For the production of suspended ceilings: HDTV machine

Stretch ceilings have not surprised anyone for a long time, but not everyone knows that their production is a consistent and rather complex process, the implementation of which is simply impossible without specialized equipment. In this case, it is a machine for soldering suspended ceilings.

Welding of PVC film is carried out with high-frequency current - hence the name “High-frequency machine”. The instructions in this article will introduce you in general terms to soldering technology.

Your attention will also be offered a video on the topic: “Machine for suspended ceilings.”

What is a HDTV machine

High-frequency film soldering is considered today to be the highest quality method of joining PVC sheets. In this case, the seams are not only sealed, but also practically invisible.

Creating a strong welded joint is the main requirement for HDTV machines:

- The essence of the soldering method is this: the edges of the film being welded are quickly heated, and their fusion is carried out at the molecular level. Since the heating is spot-based, the material itself does not heat up, which means it is impossible to spoil it.

- The machine for making suspended ceilings consists of two main elements. This is a welding press and a generator, the power of which should be determined by the size of the blades being connected. In the place where the soldering will be done, the material is clamped with a press.

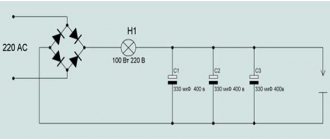

- Since the machine is electric, it has devices and components that prevent accidental damage to the material. They also ensure the safety of the equipment as a whole. One of them is a device that suppresses the occurrence of an electric arc, which poses a danger not only to the material, but also to the electrode.

All HDTV machines are equipped with magnetic diffusers that suppress interference created by electromagnetic radiation and interfere with the operation of other electrical devices. In fact, the surrounding workspace is carefully screened.

And, of course, it is impossible to do without a fuse. A special relay protects the machine from power surges.

Types of suspended ceilings

Classification of ceilings by type of material:

- PVC ceilings are made from polyvinyl chloride rolls up to 5 m wide, which are welded using special equipment. Their installation requires heating up to 70 degrees. The canvases are mounted on a special aluminum or plastic profile. Among the disadvantages of PVC canvases, one can note their low frost resistance, which is why they are rarely used for installing ceilings on loggias or in country houses that are not heated in winter. The strength characteristics of polyvinyl chloride are also quite questionable. PVC ceilings can be accidentally punctured or damaged.

- Fabric ceilings are made from impregnated textile fabric containing artificial threads. They are installed without heating, are more durable and frost-resistant. Fabric material is considered more environmentally friendly and promotes free air exchange. Fabric for ceilings costs more, but the color choice is more limited compared to PVC fabrics.

Classification by texture:

- matte - the most common type of texture, reminiscent of a traditionally whitewashed surface. Matte stretch ceilings do not glare or mirror the room;

- glossy - mirror surfaces, thereby visually enlarging the room. If there is a connecting seam on the ceiling. then on gloss it will be more noticeable;

- satin texture is considered a type of matte, but with greater reflective properties. Satin has a pearlescent sheen that is pleasant to the eye and adds light to the room.

Manufacturers of canvases for suspended ceilings produce products in the maximum color variety. Combined ceilings are very popular today: made up of canvases of different colors or decorated with photo printing.

Electrodes for PVC welding

As with any welding, electrodes are also used here, only of a special type. They look like a flat metal ruler, one edge of which is clamped in the press, and the second acts on the material being welded.

Take a look at the photo below - you can clearly see how this happens: the edges of the film are aligned, and the red line shows where the seam will go.

Welding two sheets on a machine

- Electrodes for high-frequency welding are made of aluminum, brass or steel. Depending on the thickness of the fabric, they may have different designs and sizes. Their peculiarity is that they not only heat the seam, transferring press pressure and current to the material being welded, but also cool it after soldering.

- It is very convenient that the fabric to be welded can be positioned to the electrode at any angle. This makes it possible to minimize the amount of material waste and work defects. By applying the fabric successively to the capacitor lining (the second name for the electrode), you can get a long seam.

But not every polymer material lends itself well to this type of welding. The higher the polyvinyl chloride content, the better. Its minimum content in fabric is 30%.

Materials containing polyester, polyethylene and polypropylene are not suitable for HDTV welding.

