A drilling machine is a device used to form holes in parts made of various materials. The technical capabilities of modern machines of this category allow them to be used not only for creating holes with a diameter of up to 100 mm, but also for performing a whole list of other technological operations.

For any type of activity, you can choose a suitable drilling machine, be it a home workshop, a car service or a production workshop.

Application, design and operating principle of drilling machines

Drilling machines allow you to create through or blind holes in parts made of various materials. These technological operations are performed using a cutting tool such as a drill, which ensures the removal of chips from the material being processed.

Most devices of this type are industrial drilling machines. The number of models for home use, characterized by significantly lower functionality compared to professional devices, is insignificant. Meanwhile, it is by the example of the simple design of household models that it is most convenient to get acquainted with the principle of operation of a drilling machine and its basic elements.

Small-sized household drilling machine

A household model is, as a rule, a tabletop drilling machine, which has compact dimensions and is installed on the surface of a workbench or on any other elevation that makes it easy to use. In the vast majority of cases, this is a vertical drilling machine, the design of which is the most typical for equipment of this type.

The basic elements of a drilling machine used both at home and in domestic conditions are:

- a spindle head in which a working chuck is mounted, which serves to fix the cutting tool;

- drilling head, the design of which includes a spindle head, an electric drive motor and a belt drive;

- supporting column-column on which the drilling head of the equipment is mounted;

- a massive base plate made by casting from steel or cast iron (it performs two functions: it serves as a reliable base for the machine and is used to secure the vertical equipment stand).

Main components of a drilling machine

The technological operations for which the vertical drilling machine is intended are performed through two movements of the spindle: main and auxiliary. The first movement is the rotation of the spindle assembly, and the second is its movement in the vertical direction. The vertical drilling machine got its name because its spindle makes a feed movement in the vertical direction. A special steering wheel located on the side of the device’s body is responsible for performing such a movement.

Design elements of household drilling equipment and their interaction

The spindle assembly of both industrial and household drilling machines is driven by an electric motor that imparts torque to the belt drive shaft. Drilling machines intended for domestic use are equipped with electric motors with a power of 250–1000 W.

Asynchronous motor of the Sturm BD7037 desktop drilling machine with a power of 370 W

On many models of household drilling machines, the rotation speed of the cutting tool can be adjusted, which is ensured by the use of belt drive shafts of different diameters in their design. The principle of regulating the spindle rotation speed on such machines is quite simple: when the drive motor is turned off, the belt is simply thrown into the groove of that part of the pulley that has a different diameter. Using this principle, the spindle speed can be adjusted in the range of 450–3000 rpm.

Belt drive unit for Proma PTB-16B230 machine

Machine tools for domestic use are usually equipped with drill chucks identical to the clamping devices of hand-held electric drills. These chucks with 3 self-centering jaws are designed to hold drills with a diameter of up to 12 mm. To work with this chuck, you need a special key, which is used to clamp or loosen the locking jaws.

When choosing a machine, pay attention to the minimum diameter of the drill clamped in the chuck - the jaws of some models cannot fix drills with a caliber of less than 3 mm

The technical capabilities of drilling machines for household use make it possible to process parts whose height is in the range of 200–900 mm. This parameter depends on the height to which the drilling head can be raised on the equipment rack. The principle of moving the drilling head along the machine column may vary for different models. On the simplest and lightest devices, the working head is moved to the required height manually, and on larger and heavier equipment, a special steering wheel handle is provided for this, which is connected to the drive mechanism.

A special handle is used to fix the drilling head in the required position and to set it at the required height before starting processing. It is necessary to adjust and fix the position of the working head before starting drilling because the amount of protrusion of the chuck from the spindle assembly is quite small and, depending on the model of the unit, is 50–400 mm.

Controls for adjusting the drilling depth of the NS12A machine: 1 – indicator nut; 2 – pointer protrusion; 3 – steering wheel; 4 – clamp; 5 – fixing screw; 6 – spindle sleeve

An important parameter by which any drilling machine is evaluated is drill overhang. This parameter, which can be in the range of 100–200 mm for different models of household machines, characterizes the distance from the axis of rotation of the cutting tool to the axis of the rack-column (it determines at what distance from the edge of the part a hole can be drilled).

