinder Ø 25, Vitebsk - 3M184

centerless cylindrical grinder Ø 80, Vitebsk - 3M193

cylindrical grinder Ø 560, Kharkov - 3M194

cylindrical grinder Ø 560, Kharkov - 3M196

cylindrical grinder Ø 800, Kharkov - 3M197

cylindrical grinder Ø 800, Kharkov - 3U10A

cylindrical grinder Ø 100, Vilnius - 3U12af11

cylindrical grinder Ø 200, Vilnius - 3U12vf11

cylindrical grinder Ø 200, Leninakan - 3U131

cylindrical grinder Ø 280, Lubny - 3U132

cylindrical grinder Ø 280, Lubny - 3U133

cylindrical grinder Ø 280, Lubny - 3U142

cylindrical grinder Ø 400, Lubny - 3U143

cylindrical grinder Ø 400, Lubny - 3U144

cylindrical grinder Ø 400, Lubny - 312M

cylindrical grinder Ø 200, St. Petersburg, SPZPS - 3130

cylindrical grinder Ø 280, Kharkov - 3131

cylindrical grinder Ø 280, Lubny - 3132

cylindrical grinder Ø 280, Kharkov - 3151

cylindrical grinder Ø 150, Kharkov - 3180

centerless cylindrical grinder Ø 75, Moscow - 3184

centerless cylindrical grinder Ø 75, Vitebsk - B-88

cylindrical grinder Ø 140, Leningrad - KSh-400

ultra-high precision cylindrical grinder Ø 200 × 400 - 3A227, 3A227P

internal grinding Ø 400, Saratov - 3A228

internal grinding Ø 200, Voronezh - 3K227A

internal grinding Ø 400, Saratov - 3K227V

internal grinding Ø 400, Saratov - 3K228A

internal grinding Ø 400, Voronezh, Saratov - 3K228V

internal grinding Ø 400, Voronezh, Saratov - 3K229A

internal grinding Ø 800, Voronezh, Saratov - 3M227VF2

internal grinding machine with CNCØ 400, Saratov - 32K84SF4

coordinate grinding machine with CNC - 3A423

cylindrical grinder for regrinding crankshaft journals Ø 580, Lubny - 3B423

cylindrical grinder for regrinding crankshaft journals Ø 580, Lubny - 3D4230

cylindrical grinder for regrinding crankshaft journals Ø 580, Lubny - 3451

grinding machine Moscow, MSZ - 3A64

sharpening Ø 250 x 650, Vitebsk - 3А64М

sharpening Ø 250 x 650, Vitebsk - 3A64D

sharpening Ø 250 x 600, Vitebsk - 3A662

sharpening machine for hob cutters Ø 200 x 280, Vitebsk - 3B632

sharpening and grinding machine for sharpening cutters Mukachevo - 3B633

sharpening and grinding machine Ø 300, Tiraspol - 3B634

sharpening and grinding machine Ø 400, Mukachevo - 3B641

sharpening Chita - 3B642

sharpening Vitebsk - 3B642

sharpening Vitebsk - 3D641E

grinding machine Ø 200 x 400, Vitebsk, Mukachevo - 3D642E

sharpening Vitebsk - 3D692

sharpening Vitebsk - 3E692

sharpening Vitebsk - 3E642

sharpening Vitebsk - 3E642E

sharpening Vitebsk - 3K631

sharpening and grinding machine Ø 150, Mukachevo - 3K634

sharpening and grinding machine Ø 400, Mukachevo - 3L631

sharpening and grinding machine Ø 200, Mukachevo - 3M634

roughing and grinding Saraktash - 3M636

roughing and grinding machine Armavir - 3M642

sharpening Vitebsk - 3622D

diamond sharpening machine for cutters Mukachevo - 3662

sharpening machine for hob cutters Ø 200 x 280, Vitebsk - VZ-318

sharpening Vitebsk - VZ-319

table sharpening Vitebsk - VZ-818

sharpening Vitebsk - TSH-1

tabletop sharpening and grinding machine Ø 250, Orsha - TSh-2

sharpening and grinding machine Ø 300, Orsha - TSh-3

sharpening and grinding machine Ø 400, Orsha - TSh-4

sharpening and grinding machine Ø 400, Orsha - TSh-3.20

sharpening and grinding machine Ø 400, Chelyabinsk - TS-6010S

sharpening and grinding machine Ø 49 Energomash, Sturm - TCPA-7

sharpening machine for circular, frame and band saws Kirov - ET-62

benchtop sharpening and grinding machine Ø 150, Kasimov - 3B70V

surface grinder 160 x 400, Orsha - 3B722

surface grinder 320 x 1000, Lipetsk - 3B724

