It is better to consider the design of a drilling machine using the example of compact models intended for use in domestic conditions. Such units can be used at home or in the garage. For comfortable work, it is enough to install the machine on any elevation, for example, on a regular table.

The most popular type of household drilling machines are vertical drilling units with a standard device for such equipment.

Photo No. 1: drilling machine Euroboor ECO-TUBE.30

Drilling machines: application, design, mechanism of action

Drilling machines for making holes in domestic and industrial settings have the same purpose. They are used to create holes in workpieces made of wood, concrete, metal, etc. The role of the cutting tool is performed by a drill, which carefully removes chips from the part.

To create holes in workpieces, the design of the drilling unit must include a base plate. All other elements are mounted on this plate. The design of a vertical drilling machine includes a drilling unit. The block is installed on a support stand, which fixes the processing part and displaces it.

If you want to buy a drilling machine, you need to take into account such features as:

- drill chuck type;

- maximum drill size;

- desktop dimensions;

- engine power;

- number of speeds.

It is very important to understand the operating principle of such equipment. The rotational motion is transmitted to the spindle using a speed mechanism. To start drilling, the cutting tool must be lowered, pointing it towards the workpiece. The position of the drilling unit on the vertical rod can be changed.

Features of CNC machines

Every year there are more and more CNC models on sale. This is due to the fact that they have increased productivity and allow you to obtain accurate, high-quality products. Of course, they do not replace small hand-held machines, but they are still very popular.

The features of machines with numerical control include the following points:

- Processing can be carried out automatically; the installer only enters the program.

- In most cases, the design has a head of interchangeable tools. Due to this design, the machine automatically changes the cutting tool.

- To speed up the machining process, a movable table is installed, which can change the position and orientation of the workpiece.

- The accuracy of the processing is high, the deviation is minimal.

Industrial CNC machines are in most cases used to produce cabinet products or plates with a large number of holes.

Such a purchase is justified only when large-scale production has been established. The cost of CNC machines is quite high; they require timely maintenance.

Design elements of a household drilling machine and their interaction

The design of a household-type desktop drilling machine includes several elements that interact with each other:

- A base plate that acts as the base of the unit. A vertical stand is attached to this plate. The base plate is usually cast from cast iron or steel.

- Vertical stand made in the form of a column. The drill head is attached to the stand.

- A drilling head, the design of which includes a spindle head, an electric motor and a belt drive.

- A spindle headstock to which is attached a chuck used to mount and hold a cutting tool.

Starting the electric motor, which is part of the drilling head, causes the spindle to rotate. The maximum power of household models of drilling units is one thousand watts. The spindle rotation speed is selected with the engine turned off by throwing the belt into the desired pulley groove. Depending on the machine model, the drilling head can be moved to the required height manually or using a handle connected to a drive. The movement of the cutting tool fixed in the chuck is carried out by a lever mechanism.

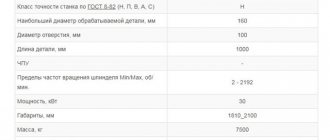

Characteristics

When choosing equipment, it is necessary to select the correct machine layout and technical characteristics according to the planned work.

- Machine type. When processing large and heavy workpieces, radial drilling is more suitable; for small workpieces, vertical drilling is more suitable.

- Power. The performance and energy consumption directly depend on this parameter.

- Supply voltage. 220 V - small hobby-class equipment, 380 V - professional machines.

- Maximum drilling diameter. This parameter characterizes the maximum drilling diameter in steel 45.

- Spindle speed. Depends on the machine gearbox and, depending on the equipment, can be 2000 - 3000 min

-1. Different materials are processed at different rotation speeds.

Additional equipment for drilling machines for household use

Additional equipment may be included in the package of drilling machines for household purposes. Some machine models are equipped with a work table attached to a stand, which can be manually raised and lowered. Another type of additional equipment is a mechanism with which you can adjust the drilling depth. To do this, the tip of the cutting tool is lowered to the mark corresponding to the desired depth of the hole, and the tightening lever of the adjusting mechanism is twisted, limiting the possibility of movement of the drill.

A protective screen is another type of additional device that is equipped with drilling machines. Such screens protect the user from flying chips during operation.

Designation

The letters and numbers in the markings can tell, if not everything, then a lot about the equipment. The abbreviation will tell a specialist who works with metal machines about its main characteristics.

The alphanumeric designation on the housing indicates:

- the first digit - into groups according to the table of classification of metalworking equipment;

- the second digit indicates the type of equipment;

- if a letter is indicated in second place, then this indicates a modernization of the base model;

- The maximum drilling diameter in mm is determined by the value of the last 2 digits.

- if at the end there are the letters “N”, “P”, “B”, “A”, “C”, then they indicate accuracy, “M” - a magazine with interchangeable tools.

Classification of machines according to ENIMS

Modernized CNC machines are marked with the letter “F” and a number in front of the type. The meaning of the number indicates:

- the machine has a digital display and a preliminary set of coordinates. The purpose of this system is to ensure that, after completing one of the specified cycles, the machine stops. To start the next operation, you must press the button. The programmed device will automatically move the drill to the required position. The movement of the tools is programmed by recording the actions on punched tape.