The main requirement for the base plate of a drilling machine, which must ensure its stable position on any horizontal surface, is its massiveness and dimensions sufficient to balance the mass of the other structural elements of the equipment.

The purpose of the upper part of such a plate is to serve as a work table, so it is made as flat as possible with several grooves. The central of these grooves is used when drilling through holes and is necessary in order to avoid damage to the drill and the surface of the work table during such a technological operation. The remaining grooves on the surface of the work table are needed to secure various clamping devices.

The base of the PROHHON-TBM-220 machine has slots for attaching a vice

The vertical movement of the drill fixed in the chuck is carried out by a lever mechanism driven by a special handle. This handle, located on the side surface of the machine body, is specially spring-loaded, which ensures that it automatically returns to its original state after the impact on it stops.

The electric motor on household models is powered primarily from an electrical network with a voltage of 220 V. It starts and stops using a push-button station. On certain models of household drilling machines, the technical capabilities of which allow cutting internal threads, reverse starting of the electric motor is provided.

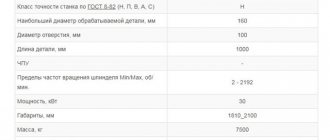

Machine characteristics

When choosing equipment, you should correctly select the layout of the machine and technical characteristics for the planned work.

- Machine type. When processing large and heavy workpieces, radial drilling is more suitable; for small workpieces, vertical drilling is more suitable.

- Power. The performance and energy consumption directly depend on this parameter.

- Supply voltage. 220 V - small hobby-class equipment, 380 V - professional machines.

- Maximum drilling diameter. This parameter characterizes the maximum drilling diameter in steel 45.

- Spindle speed. Depends on the machine gearbox and, depending on the equipment, can be 2000 - 3000 min-1. Different materials are processed at different rotation speeds.

Accessories for household drilling machines

A tabletop drilling machine intended for use at home can be equipped with additional devices that significantly increase its functionality and ergonomics.

Machine "Caliber SS-13" with an additional lifting work table

Let's list such devices.

- The work table, which is mounted on a cantilever stand, allows you to perform various actions with it: raise and lower it manually (in the simplest models of machines); use a special handle connected to a rack and pinion mechanism to change the height of its location; fix at the required height. Some models of drilling machines for home can be equipped with a work table, which can not only move in the vertical direction, but also rotate about the vertical axis.

- The mechanism that provides adjustment of the drilling depth operates on the following principle: the tip of the drill, fixed in the equipment chuck, is lowered to a mark on the side surface of the part corresponding to the required drilling depth. After this, tighten the tightening lever of the depth regulator, thereby limiting the stroke of the cutting tool.

- The protective screen, which is a folding guard made of transparent plastic, protects the machine operator from flying chips and prevents clothing and long hair from entering the processing area.

Quick release clamp for drilling machine BOSCH PBD 40

Features of controlling the main components of drilling machines

The operating modes of the equipment in question, which needs to be operated semi-automatically or manually, are set by changing the spindle speed. The spindle speed is changed using gears located inside the drill head. power units, changes in spindle speed and feed are achieved through an additional vertical motor mounted directly on the drilling head.

Precision drilling machine ZAY7016V

CNC machines consist of several autonomously located units, each of which is controlled individually. To reduce changeover time, coordinate tables and fixtures are used.

Since significant heat is generated during drilling, cutting fluids should be supplied continuously or periodically to the machining area. In equipment with manual spindle feed, machine oil is used for this; for more powerful systems, sulfofresol or water-oil emulsions are used. The cooling system is controlled based on the readings of the built-in temperature sensors.

Drilling machines for industrial use

It is enough to look at the drawings or photos of industrial drilling machines to understand that they are much more complex devices than household models. Most of the models of such machines are universal equipment that allows you to perform not only drilling in metal and other materials, but also a number of other technological operations.