surface grinder 400 x 2000, Voronezh - 3G71

surface grinder 200 x 630, Orsha - 3G71M

surface grinder 200 x 630, Orsha - 3D722

surface grinder 320 x 1000, Lipetsk - 3D725

surface grinder 630 x 2000, Voronezh - 3D711AF10-1

surface grinder 200 x 450, Orsha - 3D711VF11

surface grinder 200 x 630, Orsha - 3D756

surface grinder with vertical spindle Ø 800, Voronezh - 3E710V

surface grinder 250 x 125, Orsha - 3E711AF1

surface grinder 200 x 450, Orsha - 3E711B

surface grinder 200 x 630, Orsha - 3E711VF1

surface grinder 200 x 630, Orsha - 3E711VF2

surface grinder 200 x 630, Orsha - 3E756, 3E756L

surface grinder Ø 800, Ø 1000, Voronezh - 3L722V, 3L722A

surface grinder 320 x 1000, Lipetsk - 3L741VF10

surface grinder Ø 630, Lipetsk - 3P722V

surface grinder 320 x 1000, Lipetsk - 371

surface grinder 200 x 600, Vitebsk - 372B

surface grinder 300 x 1000, Moscow - 3711

surface grinder 200 x 630, Orsha - PSh-30540M

surface grinder 156 x 400, Tula - 3G833

honing Maikop, Krasnorechensk - 3K833

honing Maikop, Krasnorechensk - SIP-800

machine for testing abrasive wheels Derbent - 395M

profile grinding 20 x 20, Leningrad, SPZPS - 395МФ10

profile grinding with UTsI20 x 20, Leningrad, SPZPS - 3951VF1

profile grinding with digital indicator 50 x 50, Leningrad, SPZPS

3.1. Cylindrical grinding machines

3.2. Internal grinding machines

3.4. Specialized cylindrical grinding machines

3.6. Sharpening and grinding machines

3.7. Surface grinding machines

3.8. Honing machines. Special machines

Detailed description

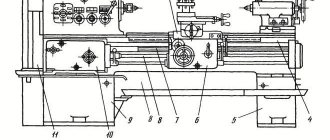

The basis of the body of the 1615 lathe is the bed on which the following working mechanisms are installed:

- Headstocks (front and back).

- Movable support.

- Apron.

- Boxes of working feed and speeds.

In addition, the equipment in question includes a spindle and a drive motor (380 Volt three-phase electric motor).

The 1616 lathe bed is made of cast iron and has diagonally arranged stiffeners, reinforced by two guides (front and rear). The first is used to move the caliper, and the second is used for the translational movement of the tailstock. The base of the 1616 lathe is attached to “powerful” cast iron stands using reinforced bolts.

Dimensions

The working dimensions of the 1616 lathe are determined based on the dimensions of its bed. Its main parameters in millimeters are presented below:

- Bed length – 1960 mm.

- Its width is 880 mm.

- The height of the lathe is 1616 – 1235 mm.

The weight of the described sample of machine equipment is 850 kg.

Location of controls

The location of the working controls of the 1616 lathe can be found in the photo below:

They include several types of handles and handwheels that perform the following operating functions:

- Turning friction clutches on or off.

- Setting the spindle speed.

- Settings of its speed and multiple multipliers for each mode.

- Changing the direction of the working feed.

- Setting thread parameters.

- Turning on the lead screw.

- Starting the transverse/longitudinal feed of the caliper (manual, including).

- Fixing the tailstock quill, etc.

The 1616 lathe's controls include a handwheel for manual movement of the carriage and slide, as well as a nut for securing the tailstock and a screw for lateral movement of the body. One three-phase asynchronous electric motor is used as the drive mechanism. The torque from it is transmitted by the actuator using 2 V-belts and a gearbox located in the left cabinet of the frame.