Marketing policy

When promoting a business, advertising can be done in all sorts of ways:

- scattering advertisements in mailboxes or sticking them on entrances: for this you can use the services of special agencies;

- posting in the media;

- by creating your own website on the Internet, posting on it, in addition to information about prices and services, photographs of finished projects;

- promoting services on social networks;

- on public transport;

- at public transport stops;

- on the most popular local radio channels.

Process of working on the machine

The HDTV machines themselves are quite simple and reliable to operate. They have two types of drives: foot or pneumatic.

They can be programmed to perform multiple operations. The duration of the welding process and the pressure of the press are also regulated, and all this is done using the control unit.

- Automation allows you to speed up work, create a canvas of any size, and also make do with a minimum number of personnel - that is, one operator. Having such equipment, making a suspended ceiling with your own hands is not at all difficult.

- This is what many private traders take advantage of, providing these services to the public. They purchase a used HDTV machine for suspended ceilings and start their own business. The price of the ceiling in this case will be lower than in specialized companies, but it is not a fact that the quality will be at the same level.

How to choose quality equipment?

Modern models of good quality machines should be equipped with additional devices to control the execution of the work cycle, for example, a laser pointer, which can connect parts of the material with high accuracy. Also, equipment for the ceiling of a suspended structure should be equipped with lighting for the convenience of the operator to monitor the correctness of the seam during work. It is very important to have safety systems during operation. The HDTV machine is controlled only if both hands of the operator are on the start buttons. This allows you to avoid the influence of the human factor and injury due to negligence.

The most modern types of machines for soldering suspended ceilings are produced by the Polish company Zemat; their high level is largely ensured by the presence of a MITSUBISHI brand command controller, which distinguishes them from their Chinese counterparts. The equipment of this company has compact dimensions, as well as a reliable protective device against current leakage and electromagnetic influence.

High-frequency machines are used not only for welding suspended ceilings, but also for the production of banners, inflatable products, albums, business card holders, upholstery for car seats, toy packaging, etc.

How harmful is a stretch ceiling to health: truth and myths

Popular models

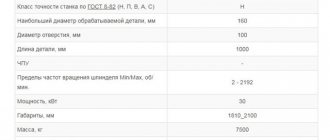

2P-3.2

The HDTV machine for suspended ceilings 2P-3.2 is a two-station unit, the country of origin is China. The presence of two workstations allows you to solder PVC film and weld a harpoon around the perimeter of the cut material. Dimensions of the desktop: 38x70 cm. Power is supplied from a network of 220 and 380 V. Dimensions of the unit: 1.05x1.6x1.45 m; weight: 320 kg; working stroke: 50 mm.

Advantages of the model:

- presence of mechanical and pneumatic drives;

- ability to regulate welding time, power, pressure and voltage;

- generator lamp DB948, FU 948 F (China) has an analogue of the domestic E3062C (Russia);

- silent operation;

- laser pointers for aligning the edges of the canvas;

- three-phase machine: in case of voltage fluctuations in the network, the film will not be burned or poorly soldered;

- high quality seams.

Flaws:

- no air purifiers;

- There is no automatic adjustment of the cooling time, raising and lowering the electrode.

RG-4000TA

The RG-4000TA machine is manufactured in China. Equipped with two workstations for soldering any PVC sheets and welding a harpoon. Voltage 220 and 380 V. Dimensions: 1.2×1.3×1.6 m; weight: 345 kg.

Advantages:

- presence of foot and pneumatic drives;

- The unit is three-phase, so voltage drops in the network are not a problem;

- high productivity: when working in two shifts at both posts, it is possible to produce 8 thousand m² of fabric for suspended ceilings per month;

- there is a timer with which the time of welding and cooling of the material under pressure is regulated, thanks to which higher quality and high-strength seams are obtained;

- the use of a 4 kW lamp helps save energy;

- it is possible to regulate the force of the press;

- as a result of improvements, the upper electrode is increased to 67 cm, the seam is uniform in length, without joints;

- the components are reliable, and prices are lower than for parts from European brands (Airtac, LG, Toshiba);

- The 7T62RB generator lamp under Toshiba license can be replaced with a Chinese or E3062C (Russia).