Multi-spindle drilling machine GILLARDON RF 25

Production drilling machines include devices of the following categories.

Tabletop machines

Such machines are small in size and light in weight. They are used for drilling holes with a small diameter.

Vertical drilling (column) machines

These machines are used to equip small-scale and individual production. With their help, you can make holes in metal workpieces with a diameter in the range of 18–75 mm.

Radial drilling machines

This equipment is used for processing massive metal parts or workpieces in which it is necessary to form holes with centers located along a circular arc. The design of a drilling machine in this category is characterized by a fairly large overhang of the spindle unit, the value of which can reach 1300–2000 mm.

Coordinate drilling devices

The use of such machines is relevant in cases where high demands are placed on the accuracy of the location of several holes in a part.

Horizontal drilling machines

These devices process holes of significant depth (shafts, axles, rods, etc.).

Centering machines

Such equipment is used to form center holes located at the ends of the workpieces.

Multi-spindle machines

On units equipped with several spindle heads, multiple holes located in vertical, horizontal and inclined planes can be processed simultaneously.

Combined machines

On devices of drilling-milling, drilling-turning, drilling-slotting and a number of other categories, various technological operations can be simultaneously performed.

Universal drilling and milling machine Stalex-LM1450-2

The most common are vertical and horizontal drilling machines. Many modern models of drilling machines are equipped with numerical control systems, which can significantly increase the productivity of such equipment and ensure high processing accuracy. Machines with such a control system are used primarily to equip serial and large-scale production enterprises.

Among the special drilling equipment, mention should be made of magnetic machines, which are used to make holes in large parts. Such devices, equipped with a special magnetic base, are placed directly on the surface of the workpiece and are securely held on it due to a powerful magnetic field. The big advantage of machines in this category is that they can be located in any spatial position.

The unique design of magnetic machines makes it possible to process metal where it is impossible to do with conventional equipment

Despite the fact that any drilling machine can be used to make holes in workpieces made of various materials, special models are created for woodworking and furniture factories that can be equipped with one or more spindles, including rotary-type working heads. Using such equipment, you can not only make holes in wood parts, but also create nests, grooves, and remove knots.

The use of modern drilling and filler equipment in furniture factories, which has great versatility and functionality, allows it to quickly produce furniture structures even according to the most complex drawings.

Equipment designation

The letters and numbers in the markings can tell, if not everything, then a lot about the equipment. The abbreviation will tell a specialist who works with metal machines about its main characteristics.

The alphanumeric designation on the housing indicates:

- the first digit - into groups according to the table of classification of metalworking equipment;

- the second digit indicates the type of equipment;

- if a letter is indicated in second place, then this indicates a modernization of the base model;

- The maximum drilling diameter in mm is determined by the value of the last 2 digits.

- if at the end there are the letters “N”, “P”, “B”, “A”, “C”, then they indicate accuracy, “M” - a magazine with interchangeable tools.

Modernized CNC machines are marked with the letter “F” and a number in front of the type. The meaning of the number indicates:

- the machine has a digital display and a preliminary set of coordinates. The purpose of this system is that, after completing one of the specified cycles, the machine stops. To start the next operation, you must press the button. The programmed device will automatically move the drill to the required position. The movement of the tools is programmed by recording the actions on punched tape.

- The machine is equipped with positional and rectangular CNCs. The purpose of this system is to simultaneously place from 1 to 5 tools in the working position.

- CNC contour systems. The pulse signal determines the required distance to move the tool to a given point.

- universal CNC system.

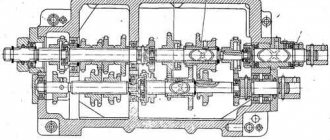

Capabilities and design of industrial drilling equipment

Drilling equipment intended for industrial use is much more complex than domestic models. This is noticeable, as mentioned above, even from photos of such units. Feeding of cutting tools on this equipment can be performed not only manually, but also in automatic mode. Almost any of these machines provides the ability to regulate the rotation speed of the spindle unit and the feed rate, for which the speed box and feed box are responsible, respectively.