Gear processing machines

- 5A12

gear shaping Ø 208, Yegoryevsk - 5A122

gear shaping Ø 250, Korsun-Shevchenko - 5A140P

gear shaping Ø 500, Egoryevsk - 5B150

gear shaping Ø 800, Yegoryevsk - 5B12

gear shaping Ø 200, Korsun-Shevchenko - 5B150

gear shaping Ø 800, wedge - 5M14

gear shaping Ø 500, Kharkov - 5M150

gear shaping Ø 800, wedge - 5M161

gear shaping Ø 1250, wedge - 514

gear shaping Ø 500, Yegoryevsk - 5111

gear shaping Ø 80, Korsun-Shevchenko - 5122

gear shaping Ø 200, Korsun-Shevchenko - 5140

gear shaping Ø 500, Korsun-Shevchenko - 5A26

tooth-cutting Ø 610, Saratov, SZTZS - 5A250P

tooth-cutting machine Ø 500, Saratov, SZTZS - 5S23P

tooth-cutting Ø 125, Saratov, SZZS - 5S276P

tooth-cutting Ø 500, Saratov, SZTZS - 5S280P

gear cutter Ø 800, Saratov, SZTZS - 5Т23В

tooth-cutting machine Ø 125, Saratov, SZZS - 5236P

tooth-cutting machine Ø 125, Saratov, SZZS - 525

gear cutter Ø 500, MZKRS Moscow - 526

dental planer Ø 610, Saratov, SZTZS - 5230

gear cutting machine Ø 320, Saratov, SZTZS - 528С

gear cutter Ø 800, Saratov, SZTZS - 5A342

gear hobbing Ø 2000, Kolomna - 5B310p

gear hobbing Ø 200, Vilnius - 5B312

gear hobbing Ø 320, Vitebsk - 5B312

gear hobbing Ø 320, Vitebsk - 5D32

gear hobbing Ø 800, Yegoryevsk - 5E32

gear hobbing Ø 800, Yegoryevsk - 5K32

gear hobbing Ø 800, Yegoryevsk - 5K32A, 5K324A

gear hobbing Ø 800, Yegoryevsk - 5K301p

gear hobbing Ø 125, Vilnius - 5K310

gear hobbing Ø 200, Vitebsk - 5K324

gear hobbing Ø 500, Yegoryevsk - 5K328A

gear hobbing Ø 1250, Egoryevsk - 5M32

gear hobbing Ø 800, Yegoryevsk - 53A11

gear hobbing Ø 1250, Yegoryevsk - 53A20

gear hobbing Ø 200, Vilnius - 53A30P

gear hobbing Ø 320, Vitebsk - 53A50

gear hobbing Ø 500, Yegoryevsk - 53A80

gear hobbing Ø 800, Yegoryevsk - 53V30P

gear hobbing Ø 320, Vitebsk - 532

gear hobbing Ø 750, Yegoryevsk - 5310

gear hobbing Ø 200, Yegoryevsk - 5327

gear hobbing Ø 1000, Yegoryevsk - 5342

gear hobbing Ø 2000, Kolomna - 5350A

spline milling Ø 150, Kuibyshev, SVSZ - 5B63

thread milling Ø 450 x 400, Melitopol - 5D07

thread-cutting Ø 39 x 320, Chita - 561

thread milling Ø 400 x 700, Kuibyshev, SVSZ - 5993

thread-cutting machine Ø 42 x 280, Chita - VMS-2A

thread-cutting Moscow - 5A841

gear grinder Ø 320, Moscow - 5B833

gear grinder Ø 200, Yegoryevsk - 5M841

gear grinder Ø 320, Moscow - 5K822V

thread grinding machine Ø 150, MZKRS Moscow - 5702

gear shaving Ø 320, Vitebsk - 5822

thread grinding machine Ø 150, MZKRS Moscow - 5822m

thread grinding machine Ø 150, MZKRS Moscow

5.1. Gear shaping machines for cylindrical wheels

5.2. Gear cutting and gear cutting machines for bevel wheels

5.3. Gear hobbing machines for cylindrical wheels

5.6. Thread milling, thread cutting machines

5.7. Gear and thread grinding, finishing machines

Milling machines

- 6A12p

cantilever-milling 320 x 1250, Lugansk - 6B11

cantilever-milling 250 x 1000, Frunze - 6D12

cantilever-milling 320 x 1250, Dmitrov - 6K11

cantilever-milling 250 x 1000, Dmitrov - 6K12

cantilever-milling 320 x 1250, Dmitrov - 6M12P

cantilever-milling 320 x 1250, Gorky - 6M13P

cantilever-milling 400 x 1600, Gorky - 6M13U

cantilever-milling 400 x 1600, Kimry - 6Н10

cantilever-milling 200 x 800, Vilnius (Zalgiris) - 6N11

cantilever-milling 250 x 1000, Dmitrov - 6N12

cantilever-milling 320 x 1250, Gorky - 6N13P

cantilever-milling 400 x 1600, Gorky, Votkinsk - 6Р10

cantilever-milling 200 x 800, Vilnius (Zalgiris) - 6Р11

cantilever-milling 250 x 1000, Dmitrov - 6Р12, 6Р12Б

console-milling 320 x 1250, Gorky - 6Р13, 6Р13Б