- The machine is equipped with positional and rectangular CNCs. The purpose of this system is to simultaneously place from 1 to 5 tools in the working position.

- CNC contour systems. The pulse signal determines the required distance to move the tool to a given point.

- universal CNC system.

Drilling machines for industrial use

Drilling machines used in industrial settings are complex machines capable of not only drilling holes, but also performing a number of other operations. There are several varieties of such units, but the most common of them are vertical and horizontal drilling machines.

Vertical drilling machines drill holes with a diameter of up to 75 millimeters. They are used to work with small parts and workpieces in workshops producing small-scale products, as well as for piece production. Horizontal drilling units are designed for deep drilling. Often, specialized machines are used in production. One of the most popular types are magnetic machines used to work on beams, pipelines, bridges, and ships. The most popular are magnetic machines from the Euroboor brand (Holland), which allow drilling holes with a diameter of up to 200 millimeters.

Photo No. 3: two-speed magnetic machine Euroboor ECO.40/2

Types of industrial models

Many devices are represented by universal equipment that can be used for drilling not only in metal, but also in other materials. The following types of drilling machines are distinguished:

- Tabletop type. This group is characterized by compact size and low weight. Area of application: obtaining small diameters.

- Column machines are installed in the case of establishing single and small-scale production. When using them, it is possible to obtain holes with a diameter from 18 to 75 mm.

- Radial drilling machines are used for processing massive parts. In this case, the resulting holes can be located strictly along a circular arc with a given pitch. A distinctive feature of the layout is the rather large overhang of the spindle assembly beyond the structure.

- Jig-drilling structures are widely used when it is necessary to obtain a workpiece with the exact location of holes relative to each other.

- Centering models are designed for processing end holes. This design is characterized by a large distance between the work table and the spindle head.

- Horizontal drilling machines are designed for processing shafts and axles, as well as rods and other similar products. The layout features make it possible to obtain holes of considerable depth.

- Multi-spindle designs can be used to produce multiple holes simultaneously. Moreover, they can be located in different planes.

- Combined devices have a layout that allows several different operations to be carried out at once: drilling, milling, chiselling, and so on.

Recently, designs that operate under CNC control have become widespread. They are used to produce the most complex high-precision products.

Design and capabilities of industrial drilling remains

The design of industrial drilling machines is more complex than that of household units, and the capabilities of such devices are very great. Such machines can process workpieces made of any metal and other materials of considerable thickness.

The electrical circuit of industrial drilling machines is reliable. Most of these units have the ability to automatically change the direction of rotation of the drill. Almost all models of industrial machines are equipped with a liquid supply system for cooling.

Photo No. 4: device of an industrial drilling machine

Operations carried out

Industrial machines of this type can be used to carry out a wide variety of operations. This is due to the fact that in addition to the drill, other tools can be installed. Most often, the equipment is used to perform the following operations:

- Processing of already obtained holes using counterbore.

- Deployment.

- Processing when using a countersink punch.

- Formation of threads inside holes.

- Boring of holes using the appropriate cutter.

- Finishing processing.

- Formation of various recesses when installing a milling tool.

Household models are suitable exclusively for drilling and reaming.

It is quite important to choose the right drill depending on the type of metal from which the workpieces are made.

A material that is too hard can cause rapid wear of the cutting edge.

Drilling machine basics

Before you use any type of drill press, you need to learn the basics of using it. First of all, it is important to buy drills for drilling machines that are exactly the right size and match the type of fastening. You can select drills for any units in the catalogs. After securing the drill, you need to make sure that it is held tightly inside the mechanism.

The parts to be processed should be secured on the table. Do not hold workpieces with your hands or change tools into a rotating spindle. Throwing belts onto pulley steps is only possible when the electric motor is switched off. When drilling parts, especially those made of fragile materials, you need to use protective clothing and safety glasses.

Types of industrial machines - the whole range of hole drilling work

The vast majority of all industrial machines offered on the market are capable of solving any problem, although this does not apply to certain specialized modifications. In addition to drilling, they can be used to perform some other operations. If we consider equipment intended for metalworking, it can be classified into the following types:

- Tabletop . These devices are designed for creating and processing holes with small diameters. Their design is initially designed for maximum tool diameters of 3, 6, 12 and 16 mm.

- Vertical drilling , which are often referred to as column ones. Their main purpose is to process holes with a diameter of 18, 25, 35, 50 and 75 mm. Equipment of this type is often used in situations where it is necessary to process workpieces and parts of small size in repair shops, as well as in small-scale and individual production.

- Radial drilling . They have become widespread for processing massive and oversized workpieces. They can also be used to process parts with circular holes. This effect can be achieved thanks to the large spindle reach, which has a value of 1300–2000 mm. It is worth noting that the axes of the tool and the holes are aligned by moving the spindle, and the workpiece does not change its position.

- Coordinate drilling . These devices have become widespread for processing parts for which it is important to maintain the exact placement of holes in relation to each other.