Professional-class benchtop drilling machines differ from household models in high-precision components, from support bearings to chucks

Since such machines are used more intensively and for solving critical tasks, their kinematic design is more complex and reliable. Many of the modern models of these devices provide the option of automatically reversing the direction of feed and rotation of the cutting tool at the moment when it reaches the required processing depth.

The spindle assembly of most models of such equipment is equipped with a mechanism for automatically approaching the surface of the workpiece. An almost mandatory option for these machines is the automatic supply of coolant to the processing zone at the moment such processing begins.

Drilling head design of an industrial machine

Recently, industrial enterprises have been actively equipped with drilling machines, the operation of which is controlled by a CNC system. The advantage of using such equipment is that they automate the main and auxiliary technological operations, which can significantly increase their productivity compared to manually controlled models.

Industrial drilling machines, as mentioned above, are capable of performing various technological operations:

- opening holes;

- processing of holes using a countersink;

- chamfering in the upper part of the holes, forming cylindrical and conical recesses - countersinking;

- processing of holes using counterbore;

- internal thread cutting;

- processing of holes using a cutter - boring;

- finishing of holes using ball or roller tools - smoothing;

- processing of parts using milling tools (forming grooves, etc.).

Countersinking a recess on an industrial machine

Design features of the machines

Radial drilling machines are metal-cutting equipment used for processing parts of various configurations and geometric dimensions, which are made of cast iron and steel, and various non-ferrous metals. Such machines are classified as equipment of the second class, if we are guided by the generally accepted classification of technical devices intended for metal processing. The most popular models of equipment of the radial drilling group (2K52, 2M55, 2A554, AS2532, 2N55 and 2532L) allow drilling holes, the axis of which is located at different angles.

The technical capabilities of a radial drilling machine allow it to process surfaces of any type: cylindrical, conical, threaded and end surfaces. A tabletop machine of this model is most often used to perform roughing, semi-finishing, and finishing technological operations.

The main tools that radial drilling machines are equipped with are drills, reamers, countersinks and thread taps. To perform individual technological operations, a special-purpose tool can be installed on the machine.

The above models, which are most widespread, are mainly used for processing internal holes, which can be cylindrical or even conical. Parts that can be processed on the equipment of these models may have fairly large dimensions and irregular geometric shapes.

The design features of radial drilling machines make the process of processing parts simple and convenient. The part on such a machine is fixed in a special device. The design of the equipment ensures smooth movement of the cutting tool in relation to the surface being processed.

CNC Radial Drilling Machine

Machines in this category, including tabletop ones, are distinguished by high power characteristics, which makes it possible to process parts made from various metals, including steel blanks. Radial drilling machines are successfully used to equip enterprises operating in various industries, this also applies to automobile and aircraft manufacturing.

Rules for working on a drilling machine

Operating drilling equipment may pose a risk of injury to the operator if safety requirements are not followed. In particular, the following may pose a risk to the health and even life of the operator working on the drilling unit:

- machine elements that rotate and move linearly during processing;

- conductive elements;

- workpieces and tools that, if not securely fixed, can fly out of the processing area.

The most important safety requirement for working with drilling equipment is the use of technically sound and proven devices and tools (and only for their intended purpose).

The cutting tool is of great importance for the proper operation of the machine and the production of high-quality holes with its help. It must be well and correctly sharpened, and also selected in accordance with the material of the part in which the holes need to be drilled. During processing, the cutting tool heats up intensely, which can lead to rapid wear and failure. To minimize this risk, during processing it is necessary to cool the tool using a special liquid or ordinary water.

The process of drilling holes whose depth is greater than 5 diameters of the tool used has some peculiarities. During the process of forming such holes, the tool should be periodically removed and the unfinished hole freed from accumulated chips, which can lead to jamming of the drill.

In general, the technique of working with drilling equipment and the rules for its regular preventive maintenance do not cause any great difficulties; you can learn them quite quickly. If these rules are followed, the equipment will serve you for a long time, and you will be able to use it effectively to produce accurate and high-quality holes.