console-milling 400 x 1600, Gorky - 6Р13Ф3

cantilever milling machine with CNC 400 x 1600, Gorky, Votkinsk - 6Р13рФ3

cantilever milling machine with CNC 400 x 1600, Gorky, Votkinsk - 6S12

cantilever-milling 320 x 1250, Lugansk - 6T10

cantilever-milling 200 x 800, Vilnius (Zalgiris) - 6T12-1

cantilever-milling 320 x 1250, Gorky - 6T12

cantilever-milling 320 x 1250, Gorky - 6T12F20

cantilever-milling 320 x 1250, Gorky - 6T13

cantilever-milling 400 x 1600, Gorky - 6T13-1

cantilever-milling 400 x 1600, Gorky - 6T13F20

cantilever-milling 400 x 1600, Gorky - 6T13F3

cantilever-milling 400 x 1600, Gorky - FSS-315

cantilever milling 315 x 1250, Heckert, GDR - FSS-400

cantilever milling 400 x 1600, Heckert, GDR - FSS350MR

cantilever milling 315 x 1250, StankoGomel - FSS450MR

cantilever milling 400 x 1600, StankoGomel - VM127

cantilever-milling 400 x 1600, Votkinsk - VM127M

cantilever-milling 400 x 1600, Votkinsk - MS-51

desktop milling 200 x 500, Lugansk - SVF-1

desktop milling 320 x 100 - SF-15

cantilever-milling 320 x 1250, Lugansk - SF-35

cantilever-milling 320 x 1250, Lugansk - 6441B

copy-milling horizontal Leningrad - 6G463

engraving copy-milling machine with pantograph Lviv - 6E463

engraving copy-milling machine with pantograph Lviv - 6L463

engraving copy-milling machine with pantograph Lviv - 6A54

milling non-cantilever 650 x 2200 - 6A56

milling non-cantilever 800 x 2000, Ulyanovsk - 6A59

milling non-cantilever 1000 x 2500, Ulyanovsk - 65A60F1

milling non-cantilever 630 x 2000, Ulyanovsk, Voronezh - 65A80

milling non-cantilever 800 x 2000, Ulyanovsk - 65A90

milling non-cantilever 1000 x 3000, Ulyanovsk - 654

milling without console 630 x 1600, Ulyanovsk - 6520F3

milling without console Lviv - 6540

milling non-cantilever 800 x 2000, Charentsavan - 6550

milling without console 1000 x 2500, Charentsavan - 6560

milling without console 630 x 1600, Ulyanovsk - MA655

milling without console 500 x 1250, Savma - 6G605

longitudinal milling 500 x 1600, Gorky - 6M610

longitudinal milling 1000 x 3150, Minsk, MZOR - 6U312, 6U316

longitudinal milling 1250 x 4000, Ulyanovsk - 6U612, 6U616

longitudinal milling 1250 x 4000, Ulyanovsk - 6605

longitudinal milling 500 x 1600, Gorky - 6606

longitudinal milling 630 x 2000, Gorky - 6610

longitudinal milling 4000 x 6000, Minsk, MZOR - 6620, 6625

longitudinal milling 2000 x 6300, Ulyanovsk - 6652

longitudinal milling 1250 x 4250 - 6A73P

milling 125 x 320, Yerevan - 6A75v

milling 200 x 630, Odessa - 6B75v

milling 200 x 630, Odessa - 6B75

milling 200 x 630, Yerevan - 6E75pf1

milling 200 x 630, Yerevan - 6M76P

milling 250 x 800, Irkutsk - 67K25

milling 320 x 800, Vilnius (Komunaras), Irkutsk - 67K25PF2

CNC milling 320 x 800, Vilnius (Komunaras) - 67L25PF2

wide-universal milling with CNC 320 x 800 Lipetsk (LSP) - 675

milling 200 x 630, Odessa - 675P

milling 200 x 630, Odessa - 676

milling 200 x 630, Irkutsk - 676P

milling 250 x 800, Vilnius (Komunaras), Irkutsk - 6720B

milling 200 x 630, Odessa - 6720VF2

milling 200 x 630, Odessa - 678M

milling 220 x 600, Odessa - 679

milling 270 x 700, Irkutsk - VM-130

milling 250 x 630, Votkinsk - NO-800

table milling Minsk - OF-55

milling 260 x 630, Vladimir - SF-250

milling 245 x 630, Vladimir - SF-676

milling 250 x 800, Kirov - F-2A (F-2M)

desktop milling machine Chistopol - FS-250

milling 250 x 620, Vladimir - FS-300

milling 250 x 620, Vladimir - Duplex 58

milling 260 x 720, GDR - FUW-250

milling 350 x 630, GDR - FUS-25 (FUS-25)

milling 250 x 850, Romania - FUS-32 (FUS-32)