Flaws:

- to work with a pneumatic drive, you must buy a compressor separately;

- no laser pointer;

- there is no noise reduction.

The price of Chinese HDTV machines is about 200 thousand rubles.

Zemat Supra MAX

Zemat Supra MAX machines are manufactured in Poland and are characterized by European quality. This is the most common of the three models produced by the company. It is equipped with two work tables on which PVC strips are soldered and the harpoon is welded. Dimensions: 1.5×1.36×1.7 m; weight: 350 kg. Table size: 75×100 cm. Working pitch: 100 mm

Advantages:

- a 7T62RB air-cooled metal-ceramic lamp is used as a generator;

- the machine is equipped with a Mitsubishi command controller;

- a special screen with a pneumatic drive for protection against high frequency radiation, which negatively affects the nervous and cardiovascular systems;

- bottom lighting of the table ensures an even seam, the brightness of the lighting is adjustable;

- the laser pointer makes it possible to accurately align the edges of the material;

- the electrode movement limiter allows you to stop it at the right time during the production process in order to change the position of the material;

- the workplace can be expanded to produce larger film sizes;

- heating the bottom plate increases the strength and elasticity of the seam;

- ZTG SafeDOWN™ anti-crush pneumatic system protects hands during operation;

- reliable shielding of electromagnetic waves, protection against electric shock and burns;

- the quality of work does not depend on changes in room temperature;

- the surface is covered with environmentally friendly materials: Plexi plastic or cork.

Flaws:

- high cost - 380 thousand rubles;

- It is not always possible to sell material at a price above average.

PWN-4000FA

Country of origin: Taiwan. The PWN-4000FA unit is equipped with two work stations: for soldering PVC film and welding a harpoon. Equipped with an E3062E generator lamp (Toshiba, Japan). Average service life is 4-5 years. Dimensions: 1.68x1.12x1.40 m; weight 350 kg.

Advantages of the model:

- availability of pneumatic and mechanical drives;

- the possibility of replacing an expensive E3062E lamp (45 thousand rubles) with a Chinese analogue for 28 thousand rubles;

- the electrode holder produces equal pressure throughout the entire seam;

- there is a breakdown protection block;

- The permissible noise level for this type of work is 70 dB.

Flaws:

- high price - 240-270 thousand rubles.

Dream-600

The single-station machine Mechta-600 is manufactured in Russia using patented technology and is intended only for welding a harpoon. The polymer connection is the same as on HDTV units, but a generator lamp is not required. Welding length: 50 cm. Dimensions: 915x385x270 mm; weight: 15 kg.

Advantages:

- compactness: can be transported in a car;

- A small area is suitable for installation: a room, a garage, can be placed on site;

- generator lamps are not required;

- high quality of harpoon welding;

- presence of non-stick coating (Japan);

- low energy intensity of the process: switched on only during welding;

- equipped with a timer for automatic start and shutdown;

- high productivity: 250-300 m² per day;

- required voltage 220 V;

- silent operation;

- no compressor needed;

- safe due to the absence of HDTV;

- easy to learn, no special training required;

- low price - 28-34 thousand rubles, upon purchase you can see the unit in action.

Flaws:

- one work post;

- There is no backlight, you have to organize the table lighting yourself.

What documents will be required

This type of business does not require licensing, but you will need permission to work with pressure cylinders. You can work as an LLC or individual entrepreneur. Registering an individual entrepreneur is much easier than opening an LLC. To register an individual entrepreneur, you will need a passport, payment of the state fee, an application for state registration, and a copy of the TIN certificate.

As a taxation system, many people choose the simplified simplified tax system: 6% of revenue or 15% of profit. This special regime will eliminate the payment of VAT, income tax, and property tax.

When registering an enterprise, you must select OKVED codes:

- 25.23 “Production of plastic products used in construction”;

- 52.46.7 “Retail trade in construction materials not included in other groups”;

- 52.61 “Retail trade by order.”

The quality of suspended ceilings must be regulated in accordance with GOST R 58324-2018. However, by Order of Rosstandart dated December 12, 2019 No. 1394-st, the date of its implementation was postponed from 2022 to January 1, 2022. A license is also not required.