- Horizontal drilling . They are used for processing deep holes, the need to create which may arise, say, in shafts, axles, rods, barrels of artillery and rifle systems.

- Central . With their help, you can create center holes, the location of which is the ends of the workpieces.

CNC: classification and explanations

Today CNC is used everywhere in machine tools, with the only caveat that it is strictly for technological needs: if it is possible to make a part, and there are no requirements for super-precision of its execution, you can simply invite an experienced craftsman to work on it, who will carry it out on a familiar manual machine.

Although for home work (for jewelers, wood and metal artists) there is a miniature tabletop machine, it is no less professional and reliable.

Video:

So the price and the question of appropriateness, although banal, are vital. Technologically, the CNC system can be divided into 2 groups:

- Positional: the drill and the workpiece move intermittently - point by point. In this case, the positions are either far away (say, when boring and drilling), or close to each other (as when turning and milling);

- Continuous movement: contour work in one movement.

The CNC positional system is the simplest type of control, but is used mainly in drilling and jig boring machines, where shaped movement is not required - only in a straight line.

The rectangular CNC system moves the drill one at a time along a specific coordinate axis, while the speed of movement is set by the program itself.

This system is also used to a limited extent (comparatively) on workpieces that can be placed parallel to the coordinate axes (turning, milling).

CNC shaping

This type of CNC needs to be discussed separately. This is a more advanced option for positioning and work in general, since the tool moves along two or more coordinates, which allows processing workpieces of any shape.

The interpolator simultaneously produces coordinates in three-dimensional space in the form of a certain number of feed drives. Today, more and more machines are being produced with CNC shaping.

Video:

Yes, they are expensive, but such professional equipment quickly pays for itself, as it allows you to produce complex parts that are not cheap.

But even such an innovative machine can offer a choice of options: 2D and 3D shaping.

2D shaping is controlled along two coordinate axes, which means you can move the drill along an arc and a straight line. A particular version of this type is 2½D shaping.

IMPORTANT TO KNOW: Operation of CNC milling machines for metal

The drill already moves along 3 coordinate axes, but the difference is that only 2 axes are controlled, and the third is used for installation, approach and retraction of the tool.

After executing a command to move in a certain plane, the system can switch to movement in another.

The current processing plane, coupled with the simultaneous control of different axes, allows the drill to operate in the XY, XZ, YZ planes.

This CNC system is used in simple machines that are equipped with a stepper feed drive.

What is noteworthy is that complex contours and surfaces can be processed on the machine, but a volumetric part is processed layer by layer in a specific vertical or horizontal plane, and not continuously.

3D shaping is the crown of machine tool engineering, which produces high-precision parts with a smooth surface.

Video:

The machine tool moves along 3 axes at once, which means you can process any spatial contour continuously. For the most part, the milling method is used rather than drilling.

However, if the machine is universal, and even with 3D, then it will perform any part, not to mention ordinary drilling. The price of such a unit sometimes reaches several thousand euros.

Homemade plywood machine

A drilling machine made of metal is durable and reliable. However, not every craftsman has a welding machine.

Therefore, we offer an alternative option - to make the frame and main parts of the drilling machine from plywood.

Please note: to assemble a homemade drilling machine, the author uses MDF, but it is better to use plywood.

Necessary materials:

- plywood;

- furniture guides;

- edged board;

- plastic legs;

- fastening clamp;

- metal plate.

First of all, we take two furniture guides, and after removing the internal movable slats, we screw them to the plywood blocks. The bars themselves will need to be secured to a wide piece, as shown in the photo.

Next, we take another pair of furniture rails - we screw them to the plywood platform between the side rails (we also remove the internal movable strips).

We make a mount for a drill. You must first cut off a metal plate and weld a clamp to it. Additionally, we make reinforcement using round or square rods (this is the only operation where welding is used).

Now you will need to make a movable platform. We saw off a piece of plywood of the required size and screw the internal strips of the furniture rails to it. We connect both parts of the structure together.

Another plywood board must be screwed to the movable platform, to which a metal plate with a clamp is attached.

After this, we cut out the base of the drilling machine and screw plastic legs to its lower part.

Next, we install a stand made of edged boards. The previously assembled structure must be attached to the rack.

Install the return spring. We fix the electric drill or screwdriver in the clamp.

Materials and tools for making the machine

Before starting work, you need to think through the sequence of all technological operations in the manufacture of a homemade machine, plan the manufacturing technology, decide on future materials and tools that will be needed during the work process.

To make a machine with your own hands, you will need the following materials and components:

- Plywood 15 mm.

- Pine board, solid;

- Furniture drawer guides;

- Sleeve;

- Furniture footwear;

- Wing nut;

- Fastening: M6 bolt, self-tapping screws of various lengths.

To make a machine from a drill or screwdriver, you will need the following tool:

- Circular saw or sawing machine.

- Jigsaw.

- Angle grinder (angle grinder or simply “grinder”).

- Drill or screwdriver.

- Grinding machine.

- Various hand tools: hammer, screwdriver, clamps, wood core drill (or simply “crown”), square, marking pencil, etc.