milling 320 x 1000, Romania - MAHO 800

milling Germany - Schaublin 13

milling 200 x 630, Switzerland - S-169

table milling - 6D81Sh

widely-universal cantilever-milling 250 x 1000, Dmitrov - 6D82Sh

widely-universal cantilever milling machine 320 x 1250, Dmitrov - 6E80SH

wide-universal cantilever-milling 200 x 800, Vilnius (Zalgiris) - 6K81Sh

widely-universal cantilever milling machine 250 x 1000, Dmitrov - 6K82Sh

widely-universal cantilever milling machine 320 x 1250, Dmitrov - 6M80

cantilever-milling 200 x 800, Vilnius (Zalgiris) - 6M82

horizontal console-milling universal 320 x 1250, Gorky - 6M82G

horizontal cantilever-milling 320 x 1250, Gorky - 6M82Sh

widely-universal cantilever milling machine 320 x 1250, Gorky - 6M83

horizontal console-milling universal 400 x 1600, Gorky - 6M83G

horizontal cantilever-milling 400 x 1600, Gorky - 6М83Ш

universal cantilever milling machine, 400 x 1600 - 6Н80

horizontal console-milling universal 200 x 800, Vilnius (Zalgiris) - 6N80G

horizontal cantilever-milling 200 x 800, Vilnius (Zalgiris) - 6Н80Ш

wide-universal cantilever-milling 200 x 800, Vilnius (Zalgiris) - 6N81

universal console-milling universal 250 x 1000, Dmitrov - 6N81G

horizontal cantilever-milling 250 x 1000, Dmitrov - 6N81A

horizontal cantilever-milling 250 x 1000, Dmitrov - 6N82

horizontal console-milling universal 320 x 1250, Gorky - 6N82G

horizontal cantilever-milling 320 x 1250, Gorky - 6P80G

horizontal cantilever-milling 200 x 800, Vilnius (Zalgiris) - 6Р80

horizontal cantilever-milling 200 x 800, Vilnius (Zalgiris) - 6Р80Г

horizontal cantilever-milling 200 x 800, Vilnius (Zalgiris) - 6Р80Ш

wide-universal 200 x 800, Vilnius (Zalgiris) - 6Р81

universal console-milling universal 250 x 1000, Dmitrov - 6R81G

horizontal cantilever-milling 250 x 1000, Dmitrov - 6Р81Ш

widely-universal cantilever milling machine 250 x 1000, Dmitrov - 6Р82

universal console-milling universal 320 x 1250, Gorky - 6R82G

horizontal cantilever-milling 320 x 1250, Gorky - 6Р82Ш

wide-universal console-milling 320 x 1250, Gorky - 6Р83

horizontal console-milling universal 400 x 1600, Gorky - 6R83G

horizontal cantilever-milling 400 x 1600, Gorky - 6Р83Ш

wide-universal console-milling 400 x 1600, Gorky - 6T80

horizontal console-milling universal 200 x 800, Vilnius (Zalgiris) - 6Т80Ш

wide-universal cantilever milling machine 200 x 800, Vilnius (Zalgiris) - 6T82

horizontal cantilever-milling 320 x 1250, Gorky - 6T82-1

horizontal console-milling universal 320 x 1250, Gorky - 6T82G

horizontal cantilever-milling 320 x 1250, Gorky - 6T82Sh

widely-universal cantilever milling machine 320 x 1250, Gorky - 6T83

horizontal console-milling universal 400 x 1600, Gorky - 6T83-1

horizontal cantilever-milling 400 x 1600, Gorky - 6T83G

horizontal cantilever-milling 400 x 1600, Gorky - 6Т83Ш

widely-universal cantilever milling machine 400 x 1600, Gorky - FU-400, FU-315

cantilever-milling 400 x 1600, Heckert, GDR - NGF-110sh1, NGF-110sh2

cantilever-milling horizontal - NGF-110sh3

cantilever-milling horizontal 100 x 400, Rostov-on-Don - NGF-110sh4

cantilever-milling horizontal 100 x 400, Rostov-on-Don - Orsha-F32Sh

widely-universal cantilever milling machine 320 x 1400, Orsha - FU-321

console-milling universal 320 x 1370, Bulgaria - 692d

key-milling Dmitrov - 692m

key-milling Dmitrov - 692r

key-milling Dmitrov - 2С150ПМФ4

drilling-milling-boring machine with CNC and ASI 500 x 1000, Sterlitamak - 400V

drilling-milling-boring vertical with CNC and ASI 400 x 900, Sterlitamak - 500V

drilling-milling-boring vertical with CNC and ASI 630 x 1200, Sterlitamak - 1711IFF3

vertical milling machine with CNC 300 x 230, Izhevsk - 1715IFF3

horizontal milling machine with CNC and ASI Ø 320, Izhevsk - 2204ВМФ4

drilling-milling-boring horizontal with CNC and ASI Ø 630, Odessa - 2206VMF4

drilling-milling-boring horizontal with CNC and ASI 630 x 800, Vitebsk - 2254VMF4

drilling-milling-boring vertical with CNC and ASI 400 x 630, Odessa - VM501PMF4

drilling-milling-boring horizontal with CNC and ASI Ø 250, Votkinsk - 6305F4

longitudinal milling horizontal with CNC and ASI 500 x 1250, Gorky - IR320PMF4

multi-purpose horizontal milling machine 320 x 320, Ivanovo - IR-500

multi-purpose horizontal milling 500 x 500, Ivanovo, Gomel - IR-800

multi-purpose horizontal milling 800 x 800, Ivanovo - IS-500

multi-purpose horizontal milling 500 x 500, Ivanovo - IS-800

multi-purpose horizontal milling 800 x 800, Ivanovo - Mini Mill

vertical milling center 305 x 914, USA Haas - GF2171

vertical milling machine with CNC and ASI 400 x 1600, Gorky - FS65MF3

vertical milling machine with CNC and ASI 360 x 780, Tver - FS85MF3

vertical milling machine with CNC and ASI 500 x 1000, Tver - DMC 635 v ecoline

vertical milling center 790 × 560, DMG MORI - DMC 1035 v ecoline

vertical milling center 1200 × 560, DMG MORI - DMU 50 ecoline

vertical milling center 5-axis Ø 630 × 500, DMG MORI - OTs1I22

vertical milling center 4-axis Izhevsk - SVM1F4

vertical milling center 4-axis Lugansk

6.1. Vertical cantilever milling machines

6.4. Copying and engraving milling machines

6.5. Vertical non-cantilever milling machines (with cross table)

6.6. Longitudinal milling machines

6.7. Widely versatile tool milling machines

6.8. Horizontal and universal cantilever milling machines

6.9. Special milling machines

CNC milling machines and machining centers

Instructions for use

The instructions for using the lathe 1616 include preparatory procedures and the main (working) part. Let's look at each of them in more detail.

Preparing the workplace and tools

Before starting work on a lathe and drilling machine, you will need to prepare the workplace (i.e., create conditions for their safe carrying out). To do this you will need:

- remove all obstructive objects and large debris from the work area;

- arrange local lighting devices in such a way that there is enough light and so that it does not blind the eyes;

- conduct a visual inspection of the 1616 lathe to ensure that it does not have faulty components and assemblies;

- check the presence of guards on rotating parts and personal eye protection from chips;

- make sure that the tool securing the workpieces has no cracks or breaks;

- visually inspect the electrical system of the 1616 lathe to ensure there are no problems;

- check the presence of a grounding bus.

In addition, you will need to prepare all the tools necessary for processing the part (including cutting and measuring), special equipment and devices for removing chips. Particular attention is paid to checking the correct sharpening of the cutters and the serviceability of the entire auxiliary tool kit. Basic work operations

Before you begin the next task, you should make sure that the footrest is in good working order. If any problems are detected, it is prohibited to start working. It is also necessary to check the quality of the lubricant of the 1616 lathe, which must be fresh and evenly distributed throughout the working cavities of the mechanisms.

Immediately before turning on the 1616 lathe, you should make sure that its startup does not endanger anyone present in the room.

After turning on the equipment, you will need to check its performance at idle. To do this you need to do the following:

- make sure that all controls are in good working order (including feed, stop mechanisms, etc.);

- check the functionality of the levers for switching on feeds and switching operating modes;

- make sure that there is no possibility of spontaneous switching from idle to working.

If at least one of the listed malfunctions is detected, it is not allowed to begin work on boring parts until they are eliminated. Warranties and DIY repairs

All equipment of this class was necessarily provided with a warranty for a period of 12 months from the date of purchase and start of operation. Throughout this time, the manufacturer guaranteed its maintenance and repair in case of breakdown of any components.

In addition, if necessary, the user could purchase at the factory all the necessary components and spare parts (units and assemblies, among others). After repairs on their own, the company manufacturing samples of 1615 machines abdicated responsibility for the performance of the equipment, and the warranty obligations became invalid.

Slotting, planing, broaching. Other machines. Groups 7, 8, 9

- 7210

longitudinal planer Ø 900 x 1000, Minsk - 7212

longitudinal planer Ø 1120 x 1250, Minsk - 7216

longitudinal planer Ø 1400 x 1600, Minsk - 7A33

cross-planing Orenburg - 7B35

cross-planing Orenburg - 7D36

cross planer Gomel - 7D37

cross planer Gomel - 7E35

cross planer Orenburg - 7M36

cross planer Gomel - 736

cross-planing Orenburg - 737

cross planer Gomel - 7303

cross-planing Orenburg - 7305

cross-planing Orenburg - 7307

cross-planing Orenburg - 7307G

cross planer Orenburg - 7307D, 7310d

cross planer Gomel - 7A412

slotting Ø 360, Saraktash - 7A420

slotting Ø 500, Saraktash - 749

cross-planing Orenburg - 7402

Slotting Orenburg, Baku - 7410

Slotting Minsk, MZOR - 7430

slotting Ø 650, Gomel - 7D430

slotting Ø 630, Gomel - 7D450

slotting Ø 800, Gomel - 7M430

slotting Ø 630, Gomel - 7403, 7405

— slotting Ø 630, Gomel - 7417

Slotting Orenburg - GD200

slotting Ø 500, Gomel - GD320

slotting Ø 770, Gomel - GD500

slotting Ø 940, Gomel - 7A510

broaching 98 kN, Minsk - 7B510

broaching 100 kN, Minsk - 7A534

broaching 250 kN, Minsk - 7B55

broaching 100 kN, Minsk - 7B56

broaching 200 kN, Minsk - 7523

broaching 100 kN, Minsk - 7534

broaching 250 kN, Minsk - 8A531

vertical band saw Maikop - 8A725

automatic hacksaw-cutting machine Leninakan - 8B72

cut-off saw Ø 250 Krasnodar - 8B66

automatic cutting circular saw Ø 280, Minsk - 8В66а

automatic cutting circular saw Ø 280, Minsk - 8G240

abrasive cut-off Ø 60 - 8G662

automatic cutting circular saw Ø 280, Minsk - 8G663

automatic cutting circular saw Ø 285, Minsk - 872A

cut-off saw Ø 250 Krasnodar - 872M

cut-off saw Ø 250 Krasnodar - 8535

band saw Ø 350 Kuvandyk - 8725

hacksaw Ø 250 Orenburg - N-1

hacksaw Ø 250 Kaunas

7.1. Longitudinal planing machines, single and double column

7.3. Cross planers

7.4. Slotting machines

7.5. Horizontal and vertical broaching machines

Cutting machines

History of the model

The production of the 1616 lathe was mastered at the Sredne-Volzhsky plant SVSZ, founded back in 1876. The company’s specialists began their serial production half a century later – in January 1926.

The predecessor of 1615 was the first screw-cutting lathe, model TV-155V, produced by the enterprise. And by 1934, the plant had developed and put into production an original product of the SP-162 brand with a large number of speeds and a wide range of spindle speeds.

The drive mechanism on these models was a domestic electric motor with an operating power of 1.5 kW, specially developed according to an individual project. The plant began producing the model we are interested in (1615) during the Second World War. After some time, the machine was successfully modernized, after which the operating speed of the spindle was increased to 1000 rpm.

A few years after the end of the war (in 1949), another modernized model was launched into production under the factory designation “1616”. In subsequent years it was improved to the 16B16 model series. Since the 90s of the twentieth century, the plant has been producing lathes sold under the SAMAT brand.

Units, equipment and accessories for metal-cutting machines

- 16B20p.070

feed box for lathes Gomel - 16B20p.061

apron for lathes Gomel - AKP 109-6.3

automatic transmission - AKP 309-16

automatic transmission - EPU 2-2

electric drives EPU2-2 - UDG-100 (UDG N-100)

universal dividing head Ø 200 LOMO - UDG-135 (UDG N-135)

universal dividing head Ø 270 LOMO - UDG-160 (UDG-D-160)

universal dividing head Ø 160 LOMO - UDG-200 (UDG-D-200)

universal dividing head Ø 200 LOMO - UDG-250 (UDG-D-250)

universal dividing head Ø 250 LOMO

Universal dividing heads

Purpose and classification of lathes

Lathes include a large group of machines designed primarily for processing workpieces in the form of bodies of revolution made of metals.

The main technological operations performed on lathes are turning cylindrical, conical, shaped, and end surfaces of workpieces rotating coaxially with the spindle axis, and thread cutting.

The functionality of lathes can be significantly expanded through the use of special devices on turning equipment that allow milling, drilling, grinding and some other types of processing.

The basis of the turning group consists of automatic and semi-automatic lathes, screw-cutting lathes, turret lathes, rotary lathes, and lobe lathes.

For external and internal surface treatment of single and small groups of workpieces, including thread cutting, various models of screw-cutting lathes are used.

Turret lathes are designed for processing small and large groups of complex-shaped workpieces made from rods or piece workpieces that require the use of a large number of tools.

Rotary lathes are used to process the surfaces of workpieces of various shapes, whose diameter is much greater than their length. They differ from other lathes in the vertical location of the axis of rotation of the faceplate, to which the workpiece is attached.

To process large-diameter workpieces (up to 5 m) used in the manufacture of parts in individual production, lathes are used.

Lathes are classified:

- by type of material being processed (steel, cast iron, non-ferrous metals, plastic, etc.);

- processing accuracy (classes N, P, B, A, C);

- type of production (single, small-scale, serial, large-scale, mass);

- weight of the machine (light, medium, large and heavy);

- the maximum diameter of the workpiece (D) of the workpiece or the height of the centers above the bed (100...5000 mm);

- the longest length of the workpiece L (125...24,000 mm).

Typically, light lathes include lathes with a maximum diameter of the workpiece D = 100...200 mm, medium - D = 260...500 mm, large - D = 630...1250 mm, heavy - D = 1600...5000 mm.

On medium-weight lathes in mechanical engineering and metalworking, 70...80% of the total volume of turning work is performed. They are used to perform semi-finishing and finishing machining of parts from workpieces and cutting threads. They have a fairly high level of automation. To expand their technological capabilities, they are equipped with various devices that facilitate the turner’s work and improve the quality of processing.

Lathes have sufficient power, high rigidity and a wide range of spindle speeds and tool feeds, which allows processing parts using advanced tools made of hard and super-hard materials.

Lightweight lathes are used in tool production, watch industry, instrument making, electrical industry, experimental and pilot production.

Large and heavy lathes are used for processing parts of heavy, power and transport engineering in the manufacture of nuclear reactors, turbine rotors, generators, traction motors of electric locomotives, etc. Machines of this type are less universal than medium-type machines and are mainly adapted for processing certain large details.

Lathes produced by machine tool factories in Russia have an alphanumeric designation. Decoding the alphanumeric designation of a lathe gives an idea of its main characteristics (type, dimensions of the workpiece being processed, processing accuracy, etc.).